Intermediate-strength coarse-denier dacron FDY (Fully drawn yarn) and method for producing same

A technology of polyester and coarse denier, which is applied in stretch spinning, filament/thread forming, textiles and papermaking, etc. It can solve problems such as quality limitations, achieve the effects of improving toughness, improving drafting and setting, and reducing production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Production of medium-strength coarse denier polyester FDY yarn with a specification of 500D.

[0033] This product adopts the one-step production route of melt direct spinning. The PET obtained by the polymerization of PTA and EG is pressurized and transported by a gear pump after passing through a melt filter, cooled by a cooler, and then distributed to each spinning position. The pump sends the melt quantitatively to each spinning assembly. After the melt is filtered evenly and pressurized by the filter layer in the spinning assembly, it is spun in a fine flow through the elliptical spinneret (the spinneret is in the spinning assembly). After the thin stream of melt is cooled by side air at constant temperature and humidity, it solidifies into silk strands, and then oiled by oil tanker, drafted and shaped, added to the main network, and wound into FDY silk cake. After that, the packaging is put into storage.

[0034] The specific production steps are: PTA+E...

Embodiment 2

[0052] Example 2 A medium-strength coarse denier polyester FDY yarn with a specification of 400D was produced. The production method is the same as in Example 1. Among them, the speed of the first pair of heat rollers is 1200m / min and the temperature is 115°C; the speed of the second pair of heat rollers is 4300m / min and the temperature is 146°C. The long axis of the oval spinneret used is 115mm; the short axis is 75mm, and the diameter of the circular micro-hole is 0.3mm.

[0053] The above products were sent to customers for warp knitting machine samples, and there was no obvious end breakage during the weaving process. The dyeing and finishing processes of the produced fabrics are all normal.

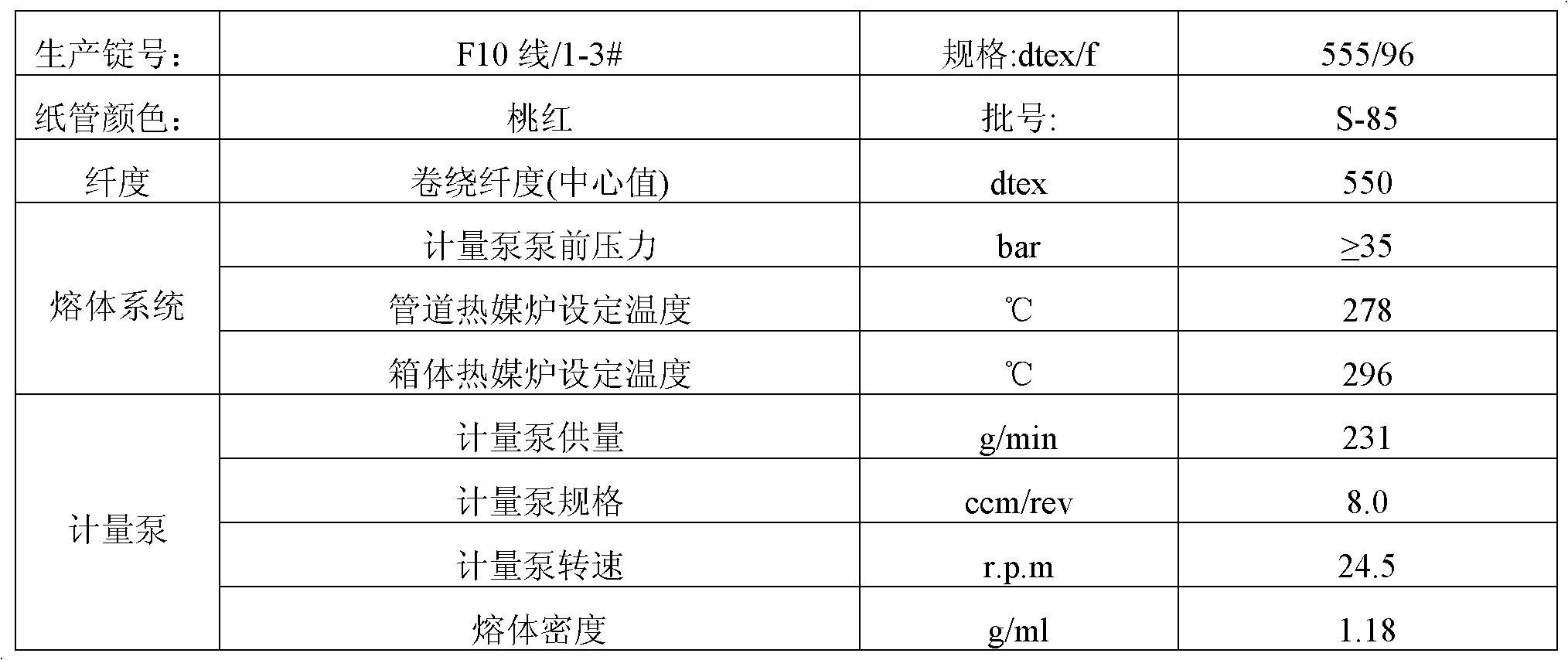

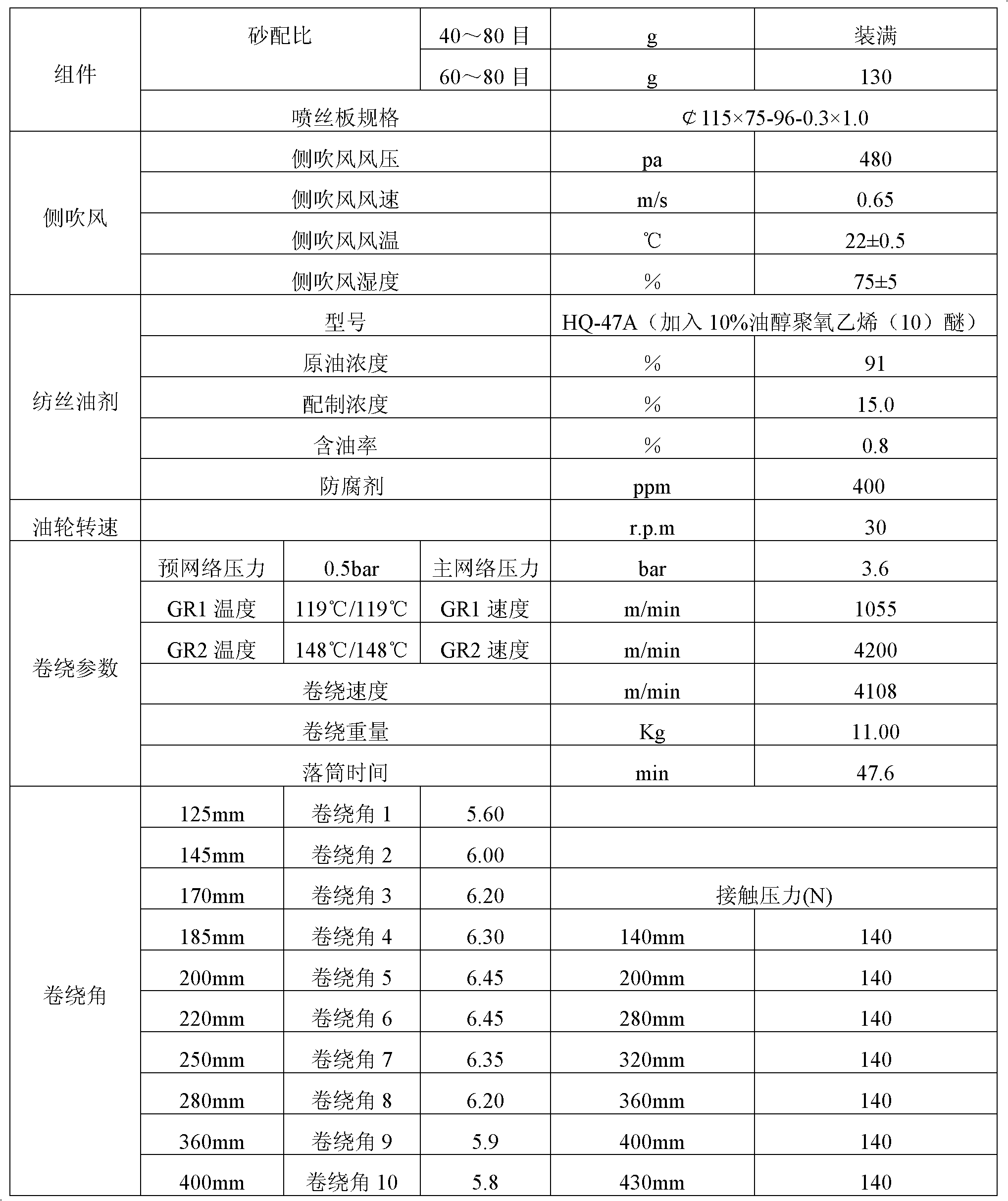

[0054] The specific process parameters are shown in Table 2.

[0055] Table 2: Table of specific process parameters for spinning in this embodiment (444 / 96)

[0056]

[0057]

[0058] According to this process, the medium-strength coarse denier polyester FDY yarn with the s...

Embodiment 3

[0069] Example 3 A medium-strength coarse denier polyester FDY yarn with a specification of 600D was produced. The production method is the same as in Example 1. Among them, the speed of the first pair of heat rollers is 1030m / min and the temperature is 122°C; the speed of the second pair of heat rollers is 4200m / min and the temperature is 152°C. The long axis of the oval spinneret used is 140mm; the short axis is 90mm.

[0070] The above products were sent to customers for warp knitting machine samples, and there was no obvious end breakage during the weaving process. The dyeing and finishing processes of the produced fabrics are all normal.

[0071] The specific process parameters are shown in Table 3.

[0072] Table 3: Table of specific process parameters of spinning in this embodiment (666 / 96)

[0073]

[0074]

[0075] According to this process, the medium-strength coarse denier polyester FDY yarn with the specification of 600D is produced. The production runs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| coefficient of variation of linear density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com