Effective elastic display transfer jig capable of folding and back flowing

A display and elastic technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of small binding area, large manpower waste, and breakage, and achieve the effects of manpower saving, high production efficiency, and good production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

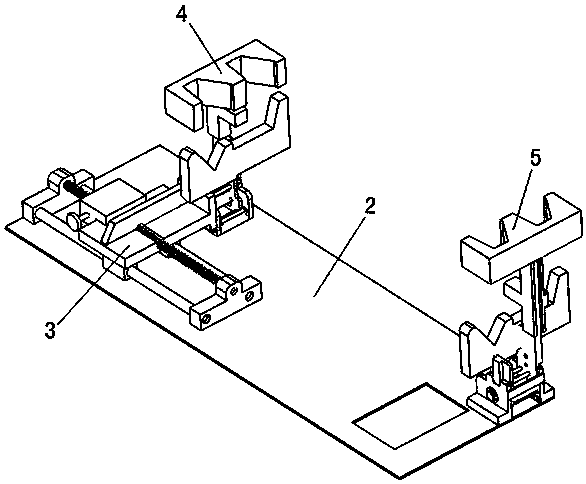

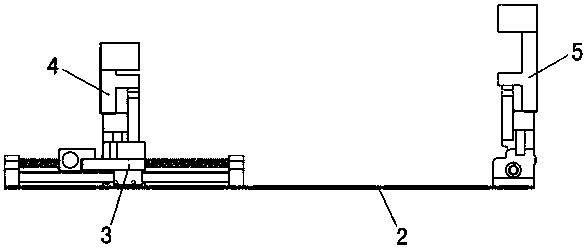

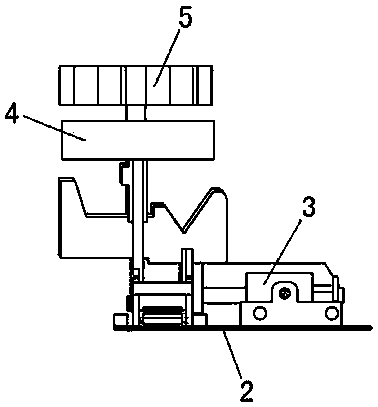

[0026] Such as Figure 1~5 As shown, a foldable reflow high-efficiency elastic display transfer fixture includes a substrate 1, a stepless adjustment module 3, a movable support handle 4, a fixed support handle 5 and a common collector plate 2. The stepless adjustment module 3 and the fixed support handle 5 are respectively installed on the left and right sides of the collector plate 2, the collector plate 2 is fixedly arranged on the base plate 1, and the stepless adjustment module 3 includes a screw rod 31, a slider 32 and a positioning button 33. The positioning button 33 is fixedly installed on the slider 32, the slider 32 is slidably installed on the screw rod 31 and locked by the positioning button 33, and the mobile support handle 4 is fixedly installed on the slider 32 of the stepless adjustment module 3 and cooperate with the fixed support handle 5 to clamp the display. Both the movable support handle 4 and the fixed support handle 5 are foldable structures.

[0027]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com