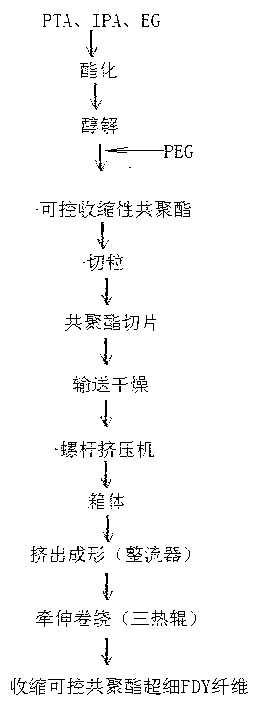

Method for preparing ultrafine contractible controllable copolyester fiber by adopting direct esterification polycondensation method

A copolyester and superfine technology, applied in the textile field, can solve problems such as abnormal production, low spinning melting temperature, and decreased rheological properties of the melt, and achieve stability, simple process, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add terephthalic acid and isophthalic acid into ethylene glycol under stirring, and perform esterification reaction at 245-260°C to obtain esterified products. The temperature at the top of the split column is controlled at 100°C; Dicarboxylic acid is 5 mol% of the content of terephthalic acid, and the molar ratio of the sum of isophthalic acid and terephthalic acid to ethylene glycol is 1:2;

[0019] (2) Copolymerize the obtained esterification product with polyethylene glycol, react for 2-4 hours, and the final temperature of polycondensation is 285-295°C to obtain copolyesters with different shrinkage rates. Polyethylene glycol consumption accounts for 1wt% of esterification product;

[0020] (3) Pre-crystallize and dry the copolyester, and melt and extrude it through a screw extruder. The relevant production process conditions are shown in Table 1;

[0021] (4) Draw and wind with 20 heads of high-speed spinning equipment with three hot rollers. See Table 1 for ...

Embodiment 2

[0024] (1) Add terephthalic acid and isophthalic acid into ethylene glycol under stirring, and carry out esterification reaction at 245-260°C to obtain esterified products. The temperature at the top of the split column is controlled at 100-110°C; Isophthalic acid is 13 mol% of the content of terephthalic acid, and the molar ratio of the sum of isophthalic acid and terephthalic acid to ethylene glycol is 1:2;

[0025] (2) Copolymerize the obtained esterification product with polyethylene glycol, react for 2-4 hours, and the final temperature of polycondensation is 285-295°C to obtain copolyesters with different shrinkage rates. Polyethylene glycol consumption accounts for 1.3wt% of esterification product;

[0026] (1) Pre-crystallize and dry the copolyester, and melt and extrude it through a screw extruder. The relevant production process conditions are shown in Table 1;

[0027] (2) Draw and wind with 20 heads of high-speed spinning equipment with three hot rollers. See Tabl...

Embodiment 3

[0031] (1) Add terephthalic acid and isophthalic acid to ethylene glycol under stirring, and carry out esterification reaction at 252°C to obtain esterified products. The temperature at the top of the split column is controlled at 100°C; isophthalic acid It is 3mol% of the content of terephthalic acid, and the molar ratio of the sum of isophthalic acid and terephthalic acid to ethylene glycol is 1:2;

[0032] (2) Copolymerize the obtained esterification product with polyethylene glycol, react for 2-4 hours, and the final temperature of polycondensation is 285-295°C to obtain copolyesters with different shrinkage rates. Polyethylene glycol consumption accounts for 0.8wt% of esterification product;

[0033] (3) Pre-crystallize and dry the copolyester, and melt and extrude it through a screw extruder. The relevant production process conditions are shown in Table 1;

[0034] (4) Draw and wind with 20 heads of high-speed spinning equipment with three hot rollers. See Table 2 for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com