Method and apparatus for directly heating protein-rich dairy product by introducing water vapor into said dairy product

A technology of dairy products and water vapor, applied in the field of equipment implementing the method, can solve the problems of continuous deterioration of heat transfer of heaters and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

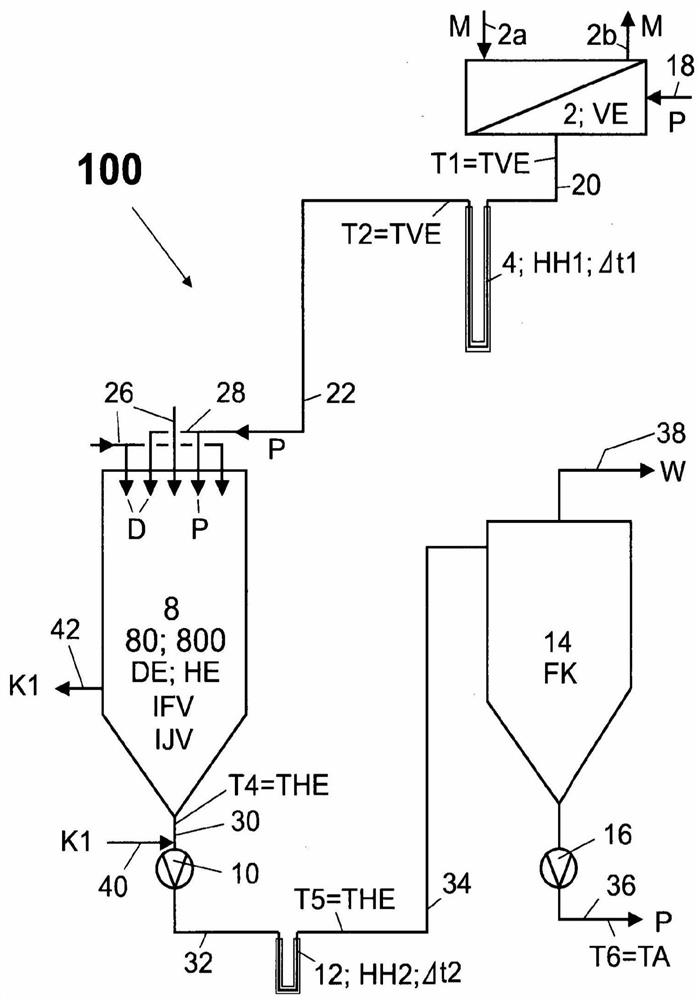

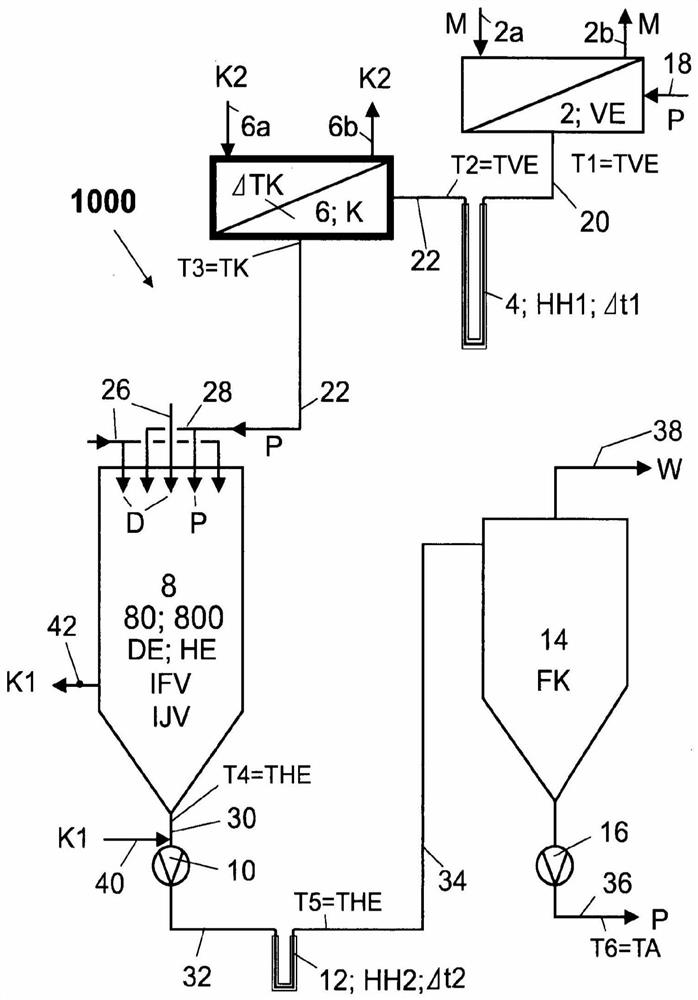

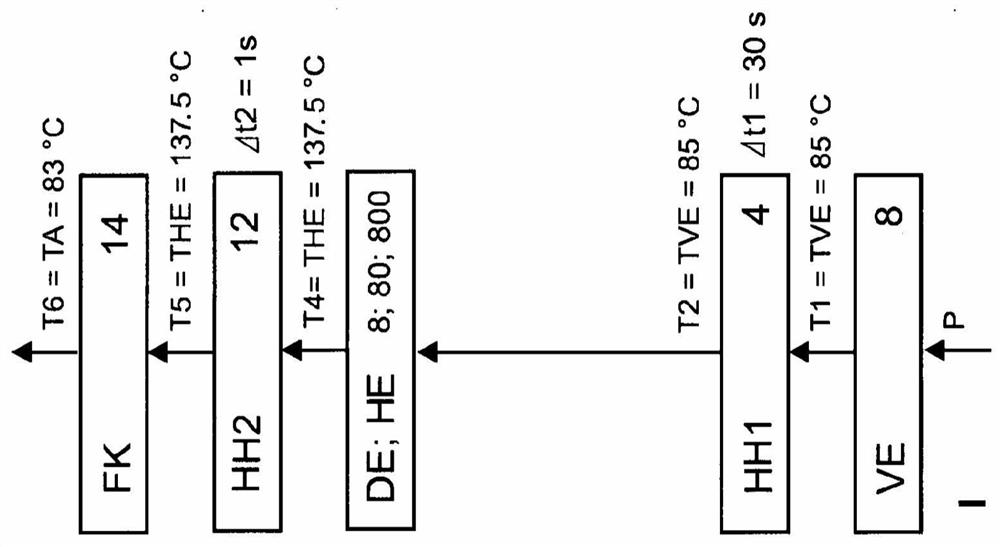

[0060]A device 100 according to FIG. 1 known from the prior art literature (so far as it concerns an immersion device and other devices arranged downstream of the immersion device) is disclosed, for example, in EP 794 706 B1 or WO 2011 / 101077 A1. The device 100 for carrying out the immersion method IFV comprises a direct heating device 8 in the form of an immersion device 80 for carrying out high-temperature heating HE in the form of direct heating DE. The immersion device 80 can have a product inlet 28 (WO 2010 / 086082 A1) in its headspace, through which the protein-rich milk product P to be heat-treated is supplied, for example, preferably centrally and annularly to the The immersion device 80 . For direct heating, the supplied milk product P is supplied with water vapor D, for example and preferably via external and internal water vapor inlets 26 radially on the outside and at the same time radially from the inside, whereby a preheating temperature T2 = TVE to high temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com