Method for selectively removing conductive layer on baseplate material

A conductive layer, selective technology, applied in electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of short laser projection path, difficult to peel off, and high temperature at the end of laser heating, and achieve a simple and fast circuit structure. , Avoid oxidation and burns, reduce the effect of oxidation and burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

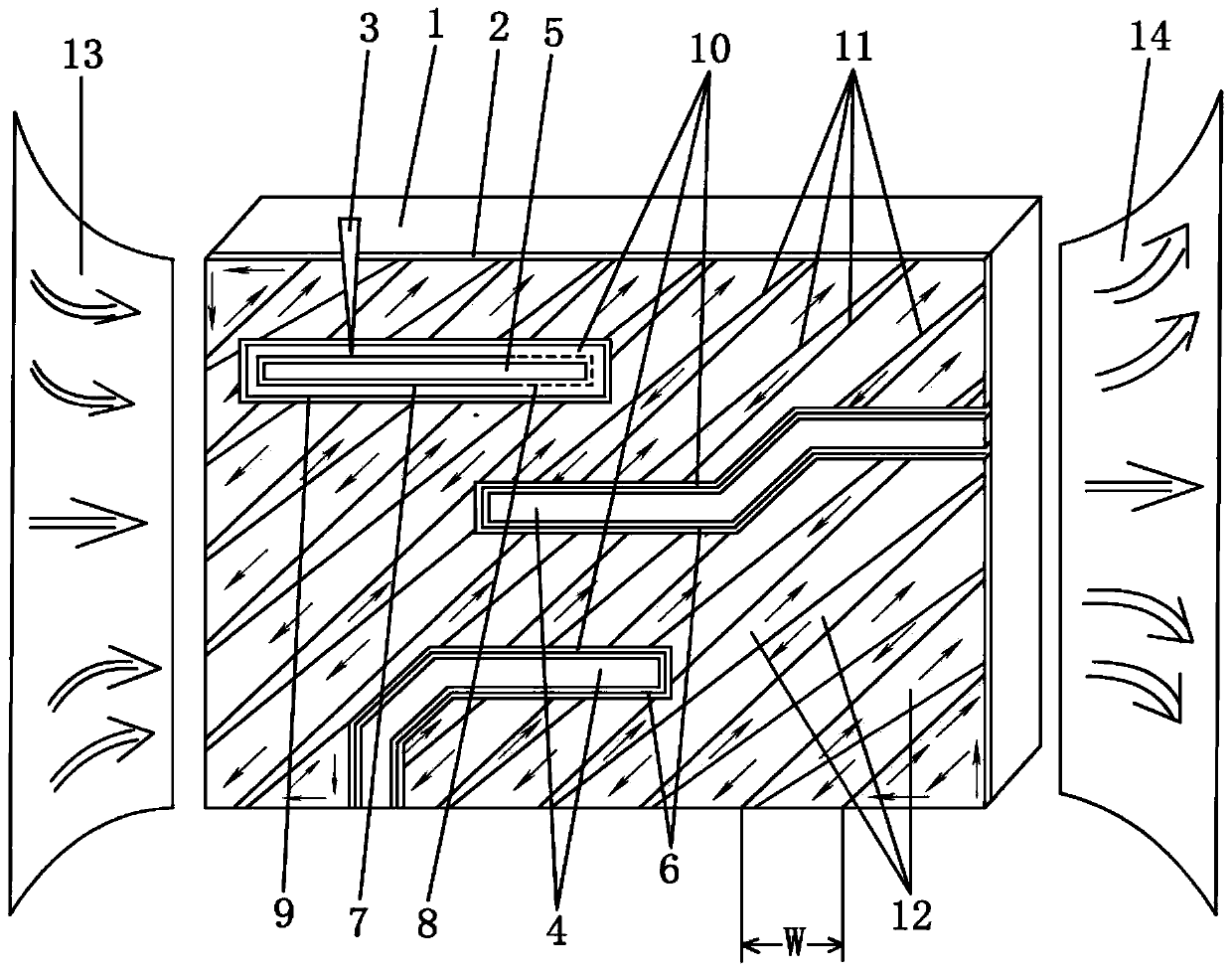

[0062] In this example, the substrate material is FR4 copper-clad laminate, using CircuitCAM V7.0 or above or DCT-DreamCreaTor software to process the data to be processed, and using DCT-DL500 laser equipment for processing.

[0063] A method for selectively removing the conductive layer on the substrate material according to design requirements to form a predetermined conductive pattern. In the method, the insulation channel path, the separation path and the heating path are as follows: figure 1 As shown, wherein, 1 is an insulating substrate material, and 2 is a metal conductive layer covering the substrate material. The operation steps are:

[0064] Step (1): Under the condition that the dust collection device 14 is turned on and the inert gas delivery device 13 is turned on, use a laser to process the insulating channel on the outer edge of the conductive layer to be retained;

[0065] First process the ultra-narrow isolated wire 5, and use the laser beam 3 to complete par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com