Woodworking saw shaving production line

A woodworking saw and production line technology, applied in the field of wood processing, can solve problems such as low efficiency, equipment damage, and difficulty in realizing automatic assembly line production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

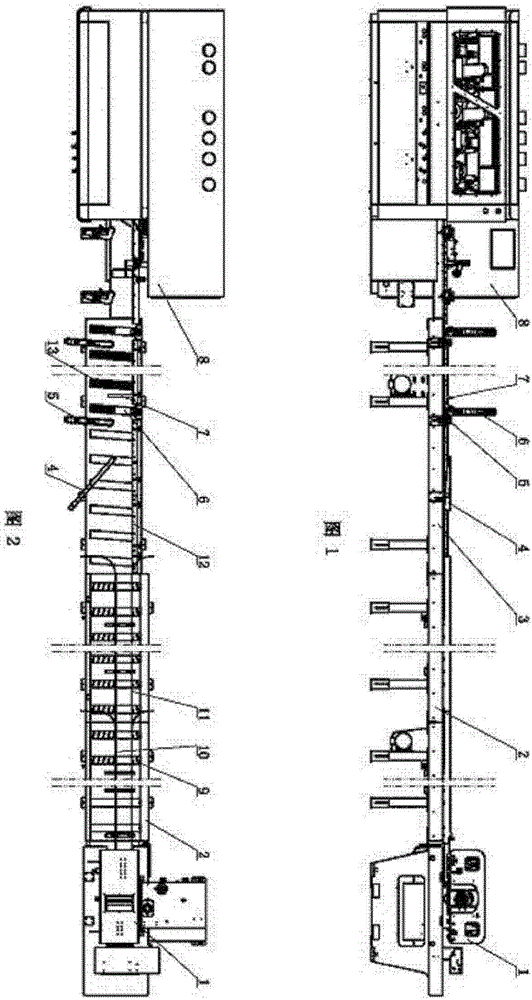

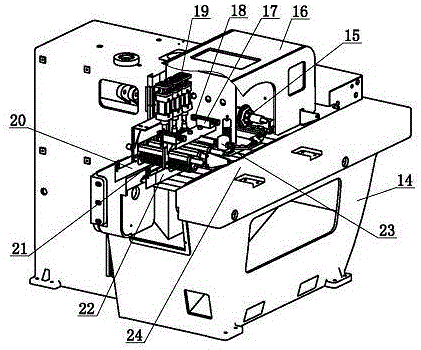

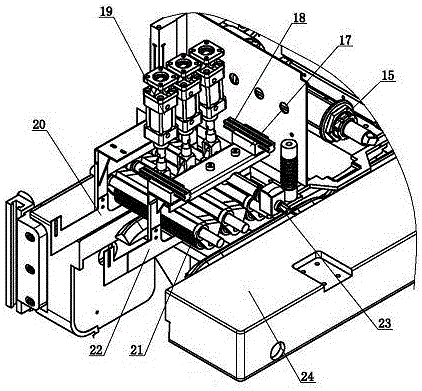

[0026] Such as figure 1 , figure 2 The shown woodworking sawing and planing production line includes a circular saw machine 1 and a planer 8, the circular saw machine 1 is a woodworking multi-blade circular saw machine, and the planer milling machine 8 is a woodworking double-sided planer. It is a wood planing and milling machine such as a woodworking single-sided planer or a four-sided planer. Between the circular saw machine 1 and the planer 8, an edge material removal frame 2 is arranged, and the edge material removal frame 2 in a frame structure is provided with an inner baffle plate 11 and an outer baffle plate 10. The tail ends of the sub-baffle plate 11 and the outer sub-baffle plate 10 are tilted outwards so as to guide waste materials to be ejected from the designated position area outside. Also supported on the frame 2 for rejecting side material is a classifying roller 9 that is rotatable and supports timber. A saw material conveying frame 3 is also arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com