Method for preparing sustained-release insecticide microcapsule by using supercritical fluid technology

A slow-release insecticide and supercritical fluid technology, applied in the direction of insecticide, microcapsule preparation, botanical equipment and methods, etc., can solve problems such as user inconvenience, inconvenient use, and odor, and achieve improved uniformity, The effect of reducing the tendency of agglomeration and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation of product A: 1) hydroxymethyl cellulose, attapulgite, jasmine essence, undecylenyl amidopropyl betaine are added to 500 parts by weight of 85 parts: 100 parts: 0.5 parts: 0.1 parts In an acetone solution of 0.1% (wt) pyrethroid amine, mix and stir at 40°C to 50°C to obtain a mixed solution;

[0016] 2) placing the mixed solution in an autoclave, adding carbon dioxide boosted by a high-pressure diaphragm pump into the autoclave, heating up to form a supercritical state and stirring to form a suspension;

[0017] 3) The suspension is sprayed and impacted by a pair of nozzles placed coaxially opposite each other, the separated coated microcapsule particles and carbon dioxide are separated by a gas-solid separator, and the separated microcapsule particles are collected to obtain the insecticide slow-release microcapsule product a.

Embodiment 2

[0019] Preparation of product B: use hydroxyethyl cellulose instead of hydroxymethyl cellulose, use undecylenyl amidopropyl betaine instead of undecylenamidopropyl betaine, repeat the preparation method of Example 1, and obtain the product b.

Embodiment 3

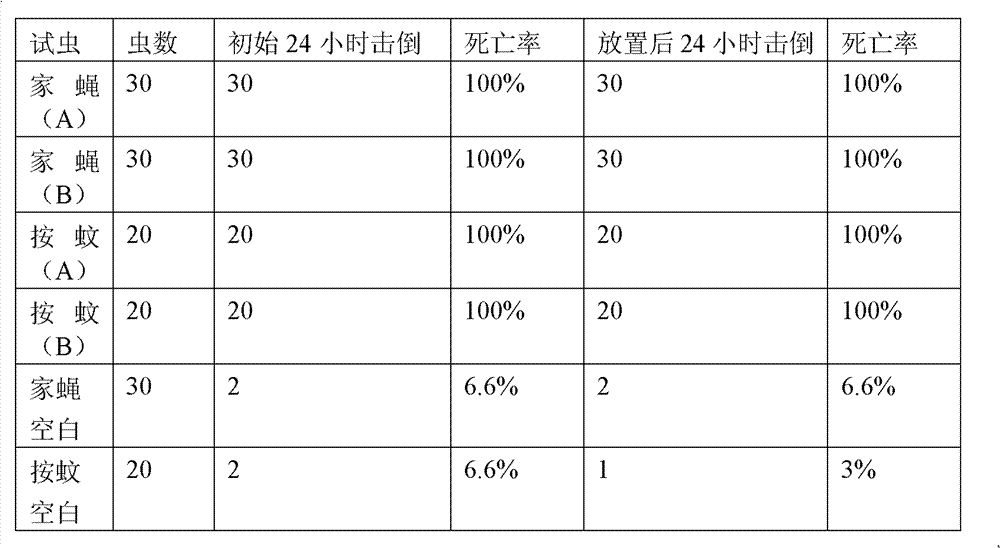

[0021] Product performance test: Add water to products A and B and mix them evenly to prepare 0.1% (wt) atomized solution for later use. Put 30 live houseflies and 20 live Anopheles mosquitoes into each airtight test chamber respectively to spray Methods Spray the atomized liquid of products A and B on the tank wall respectively, with a spray volume of 5ml. Start timing and regularly observe and record the number of knocked down after 24 hours, remove the mosquitoes and flies in the box, put the same number of mosquitoes and flies into the test box after 72 hours, start timing and regularly observe and record the knocked down after 24 hours only count. At the same time, a blank control test was carried out. See below for results.

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com