Treatment method of tobacco leaf slices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

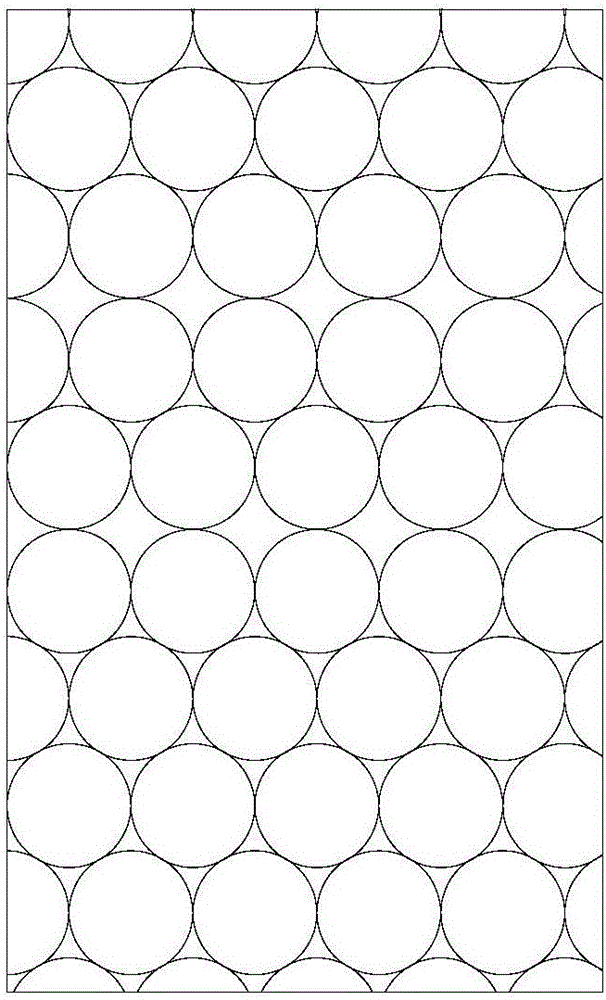

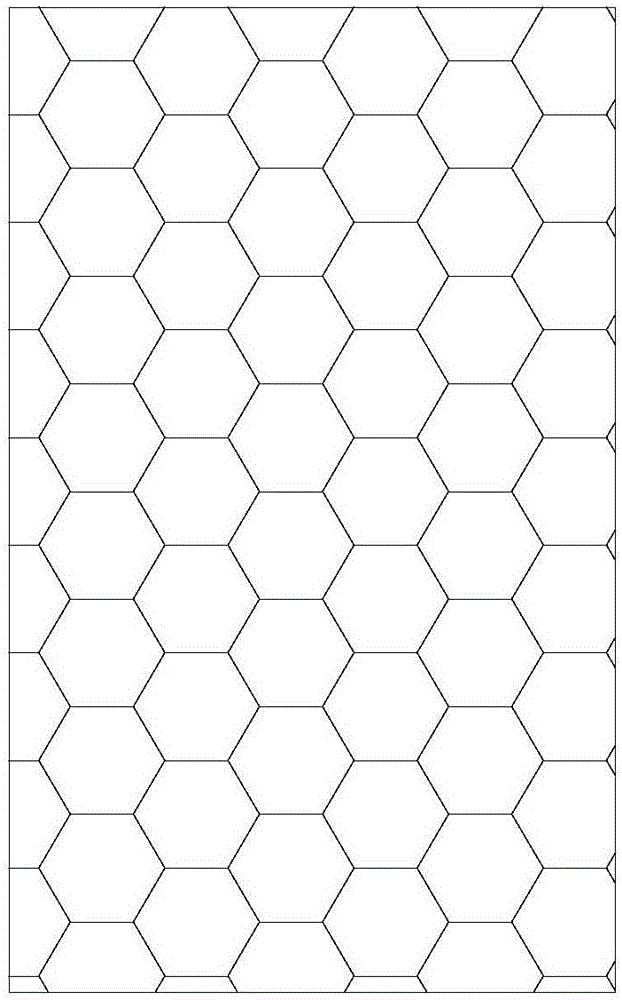

[0020] refer to figure 2 As shown in the figure, a method for processing tobacco slices is used to cut large slices of tobacco slices into hexagonal shapes for the production and processing of shredded tobacco. The hexagonal shape can best embody the characteristics of a circle and reduce the cutting loss. To the lowest level, so that the cut tobacco effect at the shredder can be optimized.

[0021] The beneficial effect of the invention is that: during the shredding process of the tobacco sheet, the shred yield of the blade can be increased and the fines and shreds can be reduced, so that the shredded tobacco is more favorable for rolling by a cigarette machine and the utilization value of the shredded tobacco is improved.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com