Preparation method of pre-dispersed clay-aramid pulp flocculation masterbatch

A technology of aramid pulp and clay, which is applied in the field of high-performance polymer structural material manufacturing, can solve problems such as easy entanglement, difficulty in dispersing, and high electrostatic tendency, so as to simplify the preparation process, reduce the tendency of agglomeration, and achieve good Effects of Compatibility and Adhesion

Active Publication Date: 2013-08-28

JIAXING BEIHUA POLYMER ADDITIVES

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

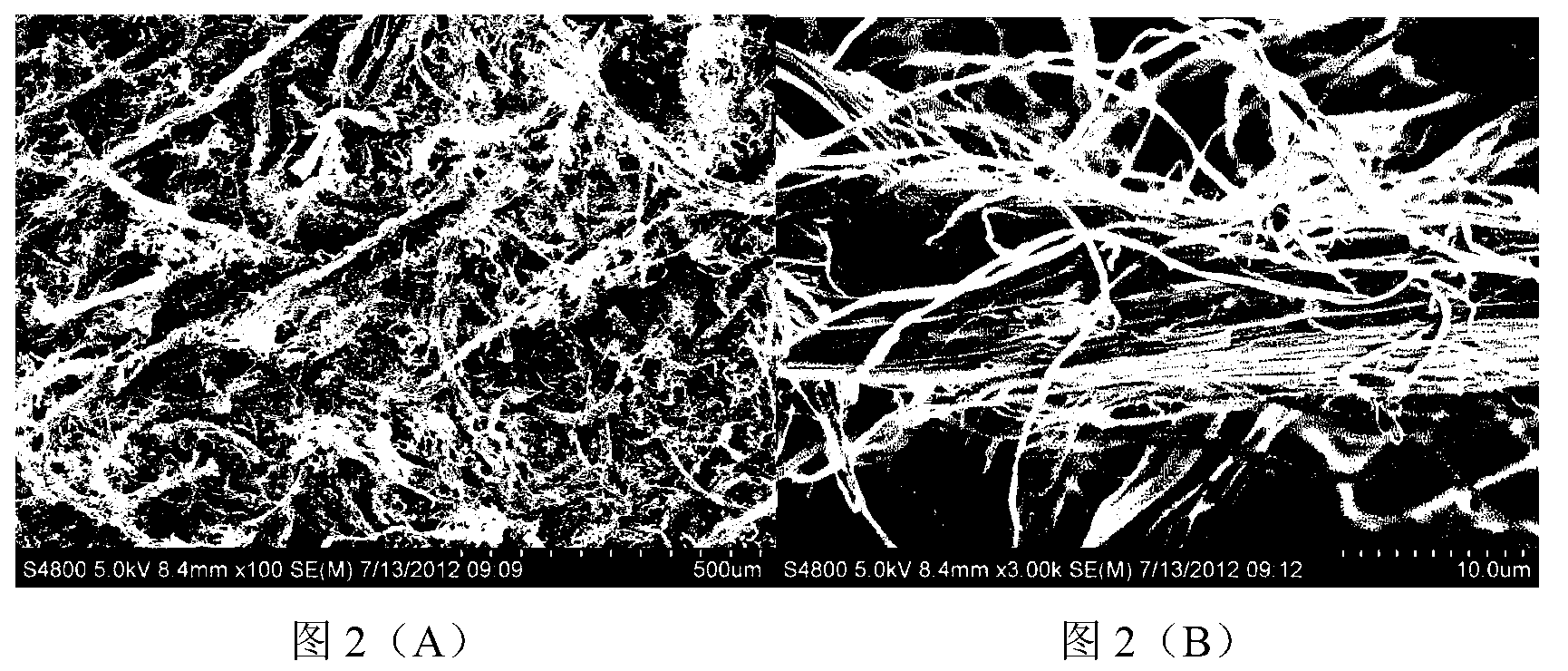

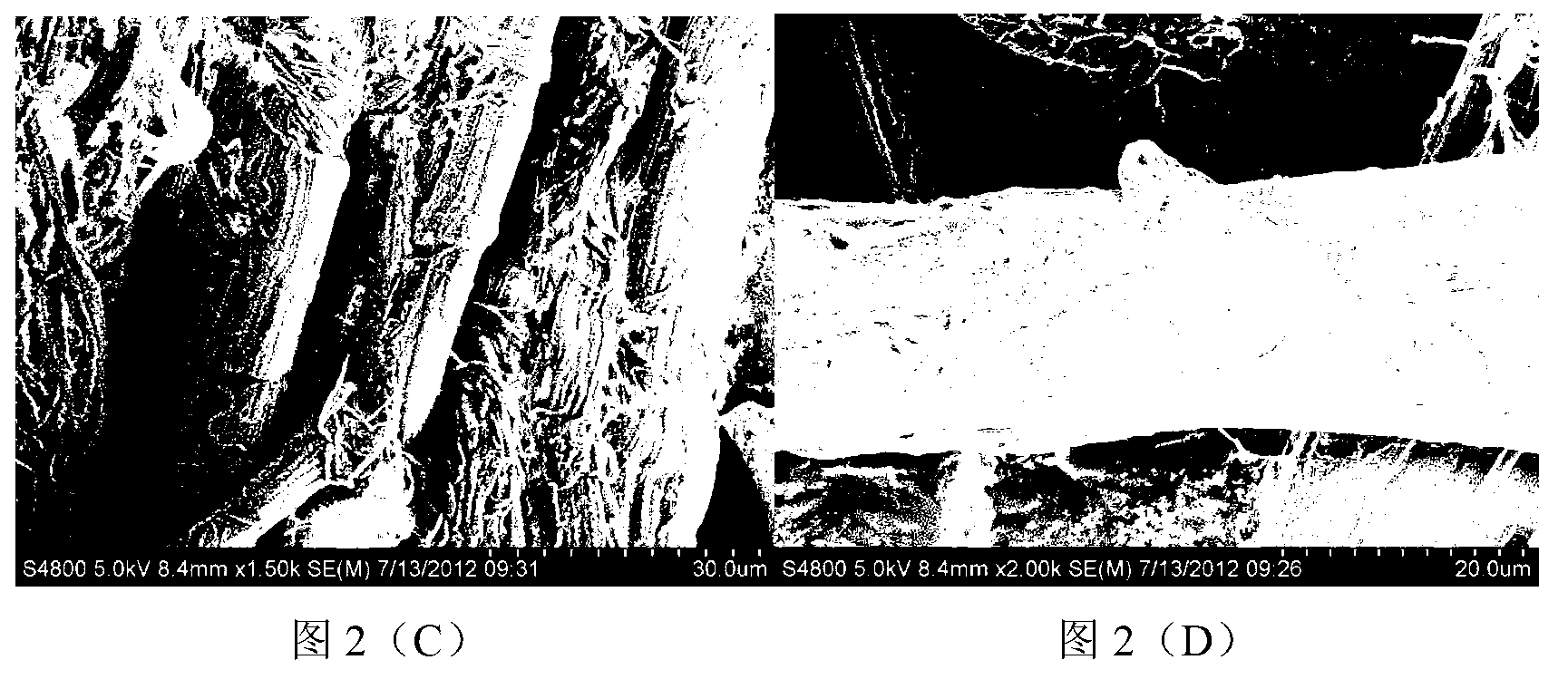

[0003] However, the excellent physical and chemical properties of aramid pulp also lead to a key problem that restricts the large-scale application of aramid pulp in rubber products: due to the strong surface polarity of aramid pulp, large electrostatic tendency, ultra-fine fibers, and specific surface area Large, so that the ultrafine fibrils near the surface of the main fiber are easily entangled with each other and adsorbed on the main fiber, making it difficult to disperse in the rubber matrix

However, the dispersing solvent is an organic solvent, and it cannot ensure that the aramid pulp is fully dispersed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

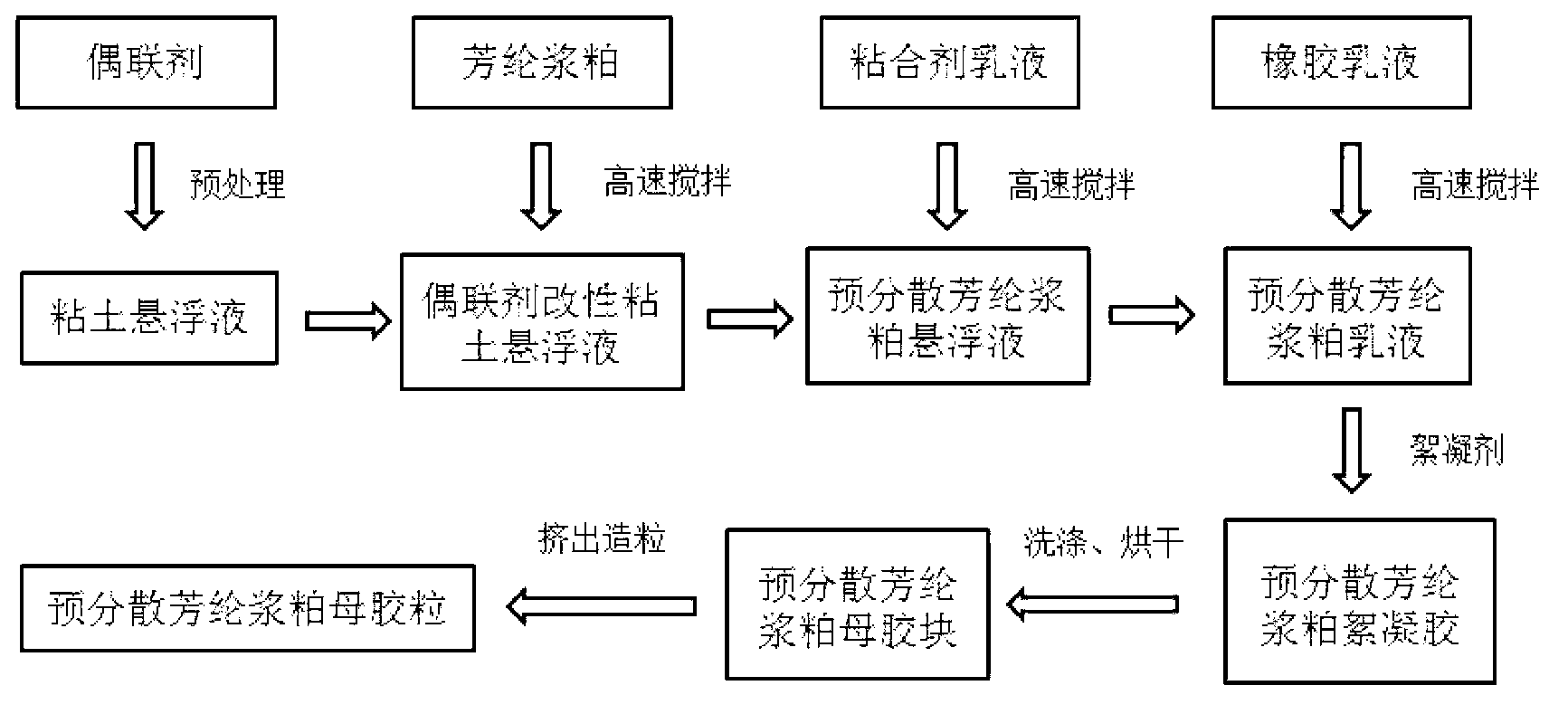

The invention discloses a preparation method of pre-dispersed clay-aramid pulp flocculation, and belongs to the field of high-performance polymer materials. According to the preparation method disclosed by the invention, an aramid pulp micro-fiber fully stretches to form effective isolation by using the high adsorption performance of an efficient coupling agent modified clay suspension system on the aramid pulp micro-fiber under a high-speed stirring effect, and simultaneously, a hydrophilic adhesive is added to endow the aramid pulp and the subsequently added rubber latex with better compatibility and adhesiveness. After the rubber latex is added into the modified clay-aramid pulp suspension system, rubber latex particles uniformly envelops the surface of the aramid pulp micro-fiber under a stirring effect, is subjected to demulsification coprecipitation and then cleaned and dried to obtain the coprecipitated masterbatch containing 40% of para aramid pulp. According to the preparation method disclosed by the invention, no organic solvent harmful to environment is used, the para aramid pulp is uniformly dispersed in the prepared pre-dispersed masterbatch without tangle, the masterbatch shares higher compatibility and adhesion with a rubber substrate and can be directly applied to enhancing systems for different rubber substrates, and the preparation method is simple in process, and quite low in cost.

Description

technical field [0001] The invention belongs to the technical field of manufacturing high-performance polymer structural materials. It relates to a preparation method of pre-dispersed clay-aramid pulp flocculation masterbatch, specifically relates to a method for preparing high-content aramid pulp by using a coupling agent to modify the clay suspension system to absorb aramid pulp microfibers The method of meal flocculation masterbatch. Background technique [0002] Aramid pulp (Aramid pulp) is a short fiber product formed by the fibrillation of the surface of aramid fibers. It has excellent properties such as high modulus, high strength, high temperature resistance, wear resistance, chemical corrosion resistance, and dimensional stability. This makes it widely used in non-asbestos friction sealing materials, high-performance insulating materials, honeycomb paper for engineering and new reinforcing additive materials, etc. However, as a new high-tech fiber, the application...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L7/02C08L9/08C08L77/10C08K9/06C08K3/34

Inventor 吴卫东许涛伍社毛张立群姚修祚宫志欣张元珂

Owner JIAXING BEIHUA POLYMER ADDITIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com