Double-resistance plate and its manufacturing method

A technology of Pirane board and plate, applied in Pirane board and its manufacturing field, can solve the problems of thickness deviation of Pirane board, inconvenient construction and installation, inability to install and use, etc., and achieve the goal of improving quality, increasing production volume and reducing production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

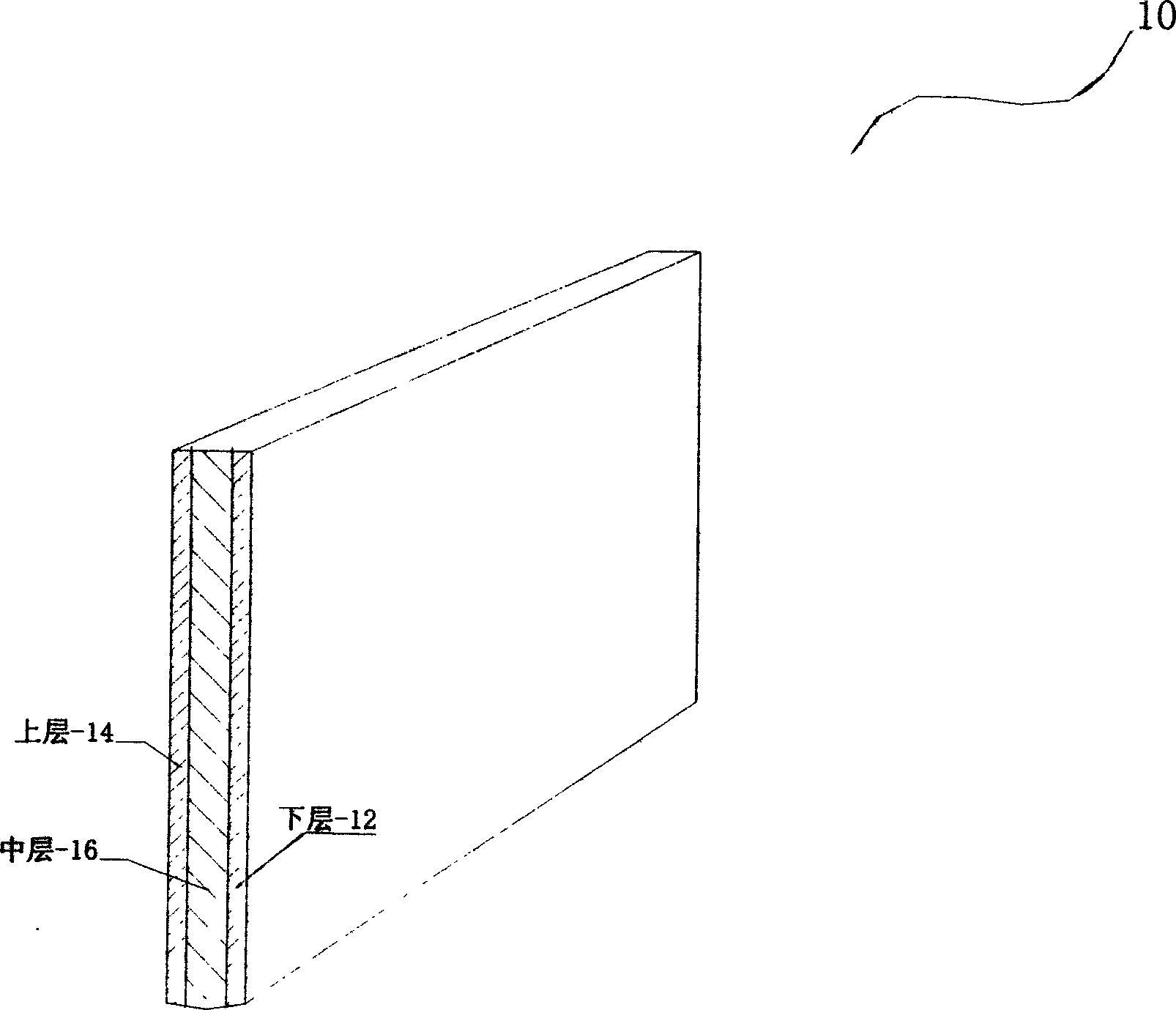

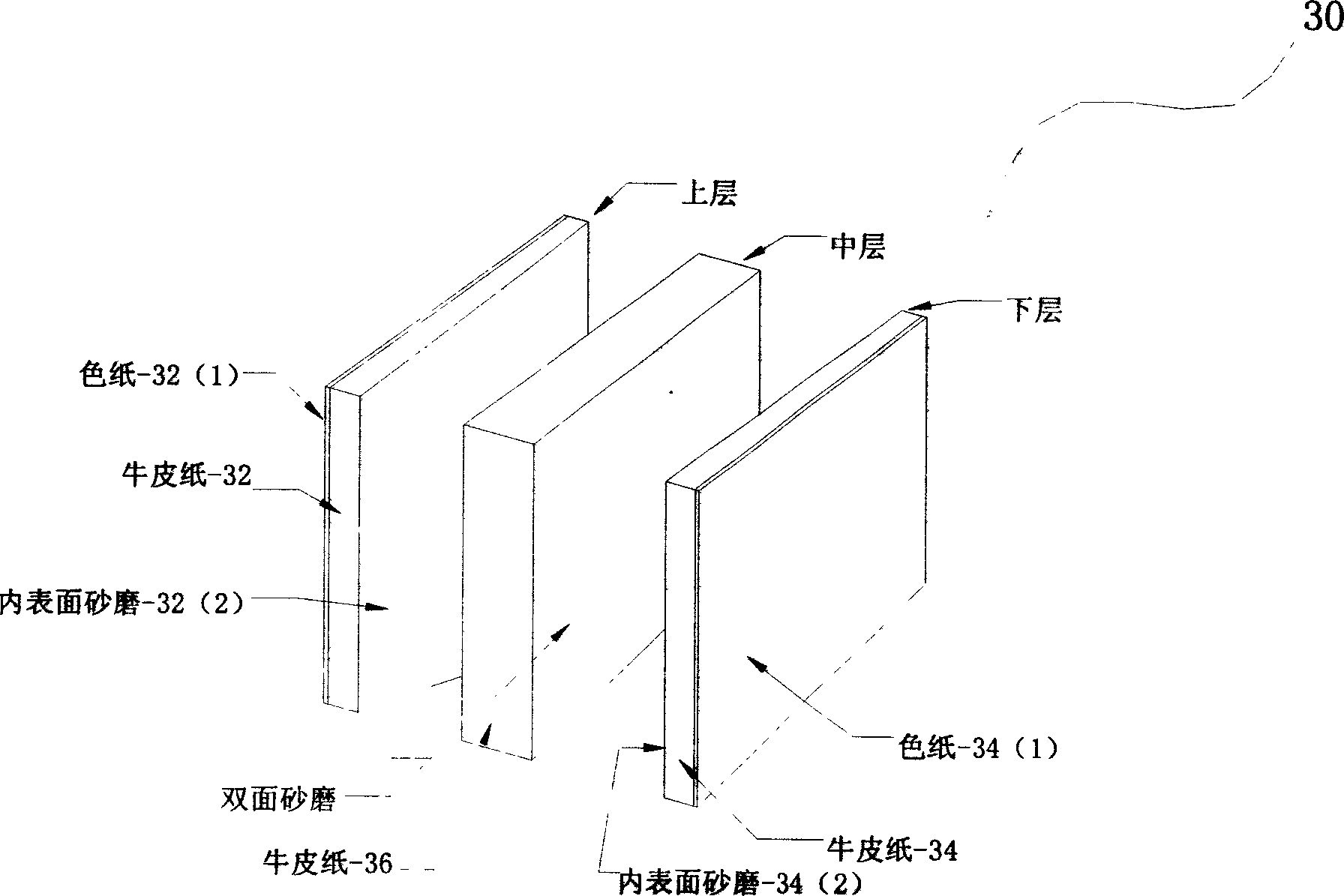

[0029] image 3 It shows a schematic diagram of the SPC 30 manufactured according to the present invention. Such as image 3 As shown, the SCR board of the present invention is divided into three prefabricated parts before synthesis, wherein the S&R board layer 32 and the lower layer 34 are made of surface paper impregnated with melamine resin and / or colored paper and kraft paper impregnated with phenolic resin by hot pressing. The middle layer 36 is made of phenolic resin impregnated kraft paper by hot pressing. After these three parts are prefabricated, apply glue on the two outer sides of the middle layer 36 of the SPC and / or apply glue on the back of the upper and lower layers of the SPC, and then paste the upper 32 and the lower layer 34 of the SPC by cold pressing or other methods. On both sides of the middle layer 36 of the Pycnid board.

[0030] Such as image 3 As shown, the outer surface 32(1) of the PPS upper layer 32 and the outer surface 34(1) of the PPS lower layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com