Method for preparing soybean whey oligosaccharide through coupling of heating, flocculating, air floating and ultra-filtering

A soybean oligosaccharide and soybean technology, which is applied in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc., can solve the problems of pioneering improvement and poor effect of technical means, and solve the problem of membrane pollution and reduce the Maillard reaction, effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

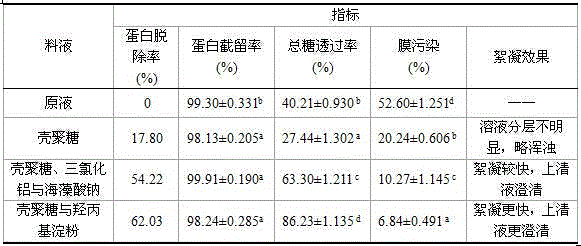

Image

Examples

Embodiment 1

[0037] A preparation method for extracting and purifying soybean oligosaccharides, characterized in that it is prepared according to the following steps:

[0038] (1) Staged pretreatment: first stage: first heat the soybean whey liquid to 50°C under the condition of pH value = 4.5, and keep it for 1 hour; second stage: then under the condition of pH value = 6.0, heat Keep at 90°C for 10 minutes; the third stage: natural cooling, and at the same time, let it stand until the temperature of the soybean whey liquid is 50°C; after that, centrifuge to obtain the centrifugate A for later use;

[0039] (2) Flocculant flocculation: Mix the flocculant with the centrifugal liquid A to flocculate the centrifugal liquid A to obtain a crude extract. The mass-volume ratio of the flocculant and the centrifugal liquid is calculated: the total amount of the flocculant is 0.7g / L centrifugal liquid A, the flocculation condition is pH 4.5, temperature 50°C, and static settling time 40 minutes; aft...

Embodiment 2

[0046] A preparation method for extracting and purifying soybean oligosaccharides, characterized in that it is prepared according to the following steps:

[0047] (1) Stage-based pretreatment: the first stage: first heat the soybean whey liquid to 55°C under the condition of pH value = 5.0, and keep it for 2 hours; the second stage: then heat it to 92 under the condition of pH value = 8.5 ℃, keep for 15 minutes; the third stage: natural cooling, and at the same time, let it stand until the temperature of soybean whey liquid is 60 ℃; after that, centrifuge to obtain centrifugate A for later use;

[0048] (2) Flocculant flocculation: Mix the flocculant with the centrifugal liquid A to flocculate the centrifugal liquid A to obtain a crude extract. The mass-volume ratio of the flocculant and the centrifugal liquid is calculated: the total amount of the flocculant is 0.7-0.9g / L Centrate A, the flocculation condition is pH4.5-6.0, temperature 50-60°C, static settling time 40-90min; ...

Embodiment 3

[0054] A preparation method for extracting and purifying soybean oligosaccharides, characterized in that it is prepared according to the following steps:

[0055] (1) Stage-based pretreatment: the first stage: first heat the soybean whey liquid to 55°C under the condition of pH value = 5.0, and keep it for 2 hours; the second stage: then heat it to 92 under the condition of pH value = 8.5 ℃, keep for 15 minutes; the third stage: natural cooling, and at the same time, let it stand until the temperature of soybean whey liquid is 60 ℃; after that, centrifuge to obtain centrifugate A for later use;

[0056] (2) Flocculant flocculation: Mix the flocculant with the centrifugal liquid A to flocculate the centrifugal liquid A to obtain a crude extract. The mass-volume ratio of the flocculant and the centrifugal liquid is calculated: the total amount of the flocculant is 0.07-0.09g / L Centrifuge liquid A, the flocculation condition is pH4.5-6.0, temperature 50-60°C, static settling time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com