Method for continuously producing lactam copolymer

A technology of lactam and copolymer, which is applied in the field of continuous production of lactam copolymer, can solve problems such as weak crystallization ability, thermal performance, deterioration of solvent resistance, poor molecular structure regularity, etc., to improve stability and reduce production energy consumption , Improve the effect of production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

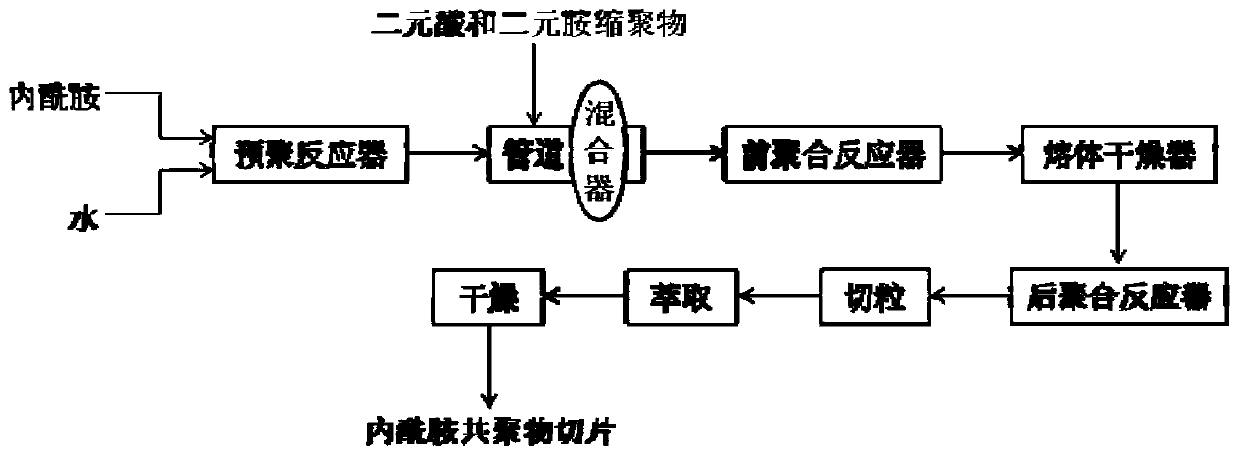

Method used

Image

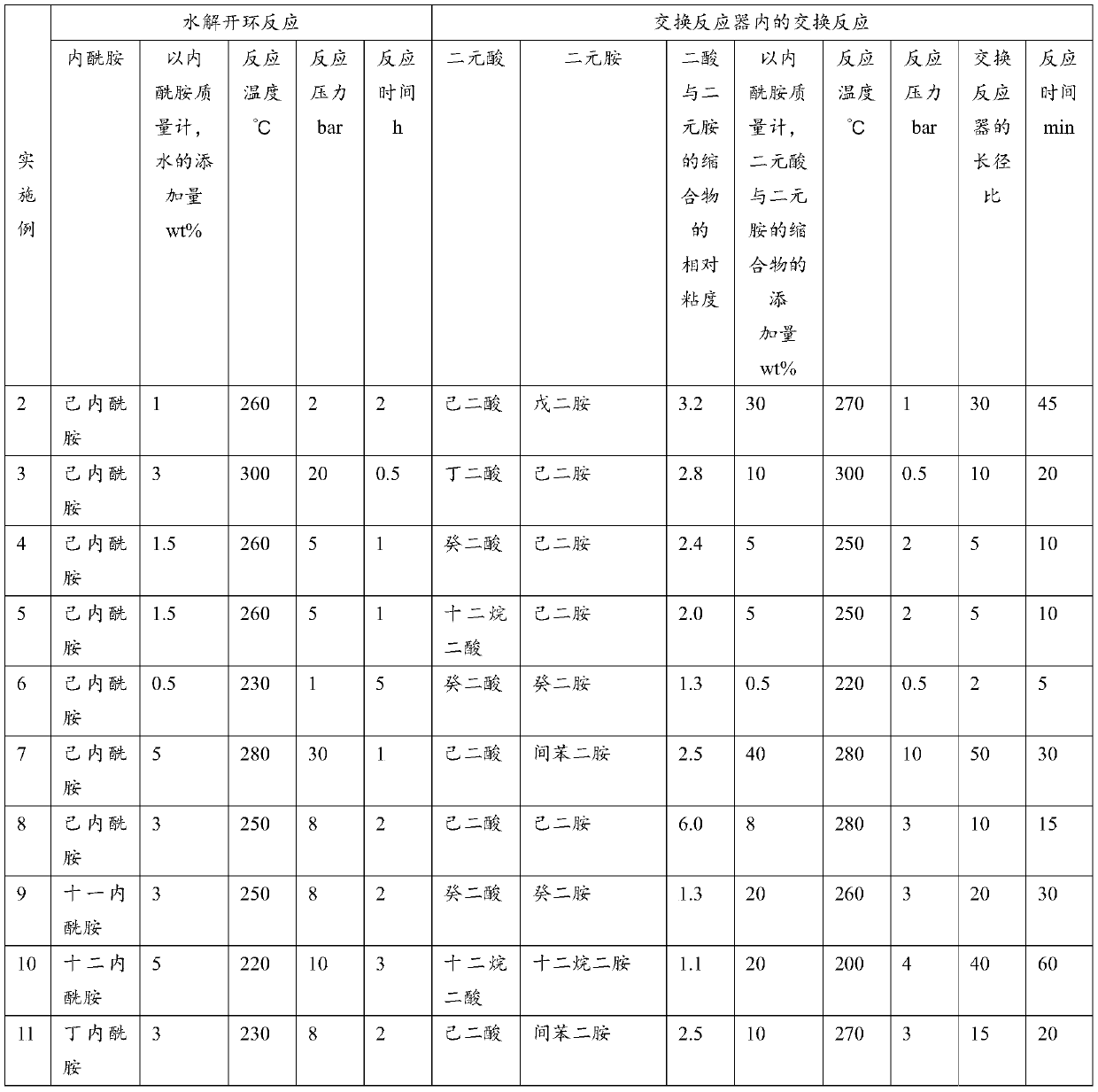

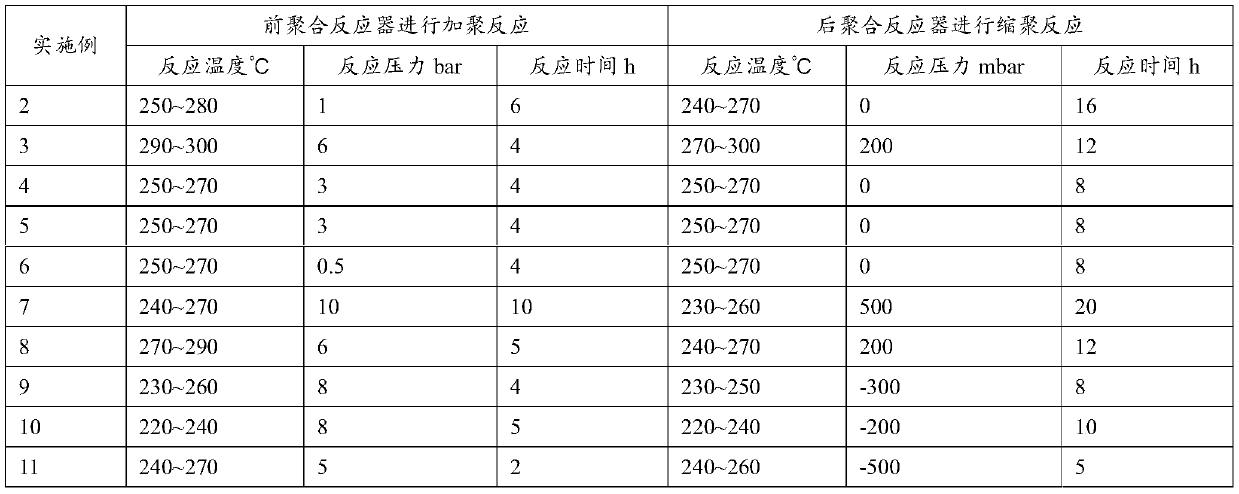

Examples

Embodiment 1

[0052] A1. After mixing the caprolactam melt and water evenly, enter the prepolymerization reactor for hydrolysis and ring-opening reaction. The amount of water added is 1.5wt% of the mass of caprolactam. The reaction temperature of the hydrolysis ring-opening reaction is 250°C and the reaction pressure is 2bar , The reaction time is 2h, obtains caprolactam oligomer;

[0053] A2. The caprolactam oligomer prepared in step A1 and polyhexamethylene adipamide, the condensation polymer of adipic acid and hexamethylenediamine added online, are mixed evenly by a 3-stage high-shear homogenizing pump, and then enter the exchange reactor for exchange. Reaction, wherein the relative viscosity of polyhexamethylene adipamide is 2.0, the addition amount is 15wt% of the caprolactam oligomer, the aspect ratio of the exchange reactor is 10, the exchange reaction temperature is 270 ° C, the reaction pressure is 2bar, the reaction Time is 30min, obtains the oligomer melt of lactam copolymer;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com