Patents

Literature

174results about How to "Fully stretched" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

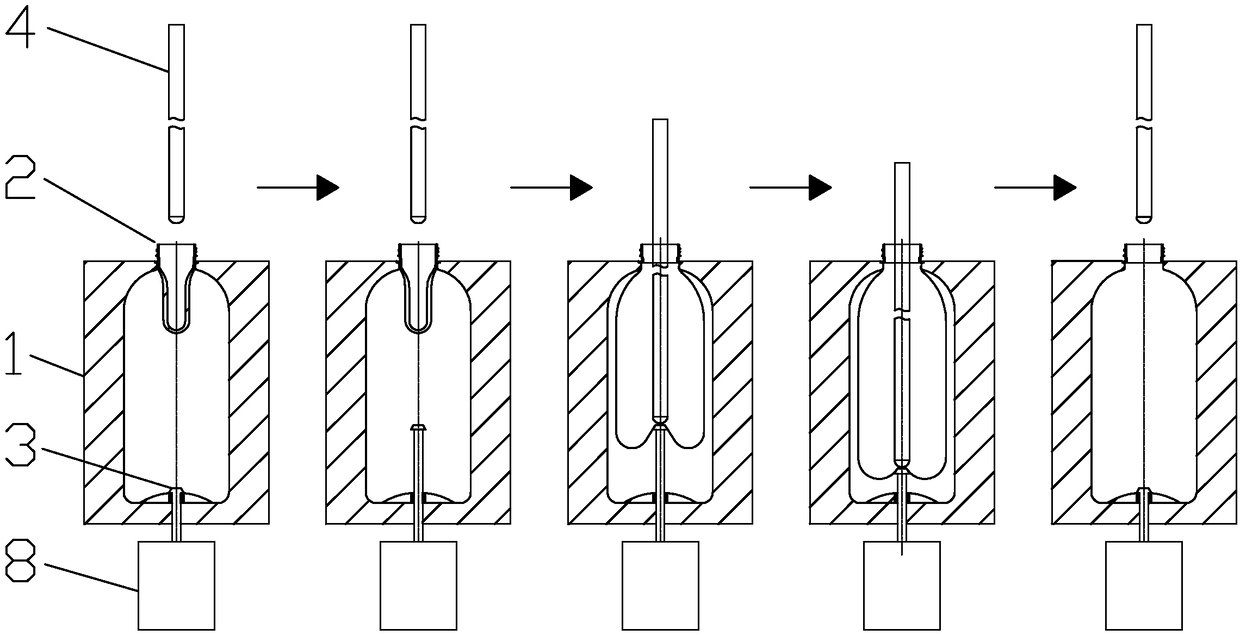

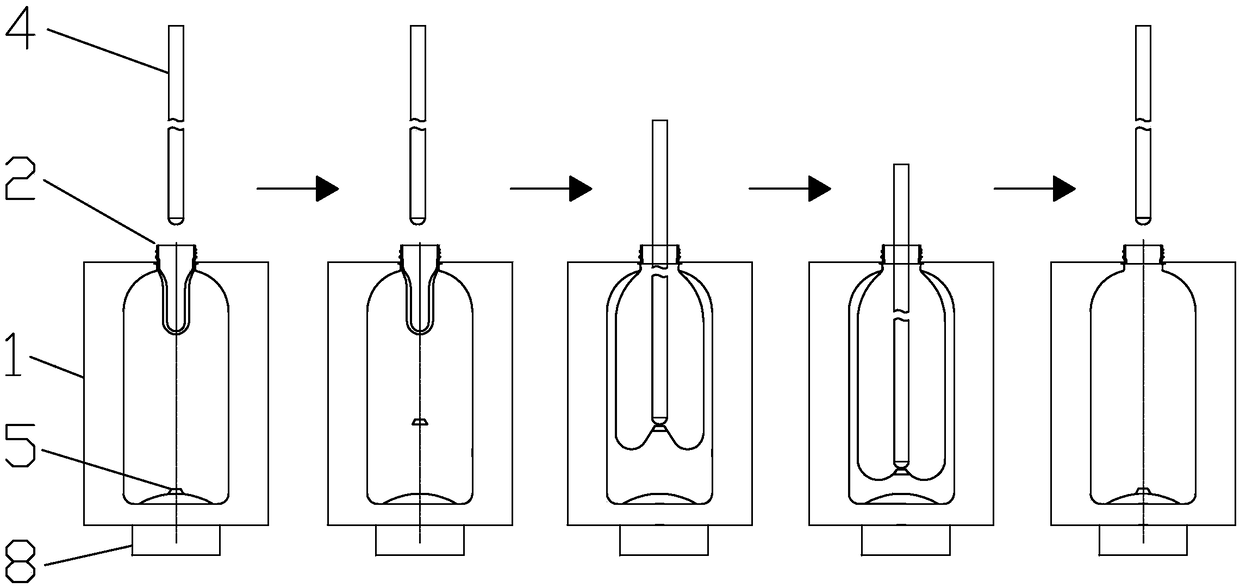

Axial dual-direction positioning and stretching hollow blow molding method

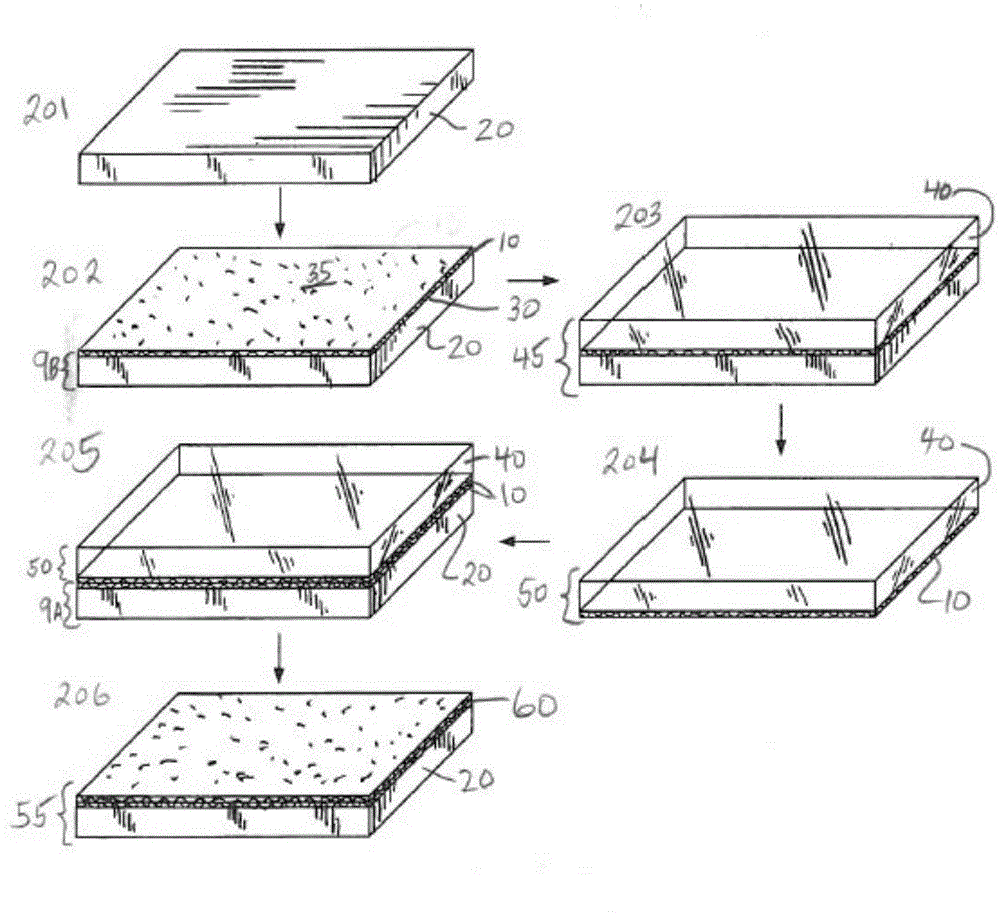

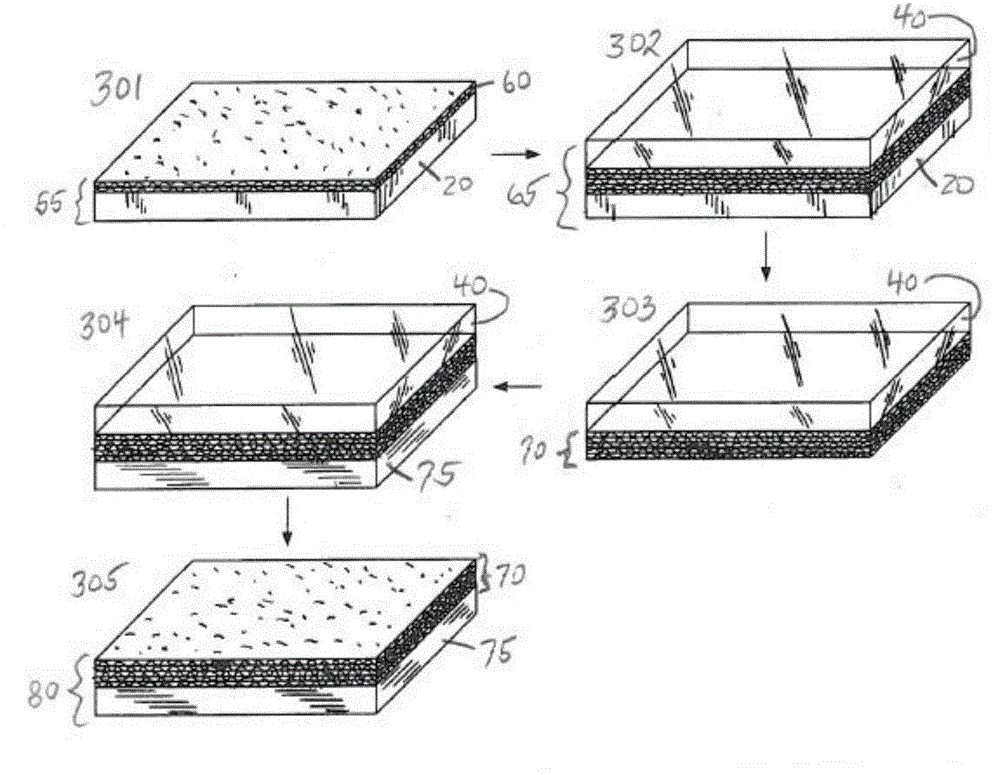

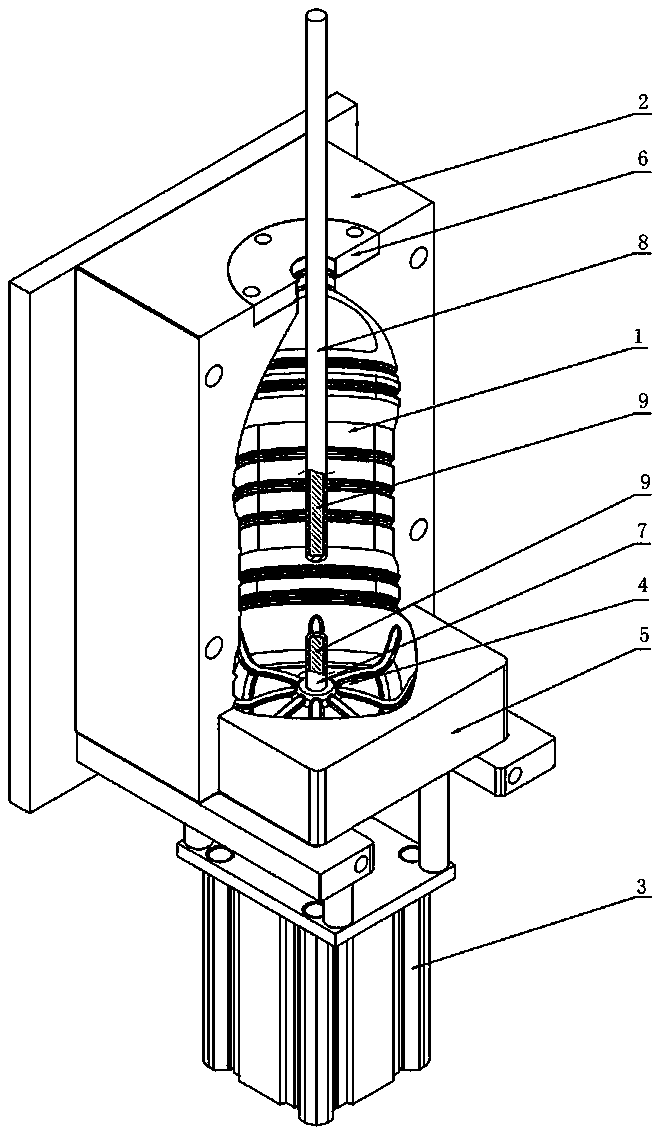

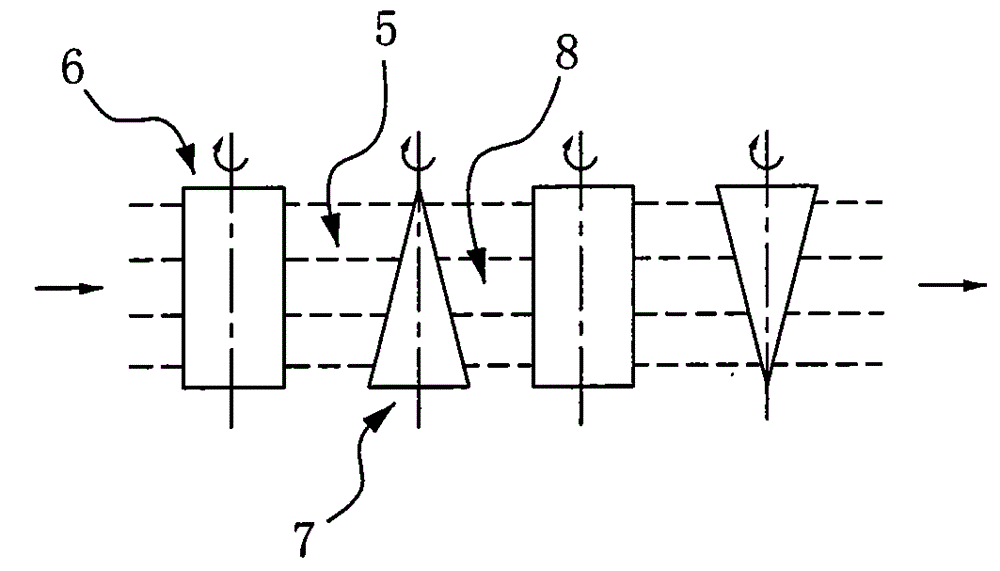

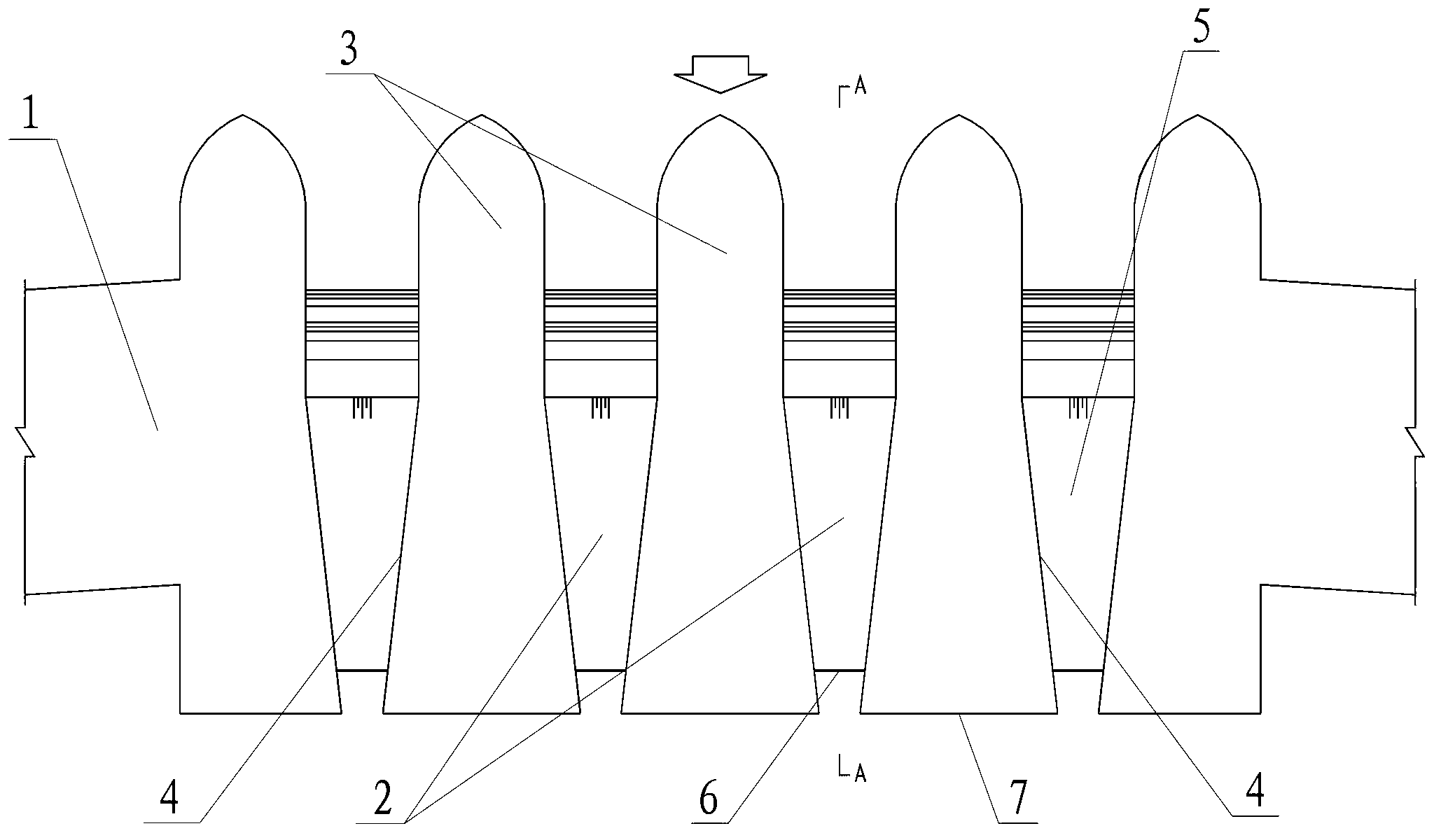

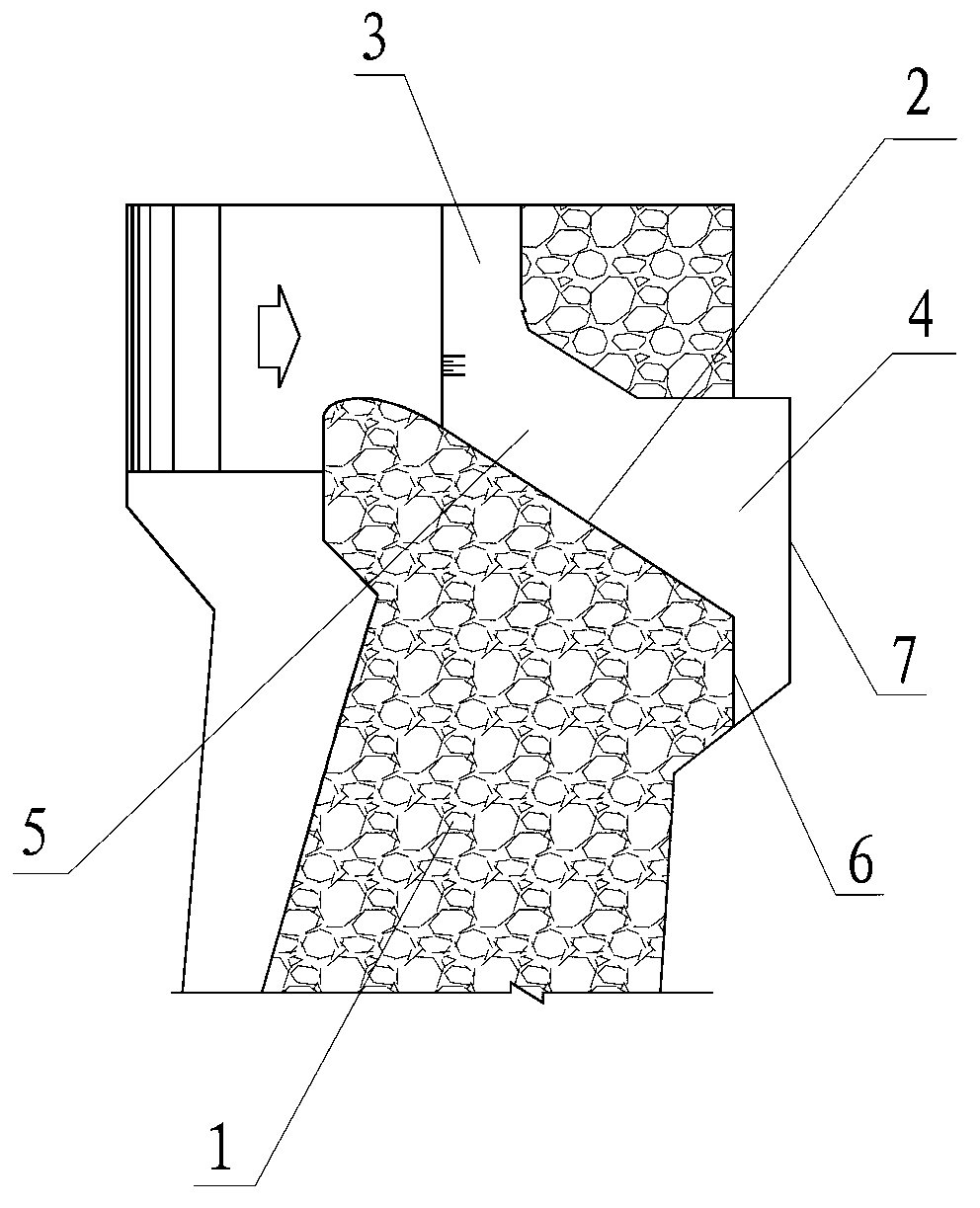

The invention provides an axial dual-direction positioning and stretching hollow blow molding method. Bearing devices for transitorily bearing the bottoms of bottle blanks are arranged in die cavities. A blow-molded container molding method includes the following steps that 1, the bottle blanks are heated to the stretching temperature, and stretching and pre-blow molding are carried out at the same time; 2, when the bottle blanks are stretched to the positions where the bearing devices are located, the bearing devices bear the centers of the bottoms of the bottle blanks which are gradually stretched and expand, the stretching speed is reduced or stretching is suspended at the positions where borne points of the bottoms of the bottle blanks are located, and the peripheries of the borne points are continuously stretched under the effects of air pressure and the inertia of materials; and 3, after cone bases are pre-formed, the bearing devices withdraw or move along with stretching rods, the stretching rods continue to stretch, the air pressure is injected, then cooling is carried out, and blow-molded containers are formed. The materials at the bottoms of the bottle blanks are fully stretched through bearing in the step 2, the materials are more evenly distributed at the bottoms of bottles, and better cooling shaping can be achieved.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

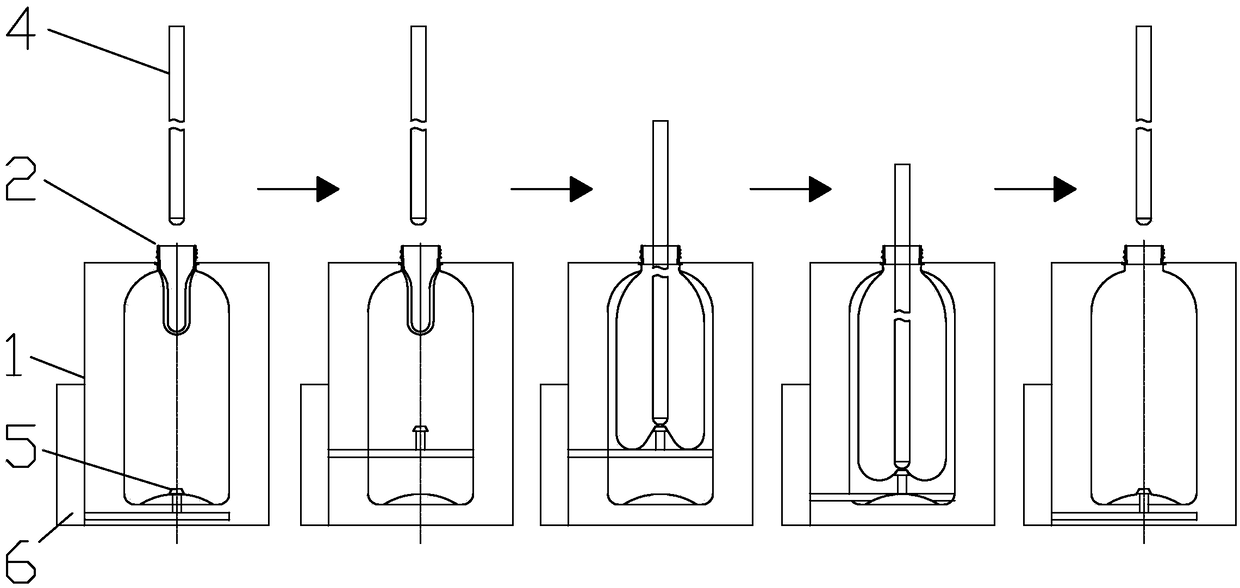

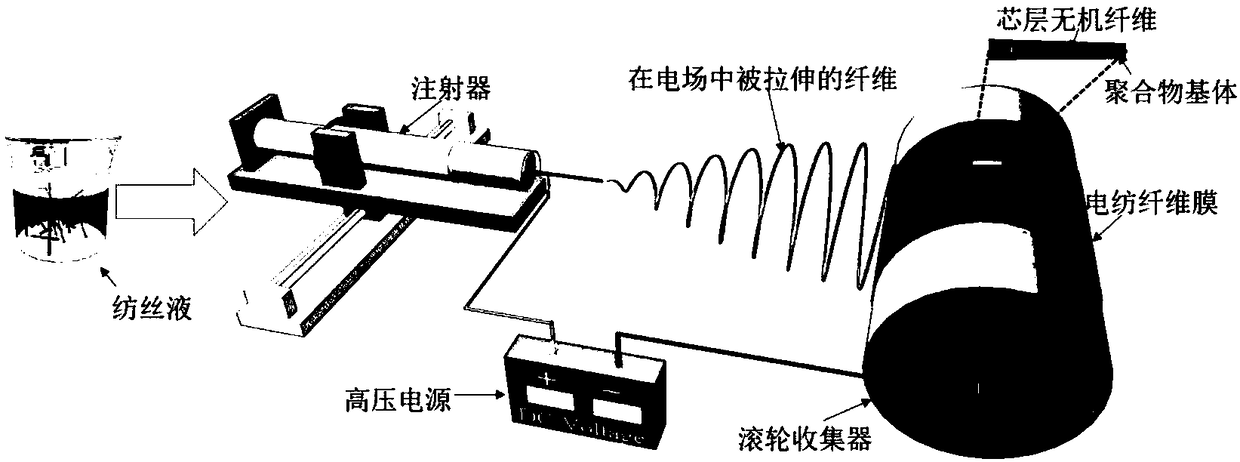

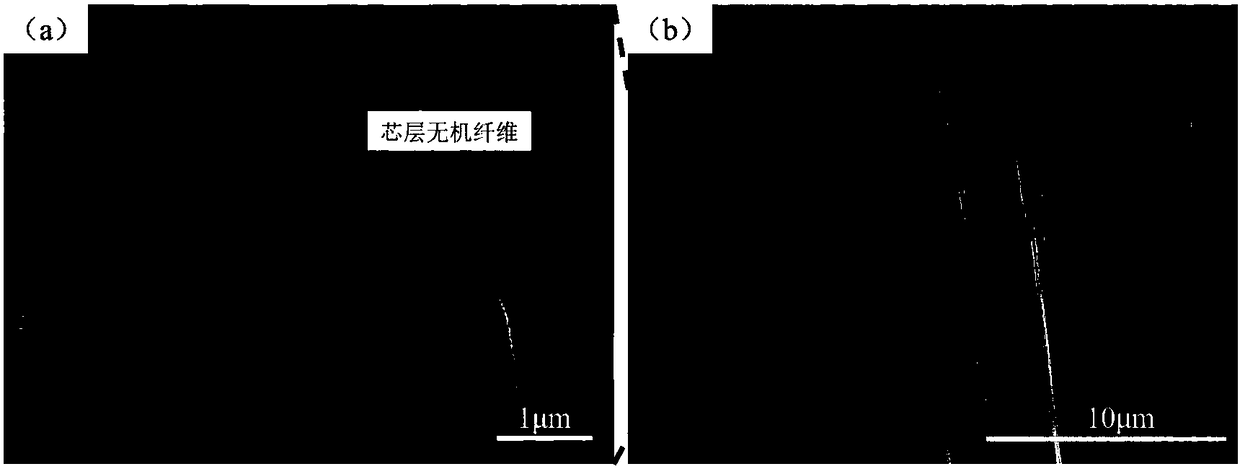

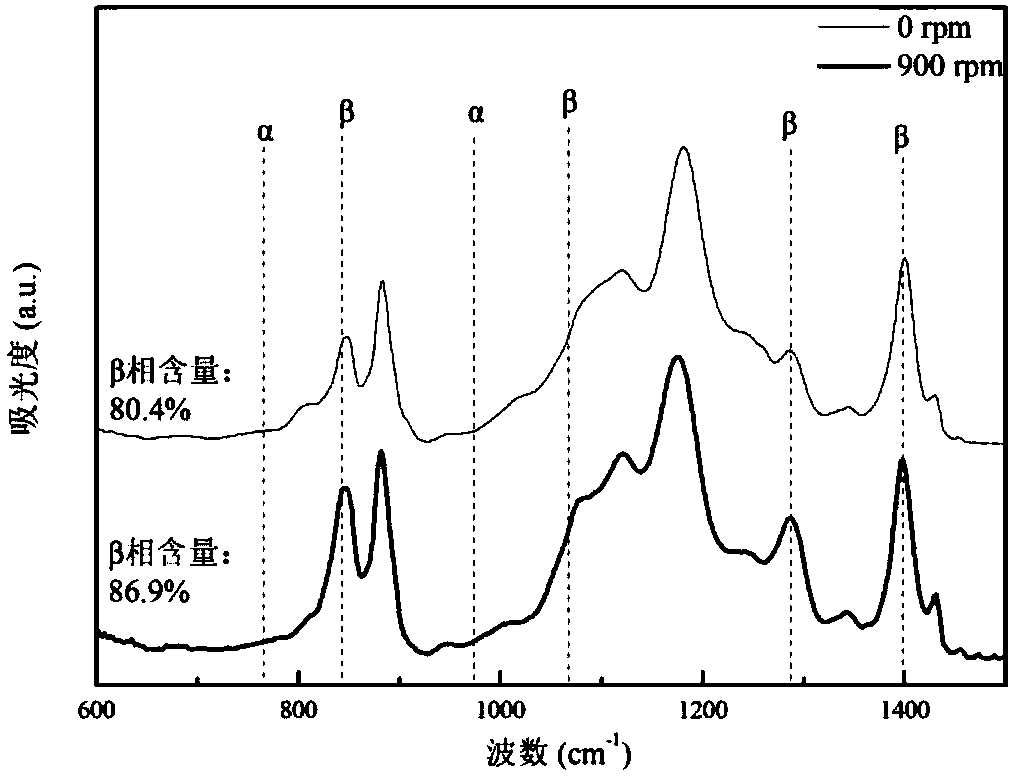

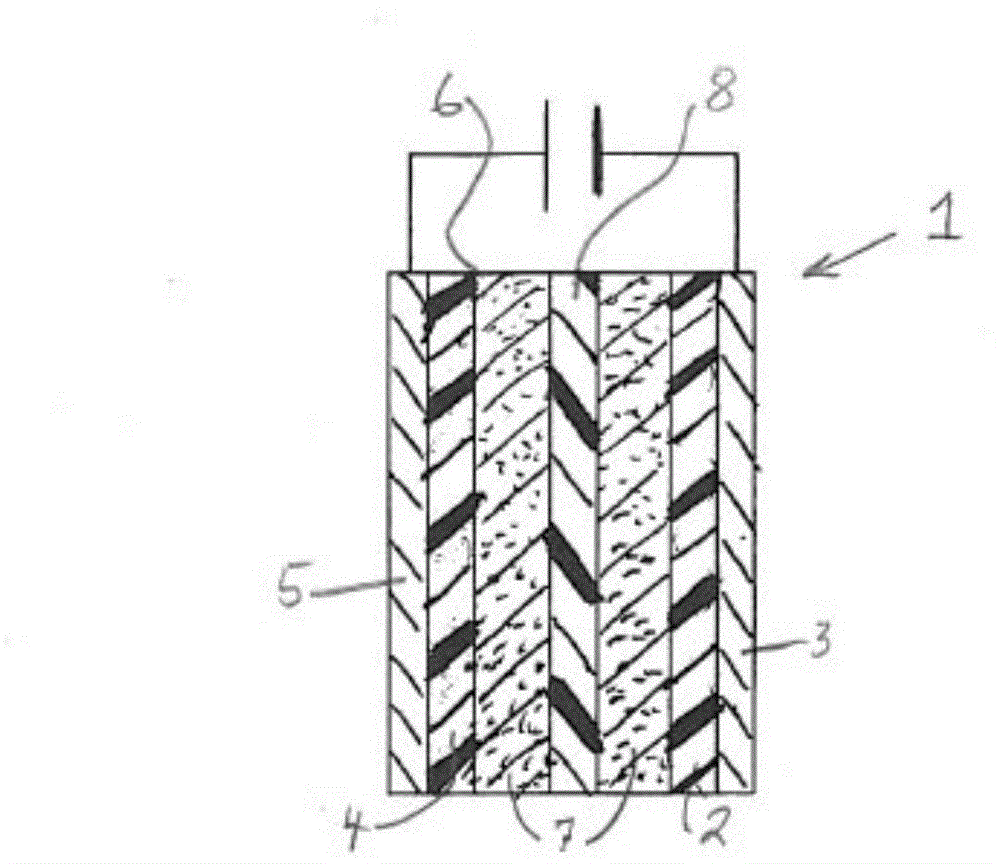

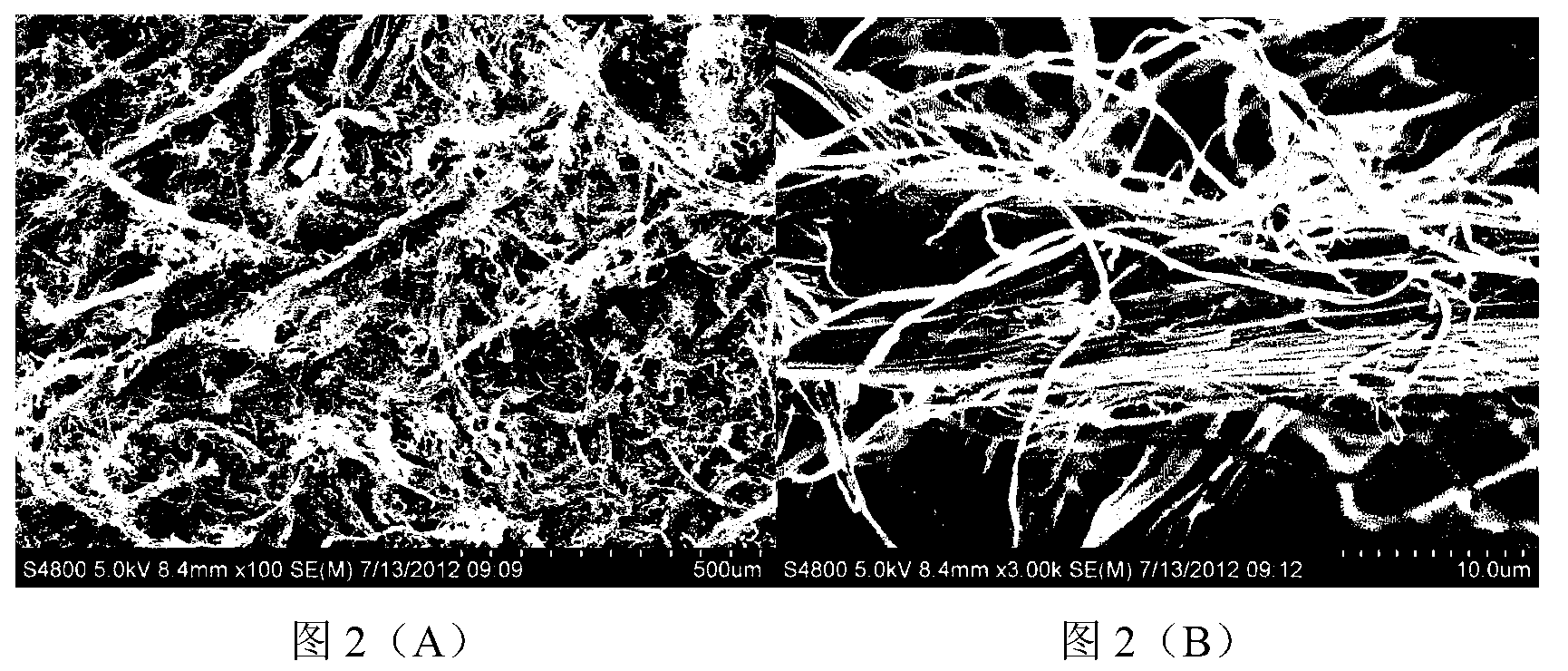

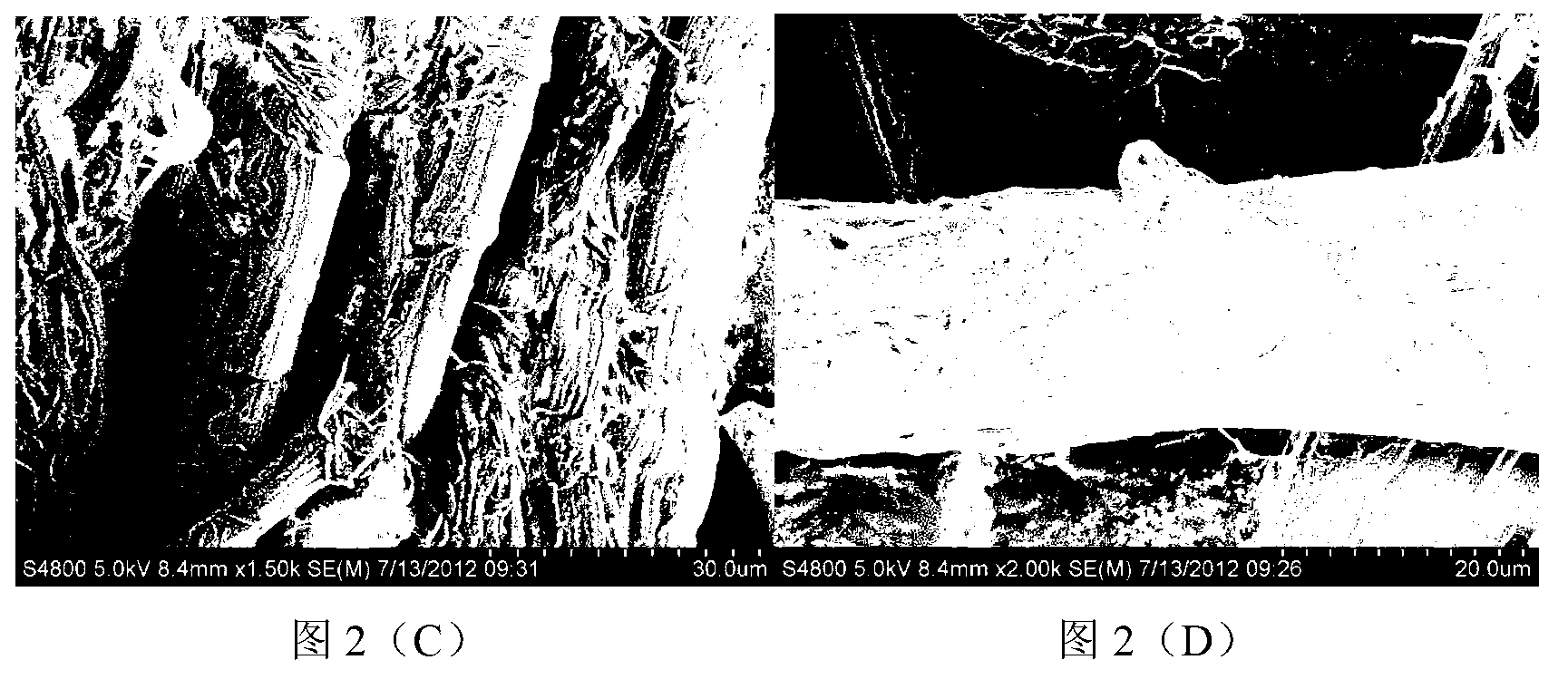

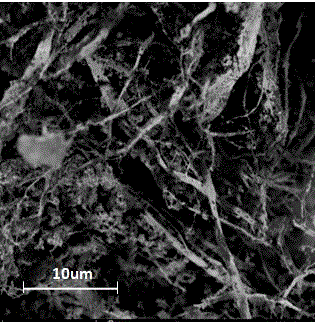

Flexible piezoelectric fiber thin film with high output and preparation method thereof

ActiveCN108442038AEasy to prepareIncreased piezoelectric phase contentElectro-spinningNon-woven fabricsPolyvinylidene fluorideElectrospinning

The invention provides flexible piezoelectric fiber thin film with high output and a preparation method thereof, and belongs to the technical field of electron composite materials and micro-nano function materials. An electrostatic spinning technology is adopted, and ceramic fibers, conductive fibers and other one-dimensional inorganic materials are taken as filler to prepare polymer-based composite film of a sleeve structure and in directional alignment. The filler core of the fiber composite thin film of the sleeve structure is barium titanate, barium strontium titanate, lead zirconate titanate and other piezoelectric ceramic fibers or silver nanofibers, multiwalled carbon nanotubes and other one-dimensional conductive fillers, and inorganic fillers are wrapped with polymer matrix fibers. The polymer matrix can be polyvinylidene fluoride, polyvinylidene fluoride-trifluoroethylene, polyvinylidene fluoride-trifluoroethylene-hexafluoropropylene and other materials. By adjusting contentand types of the filler, piezoelectric output voltage can reach 20 V, the output current can reach 250 nA. The cokmposite material has the advantages of good flexibility, high piezoelectric output, high sensitivity and light weight, and can be taken as a power supply of wearable equipment and a flexible sensor to detect human activities.

Owner:UNIV OF SCI & TECH BEIJING

Method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup

The invention discloses a method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup in the production of enzymatic corn starch sugar, comprising the steps of size mixing, liquefying, saccharifying, standing separation, centrifugal separation, proteolysis, concentration, drying, compounding, and the like. In the invention, protein is condensed under the heat flash of liquefying, the protein sugar dregs concentrate and float upwards in saccharifying, the sugar dregs are recovered through the steps of standing separation and centrifugal separation, the sugar dregs are dried into protein, or the sugar dregs are hydrolyzed to prepare protein nitrogen sources, and the nitrogen sources can be compounded with syrup to form nitrogen-containing starch syrup for fermenting. Clarified saccharification liquid after centrifugal separation is decolored, filtered, refined and concentrated, and starch syrup products are obtained. The majority of lentous sugar dregs in the saccharification liquid are removed before the treatment of decoloring and filtering, and the decoloring and filtering performance of the material is better. The use level of active carbon, and the like can be properly reduced, the production capability of filtering equipment is improved, and the frequency of the loading and unloading of filters as well as the consumption of washing waste water and various kinds of loss are greatly reduced.

Owner:广州双桥(重庆)有限公司

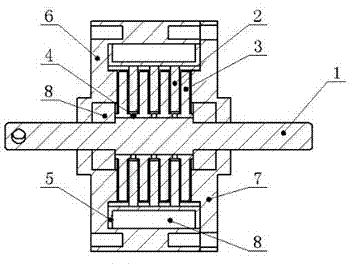

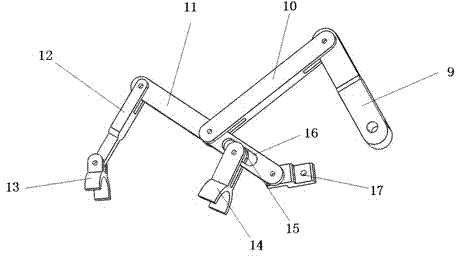

Finger movement function rehabilitation training device

InactiveCN104840334AActive training worksSports comfortGymnastic exercisingChiropractic devicesDrive shaftEngineering

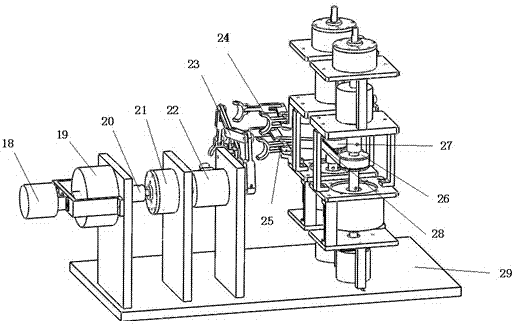

The invention discloses a finger movement function rehabilitation training device which comprises a supporting seat and a finger training mechanism arranged on the supporting seat. The finger training mechanism consists of a finger motion mechanism and a hybrid driving and sensing mechanism, wherein the finger motion mechanism comprises a driving rod, a driving connection rod, a front-rear-end connecting rod, a front-end connecting rod, a front-end finger sleeve, a rear-end finger sleeve and a fixing seat. One end of the driving rod is fixedly connected with a driving shaft, the fixing seat is fixe to the supporting seat, one end of the front-rear-end connecting rod is rotatably connected to the fixing seat, the other end of the front-rear-end connecting rod is rotatably connected with the front-end connecting rod, one end of the driving connection rod is rotatably connected to the middle of the front-rear-end connecting rod, and the other end of the driving connection rod is rotatably connected with the other end of the driving rod. The finger motion mechanism can accurately control movements of all joints of fingers, enables a hemiplegic patient to perform training in a correct finger movement mode and facilitates rehabilitation of normal movement functions of the fingers of the patient.

Owner:SOUTHEAST UNIV

Poly N-vinyl pyrrolidone-contained amphiphilic copolymer grafted by natural high polymer or water-solubility derivative thereof and preparation method thereof

InactiveCN101643531AImprove complexation stabilization effectGood hydrophobic associationSolubilityPolymer science

The invention provides a poly N-vinyl pyrrolidone-contained amphiphilic copolymer grafted by natural high polymer or water-solubility derivative thereof and a preparation method thereof, and a complexof the copolymer and iodin. After natural high polymer or the water-solubility derivative thereof is dissolved, an initiating agent is added to initiate grafting copolymerization; hydrophilic monomercontaining poly N-vinyl pyrrolidone is added to be polymerized into hydrophilic chain segments, and meanwhile, hydrophobic monomer is added to carry out grafting copolymerization, and then an amphiphilic grafting copolymer derivative containing the polyvinyl pyrrolidone chain segments of natural high polymer or water-solubility derivative thereof, is obtained. The derivative keeps high biologicalactivity and degradability of the natural high polymer or water-solubility derivative thereof and good fixing effect of polyvinyl pyrrolidone having good complexing performance to iodin, and meanwhile, an amphiphilic structure gives the good hydrophobic association and surface activity to the derivative; moreover, the complexing effect of the polyvinyl pyrrolidone chain segments and iodin in thecopolymer is further enhanced.

Owner:陈煜

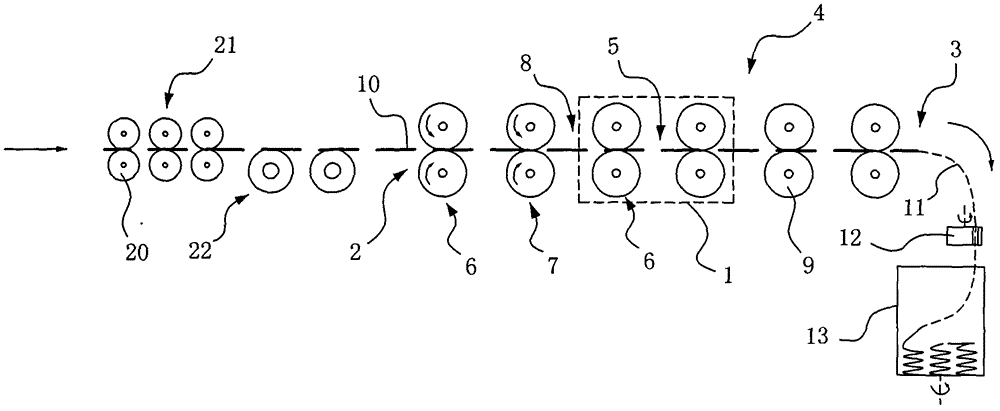

Segment color yarn spinning device and segment color yarn spinning method

ActiveCN105821532ARealize spinningFully stretchedDrafting machinesContinuous wound-up machinesYarnPulp and paper industry

The invention provides a segment color yarn spinning device and a segment color yarn spinning method. The segment color yarn spinning device comprises a front roller, a middle roller and a rear roller, wherein the middle roller comprises a roller shaft; the roller shaft is connected with a first roller sleeve and a second roller sleeve from left to right; the front roller, the middle roller and the rear roller are driven by a first server motor, a second server motor and a third server motor respectively; a first bell mouth, a second bell mouth and a third bell mouth are additionally arranged at the upper parts of the front roller, the middle roller and the rear roller; the first roller sleeve is integrally connected with the roller shaft; the second roller sleeve is connected with the roller shaft through a bearing; and the bearing is connected with an electromagnetic switch. In the production process, main body rough yarns are fed into the rear roller from the first bell mouth, and auxiliary rough yarns are fed into the second roller sleeve of the middle roller from the second bell mouth; and the spinning of white yarn segments and colored yarn segments is realized by switching on / off of the bearing.

Owner:ZHANJIANG ZHONGZHAN TEXTILE

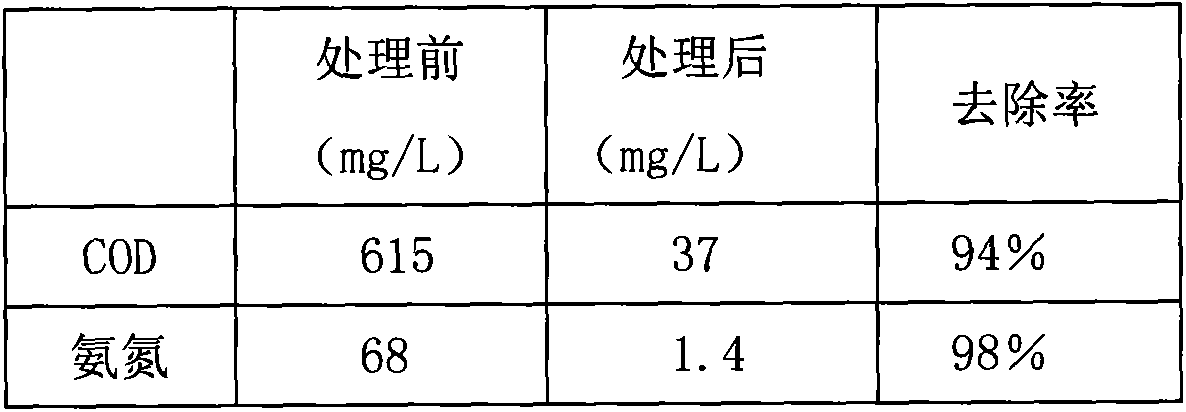

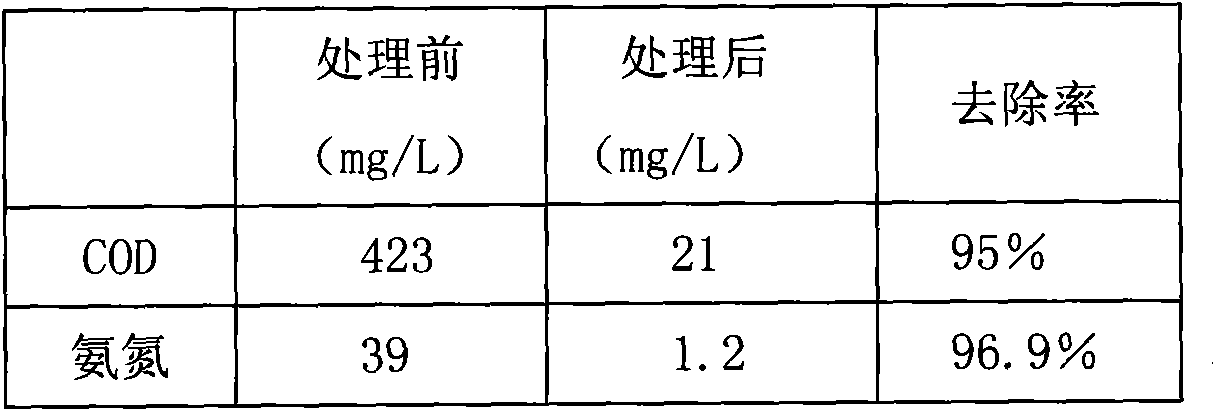

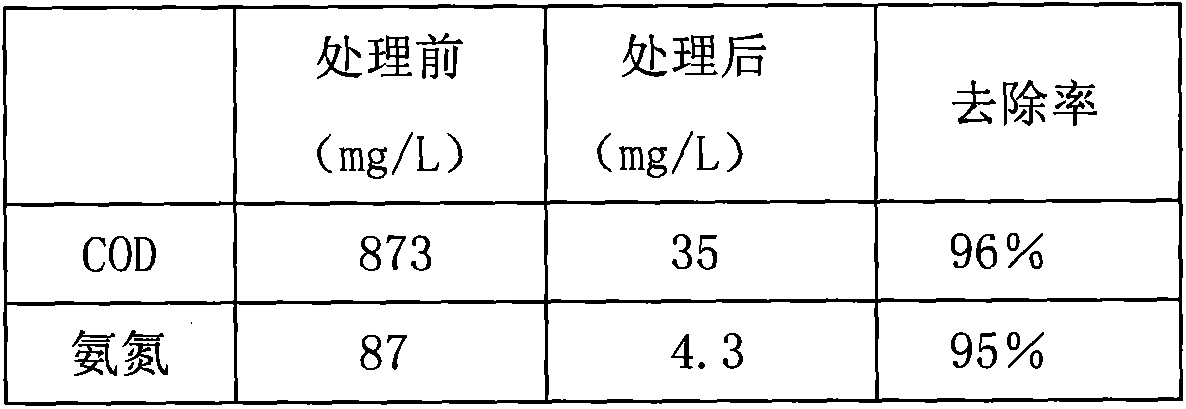

Method for anaerobic-aerobiotic-microbial flocculation reinforced wastewater treatment

InactiveCN103964646AEfficient removalImprove biodegradabilityMultistage water/sewage treatmentAluminium chlorideFlocculation

The invention discloses a method for anaerobic-aerobiotic-microbial flocculation reinforced wastewater treatment. The method comprises the following steps of: 1) treating the wastewater to be treated in a regulation tank; 2) removing large floating matters and impurities out of the wastewater (treated in the regulation tank) by a grating device; 3) pumping the effluent obtained in the step 2) in a quick mixing tank, and adding a flocculant PAC (poly aluminium chloride) in the quick mixing tank and carrying out flocculation pre-precipitate; 4) carrying out anaerobic-aerobiotic treatment; 5) feeding the water body in a secondary sedimentation tank and adding 7.5vol% of a microbial flocculation agent and 5vol% of CaCl2 solution with a concentration of 1-1.5%, mixing for 8-10 minutes and then enabling the liquid to pass through a high-performance ceramic filter material with a particle size of 3-5mm and a quartz sand cushion laid on the bottom of the high-performance ceramic filter material; and 6) feeding the effluent obtained in the step 5) in an attapulgite adsorption tank for further adsorption bleaching, removing micropollutants, and disinfecting the effluent, wherein attapulgite is arranged in the attapulgite adsorption tank, a Pt metal screen is arranged on the attapulgite, and the attapulgite is loaded with Fe2O3 or CuO and NaCl; and finally draining water in a water collection tank.

Owner:NANJING UNIV

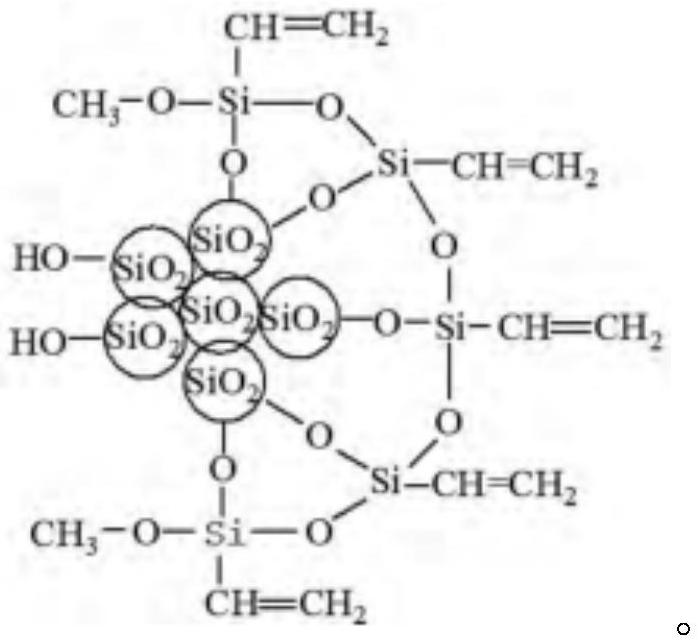

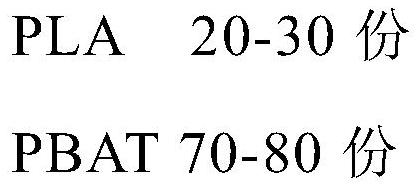

Full-biodegradable high-barrier PLA/PBAT composite packaging film

InactiveCN112280261AImprove the performance of oxygen barrierGood dispersionDouble bondPack material

The invention relates to the technical field of packaging materials, in particular to a high-barrier PLA / PBAT composite packaging film. The biodegradable PLA / PBAT composite material is poor in barrierproperty to oxygen and water vapor. Aiming at the problems, the invention provides the high-barrier PLA / PBAT composite packaging film, the molecular structure of the modified nano silicon dioxide contains C=C double bonds, and the modified nano silicon dioxide can be polymerized with the modified graphene in the extrusion granulation process to form a tightly interlaced network structure, so thatthe internal free volume in the PLA / PBAT composite material system is filled to a certain extent; the oxygen blocking performance of the PLA / PBAT composite material is greatly improved; a tightly interlaced network structure formed by the modified nano silicon dioxide and the modified graphene and a molecular chain of polylactic acid are interpenetrated and intertwined together through hydrogen-bond interaction, so that the water vapor blocking performance of the PLA / PBAT composite material is further improved.

Owner:吴建

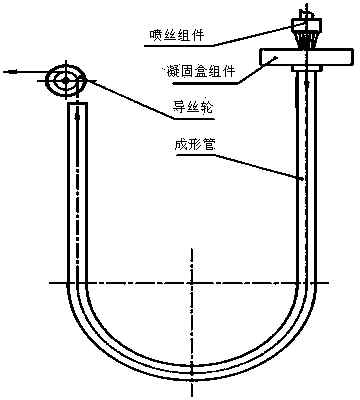

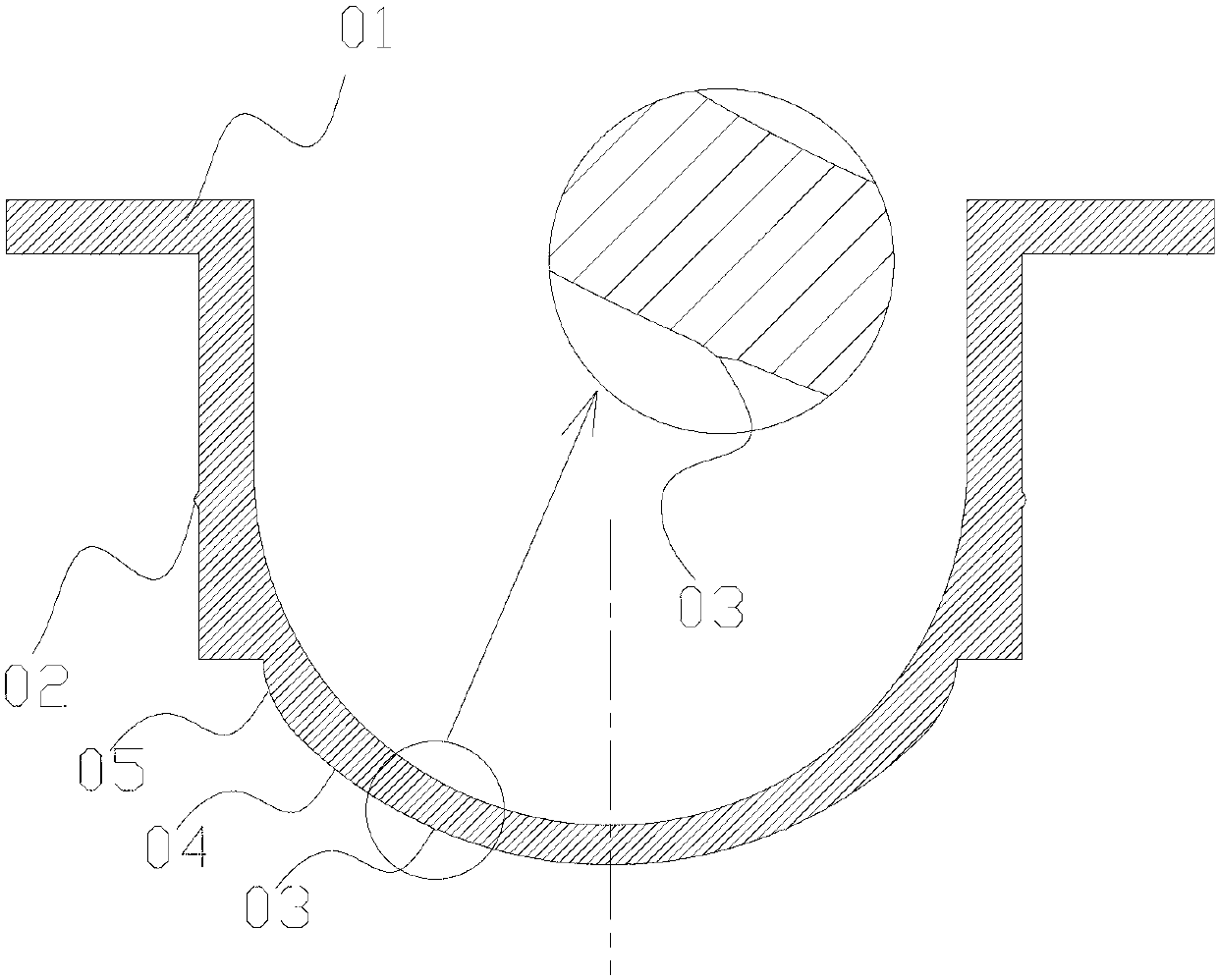

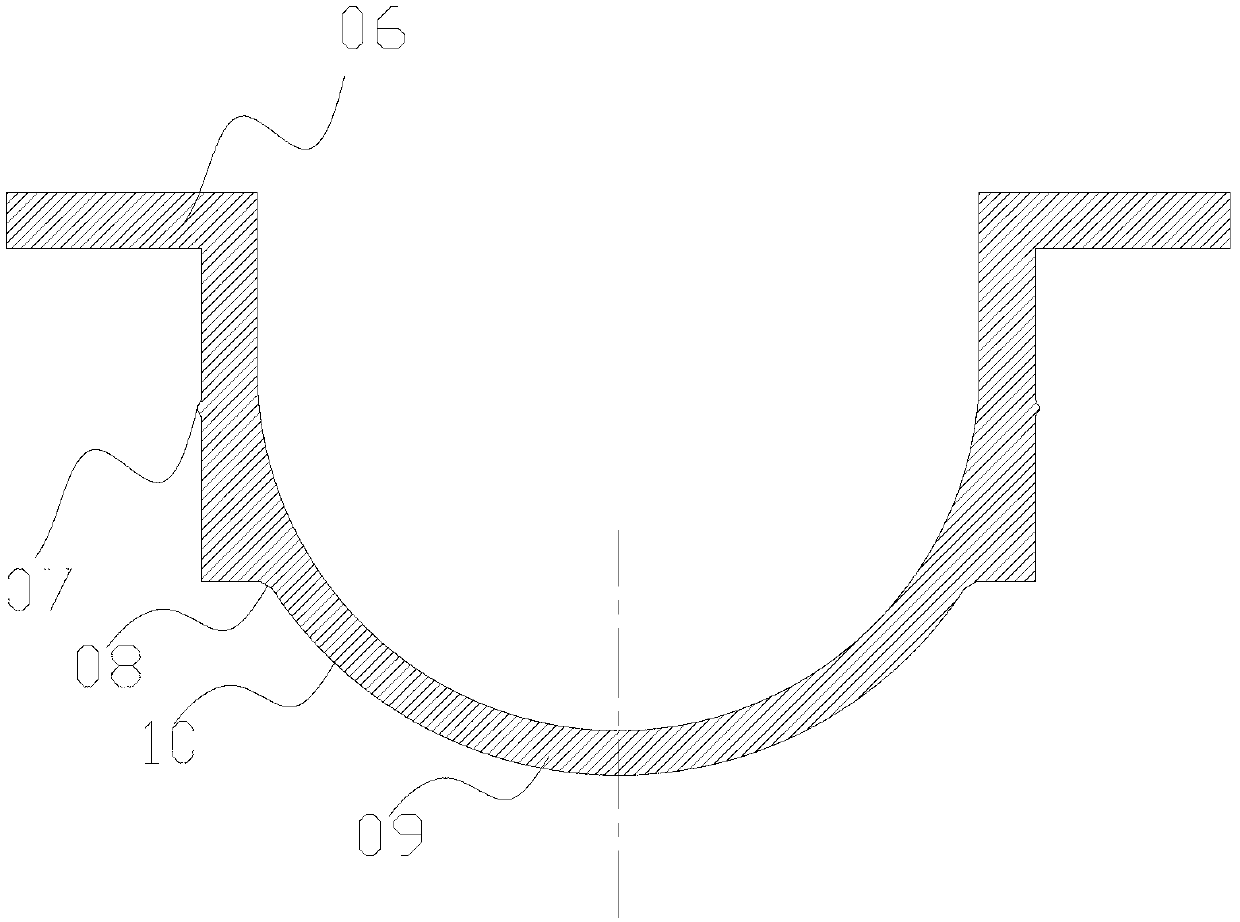

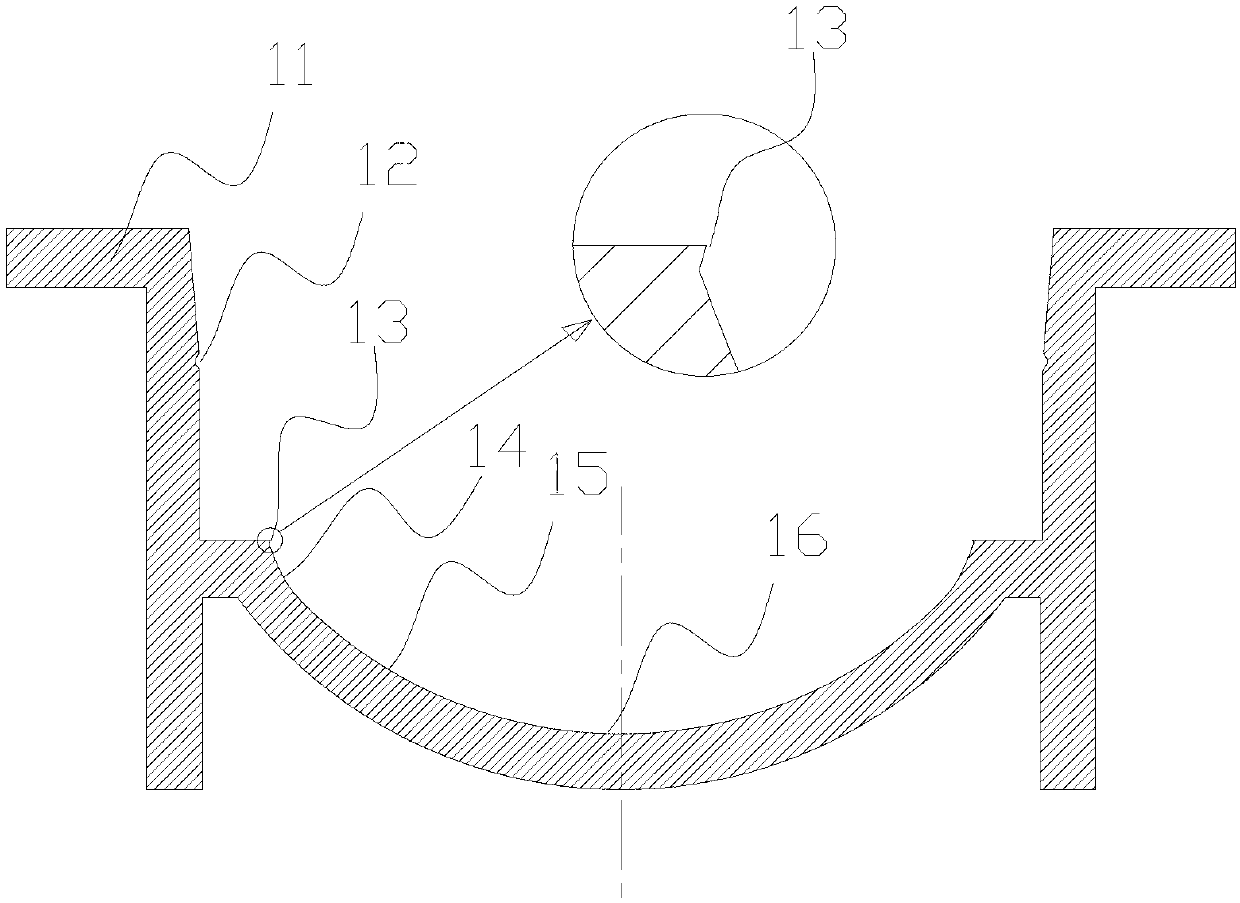

Dry spraying-wet spinning method for manufacturing aramid III fiber

ActiveCN103572390AIncrease spinning speedIncrease productivityWet spinning methodsDry spinning methodsYarnEngineering

The invention discloses a dry spraying-wet spinning method for manufacturing an aramid III fiber. The method comprises the following processing steps that A, a spinning stock solution is subjected to fine filtering and defoaming, and then extruded by a spinneret plate to form trickle; the trickle passes through an air layer and then enters a coagulating bath; B, the spinneret plate extruded trickle is coagulated in a coagulating forming device by the coagulating bath; a nascent fiber is obtained; the coagulating forming device comprises a coagulating disc and a U-shaped coagulating pipe; C, a solvent and an impurity of the coagulated and formed aramid III nascent fiber are removed by a washing technology; D, the washed fiber is oiled and dried; an aramid III fiber grey yarn is obtained; and E, the aramid III fiber grey yarn is subjected to heat treatment by heat shaping equipment; and the finished fiber is obtained. According to the method, a spinning speed and the production efficiency of the aramid III fiber are increased and improved greatly, so that the production cost of the fiber is lowered effectively; the manufactured aramid III fiber has excellent fiber performance and appearance quality and high cost performance; and the strength of the aramid III fiber is higher than that of a commercially available aramid 1414 high-strength product K129.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Manufacture method for colored soft contact lenses

InactiveCN103341951APrevent drynessSafe and comfortable to wearOptical articlesSurface layerOptoelectronics

A manufacture method for colored soft contact lenses successively comprises the following steps: 1) injection molding of a mould; 2) preparation of a lens outer surface layer; 3) preparation of a lens color layer; 4) preparation of a lens inner surface layer; and 5) parting, hydration, detection, packaging and disinfection of the lens. The color layer is disposed in the middle of a soft contact lenses material non-optical area interlayer; the prepared colored soft contact lenses have the advantages of sufficient hydration, complete unfoldment, natural transition of radian and corners, intact combinations among the lens outer surface layer, an ink layer and the lens inner surface layer, improved hydrophilia and moisture retention, and dryness preventing effect on eyes; and therefore the purpose of safe and comfortable wearing for consumers is realized.

Owner:JIANGSU HORIEN CONTACT LENS

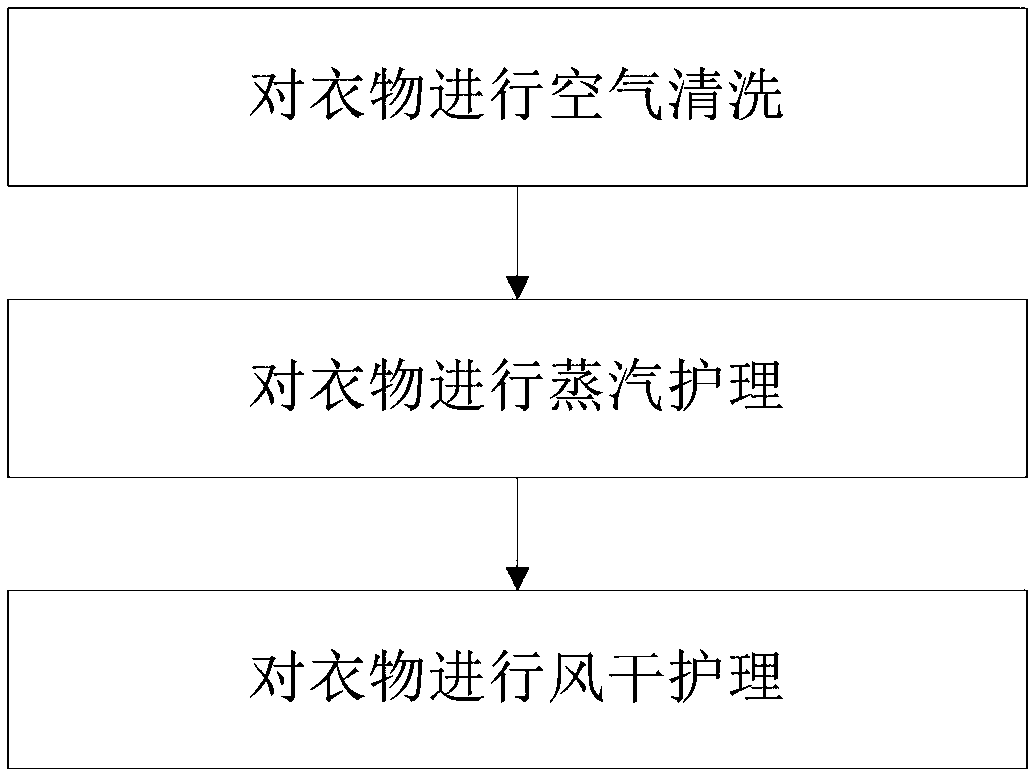

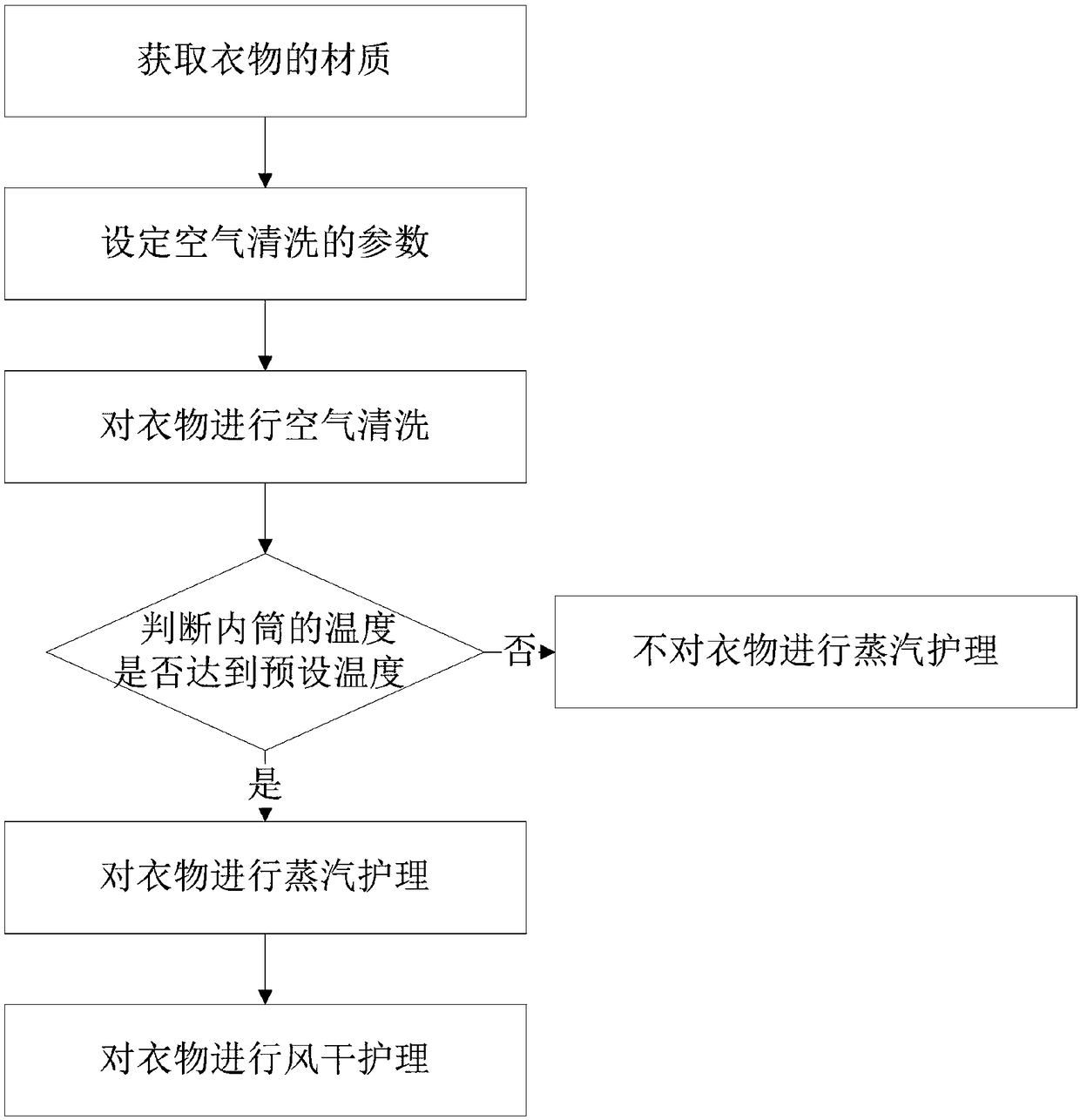

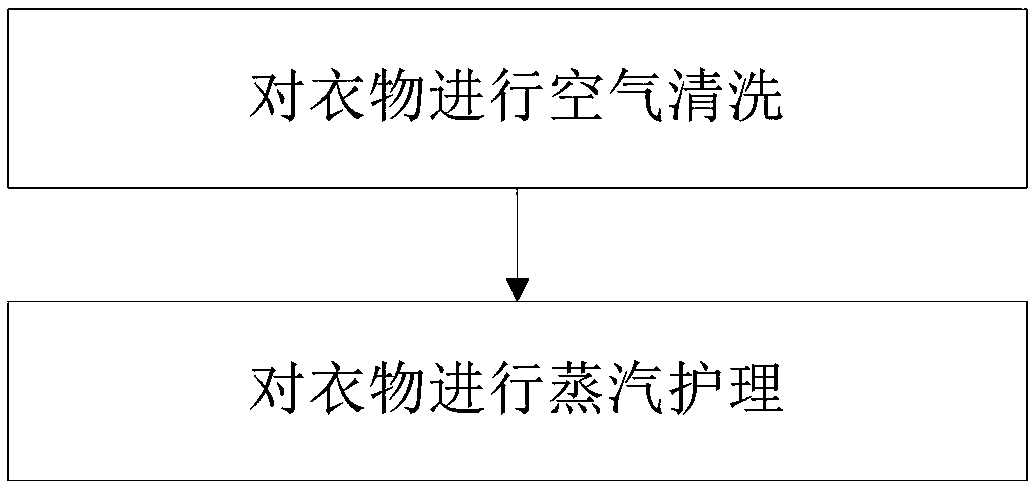

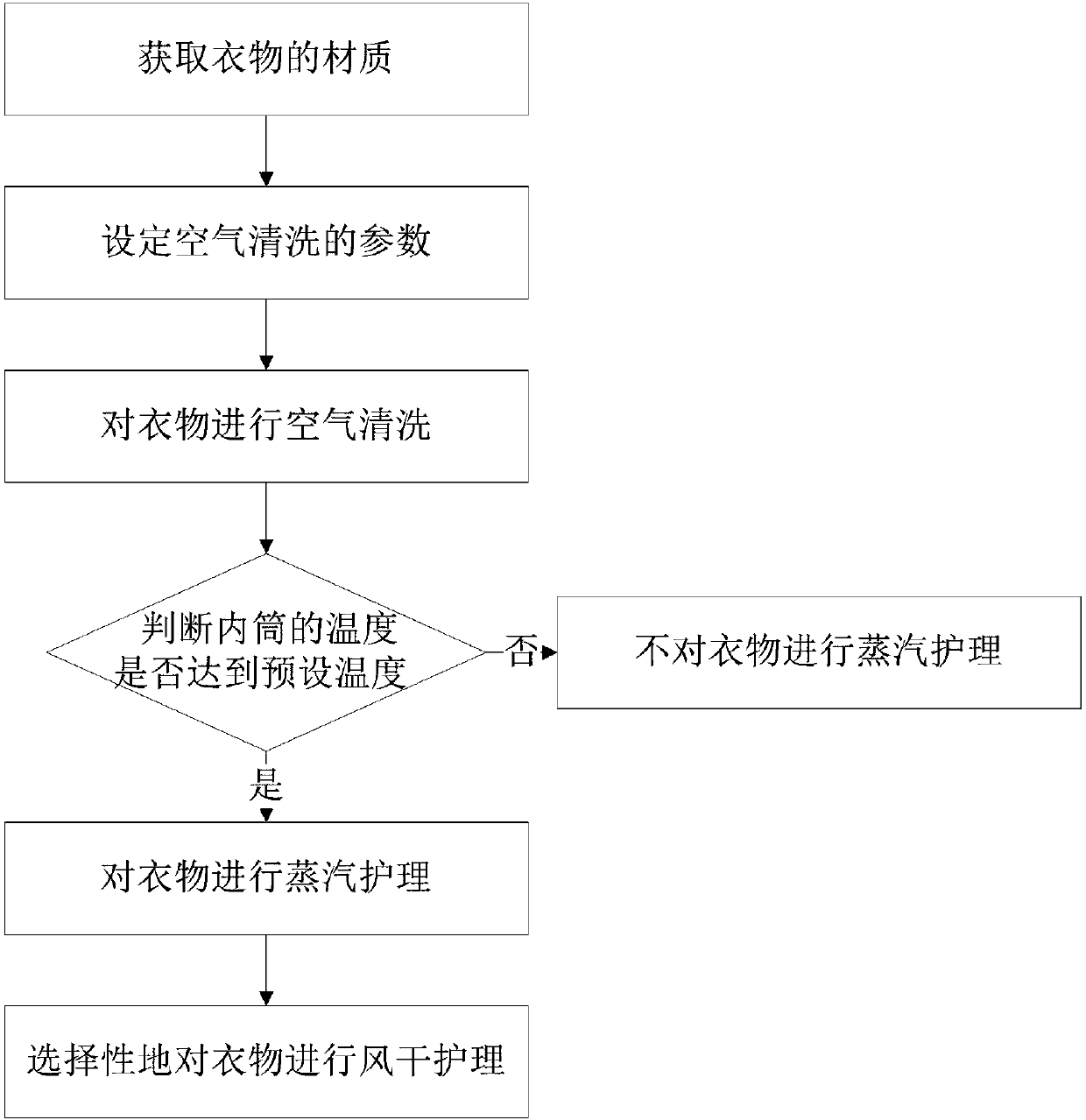

Clothes processing method for clothes processing device and clothes processing device

ActiveCN108315945AImprove wearing comfortFully stretchedOther washing machinesControl devices for washing apparatusAir cleaningEngineering

The invention belongs to the technical field of clothes processing, and aims at solving the problem that a traditional washing mode cannot meet cleaning requirements of users on clothes made of mediumand high-grade materials. For this purpose, the invention provides a clothes processing method for a clothes processing device and the clothes processing device. The clothes processing method includes the steps of conducting air cleaning on the clothes; conducting steam nursing on the clothes; conducting air drying nursing on the clothes. Through air cleaning, the fibers of the clothes are fullyextended, the elasticity of the clothes is increased, and the shell fabric of the clothes is softer; through steaming nursing, blots on the clothes are cleared away quickly, and steaming nursing has abactericidal effect; through air drying nursing, water vapor on the clothes is evaporated quickly, and the clothes is aired quickly. Through the combined processing mode, the shell fabric of the clothes is softer and more elastic, the wearable comfort level of the clothes is increased, the cleaning effect is good, the washing cleanliness is high, no damage is caused to the clothes, and thereforethe user experience is improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

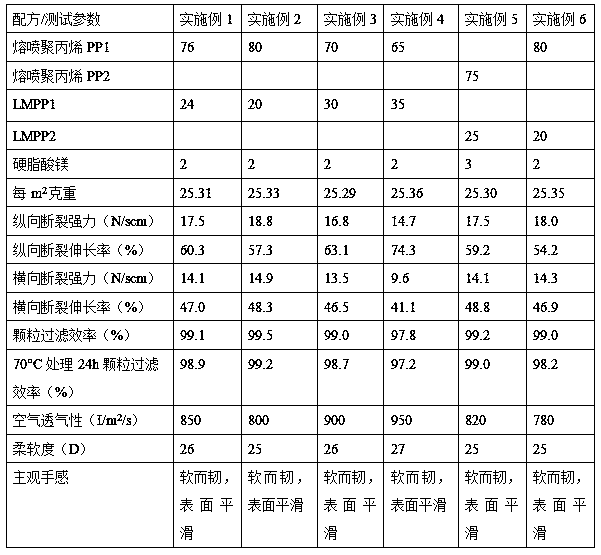

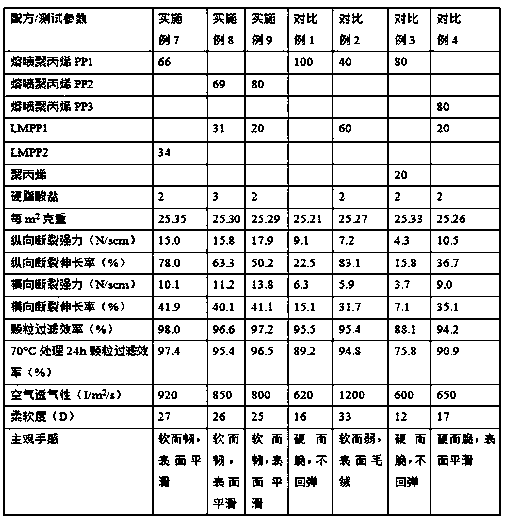

Melt-blown polypropylene material as well as preparation method and application thereof

ActiveCN111548566AFeel goodGood flexibilityDispersed particle filtrationFiltration separationPolymer scienceNonwoven fabric

The invention discloses a melt-blown polypropylene material as well as a preparation method and application thereof. The melt-blown polypropylene material is prepared from the following components inparts by weight: 65-80 parts of melt-blown polypropylene, 20-35 parts of low-isotacticity polypropylene and 2-3 parts of stearate. According to the invention, low isotacticity polypropylene LMPP and melt-blown polypropylene are blended; the hand feeling of the melt-blown non-woven fabric can be effectively improved; the prepared melt-blown non-woven fabric has the advantages of being soft in handfeeling, high in strength, high in toughness and the like; meanwhile, the particle filtering efficiency and air permeability of the melt-blown non-woven fabric can be improved, and the material has wide application prospects in preparation of high-filtering and low-resistance female / child masks which are required to be perfectly attached to the face.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

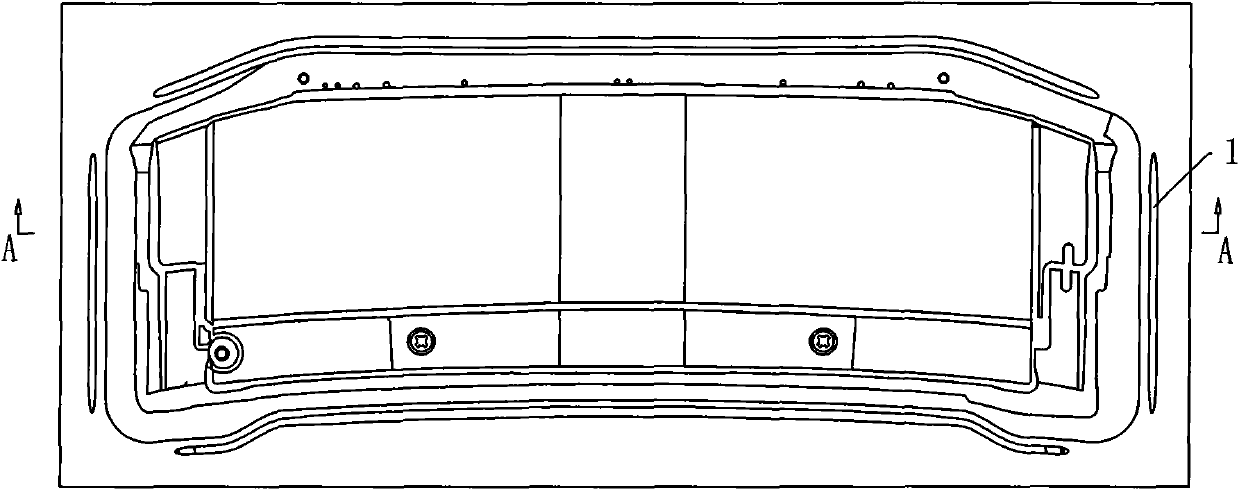

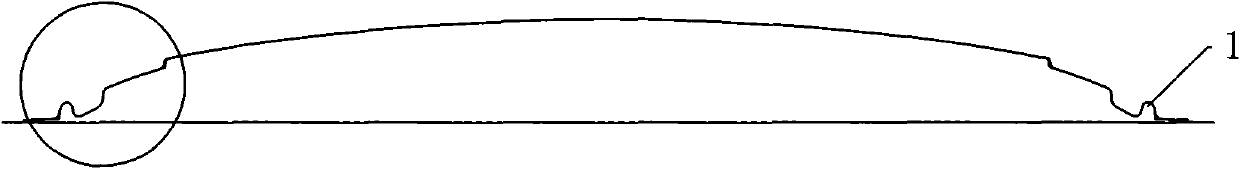

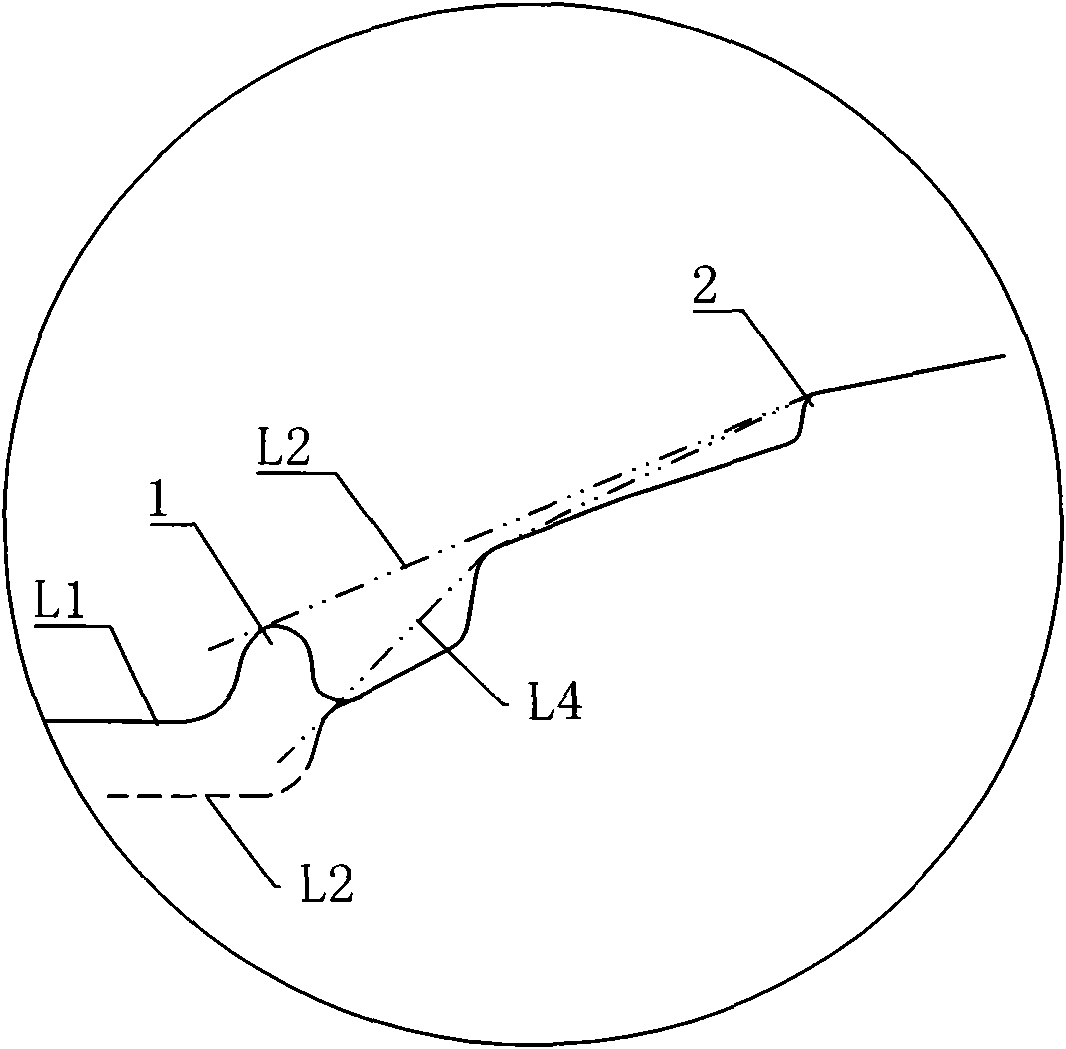

Method for stamping dash middle board of automobile

InactiveCN102000731AFully stretchedSolve the problem of wrinkling at the endEngineeringStamping process

The invention discloses a method for stamping a dash middle board of an automobile. A convex rib for absorbing excess materials is formed by drawing a board outside the dash middle board; the protrusion direction of the convex rib is the same as that of the dash middle board; the convex rib is used for absorbing the excess materials produced during the stamping process, so that the problem of end wrinkling of a product is solved; meanwhile, the dash middle board is also fully drawn to guarantee high rigidity of the product.

Owner:SHANDONG WEIFANG FOTON MOLD

Productive technology of terylene-chinlon interweave fabric

InactiveCN101974856AImprove smoothnessFeel goodDyeing processLiquid/gas/vapor textile treatmentChemistryDyeing

The invention relates to a productive technology of terylene-chinlon interweave fabric, which comprises the following procedures of preparing terylene-chinlon gray fabric, desizing, dyeing and air washing, wherein the dyeing adopts a pad dyeing mode; dyebath comprises acidic dye X, an acidic levelling agent with 1.5% o.w.f and water; the pH value of the dyebath is 4 to 6; the dyebath ratio is 1 to 50; and the temperature of the dyebath is controlled between 95 DEG C and 105 DEG C. The invention has the advantages that the adopted dyeing system dyes nylon yarns in the terylene-chinlon interweave fabric and does not dye terylene yarns when dyeing; the subsequent processing such as oil pressing and staining of the terylene and nylon in a coating can be effectively avoided; fibers can be fully stretched and the elasticity is recovered in the subsequent processing combined with the air washing; the hand feeling of the fabric is good; and the white trace of the fabric can be simultaneously eliminated. Thus, the fabric obtained by the invention has the advantages of no white trace and good hand feeling.

Owner:WUJIANG FUHUA WEAVING

Method for preparing graphene substrate electrode and battery and super capacitor

ActiveCN105304860AImprove electrochemical performanceFully bentHybrid capacitor electrodesCell electrodesSupercapacitorOptoelectronics

The invention discloses a method for preparing a graphene substrate electrode and a battery and a super capacitor. The method comprises the steps as follows: (a) a first graphene thin film is formed on a first substrate; (b) a second graphene thin film is formed on a second substrate; (c) an anti-corrosion compound is applied to the second graphene thin film, and the second graphene thin film is covered to form an anti-corrosion coating; (d) the anti-corrosion coating is dried; (e) the second substrate is removed; (f) the second graphene thin film is arranged on the first graphene thin film and contacts the first graphene thin film to form a graphene thin film superposition layer; (g) the anti-corrosion coating is removed from the graphene thin film superposition layer; (h) the steps (b) to (g) are repeated, and the graphene thin film is further superposed on the superposition layer until the required thickness of the graphene thin film superposition layer is obtained; and (i) the first substrate is removed from the bottom of the graphene thin film superposition layer to form the electrode.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

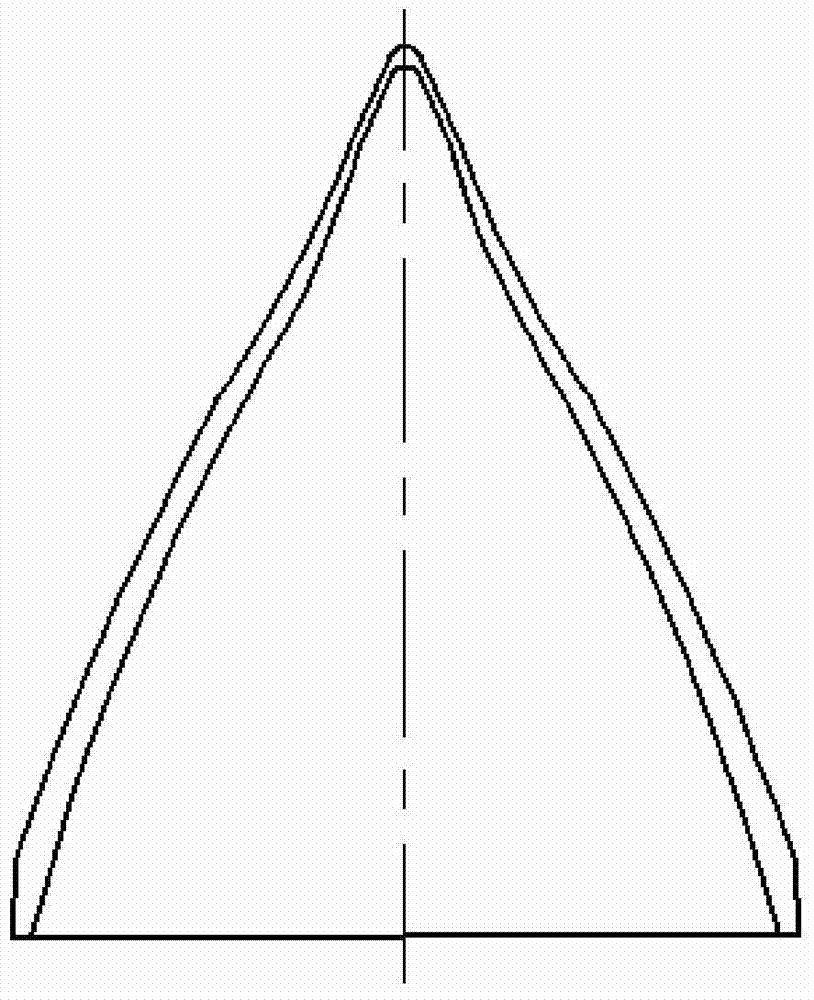

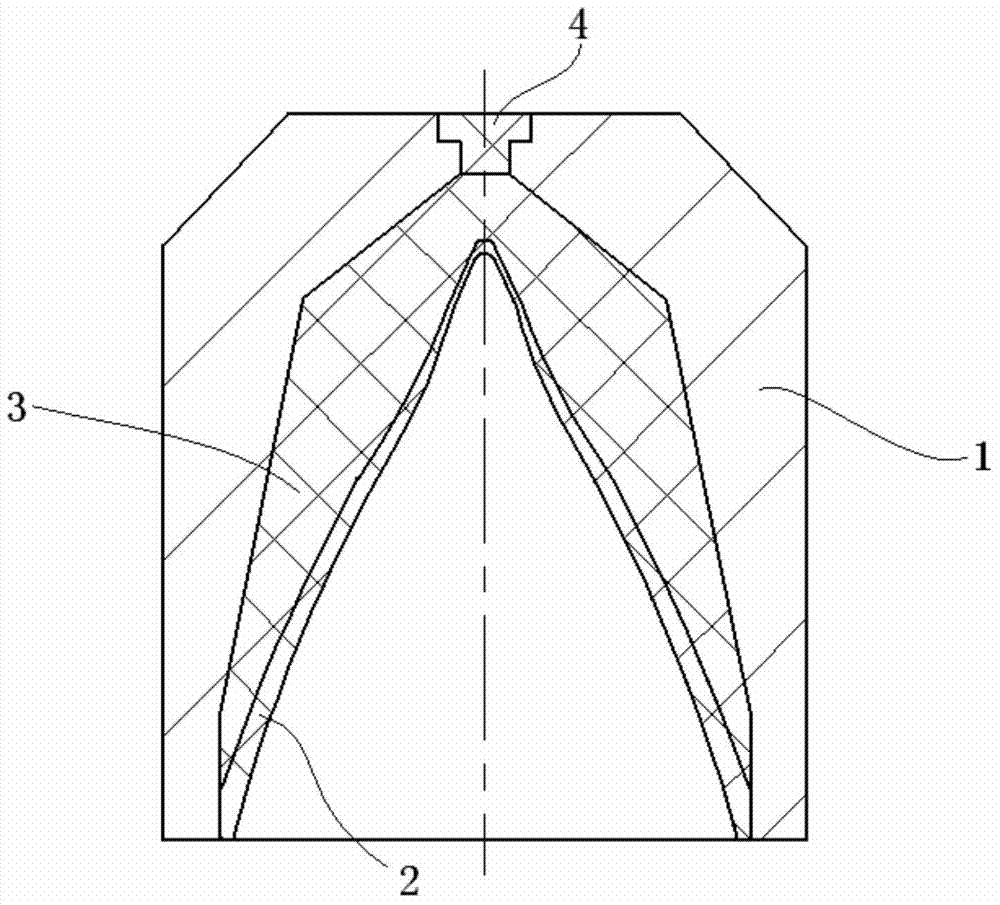

Catridge shape cover, perforating bullet shell and ultra-deep penetrating perforating bullet

The invention relates to a catridge shape cover, a perforating bullet shell and an ultra-deep penetrating perforating bullet. The catridge shape cover has a wall thickness-varying structure composed of an inner conical surface and an outer conical surface; an inner bus and an outer bus are formed by randomly combining multiple sections of line segments; each of the line segments comprises a straight line and a quadric curve; a conical and curve surface multi-sectional combined wall thickness-varying structure is adopted as the structure of the catridge shape cover, so that the sufficient long and thin state of a formed jet flow is ensured and the middle breakage is prevented; the bus of the inner wall of the perforating bullet shell is formed by connecting a plurality of straight lines; the slopes of the adjacent straight lines are different; the bus of the inner wall of another perforating bullet shell is formed by connecting straight and arc curved line segments; the perforating bullet comprises the catridge shape cover and the perforating bullet shell; the perforating bullet has a small-dose loading structure; compared with the large-dose loading structure design, the small-dose loading structure combined with whole structure optimal design has the advantages that the ultra-deep penetrating perforating effect is achieved and the safety of perforating equipment operation is greatly increased.

Owner:NORTH SCHLUMBERGER OILFIELD TECH XIAN

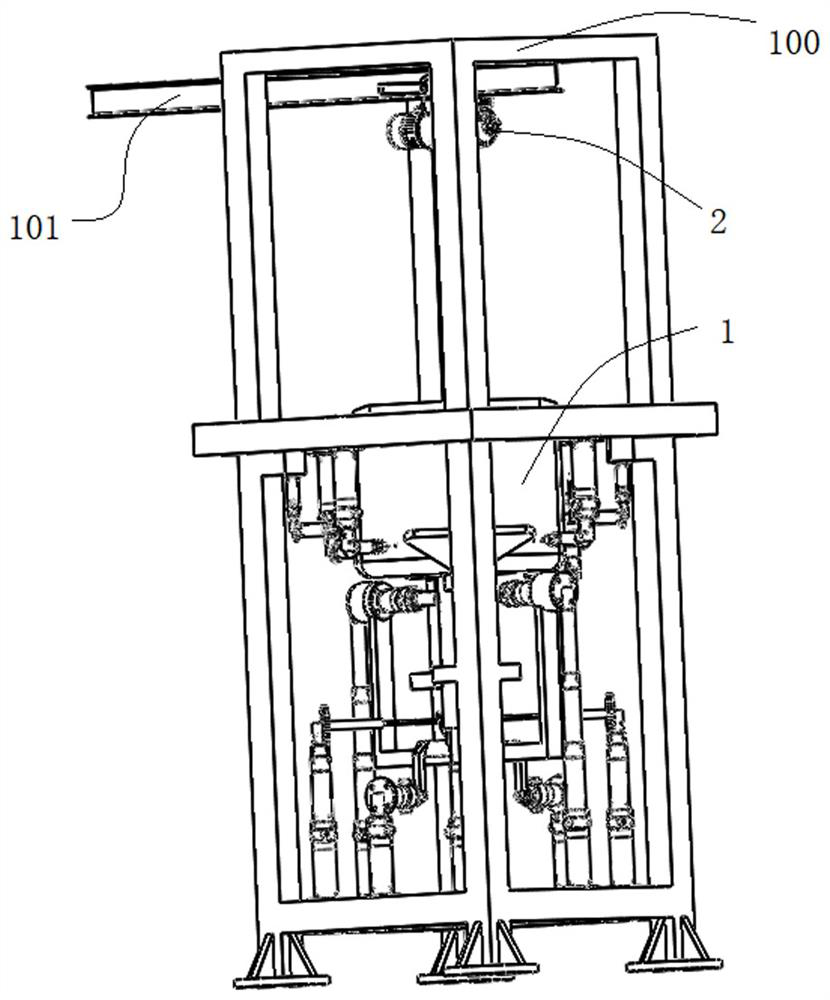

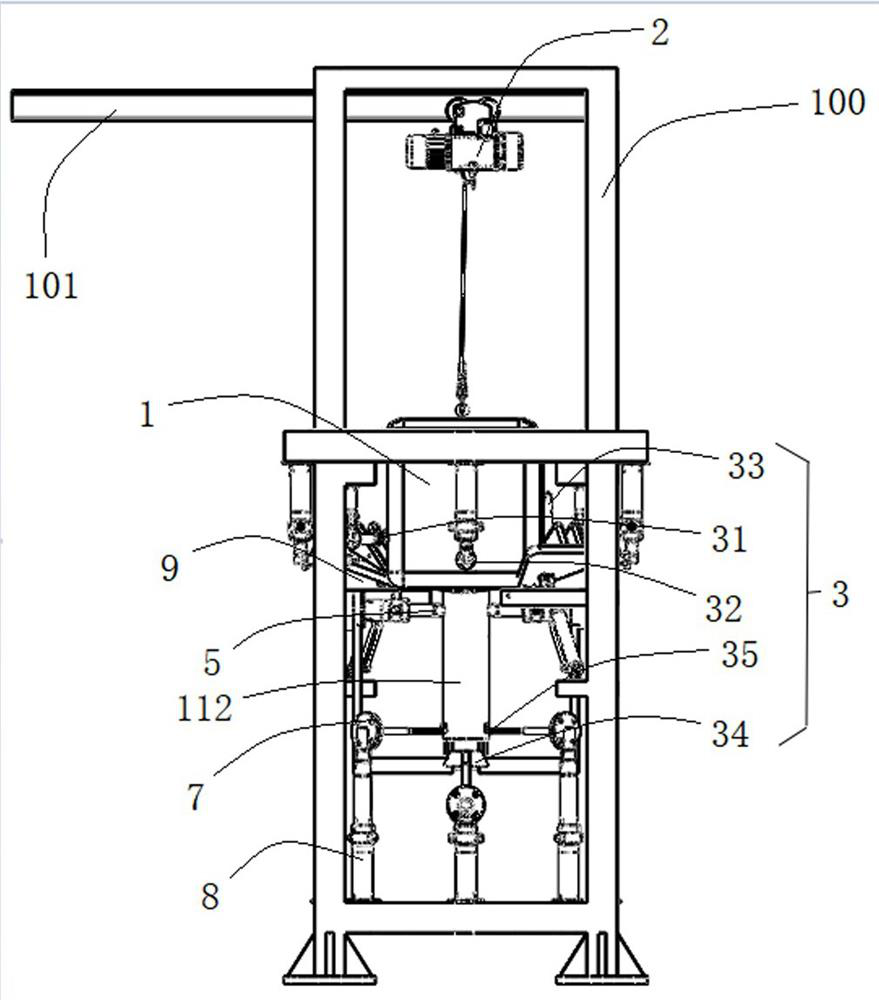

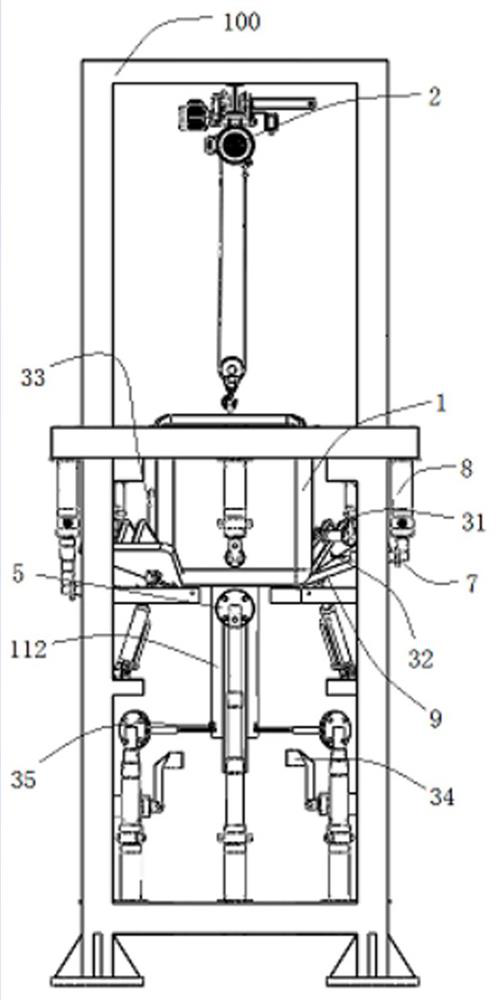

Automatic ton bag unpacking device and method

ActiveCN112429353ARealize automatic bag unpackingNo human assistance requiredFlexible bulk container emptying systemsBinding material removalHydraulic cylinderElectric machinery

The invention discloses an automatic ton bag unpacking device. The automatic ton bag unpacking device comprises a ton bag with an outer layer and inner tongue double-layer structure, a supporting frame made of an aluminum alloy material and used for mounting components, a rail arranged at the top of the supporting frame and a power device for driving the ton bag to transversely move and longitudinally move along the rail. The automatic ton bag unpacking device is characterized in that disassembling devices, a discharging barrel arranged at the bottom end of the supporting frame, ascending anddescending in the longitudinal direction and connected with an inner tongue in a sleeved mode, an inner bag knife arranged in the discharging barrel, and a barrel hoop arranged at the outer end of thejoint of the inner tongue and the discharging barrel and used for sealing and fixing are further included; and the disassembling devices are connected with three-level hydraulic cylinders through transition pieces separately and are driven by a control unit, the three-level hydraulic cylinders are all fixedly arranged on the supporting frame, the rail for lifting of the inner bag knife is arranged in the discharging barrel, and the inner bag knife drives a rope to ascend and descend in the rail through a motor. By means of the automatic ton bag unpacking device, automatic bag unpacking operation is achieved, and accidental leakage of powder in the bag unpacking process is avoided.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

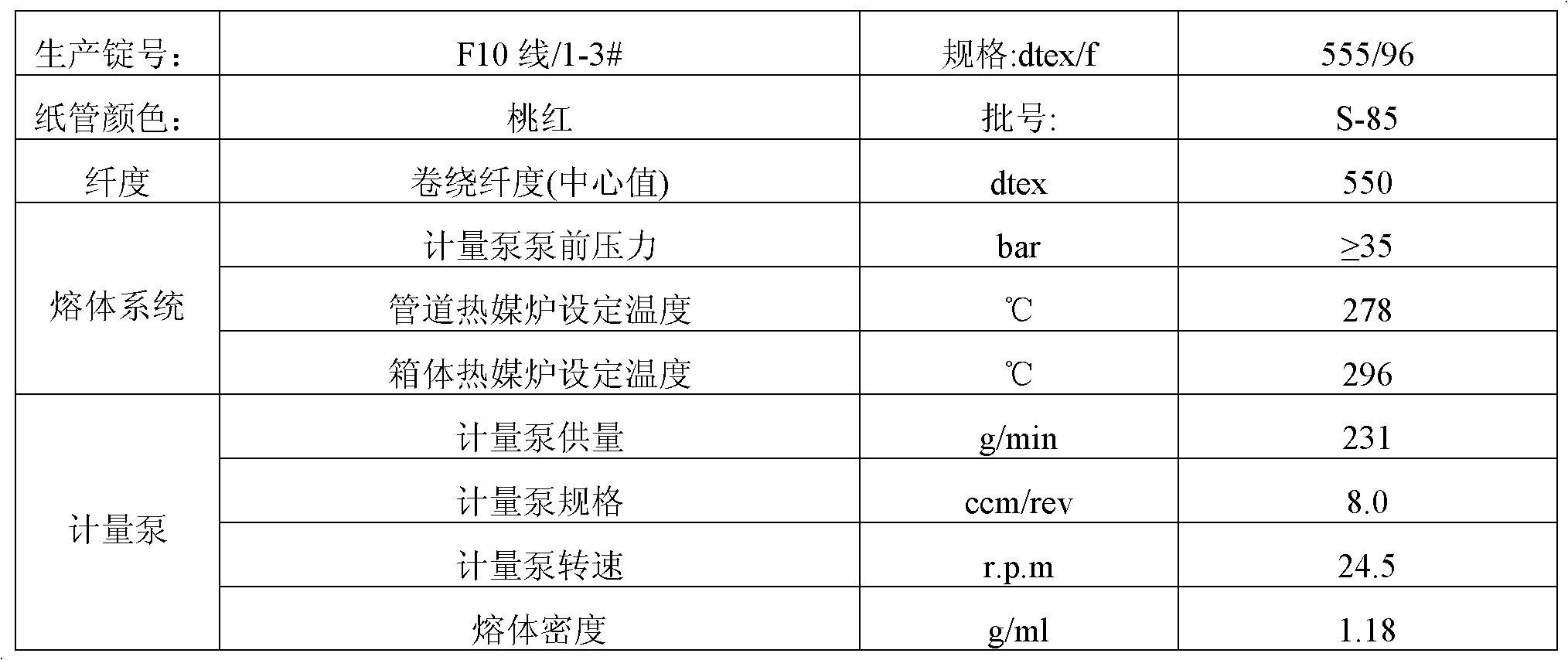

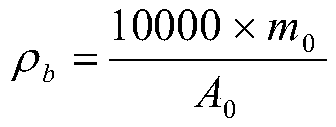

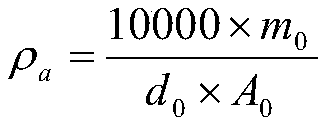

Intermediate-strength coarse-denier dacron FDY (Fully drawn yarn) and method for producing same

InactiveCN102443861AFully stretchedFully orientedStretch-spinning methodsYarnPolyethylene terephthalate

The invention discloses an intermediate-strength coarse-denier dacron FDY (Fully drawn yarn) and a method for producing the same. The method for preparing the dacron FDY includes the steps of enabling a PET (polyethylene terephthalate) melt to be extruded from spinneret orifices of an elliptical spinneret plate for spinning according to a direct spinning FDY process route prior to being cooled through cross air blowing and being solidified to a sliver sequentially, then being oiled by an oil wheel prior to being rolled by two pairs of heat rollers, and finally being placed in a major net to be wound into a FDY spinning cake. The acquired dacron FDY is of a coarse-denier yarn variety with the fineness degree ranging from 400D to 600D. The method breaks the convention that coarse-denier yarns with the fineness degree higher than 300D are produced by means of double-strand combination, so that production capacity of the coarse-denier yarns with one machine is improved, and production and processing cost is greatly reduced.

Owner:JIANGSU HUAYA FIBER

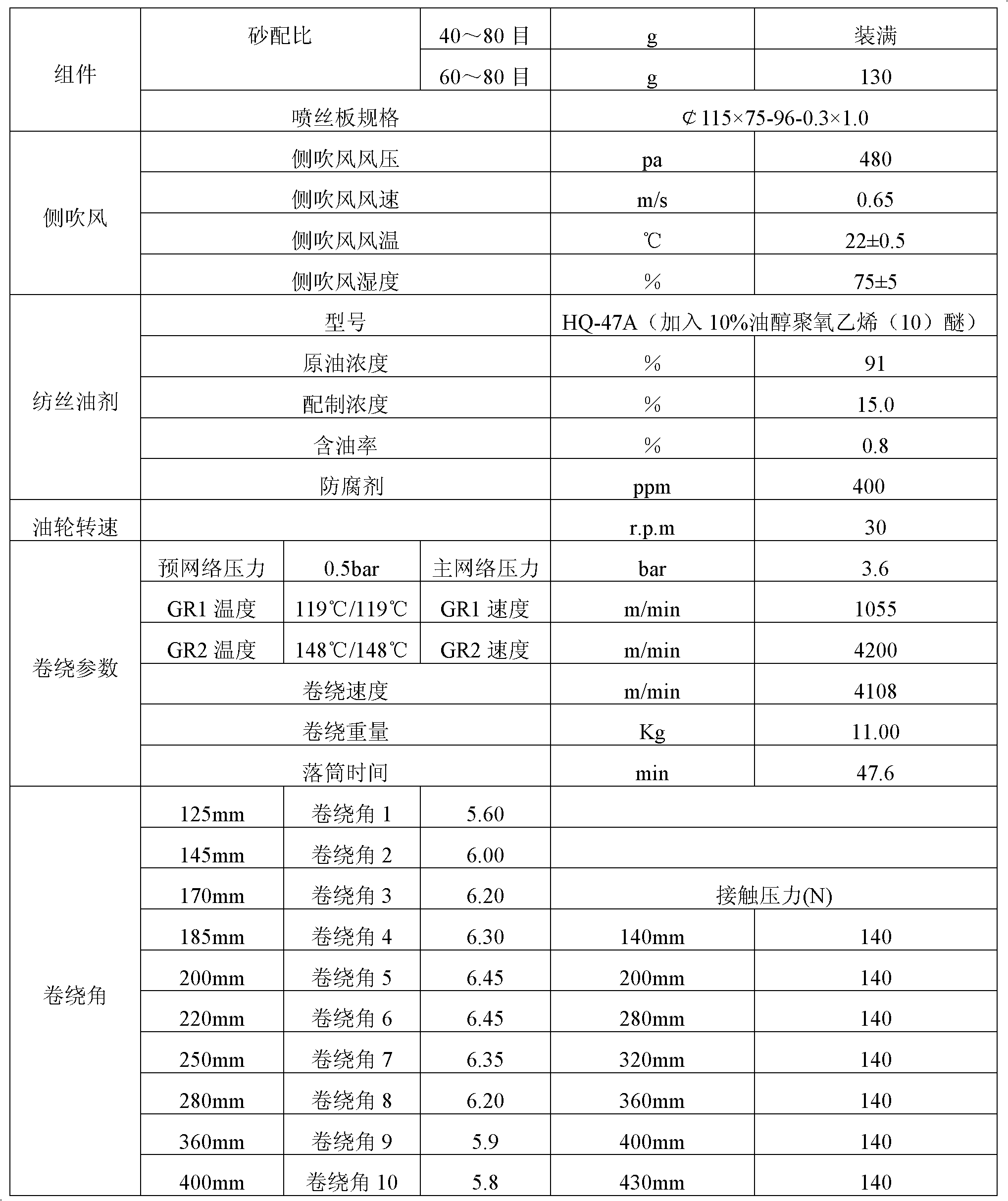

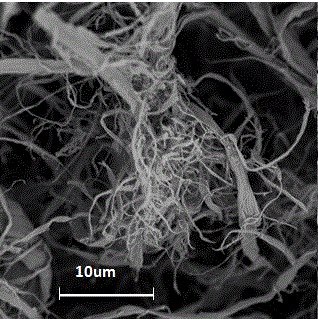

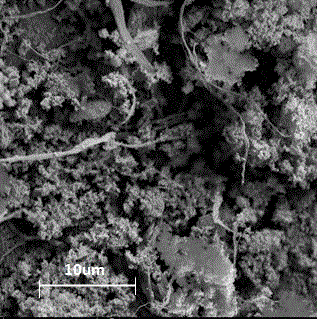

Preparation method of pre-dispersed clay-aramid pulp flocculation masterbatch

The invention discloses a preparation method of pre-dispersed clay-aramid pulp flocculation, and belongs to the field of high-performance polymer materials. According to the preparation method disclosed by the invention, an aramid pulp micro-fiber fully stretches to form effective isolation by using the high adsorption performance of an efficient coupling agent modified clay suspension system on the aramid pulp micro-fiber under a high-speed stirring effect, and simultaneously, a hydrophilic adhesive is added to endow the aramid pulp and the subsequently added rubber latex with better compatibility and adhesiveness. After the rubber latex is added into the modified clay-aramid pulp suspension system, rubber latex particles uniformly envelops the surface of the aramid pulp micro-fiber under a stirring effect, is subjected to demulsification coprecipitation and then cleaned and dried to obtain the coprecipitated masterbatch containing 40% of para aramid pulp. According to the preparation method disclosed by the invention, no organic solvent harmful to environment is used, the para aramid pulp is uniformly dispersed in the prepared pre-dispersed masterbatch without tangle, the masterbatch shares higher compatibility and adhesion with a rubber substrate and can be directly applied to enhancing systems for different rubber substrates, and the preparation method is simple in process, and quite low in cost.

Owner:JIAXING BEIHUA POLYMER ADDITIVES

Method for preparing aramid-pulp composite master batches

The invention relates to a method for preparing aramid-pulp composite master batches. The method includes the steps that aramid pulp is fully separated through inorganic filler generated through in-situ polymerization, the aramid pulp after separation is further modified with a coupling agent, the product is dried and bulked at a high speed, then the product and thermoplasticity particles or powder are subjected to extrusion pelletizing, and the corresponding aramid-pulp composite master batches are prepared. By means of the method, microfibril of the aramid pulp can be fully extended, the in-situ-generated particles have the better separating effect on the microfibers, and after modification is carried out through the coupling agent, the combination effect of the pulp and a base body can be further improved; compared with the method that aramid pulp is directly separated with inorganic powder, the method is more obvious in separating effect, and all properties of a base body material are also improved.

Owner:SOUTH CHINA UNIV OF TECH

Treatment and rehabilitation instrument for cervical spondylosis

InactiveCN102319164AMaintain physiological curvatureAvoid sideways twistingChiropractic devicesVertebraLesion site

The invention discloses a treatment and rehabilitation instrument for cervical spondylosis. The treatment and rehabilitation instrument comprises a base, a sliding plate and a traction mechanism, wherein the middle of the base is bulged upwards to form an indent cavity body; the sliding plate is arranged on the indent cavity body; an inclined plate which inclines downwards is arranged at the outer lateral end of the sliding plate; and the traction mechanism is connected with the sliding plate. In the treatment and rehabilitation instrument, the sliding plate supports heads and necks to drag forwards in the state of keeping cervical vertebra physiological curvature by utilizing the self weight of the heads and the necks of users through the traction mechanism and stretches naturally according to the cervical vertebra physiological curvature to promote the recovery of the cervical vertebra physiological curvature and relieve and remove symptoms at lesion sites gradually, so that the symptoms are treated and relieved. The treatment and rehabilitation instrument has the advantages of simplicity in operation, easiness to understand and accept by patients and the like, is controlled automatically by utilizing the self weight of the heads and the necks and is safe and effective.

Owner:雷龙 +1

Clothes processing device and clothes processing method for same

ActiveCN110042619AIncrease elasticitySoft fabricOther washing machinesTextiles and paperFiberAir cleaning

The invention belongs to the technical field of clothes processing, and aims at solving the problem that a traditional washing mode cannot meet the requirement of users for cleaning middle and top grade material clothes. In order to solve the problem, the clothes processing method comprises the steps of performing air cleaning on clothes, and performing steam nursing on the clothes. By performingair cleaning on the clothes, fiber of the clothes can be stretched sufficiently, elasticity of the clothes is improved, the fabric of the clothes is more flexible, by performing steam nursing on the clothes, stains on the clothes can be rapidly removed, and the clothes can be sterilized to a certain degree. Due to the clothes combined processing mode, the fabric of the clothes is more flexible andhas elasticity, the clothes wearing comfort is improved, the cleaning effect is good, the cleanness is high, no damage is caused to clothes, and therefore the user experience is improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

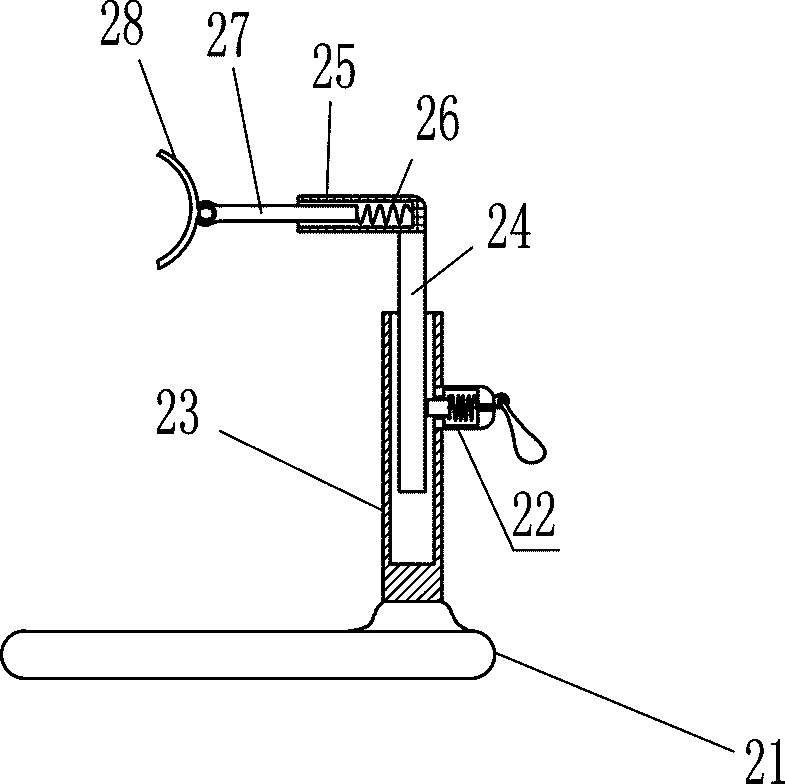

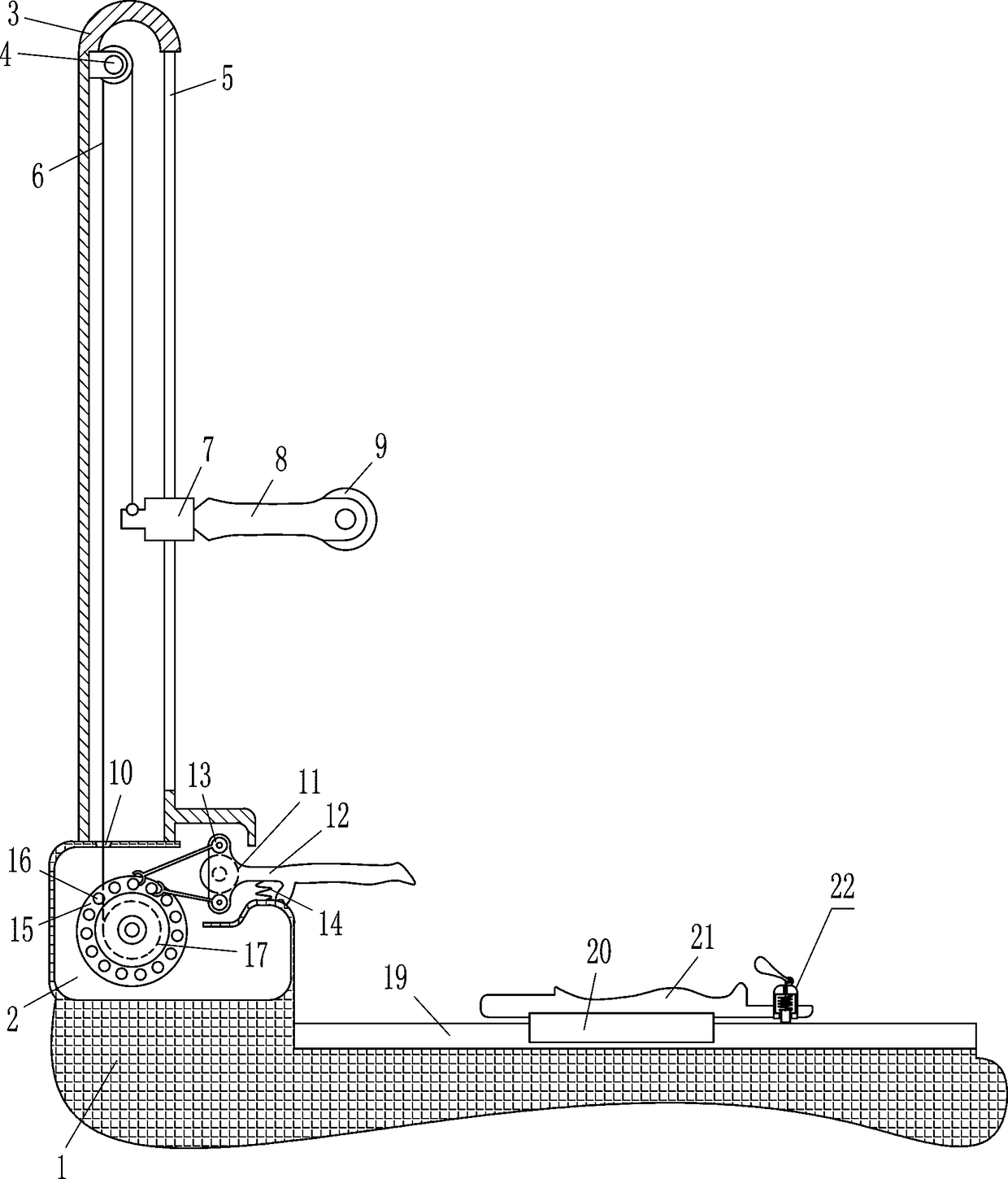

A height-adjustable leg press for sports athletes

ActiveCN109200543ALower the altitudeFree to adjust the distanceGymnastic exercisingLeg pressEngineering

The invention relates to a height adjustable leg press, in particular to a height adjustable leg press for sports athletes. A leg press is capable of freely adjusting that height of a leg press for asports athlete, and capable of keeping a standing leg of a person in an upright state so as to fully stretch the leg, is provided. The invention relates to a height-adjustable leg press for sports athletes, comprising a base, a hollow plate, a guide wheel, a guide rod, a wire rope, a guide sleeve, a lifting plate, a roller, a mounting rod, a swinging rod, etc. A left side of that top of the base is provided with a first cavity, a left side of the top of the base is provided with a hollow plate, a guide wheel is arranged on the upper part of the left wall of the hollow plate, and a guide rod isembedded on the right side of the hollow plate. Through the push rod and the clamp rod, the height of the leg press can be adjusted freely according to individual needs; By setting up the clamping mechanism, people can lower the height of the leg press according to their personal needs. The distance of the leg can be adjusted freely by the cooperation of the slide rail and the slide block.

Owner:浙江君昌电器有限公司

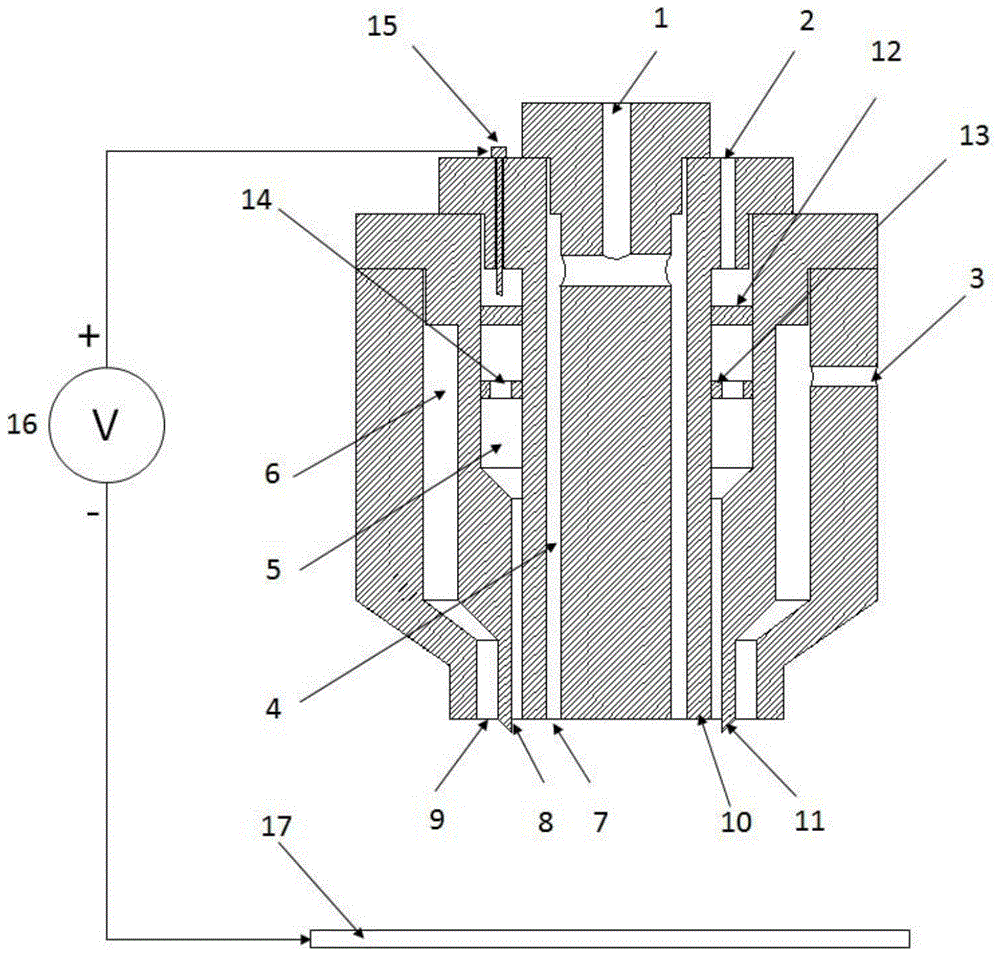

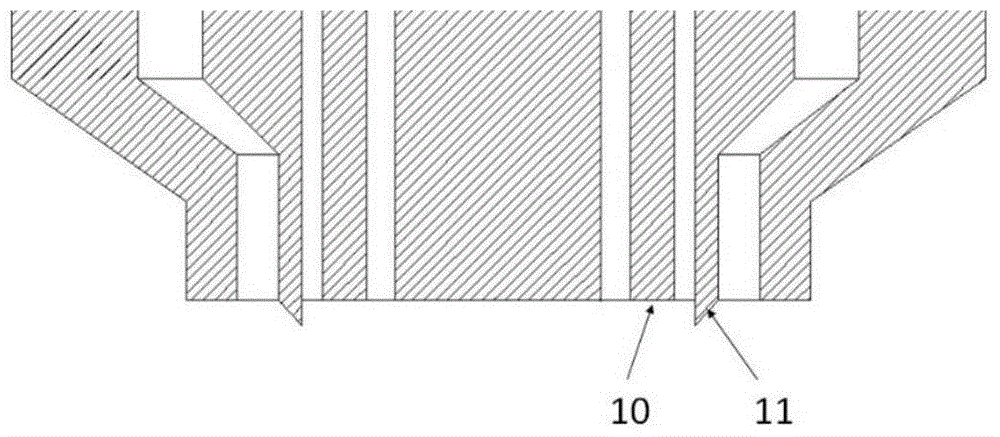

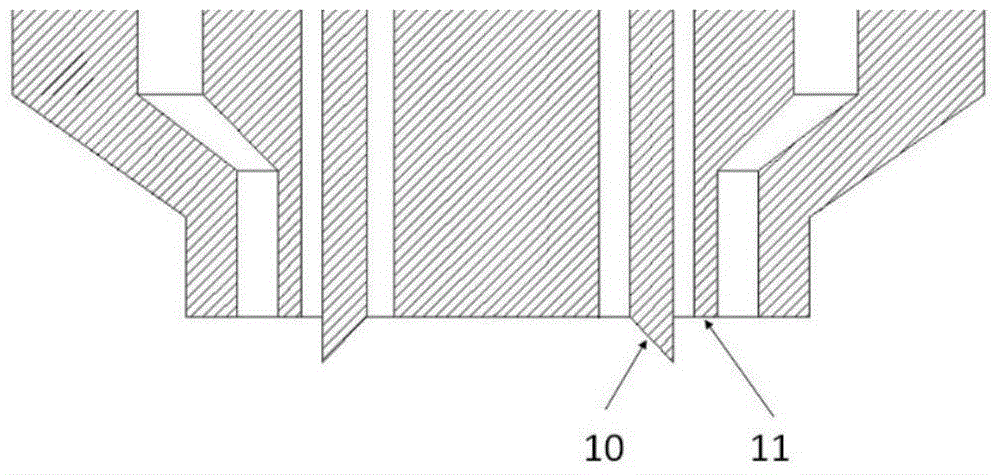

Internal and external circular air assisted electrospinning nozzle unit

ActiveCN104928768AEvenly distributedPrevent volatilizationFilament/thread formingElectrospinningNanofiber

The invention belongs to the field of electrospinning and relates to an internal and external circular air assisted electrospinning nozzle unit, comprising a nozzle body and a positive electrode. The nozzle body is composed of a first component, a second component, a third component and a fourth component nested to one another and detachably arranged from inside to outside. The four components of the nozzle body form an internal circular air passage, an external circular air passage, a middle circular liquid passage and an internal circular air inlet; an external circular air outlet and an external circular liquid outlet are concentrically circular; a guide plate is disposed within the middle circular liquid passage. The positive electrode extends into the middle circular liquid passage and contacts liquid. The nozzle unit is assisted by both internal and external air flows, is simple in structure, high in controllability and good in airtightness, helps avoid volatilizing of solvents in the liquid during spinning, has the yield up to ten times as high as the needle type, roller type or spiral type electrospinning unit, and is suitable for continuous industrial production of nanofibers.

Owner:烟台森森环保科技有限公司 +1

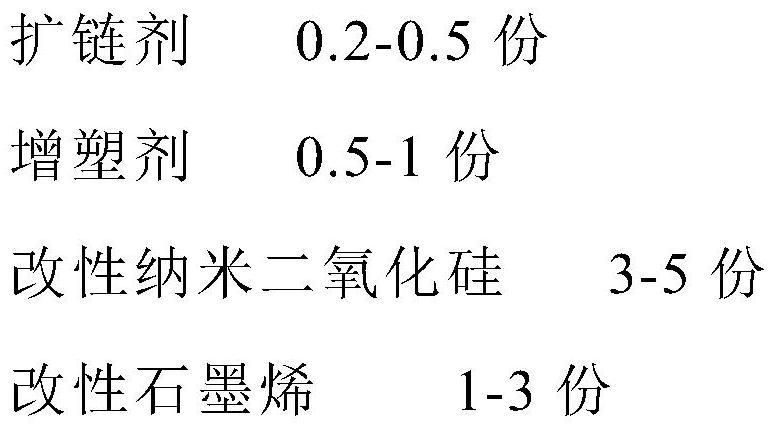

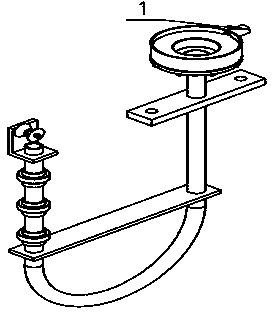

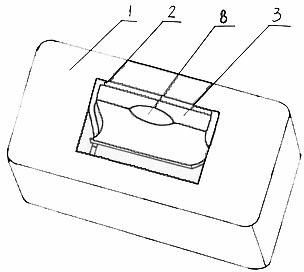

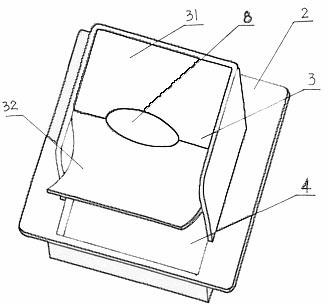

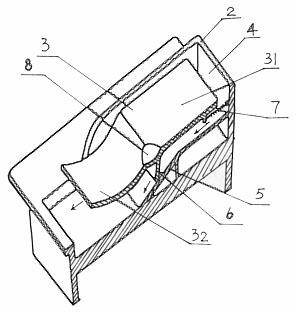

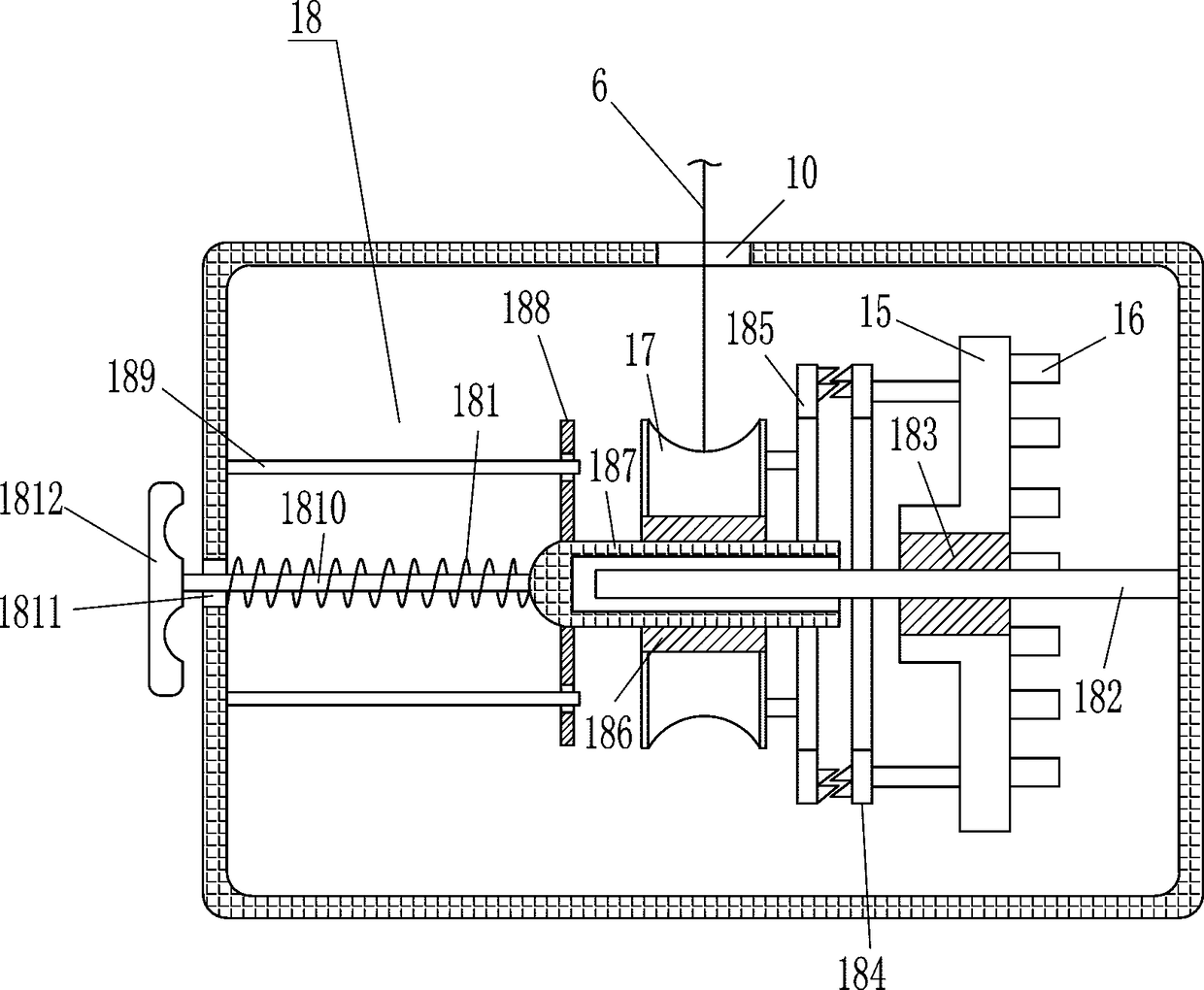

Blow molding mold and method equipped with heating stretching system

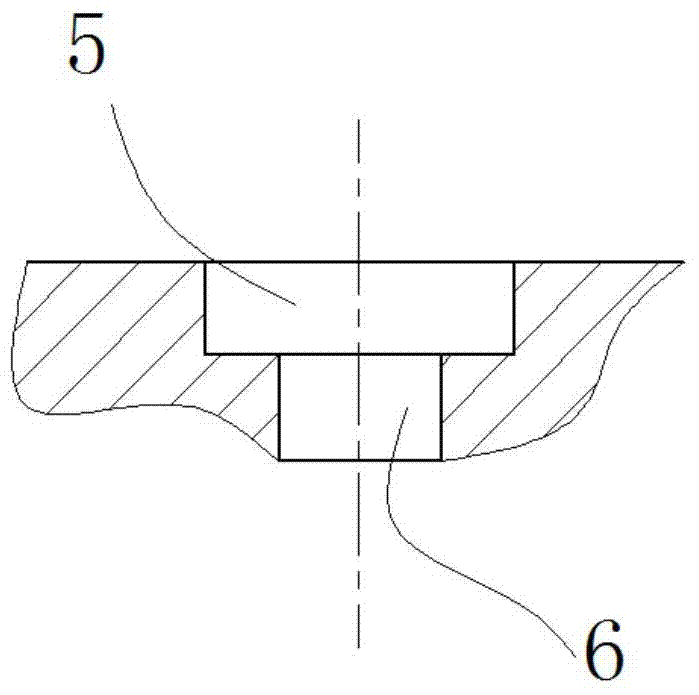

PendingCN110303664AFully stretchedUniform wall thicknessBlowing machine gearingsBlow headsBlow moldingBottle

The invention discloses a blow molding mold equipped with a heating stretching system. The blow molding mold equipped with the heating stretching system comprises a front mold and a rear mold which form a mold cavity in an encircling mode, a bottom mold located at the bottom of the mold cavity, a bottom mold plate used for installing the bottom mold and a stretching rod stretched from the top of the mold cavity into the mold cavity, wherein a bearing mechanism is arranged in the mold cavity, the bearing mechanism comprises a bearing rod and a drive mechanism which drives the bearing rod to stretch into the middle of the mold cavity, and heating elements are arranged in the stretching rod and / or the bearing rod. According to the blow molding mold equipped with the heating stretching system,the heating elements are arranged in the stretching rod and / or the bearing rod, and when a bottle is blown, temperature of the stretching rod and the bearing rod is approximate to temperature of a bottle blank, situations of early cooling and the like cannot occur, and materials at the bottom of the bottle blank are fully stretched, uniformly distributed at the bottom of the bottle, and cooled and shaped well. Due to the fact that the materials are fully stretched, not only is inner stress at the bottom of the bottle reduced, but also a bursting probability is reduced.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

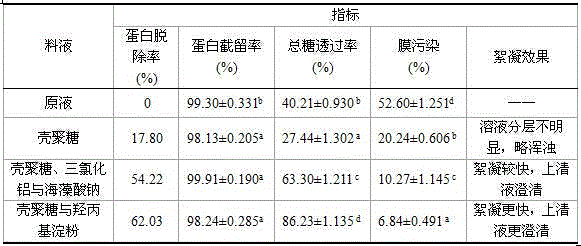

Method for preparing soybean whey oligosaccharide through coupling of heating, flocculating, air floating and ultra-filtering

InactiveCN104530143AReduce Maillard reactionIncrease contentSugar derivativesOligosaccharidesCouplingUltrafiltration

The invention relates to a method for extracting a soybean whey oligosaccharide from soybean whey. The method concretely includes the steps that heating, flocculating, air floating and intermittent flow-crossing ultra-filtering are coupled; a segmented treatment mode is adopted in a ground-breaking mode at a pretreatment stage, and ingeniously combined with air floating separation; composite flocculants with specific components and a specific proportion are selected. The high-quality soybean oligosaccharide product low in maillard browning reaction occurrence rate is provided, the extraction ratio of the soybean whey oligosaccharide can reach 85% and is much higher than that at a common level in the field, the effect that all steps and parameters supplement each other and act in a coordinated mode is achieved, the cost is lowered, and the method is high in operability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Electrolyte resistant wrinkle lithium ion battery diaphragm preparation method and prepared diaphragm

ActiveCN109702977AStress Reduction Phenomenon ResistanceAvoid wrinklesCell component detailsWrinkle skinPhysical chemistry

The invention provides an electrolyte resistant wrinkle lithium ion battery diaphragm preparation method. The electrolyte resistant wrinkle lithium ion battery diaphragm preparation method comprises the following steps that polypropylene raw materials are provided; the polypropylene raw materials are melted and extruded, a piece is made into a diaphragm by casting, and cooling is performed to obtain a diaphragm piece; heat treatment is performed on the diaphragm piece to make the diaphragm piece be perfect in crystallization, and then the cooling is performed; the diaphragm piece is subjectedto cold stretching to form microdefects, and then hot- stretching pore broadening is performed; heat shaping is performed on the stretched diaphragm piece; and natural cooling annealing is performed on the diaphragm piece after the heat shaping to obtain a lithium ion battery diaphragm finished product. According to the electrolyte resistant wrinkle lithium ion battery diaphragm preparation method, the melt index of the polypropylene raw materials is 0.8-1.8 g / 10min, the isotacticity is 98-99%, the number-average molar mass is 410000-480000, and in the stretching step, the cold stretching temperature is 80-100 DEG C, the cold stretching multiple ratio is 1.03-1.07, the hot stretching temperature is 135-145 DEG C, and the hot stretching multiple ratio is 3-5. The invention further providesan electrolyte resistant wrinkle lithium ion battery diaphragm obtained by the electrolyte resistant wrinkle lithium ion battery diaphragm preparation method.

Owner:深圳市博盛新材料有限公司

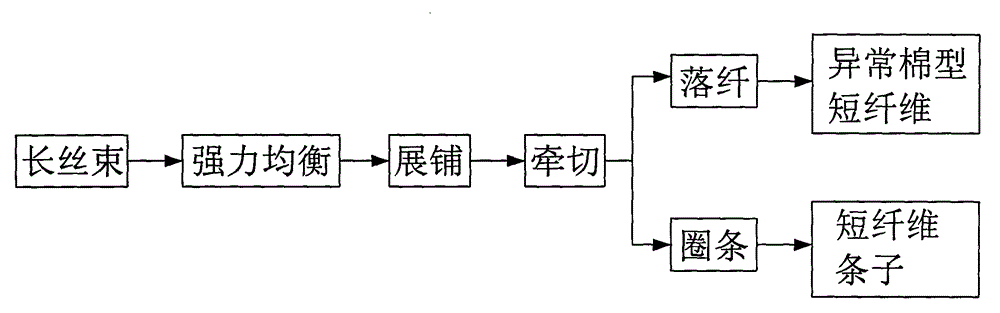

Cotton type fiber stretch-breaking strip making method

The invention discloses a cotton type fiber stretch-breaking strip making method, which comprises the following steps that (1) tows requiring stretch-breaking strip making are prepared; (2) stretch-breaking strip making treatment is carried out: 1) the tows led out from a tow box are fed into a stretch-breaking device provided with four stretching regions and four groups of stretch-breaking rollers, and first-time stretch-breaking processing is firstly carried out through a first stretch-breaking region; 2) the tows subjected to the first-time stretch-breaking processing enter a second stretching region for second stretch-breaking processing; 3) the tows subjected to the second stretch-breaking processing enter a third stretching region for third stretch-breaking processing; 4) the tows subjected to the third stretch-breaking processing enter a fourth stretching region for fourth stretch-breaking processing; (3) coiling processing is carried out. The method has the advantages that cotton type short fiber strips can be directly manufactured, and the severe carding effect of a cotton carding machine can be avoided, and the cotton type short fiber strips can be directly mixed with other fiber strips in the drawing work procedure.

Owner:湖北立天生物工程有限公司

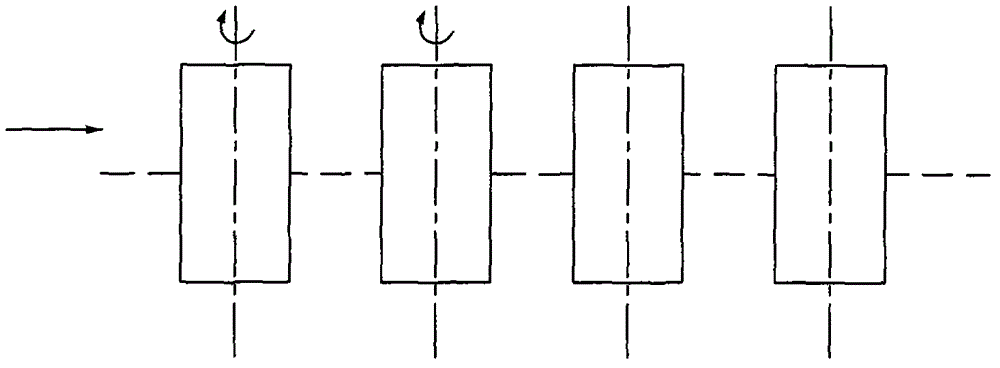

Low-strength fiber stretch-breaking and slivering device

The invention discloses a low-strength fiber stretch-breaking and slivering device. The low-strength fiber stretch-breaking and slivering device comprises a stretch-breaking device which is composed of multiple sets of stretch-breaking roller set and provided with a feeding end and a discharging end, a stretch-breaking area is formed between each set of the stretch-breaking roller set, each set of the stretch-breaking roller set is composed of a pair of stretching rollers and a pair of stretch-breaking rollers which are meshed with each other respectively, a stretch-breaking transition area is formed by the stretching roller and the stretch-breaking roller which are located between adjacent stretch-breaking roller sets, the stretching roller and the stretch-breaking roller are both composed of two roller bodies, and the size of the horizontal distance between the stretching roller and the stretch-breaking roller in the axial direction of the roller body in each stretch-breaking area is changeable. Through arranging tapered or trapezoid structure, the tractive force of the stretch-breaking areas is greatly reduced, the diameters of the stretch-breaking rollers are decreased, the distance of the stretch-breaking areas formed by the stretch-breaking roller sets is shortened, the distance between the stretching roller and the stretch-breaking roller can be set to be small enough, stretch-breaking can be conducted on short fiber with smaller cotton fiber level, and the production efficiency is greatly improved. The low-strength fiber stretch-breaking and slivering device has the advantages that the structure is simple and compact, the occupied area is small, the cost is low, and popularization and application are applicable.

Owner:QINGDAO UNIV

Flow channel outlet structure of flood discharge surface hole of high arch dam

The invention discloses a flow channel outlet structure, particularly relates to the flow channel outlet structure of a flood discharge surface hole of a high arch dam, and belongs to the technical field of civil design construction. The flow channel outlet structure is capable of forming nappe which is fully stretched in a longitudinal direction and has a stable flow state in a transverse direction. The flow channel outlet structure comprises a flood discharge flow channel with a bottom plate formed by an arch dam and a side wall formed by a dam pier, wherein the side wall is linearly shrunk inwards in the longitudinal direction and the tail end of the bottom plate is positioned on the inner side at the tail end of the side wall.

Owner:POWERCHINA CHENGDU ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com