Stem crutch removing system

A technology for removing mechanism and tobacco stems, which is applied in the fields of tobacco, tobacco processing, food science, etc. It can solve the problems of increasing the effect and efficiency of visual elimination, failure of vibrating conveyor, inaccurate transportation path of stems, etc., so as to improve the removal efficiency and Process index, reduce the database load, and avoid the effect of removing tobacco stems by mistake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

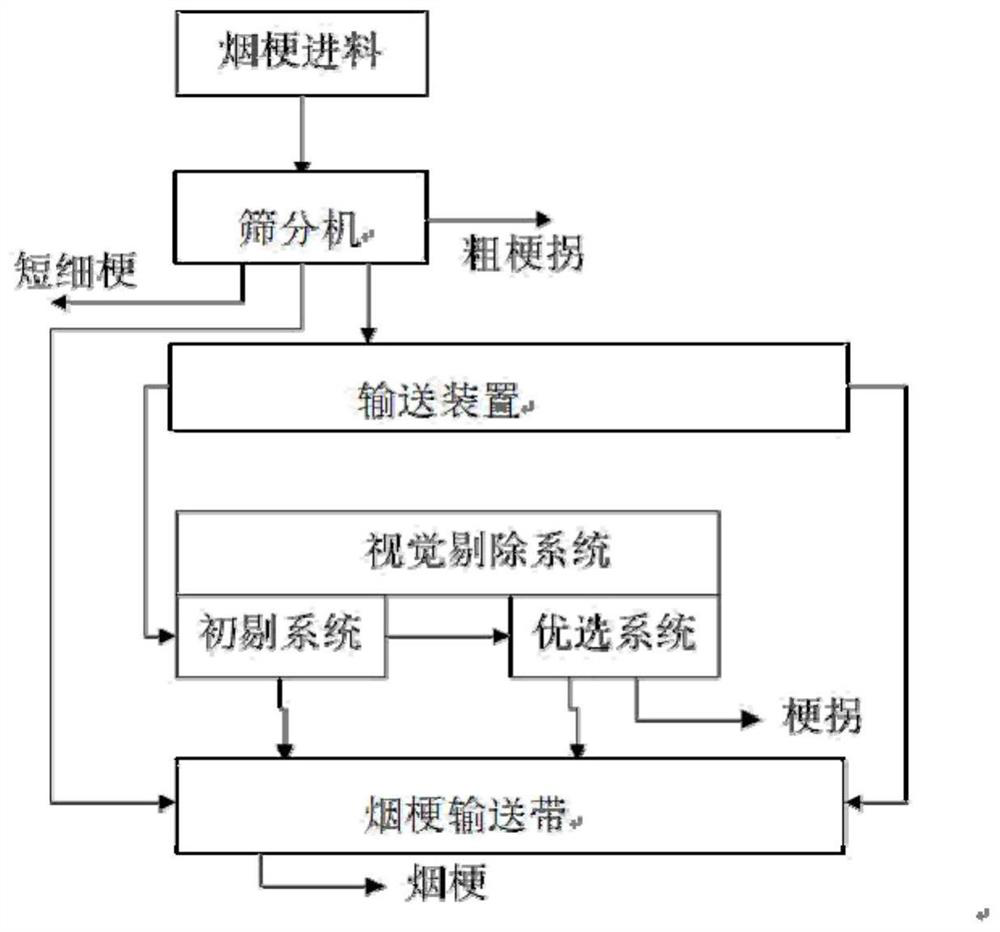

[0060] figure 1 The process flow diagram of the method according to the present invention is shown. After the tobacco stems are fed, they are classified and processed by a screening machine, and the feed tobacco stems are divided into four parts by different screen sizes: 1. Size≤3x20mm (that is, stem diameter≤3mm , length ≤ 20mm) short and thin stems, as waste; 2, 3mm 10mm are treated as waste. Among them, the 6mm<stem diameter≤10mm stems containing stems are sent to the visual rejection system through the conveying device, and a small amount of tobacco stems with smaller diameters are missed (the size of the stem diameter can be set according to actual needs) and then directly enter the next step. , and the remaining tobacco stems containing stems are sent to the visual rejection system to further reduce the processing capacity of the visual rejection system. The visual culling system is divided into the primary culling system and the optimization system. First, the primar...

Embodiment 2

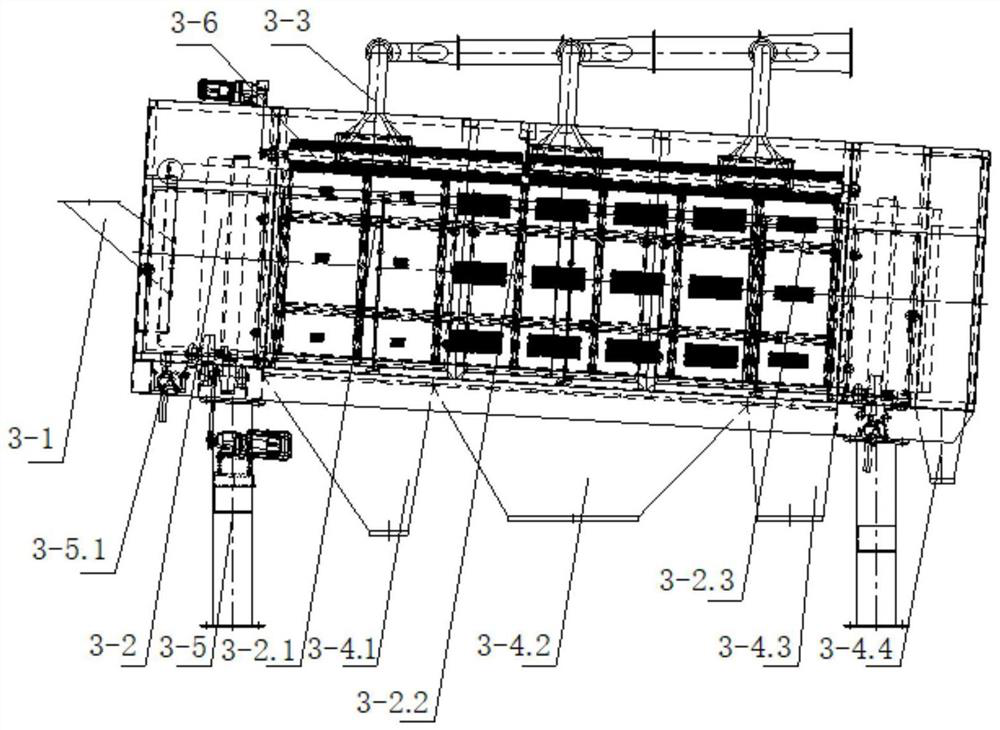

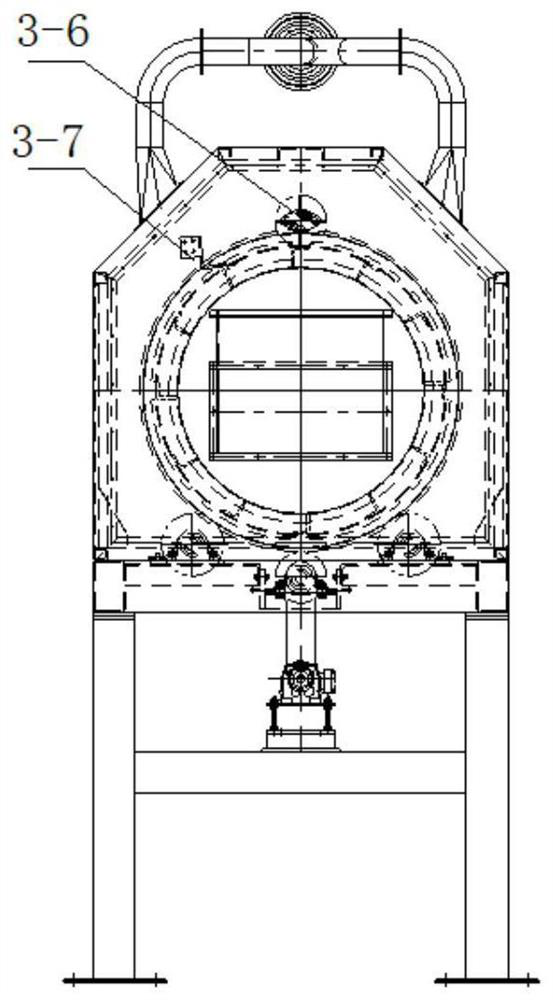

[0086] combine Figure 14 The stalk removal system of the present invention includes a flow control unit 1, a hemp silk removal machine 2, a drum screening machine 3, a vibrating screen 4, auxiliary connection equipment 6, a visual elimination system 8, main line auxiliary connection equipment 9, auxiliary connection equipment 11 and The wind conveying pipeline 10, wherein, the flow control unit 1 and the hemp silk rejecting machine 2 are sequentially arranged before the drum screening machine 3, and are used for the pretreatment process of tobacco stem material screening; the auxiliary connecting equipment 6, the main line auxiliary connecting equipment 9, the auxiliary connecting equipment Even the equipment 11 is a conveying line, which has the same function as the wind conveying pipeline 10, mainly conveying materials, which is convenient for the efficient operation of the whole system, and does not involve the treatment process of tobacco stem materials.

[0087] combine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com