Device suitable for defect detection of mobile-phone flat motors and achievement method thereof

A flat motor, defect detection technology, applied in the direction of optical testing defects/defects, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, low automation, low production efficiency, etc., to achieve high removal efficiency, High degree of automation and good factory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

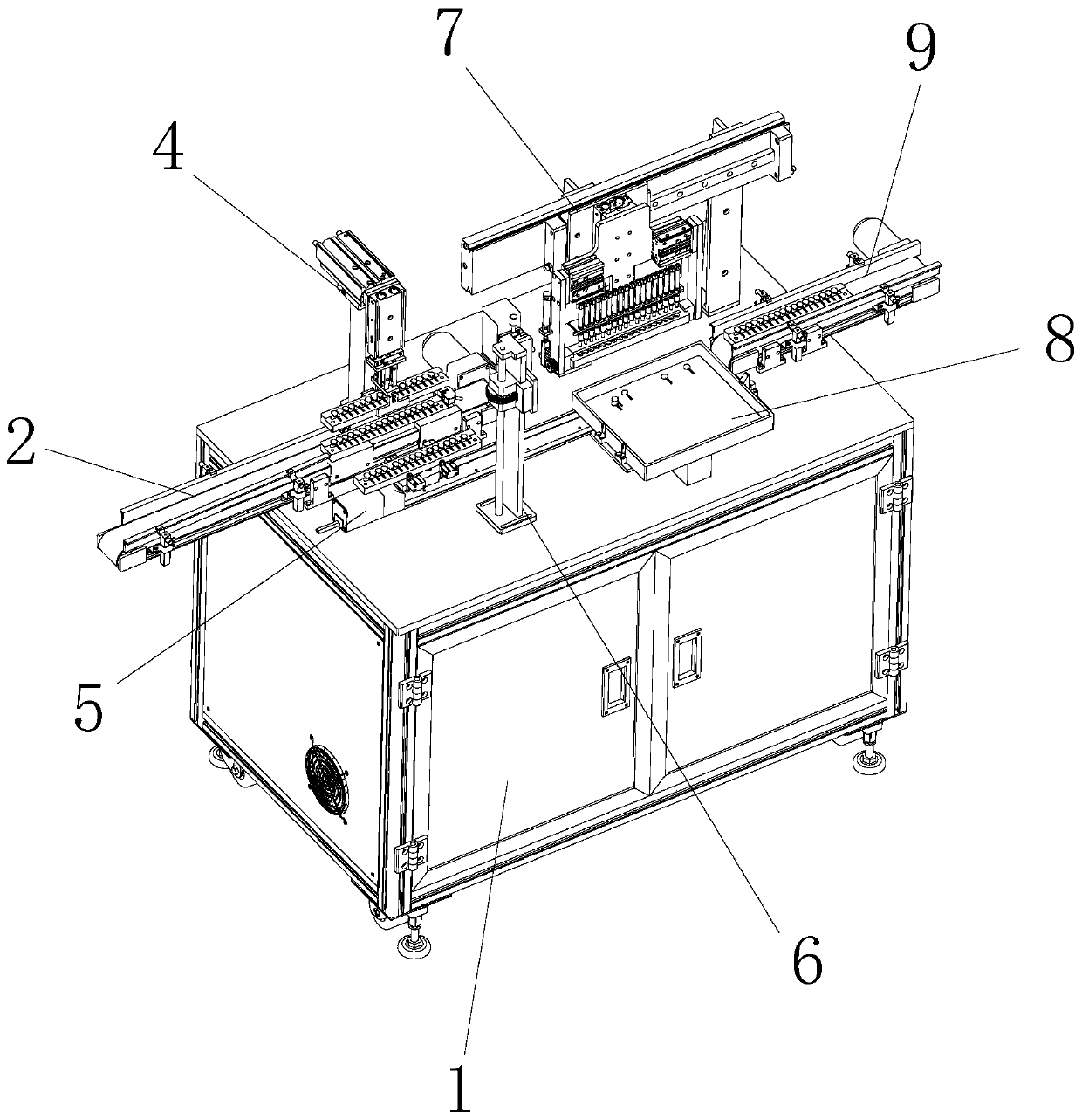

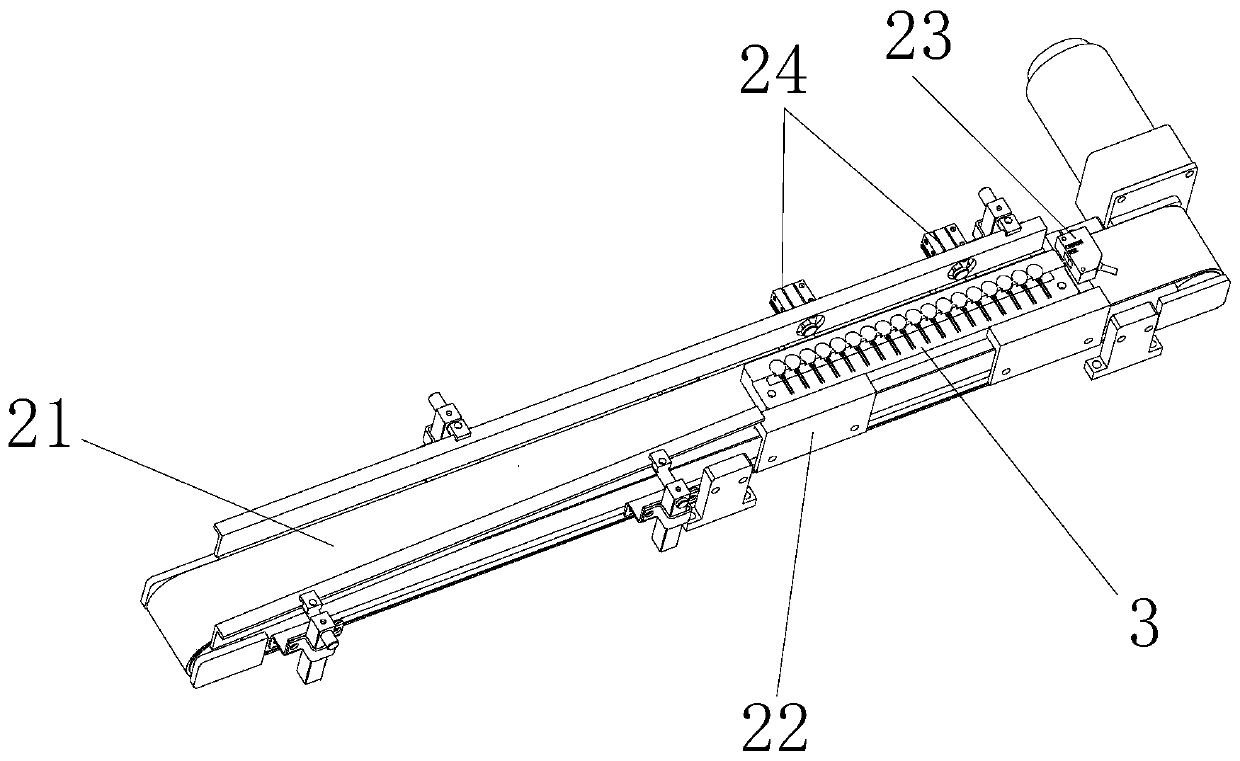

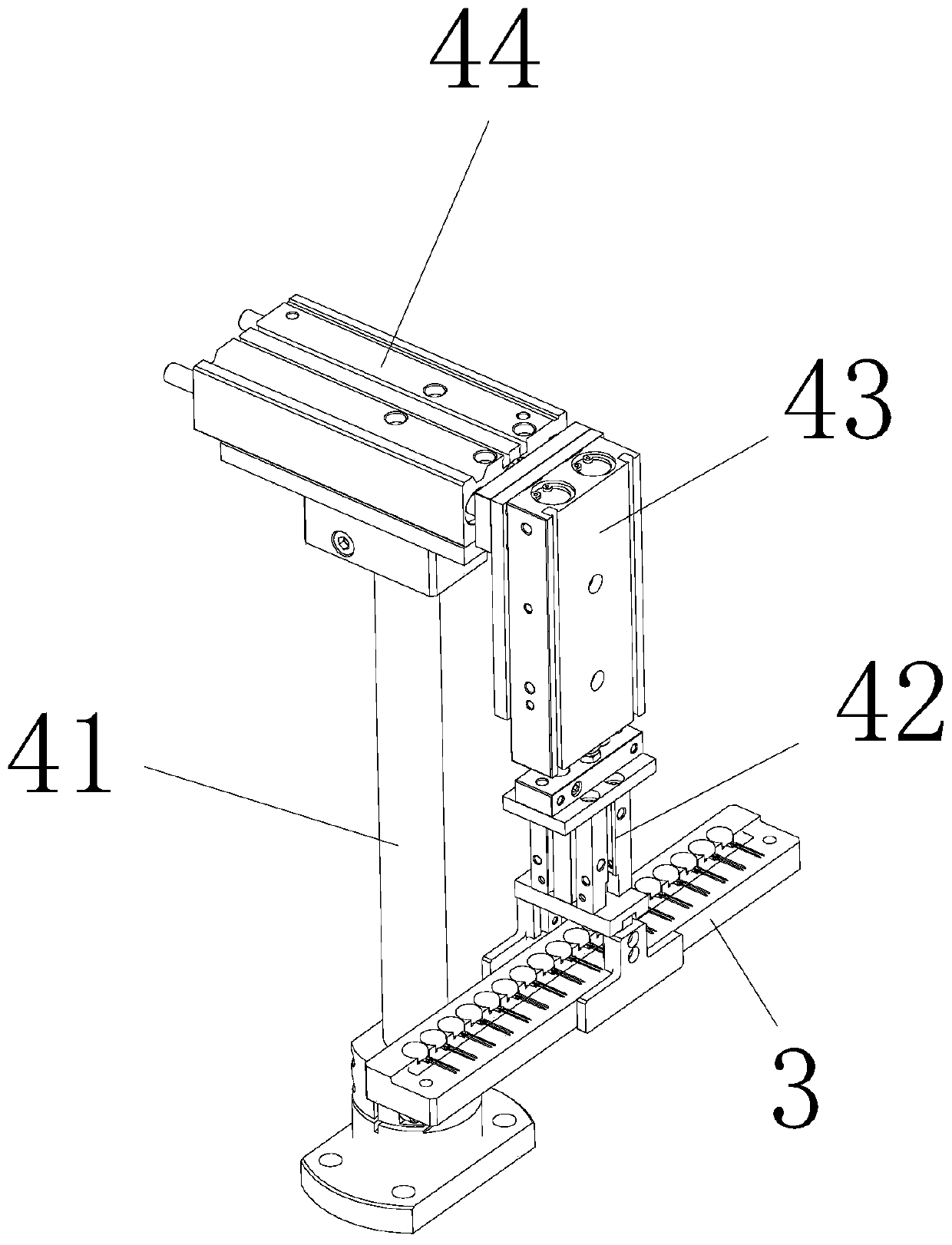

[0038] see Figure 1-8 , the present invention provides the following technical solutions: a device suitable for defect detection of mobile phone flat motors, including a frame 1, and the top of the frame 1 is respectively connected with a feeding positioning mechanism 2, a transplanting mechanism 4, and a stepping and shifting mechanism 5 And CCD photographing detection mechanism 6, wherein, transplanting mechanism 4 is positioned at the side of the discharge end of loading positioning mechanism 2, and step shift mechanism 5 is positioned at the other side of feeding positioning mechanism 2 discharge ends, CCD photographing detection mechanism 6 Located on the side of the stepping and shifting mechanism 5 far away from the feeding positioning mechanism 2, a carrier 3 is placed on the feeding positioning mechanism 2, and a transplanting and rejecting mechanism 7, a defective product collecting mechanism 8 and The second conveyor 9, wherein the defective product collection mech...

Embodiment 2

[0059] see Figure 8 , the difference between this embodiment and embodiment 1 is:

[0060] In this example, if Figure 8 As shown, the camera detection mechanism installation seat 61 includes a slide seat 611, a screw rod 612, an adjustment knob 613, a slide sleeve 614 and a slide block 615, wherein one end of the slide seat 611 is connected to the top of the frame 1 by bolts, and on the slide seat 611 A screw rod 612 is engaged and connected, and a sliding sleeve 614 and an adjusting button 613 are slidably connected to the screw rod 612. The adjusting button 613 is embedded in the inside of the sliding sleeve 614, and the adjusting button 613 is meshed with the screw rod 612. The sliding sleeve 614 is integrally formed with a slider 615.

[0061] By adopting this scheme, the position of the sliding sleeve 614 can be adjusted up and down by rotating the adjustment knob 613 in the forward and reverse directions, thereby adjusting the position of the camera 62 up and down, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com