Beef fascia removing equipment for beef product processing

A beef and fascia technology, applied in meat processing equipment, processed meat, applications, etc., can solve the problems of large waste of beef and difficult removal of fascia on beef, reducing beef loss and high fascia removal efficiency. , The effect of preventing hand injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

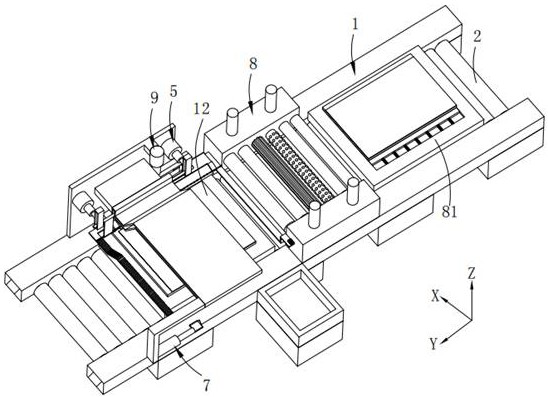

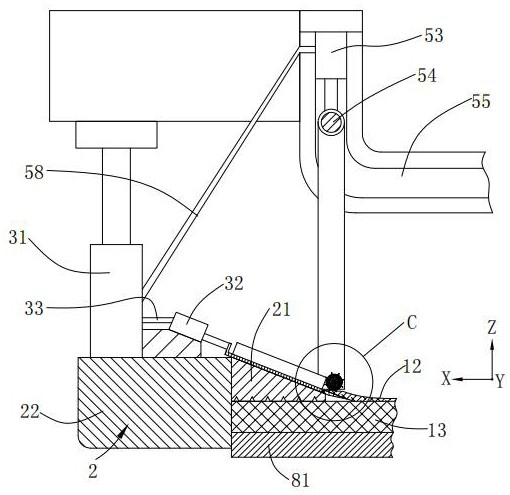

[0056] Such as Figure 1-6 As shown, the invention provides a kind of equipment for removing beef fascia for processing beef products, including a frame 1;

[0057] The pressing assembly 2, which is used to press the side of the beef 13, is arranged on the frame 1;

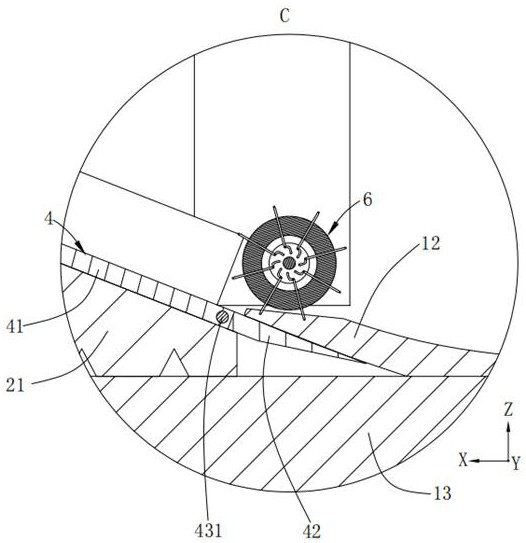

[0058] The cutter drive assembly 3; the cutter assembly 4 is driven by the cutter drive assembly 3, and the cutter assembly 4 obliquely cut into the beef 13 below the fascia 12 is arranged on the side of the pressing assembly 2;

[0059] The film roller drive assembly 5; the surface is evenly provided with the film winding roller 6 for picking up the needle body 61 of the fascia 12, driven by the film roller drive assembly 5, first cut into the beef 13 and interfere with the upper surface of the cutter assembly 4 and then The film winding roller 6 that picks up and winds the fascia 12 of the beef 13 by rotation is arranged on the side of the cutter assembly 4 .

[0060] This equipment also comprises conveying ro...

Embodiment 2

[0074] Such as figure 1 and 7 As shown in -13, the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of brevity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the tray 81 includes a plate body 811, and the plate body 811 is provided with a groove 8111 for holding beef 13;

[0075] The meat pushing assembly 812, which is used to push the beef 13 so that the beef 13 is close to the side of the groove 8111 in the positive direction of the X-axis, is arranged on the side of the groove 8111 in the negative direction of the X-axis.

[0076] The meat pushing assembly 812 includes a meat pushing plate 8121 and a first elastic piece 8122 connecting the meat pushing plate 8121 and the side of the groove 8111. The first elastic piece 8122 is a spring. Compress to allow the spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com