Flexible tool clamp for car glass

A technology of flexible tooling and automotive glass, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as inconvenient, different surface arc angles, and time-consuming adjustment processes, so as to improve production efficiency, high production flexibility, Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

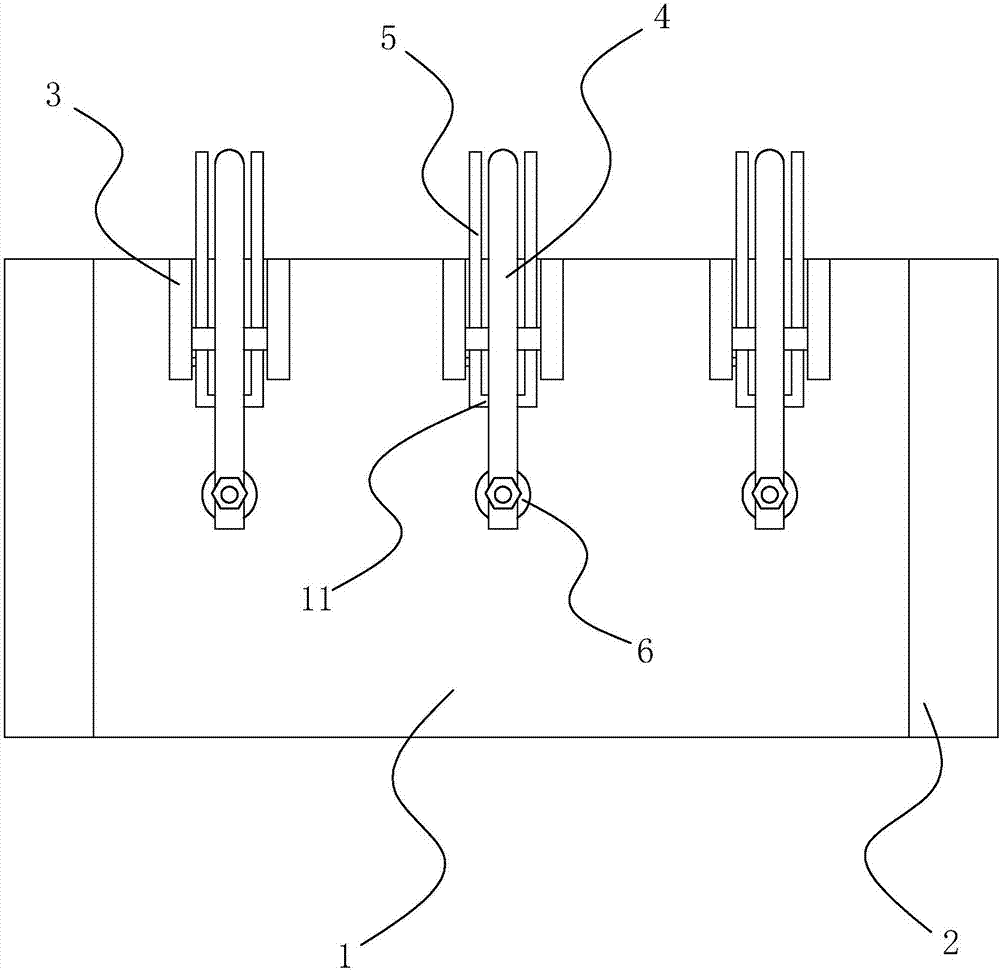

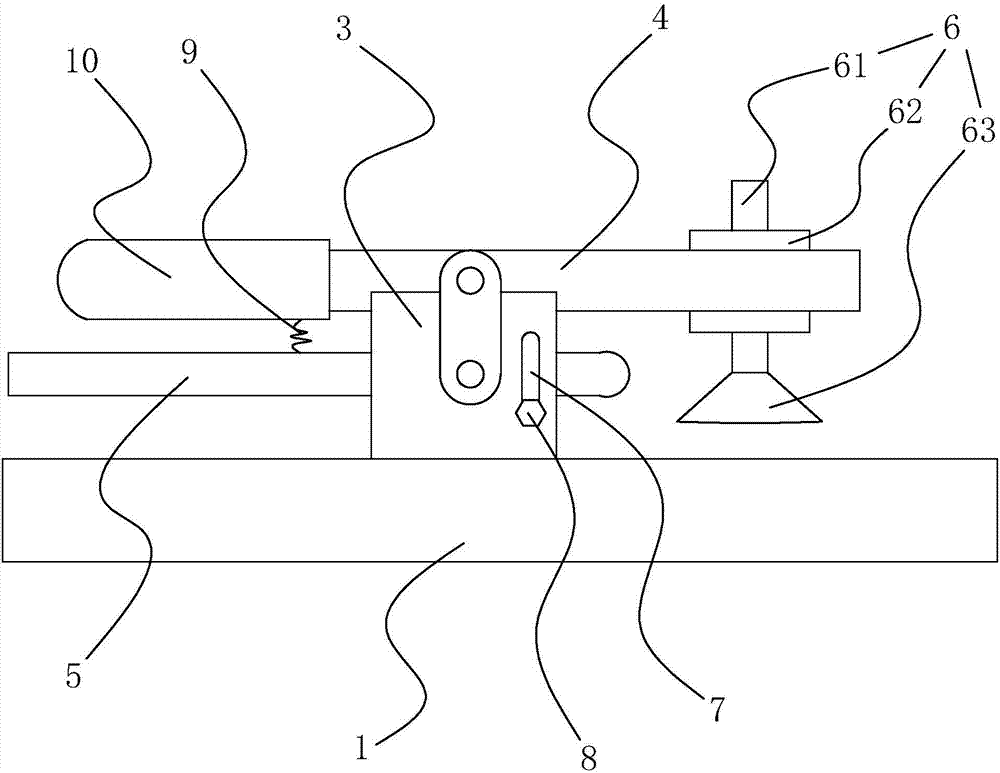

[0016] Such as Figure 1-Figure 2 As shown, a flexible tooling fixture for automobile glass includes a bottom plate 1, baffles 2 are arranged on both sides of the top of the bottom plate 1, and a clamping mechanism is arranged between the baffles 2 on both sides; The bracket 3 on the bracket 3 is hinged with a pressure rod 4 and a push rod 5, the pressure rod 4 is located above the push rod 5, and the end of the pressure rod 4 is provided with a crimping piece 6 located above the bottom plate 1, and the push rod 5 corresponds to The end of the crimping piece 6 can crimp the bottom of the pressure rod 4 during the rotation process of the push rod 5 relative to the support 3. The support 3 is provided with a vertical chute 7, and the vertical chute 7 is slidably provided with a crimping top. The bolt 8 at the bottom of the rod 5, the bolt 8 can be locked in the vertical slide 7.

[0017] The positioning references for clamping the automobile glass in this embodiment include the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com