Patents

Literature

32results about How to "Reduce the propensity to reunite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of pre-dispersed clay-aramid pulp flocculation masterbatch

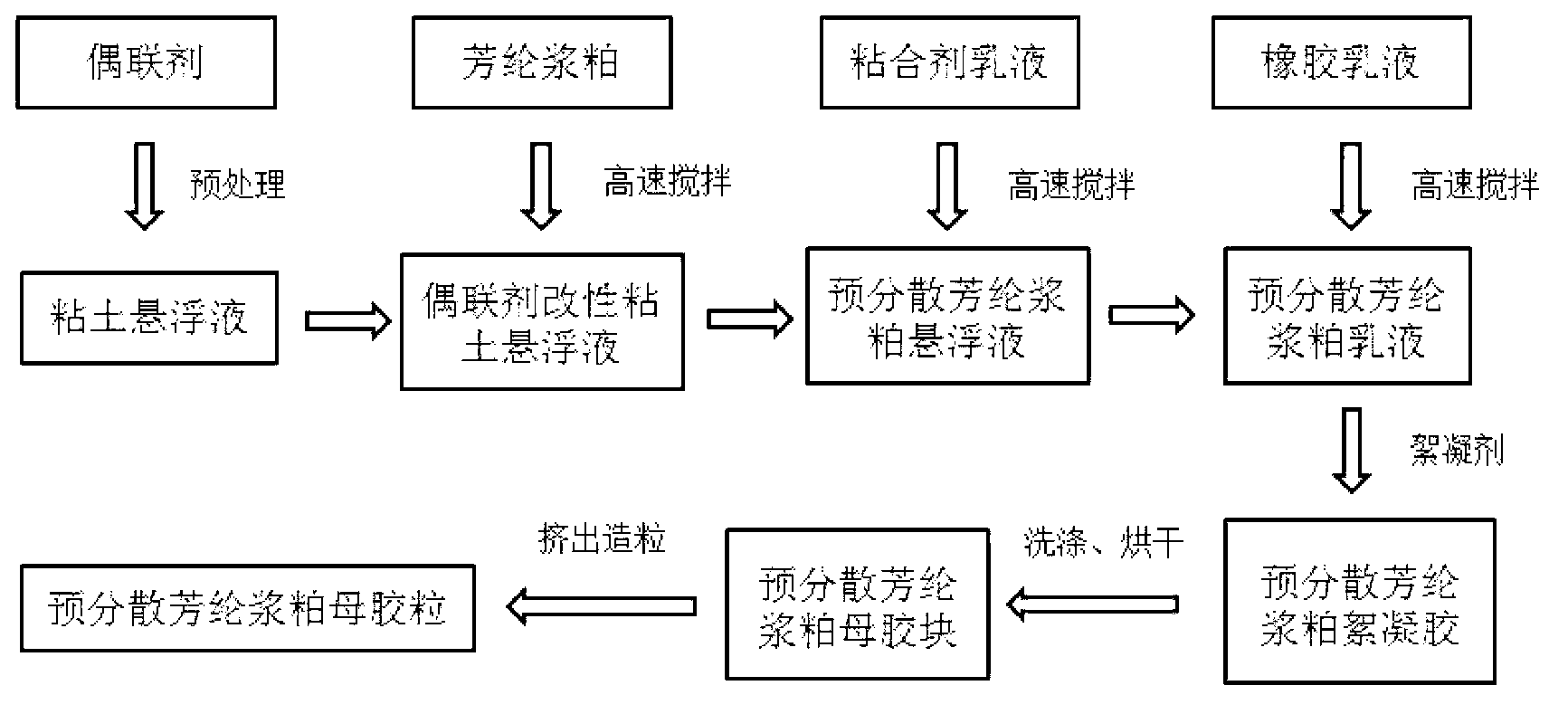

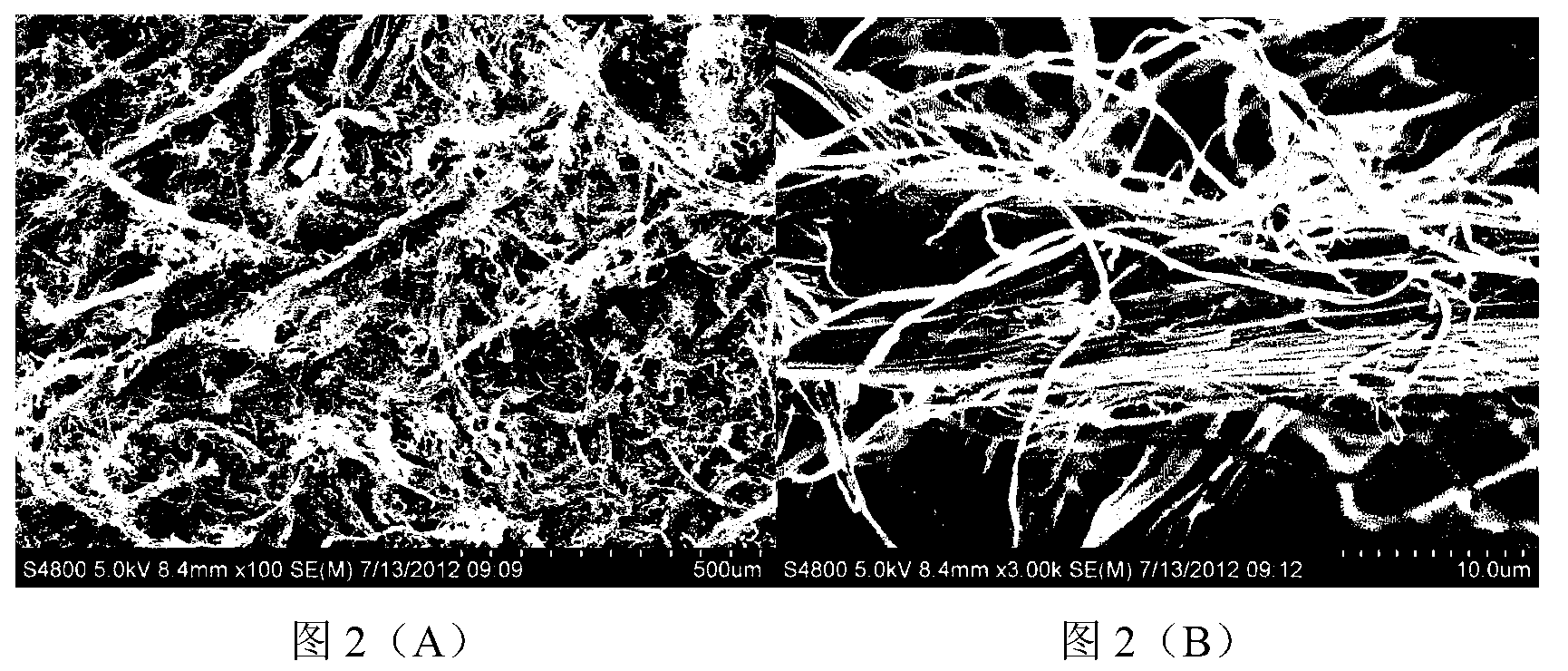

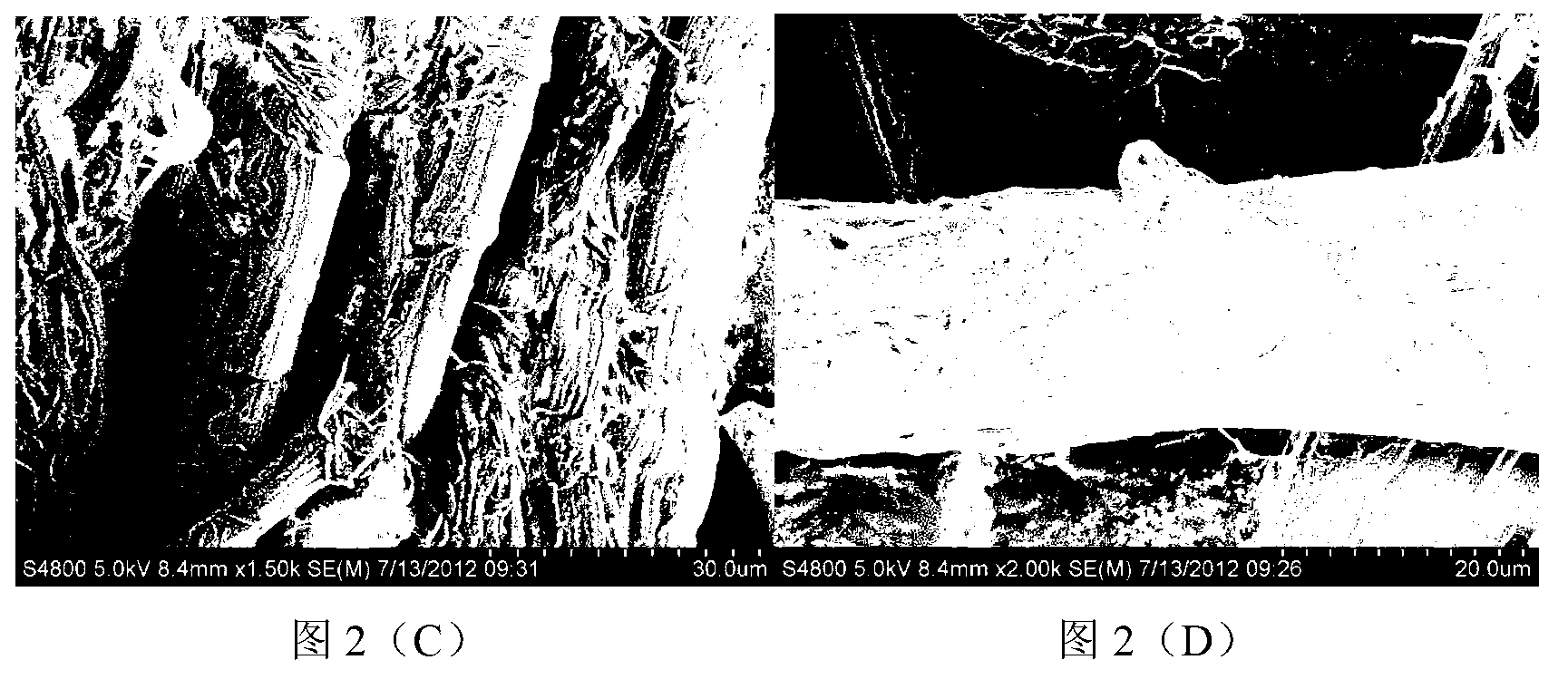

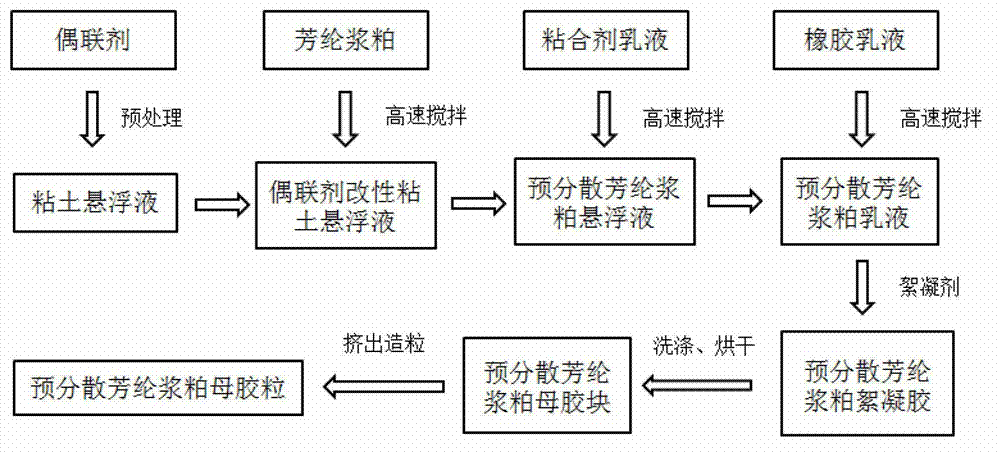

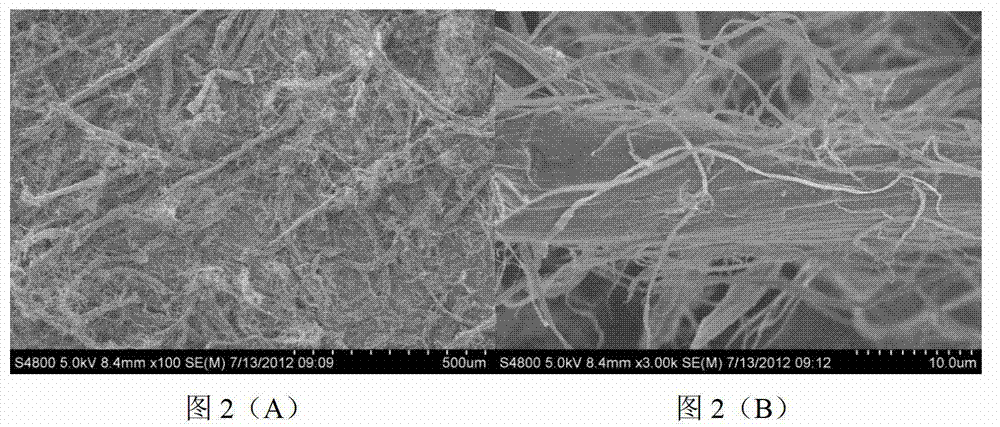

The invention discloses a preparation method of pre-dispersed clay-aramid pulp flocculation, and belongs to the field of high-performance polymer materials. According to the preparation method disclosed by the invention, an aramid pulp micro-fiber fully stretches to form effective isolation by using the high adsorption performance of an efficient coupling agent modified clay suspension system on the aramid pulp micro-fiber under a high-speed stirring effect, and simultaneously, a hydrophilic adhesive is added to endow the aramid pulp and the subsequently added rubber latex with better compatibility and adhesiveness. After the rubber latex is added into the modified clay-aramid pulp suspension system, rubber latex particles uniformly envelops the surface of the aramid pulp micro-fiber under a stirring effect, is subjected to demulsification coprecipitation and then cleaned and dried to obtain the coprecipitated masterbatch containing 40% of para aramid pulp. According to the preparation method disclosed by the invention, no organic solvent harmful to environment is used, the para aramid pulp is uniformly dispersed in the prepared pre-dispersed masterbatch without tangle, the masterbatch shares higher compatibility and adhesion with a rubber substrate and can be directly applied to enhancing systems for different rubber substrates, and the preparation method is simple in process, and quite low in cost.

Owner:JIAXING BEIHUA POLYMER ADDITIVES

Circulation box material and preparation method thereof

The invention discloses a circulation box material and a preparation method thereof, and belongs-the technical field of plastic products. The circulation box material is mainly prepared from, by weight, 100-150 parts of high-density polyethylene, 15-25 parts of polypropylene, 2-10 parts of polyacrylonitrile carbon fibers, 10-15 parts of a filler, 2-10 parts of a pigment, 10-25 parts of a compatibilizer, 0.5-3.5 parts of a dispersant, 0.2-0.7 parts of an antioxidant, 0.1-0.6 parts of an antibacterial agent, 0.3-0.6 parts of a coupling agent and 0.2-0.6 parts of a stabilizer. Circulation boxes made through adopting the method have the advantages of large mechanical strength, uniform color and strong antibacterial property, and are suitable for loading and transporting refrigerated and frozen foods.

Owner:广西睿桂涵农业有限公司

Preparation method of predispersed clay-aramid pulp flocculation masterbatch

The invention discloses a preparation method of pre-dispersed clay-aramid pulp flocculation, and belongs to the field of high-performance polymer materials. According to the preparation method disclosed by the invention, an aramid pulp micro-fiber fully stretches to form effective isolation by using the high adsorption performance of an efficient coupling agent modified clay suspension system on the aramid pulp micro-fiber under a high-speed stirring effect, and simultaneously, a hydrophilic adhesive is added to endow the aramid pulp and the subsequently added rubber latex with better compatibility and adhesiveness. After the rubber latex is added into the modified clay-aramid pulp suspension system, rubber latex particles uniformly envelops the surface of the aramid pulp micro-fiber under a stirring effect, is subjected to demulsification coprecipitation and then cleaned and dried to obtain the coprecipitated masterbatch containing 40% of para aramid pulp. According to the preparation method disclosed by the invention, no organic solvent harmful to environment is used, the para aramid pulp is uniformly dispersed in the prepared pre-dispersed masterbatch without tangle, the masterbatch shares higher compatibility and adhesion with a rubber substrate and can be directly applied to enhancing systems for different rubber substrates, and the preparation method is simple in process, and quite low in cost.

Owner:JIAXING BEIHUA POLYMER ADDITIVES

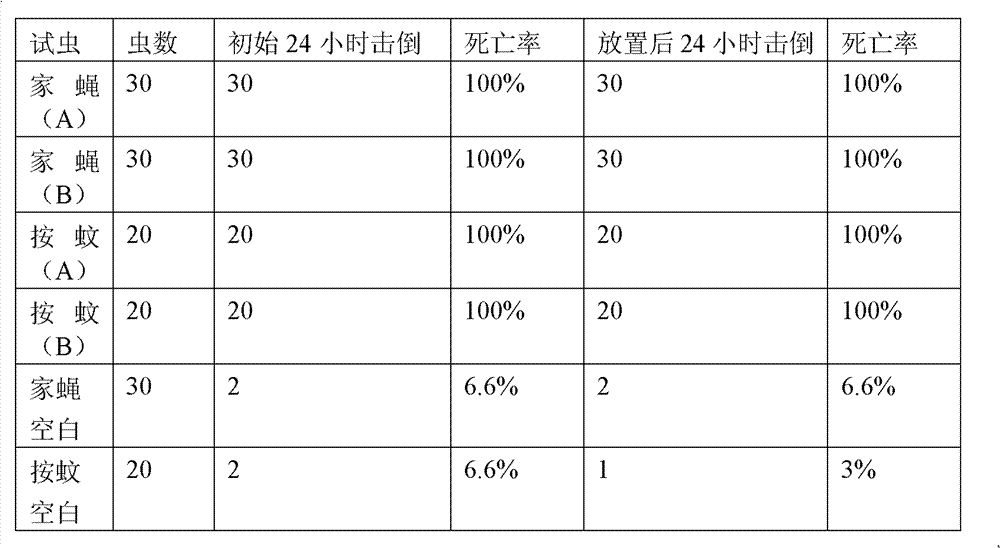

Method for preparing sustained-release insecticide microcapsule by using supercritical fluid technology

The invention discloses a method for preparing a sustained-release insecticide microcapsule by using a supercritical fluid technology. A composition prepared with the method comprises ingredients, such as cellulose, attapulgite, essence, a betaine ampholytic surface active agent and the like. The method comprises the following steps of: compounding the above ingredients; and further evenly covering particles with a supercritical impact micro-granule wrapping method. With the method, the agglomeration tendency which easily appears when the common means are adopted is lightened so as to improvethe evenness of the microcapsule. Meanwhile, the method also has the universal advantages of the traditional supercritical wrapping method. The composition prepared with the method has a good insecticidal effect and an obvious sustained-release effect.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

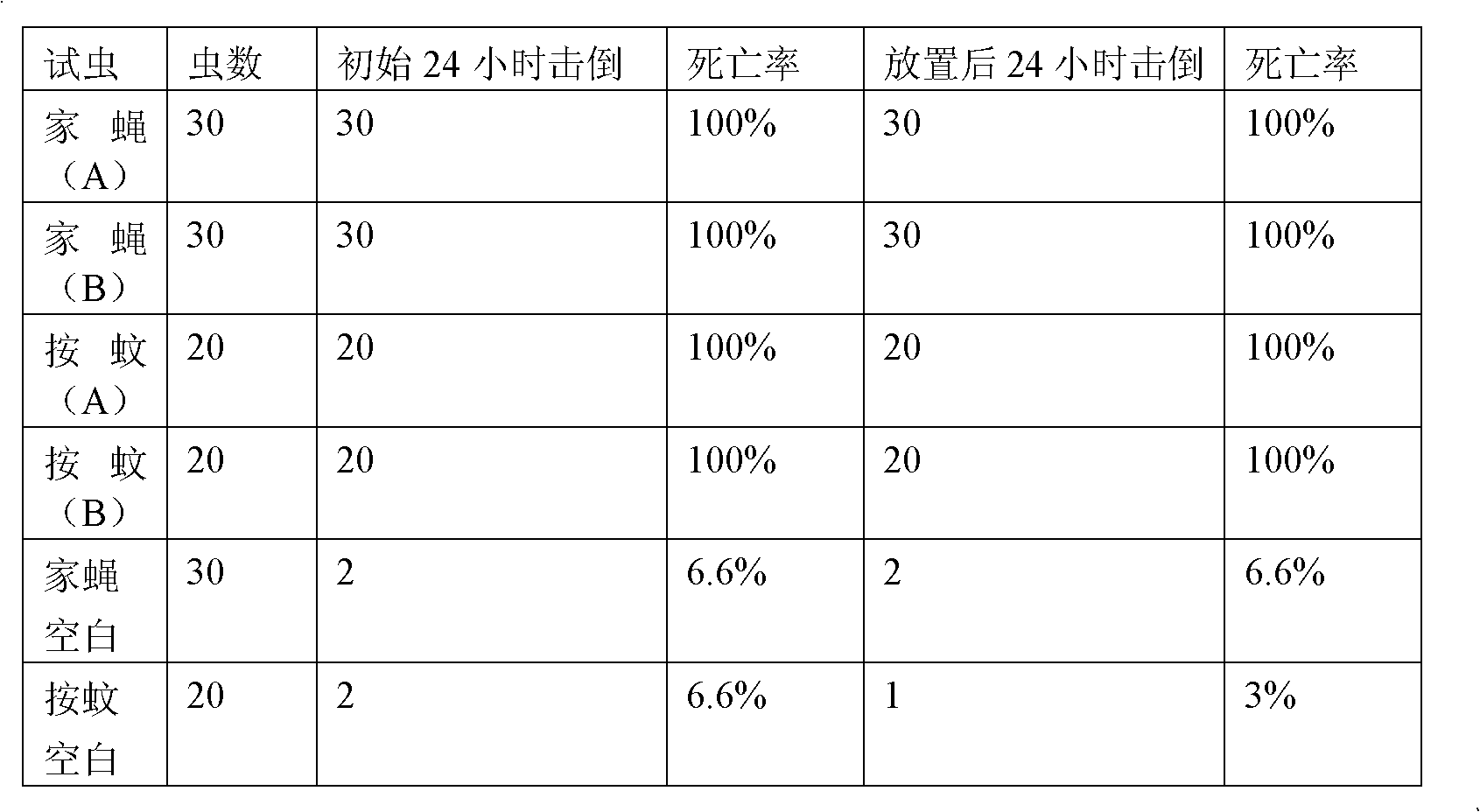

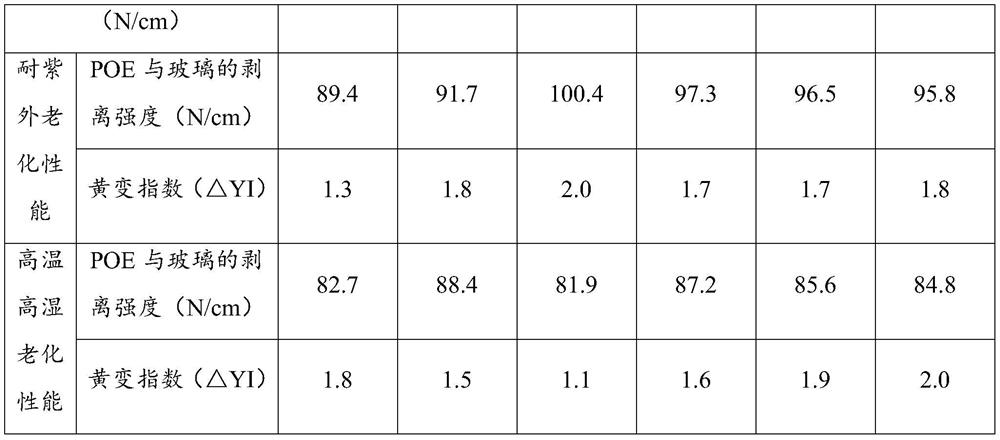

White carbon black modified polyamine dispersant-containing rubber composition and applications thereof

The invention discloses a white carbon black modified polyamine dispersant for rubber shown in formula (I) and a preparation method thereof, wherein the white carbon black modified polyamine dispersant is prepared by mixing and reacting polyamine with organic carboxylic acid or organic carboxylic ester. The white carbon black modified polyamine dispersant has polar amino functional group and nonpolar side chain hydrocarbon structure, and is used for preparing a rubber composition, the polar functional group and white carbon black can be formed into a hydrogen bond or a chemical bond, so that intermolecular force of white carbon black can be weakened, the clustering tendency can be reduced, the nonpolar side chain hydrocarbon structure can improve the compatibility of rubber, the dispersionof white carbon black in rubber and the lagging performance of vulcanized rubber can be improved. The invention further discloses a white carbon black modified polyamine dispersant-containing rubbercomposition, which at least comprises (i) rubber component selected from natural rubber or synthesized rubber; (ii) white carbon black component; and (iii) white carbon black modified polyamine dispersant for rubber and with a structure shown in the formula (I).

Owner:RACHEM CHINA CO LTD +1

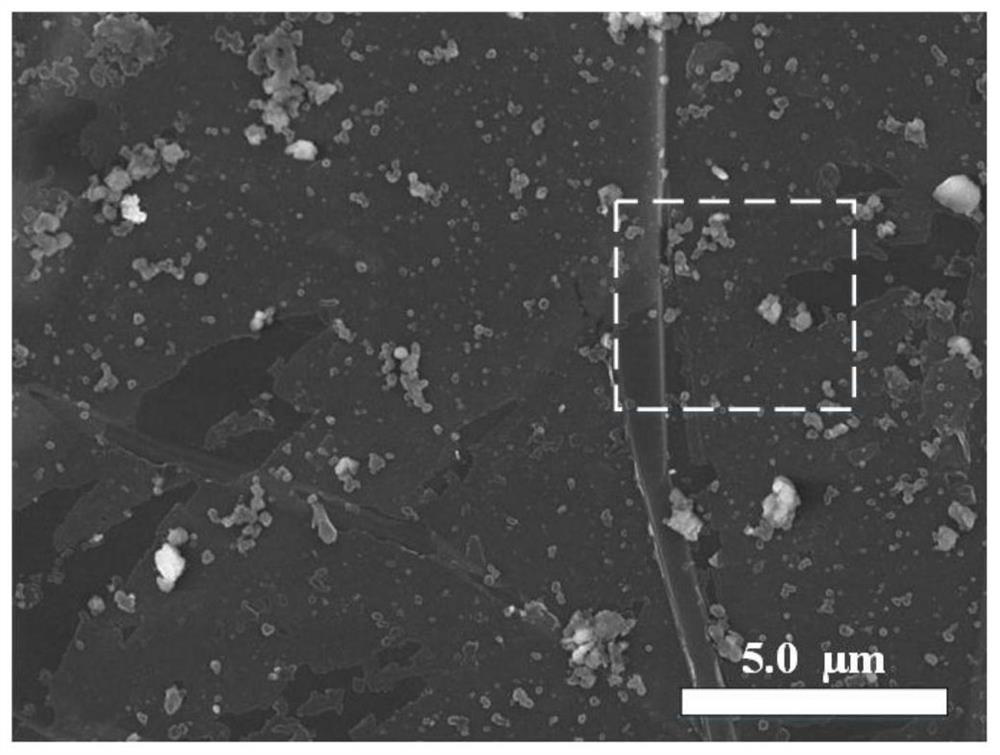

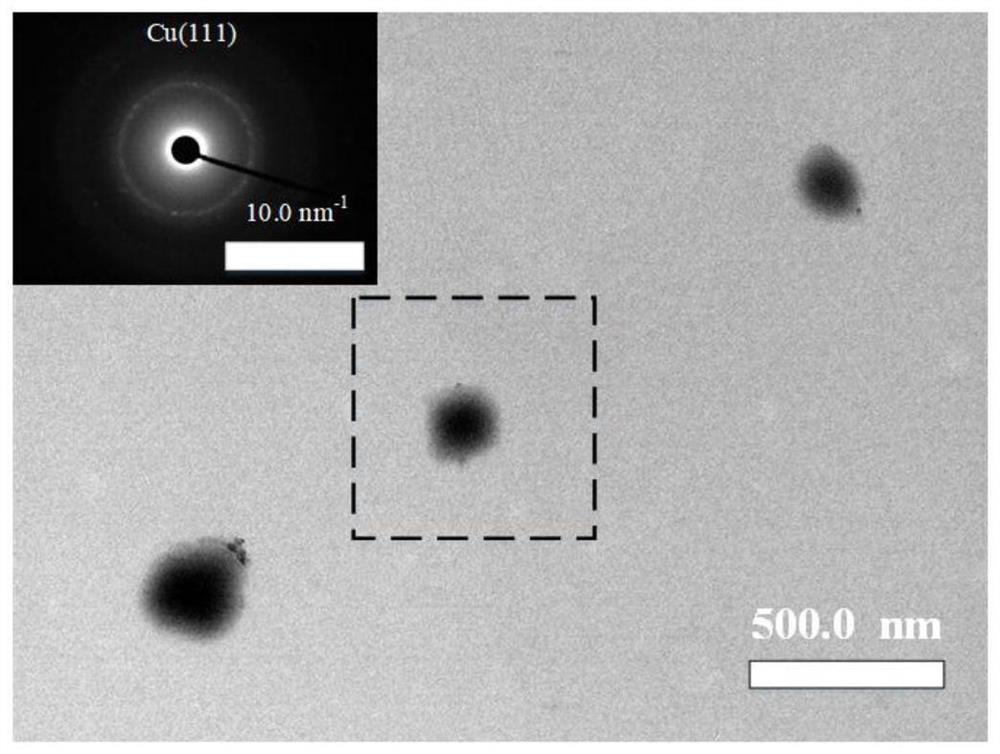

Graphene surface dispersity modification method

InactiveCN112624096AChange the surface energy stateGood dispersionMaterial nanotechnologyCarbon compoundsGraphiteGraphene

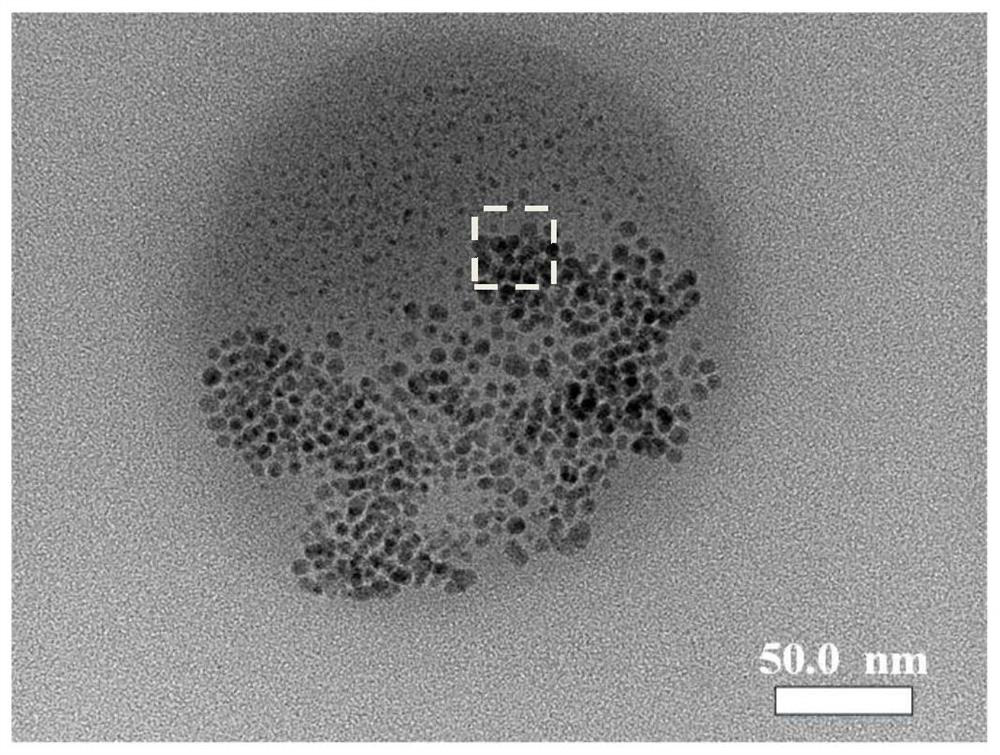

The invention discloses a graphene surface modification method, and relates to the field of graphene surface modification. The surface-modified graphene prepared by the method is characterized in that nanoscale copper particles are aggregated into small particles to be dispersed on the surface of the graphene. The method comprises the following steps: by taking graphene as a reinforcing phase, adding graphene into a dopamine hydrochloride solution, then adding CuSO4 into a polydopamine graphene solution, and reducing Cu <2+> to form Cu nanoparticles on the surface of graphene. The surface-modified graphene prepared by the process is stable in microstructure, and can effectively improve the dispersity of the composite material and improve the performance of the composite material when being added into the composite material as a reinforcing phase.

Owner:XI AN JIAOTONG UNIV

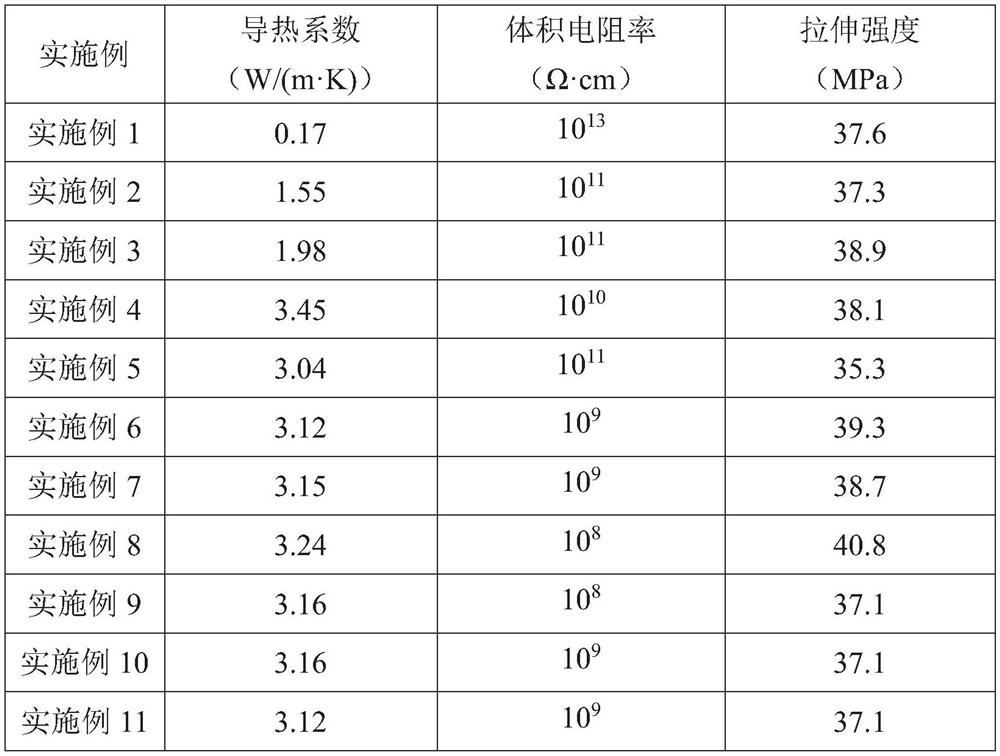

Heat-conducting and insulating composite high polymer material containing expanded graphite subjected to in-situ surface coating and preparation method thereof

PendingCN114045031AImprove thermal conductivityImprove insulation performanceSilica gelCompatibilization

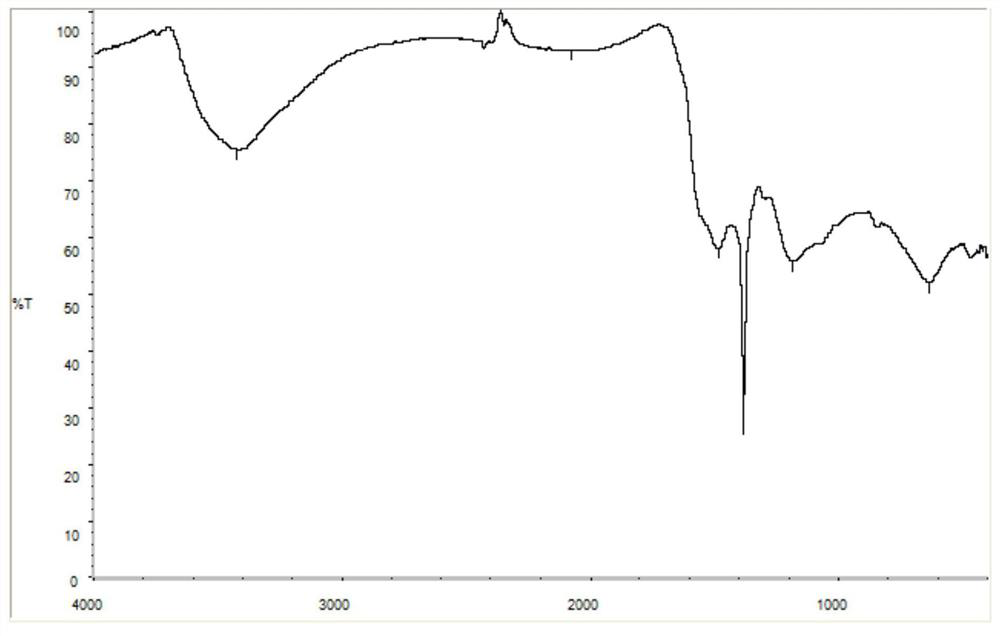

The invention discloses a heat-conducting and insulating composite high polymer material containing expanded graphite subjected to in-situ surface coating and a preparation method thereof; the preparation method specifically comprises the following steps: synthesizing nano silicon dioxide (nano SiO2) by adopting a sol-gel method, and coating the surface of expanded graphite (EG-SiO2) in situ; and doping the mixture into methyl vinyl silicone rubber (VMQ) to prepare the heat-conducting and insulating polymer composite material. According to the invention, the interface compatibility of EG and VMQ is effectively improved through the interaction of the nano SiO2 layer and a silicone rubber molecular chain, so that EG can be uniformly dispersed in silicone rubber to construct a continuous heat conduction path, scattering of phonons on a two-phase interface is reduced through good interface combination, and the heat conduction performance is improved; and on the other hand, nano SiO2 is introduced into a two-phase interface to serve as an electron conduction barrier layer, so that the insulating property is improved. Compared with a traditional composite material, the silica gel-based heat-conducting material prepared by the method has excellent heat-conducting property, good insulating property and mechanical property, and can be widely applied to the field of heat management materials. In addition, the heat-conducting insulating polymer composite material is simple and efficient in production process, low in cost and suitable for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH +1

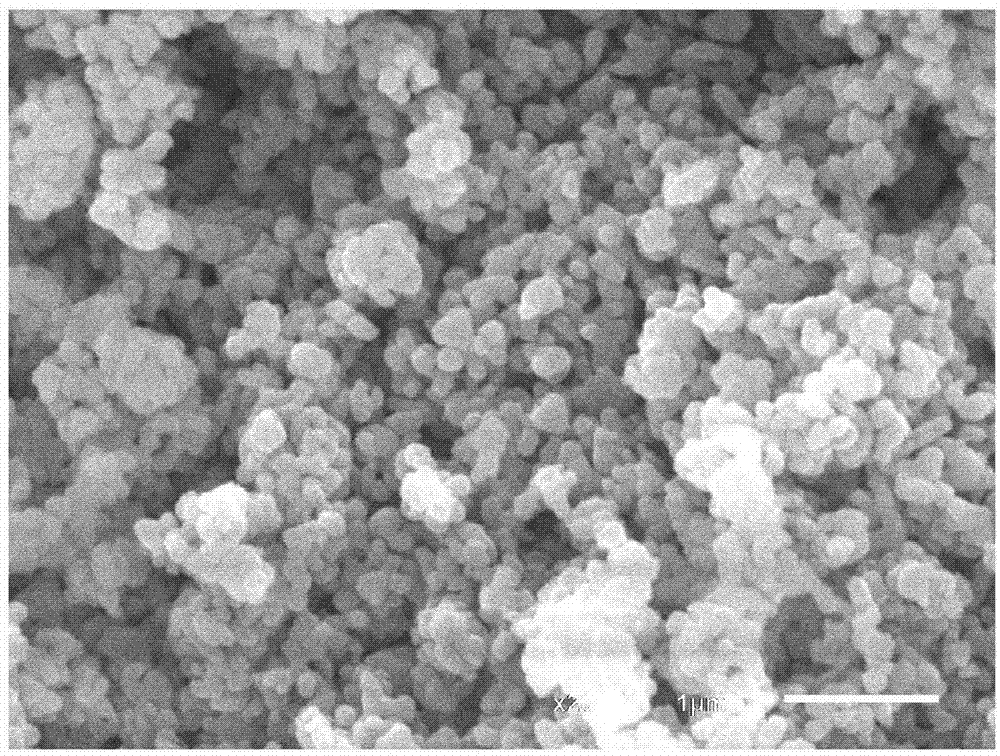

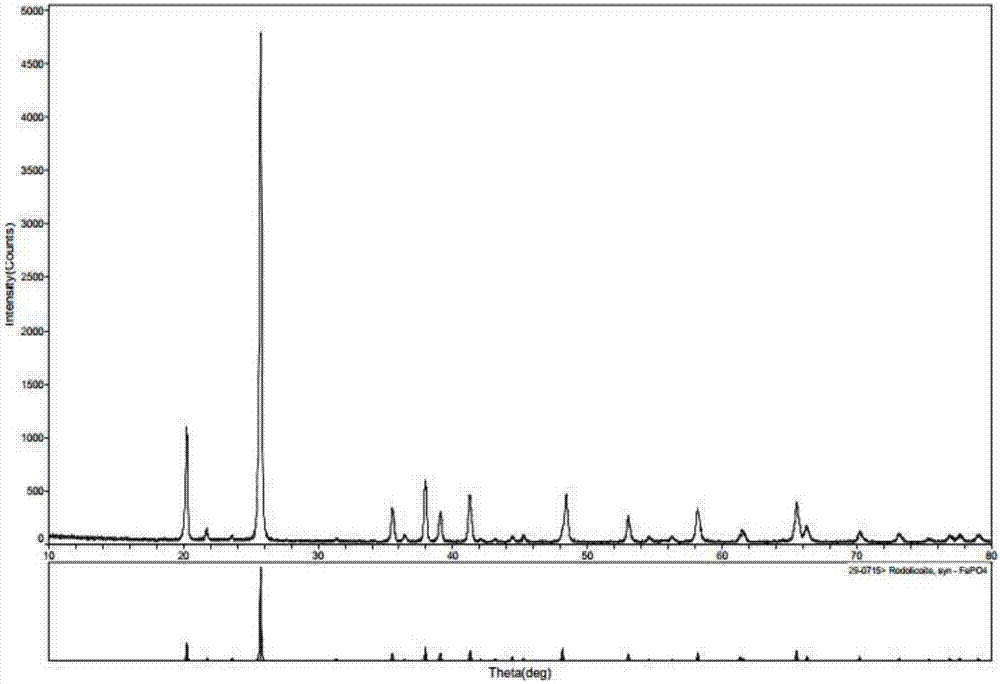

Spherical iron phosphate and preparation method and application thereof

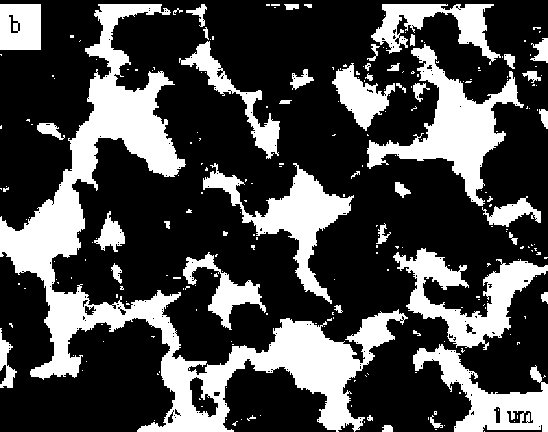

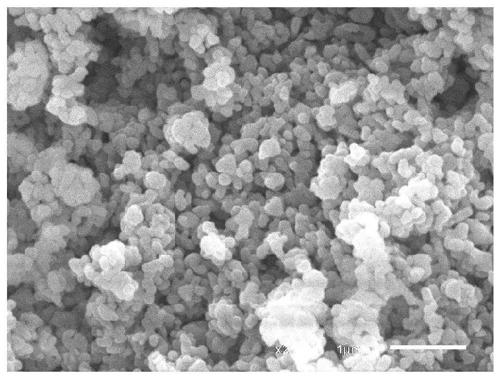

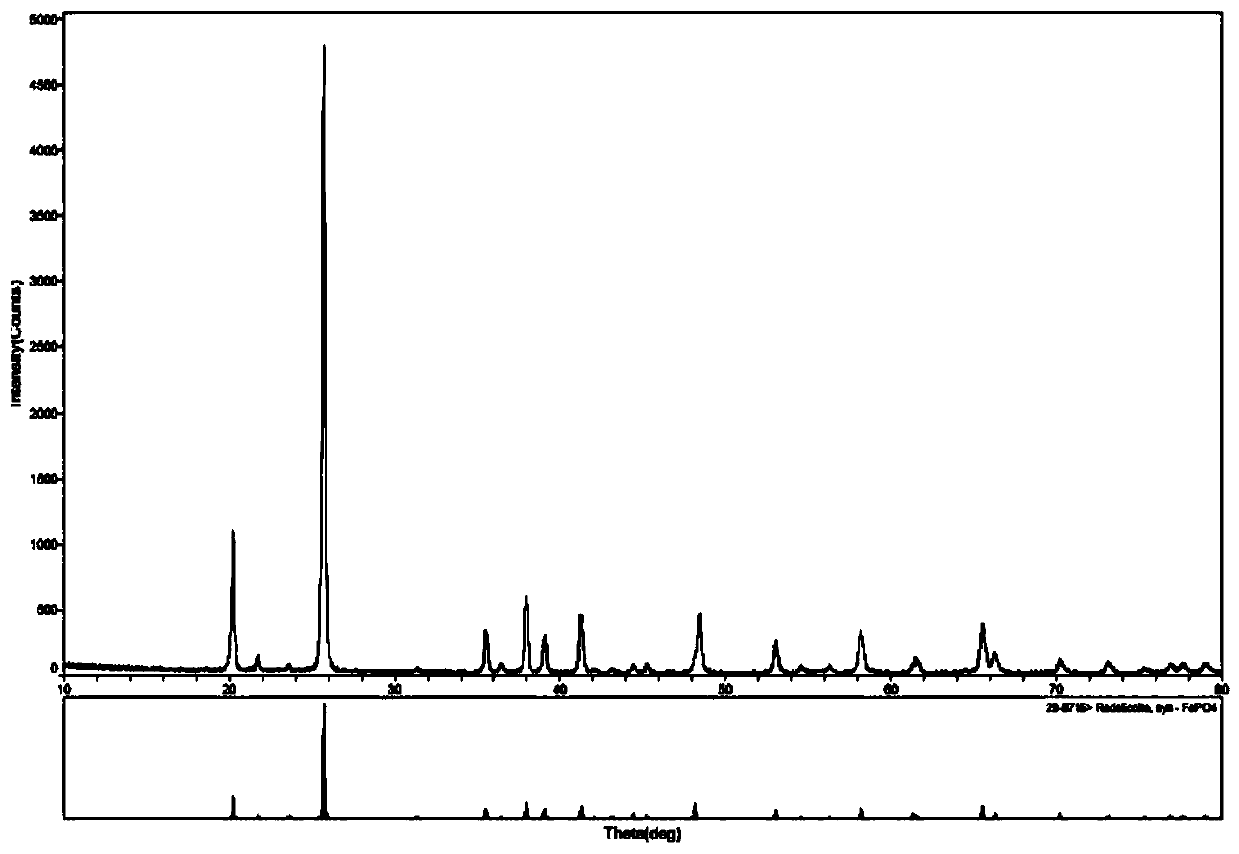

ActiveCN107986253AWeakened molecular forcesReduce the propensity to reuniteCell electrodesSecondary cellsPhosphate ionPhosphoric acid

The invention discloses spherical iron phosphate and a preparation method and application thereof. The preparation method comprises the following steps: adding a disperser into iron-phosphorus mixed liquor containing iron ion and phosphate anion, thus obtaining mixed liquor A; under a heating condition, adding urea into the mixed liquor A to regulate a pH value, and continuously heating to obtainmixed liquor B containing crystal-form iron phosphate; filtering the mixed liquor B, adding a filter cake into water to prepare mixed liquor C, atomizing the mixed liquor C by a spray gun, leading into a roasting furnace, and roasting at a temperature of 550 to 750 DEG C to obtain the spherical iron phosphate. The spherical iron phosphate is pure in crystalline phase, good in crystallinity, spherical in shape, uniform in grain fineness distribution and high in tap density, and can serve as a precursor for synthesizing spherical lithium iron phosphate with high tap density; the spherical iron phosphate can eliminate microscopic composition difference caused by different diffusion paths in a reaction, so as to generate the lithium iron phosphate with a uniform structure, and thus the performance of the lithium iron phosphate is improved.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

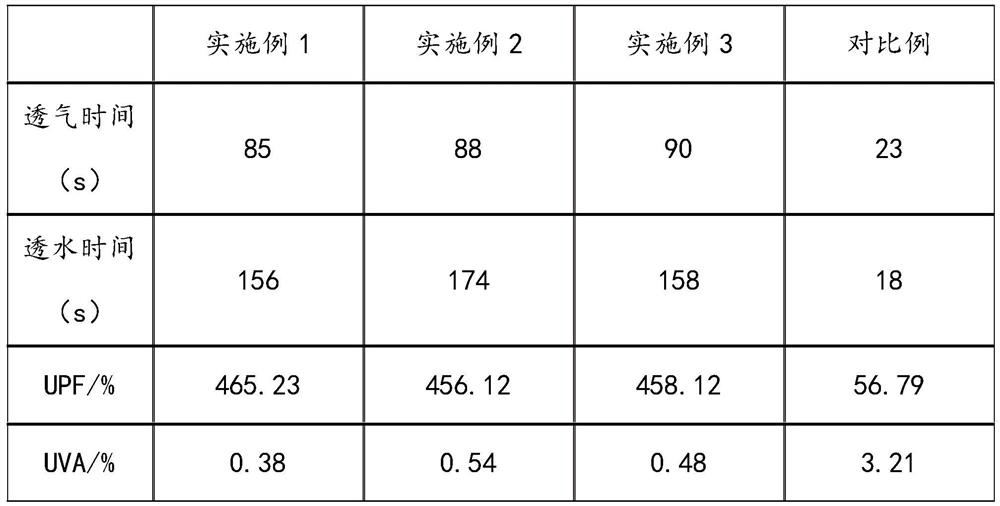

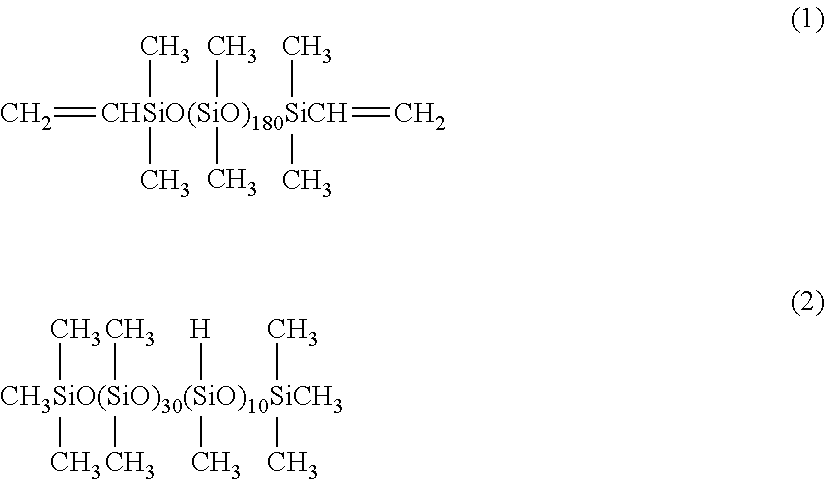

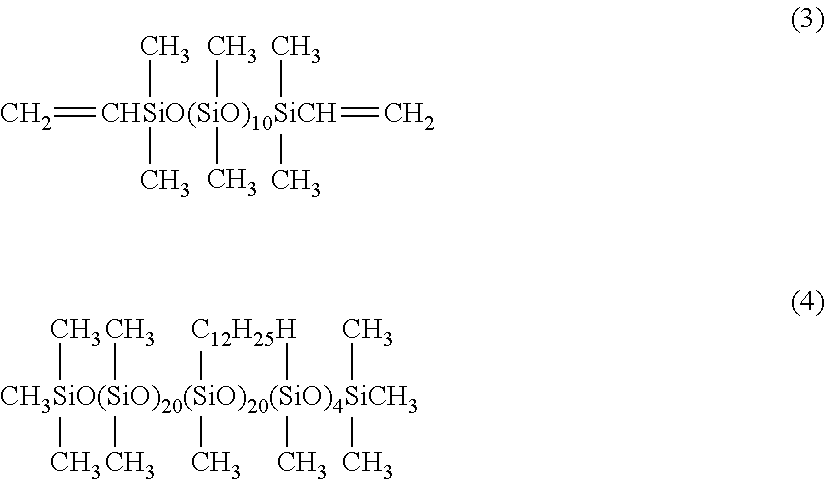

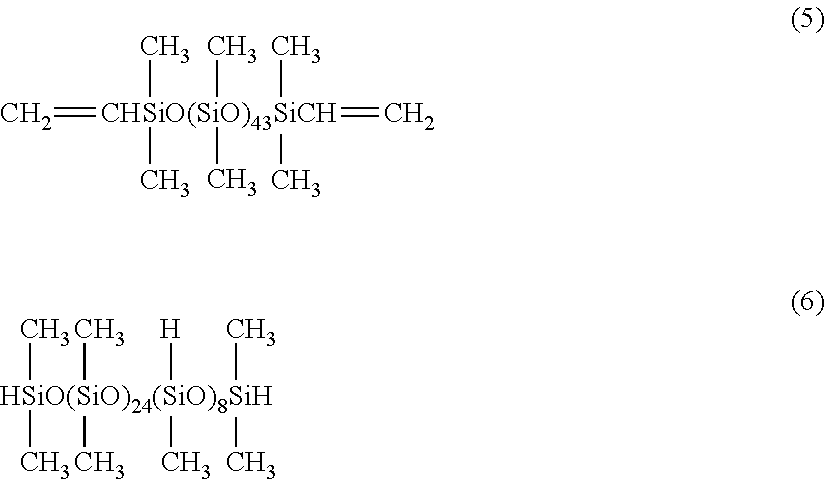

Waterproof and windproof elastic fabric and preparation method thereof

InactiveCN113622196ALower surface energyReduce the degree of hydroxylationLight resistant fibresLiquid/gas/vapor removalPolyesterPolymer science

The invention discloses a waterproof and windproof elastic fabric. The elastic fabric is prepared from the following raw materials in parts by weight of 30-40 parts of polyester fibers, 10-15 parts of elastic spandex fibers, 4-6 parts of bamboo charcoal fibers, 5-10 parts of cotton fibers and 50-70 parts of modified emulsion. The invention further discloses a preparation method of the elastic fabric, multiple types of fibers are woven into an elastic fabric blank through a warp and weft interweaving twill weave method, and the elastic fabric is prepared through dyeing, soaping and modification additive finishing; and amino silicon oil is grafted on the surface of the titanium dioxide sol, and the hydrophobic property of organic silicon and the characteristic of absorbing ultraviolet rays in a medium wave region of titanium dioxide are combined, so that the prepared elastic fabric has the waterproof and windproof performance and the ultraviolet-proof function at the same time, and has potential application value in the fields of clothes and daily necessities.

Owner:深圳市蔚览实业有限公司

Silicone microparticle and method for producing the same

ActiveUS20130040144A1Reduce decreaseReduce the propensity to reuniteCosmetic preparationsLiquid surface applicatorsMicroparticleVolume average

The present invention provides a silicone microparticle, wherein the silicone microparticle comprises 100 parts by mass of a silicone elastomer spherical microparticle having volume-average particle diameter of 0.1 to 100 μm and 0.5 to 25 parts by mass of a polyorganosilsesquioxane to cover surface of the silicone elastomer spherical microparticle, wherein the polyorganosilsesquioxane has a shape of granule with the size thereof being 60 nm or less. There can be provided a silicone microparticle having low agglomerating tendency and excellent dispersibility even if rubber hardness of a silicone elastomer microparticle is low and a particle diameter thereof is small.

Owner:SHIN ETSU CHEM IND CO LTD

Anti-wear coating for chemical pump

InactiveCN107141986AImprove easy reunion phenomenonImprove wear resistancePolyether coatingsEpoxy resin coatingsStress concentrationEmulsion

The invention discloses an anti-wear coating for a chemical pump. The anti-wear coating is prepared according to the following step: mixing color paste with emulsion. By modification treatment of sericite powder, the surface of the sericite powder is covered by an organic group, so that the surface group property and the surface energy of the sericite powder can be effectively changed, and the compatibility between the modified sericite powder and other components in the coating can be fundamentally improved; by adding of isosorbide, the phenomenon that the sericite powder is easy to agglomerate can be improved, and the interfacial force between the sericite powder and a base body can be enhanced; therefore, the sericite powder can be dispersed more uniformly; in a friction process, damage within a relatively large range due to stress concentration can be avoided.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

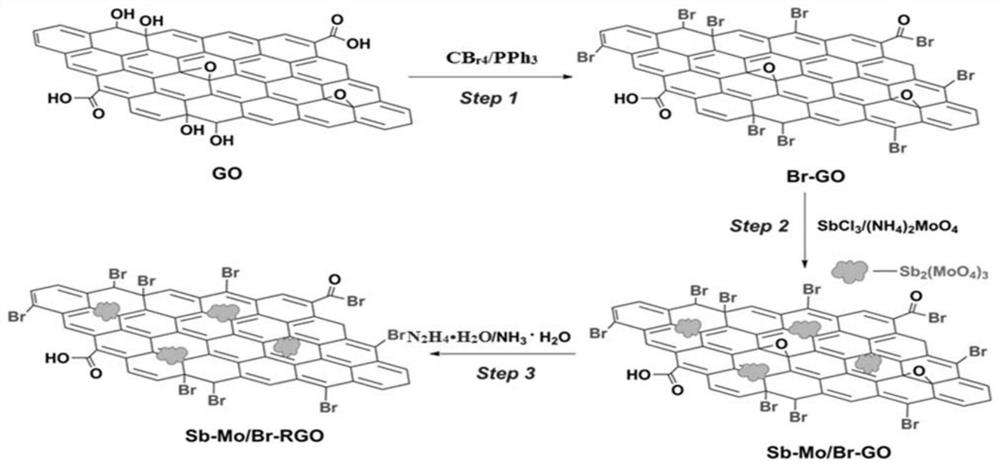

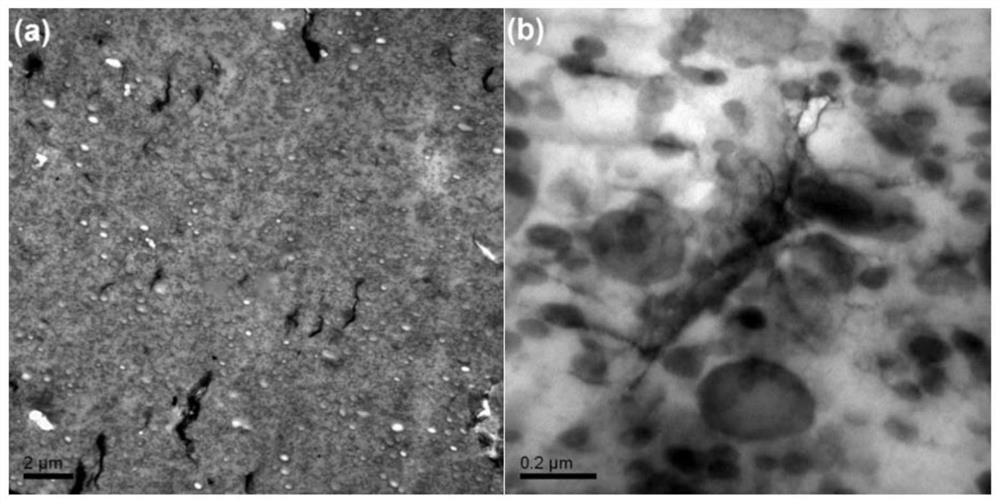

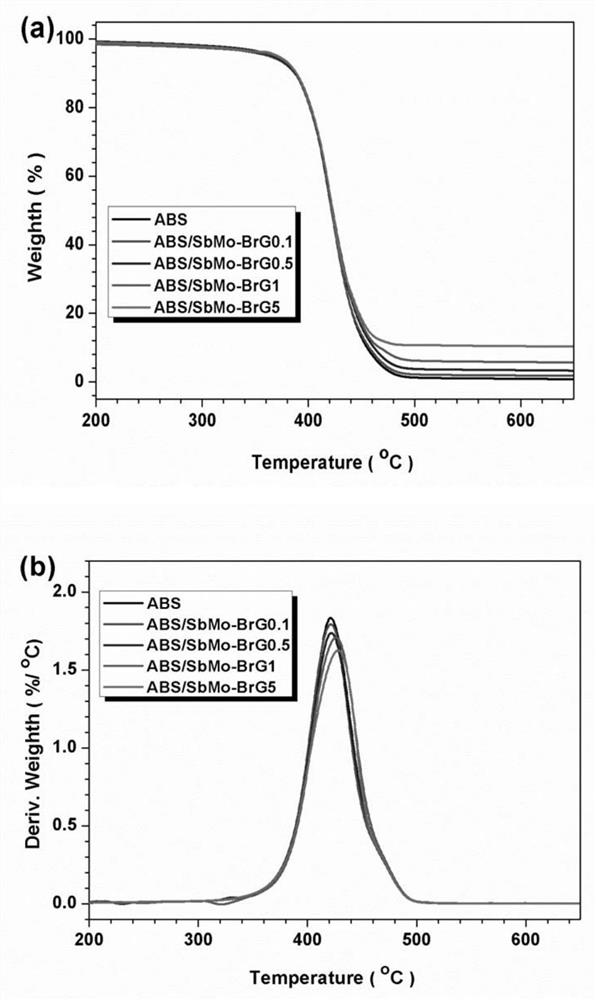

A molybdenum-antimony brominated graphene oxide modified ABS composite flame retardant material and preparation method thereof

ActiveCN109181207BHigh flame retardant efficiencyHigh smoke suppression effectHeat flowThermal solution

Owner:浙江力安电缆有限公司

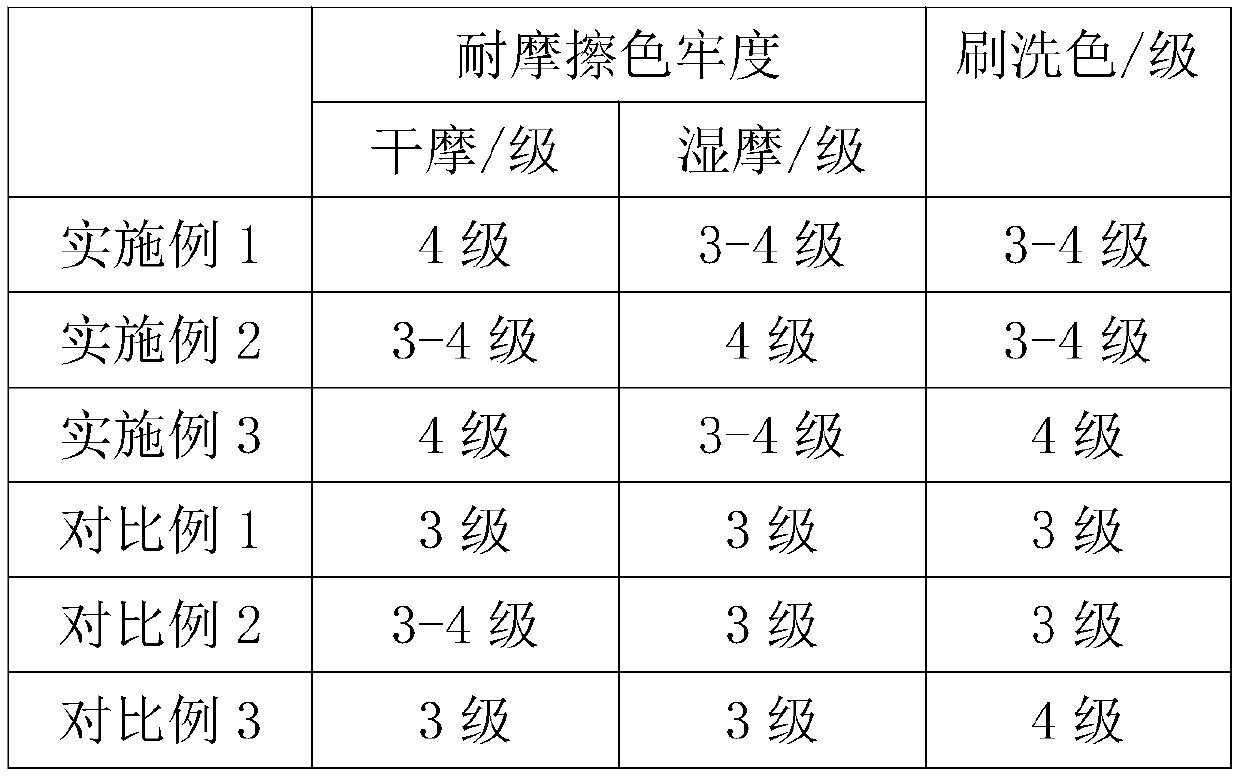

Printing fabric production process

InactiveCN110117906AOvercome the defect of single functionTo achieve a sustained antibacterial effectBiochemical fibre treatmentHeating/cooling textile fabricsAgricultural engineeringDesizing

The invention discloses a printing fabric production process, and relates to the technical field of textile processing. The printing fabric production process includes the working procedures of preparing base fabric, desizing and boiling, dyeing, high-temperature setting, printing, re-setting treatment and the like. The invention further discloses an antibacterial microcapsule preparation method,which realizes uniform coating of particles, lightens the agglomeration tendency easy to occur in conventional means, improves the uniformity of microcapsules, and the obtained printed fabric has a good antibacterial effect, good color fastness, uniform color, high use performance and a good market prospect.

Owner:安徽省翰先纺织科技有限公司

Preparation method of metal ion doped modified silver zinc oxide electric contact material

ActiveCN113957282AEasy reunionGuaranteed efficient densificationOxide conductorsCable/conductor manufactureLithium metalIon doping

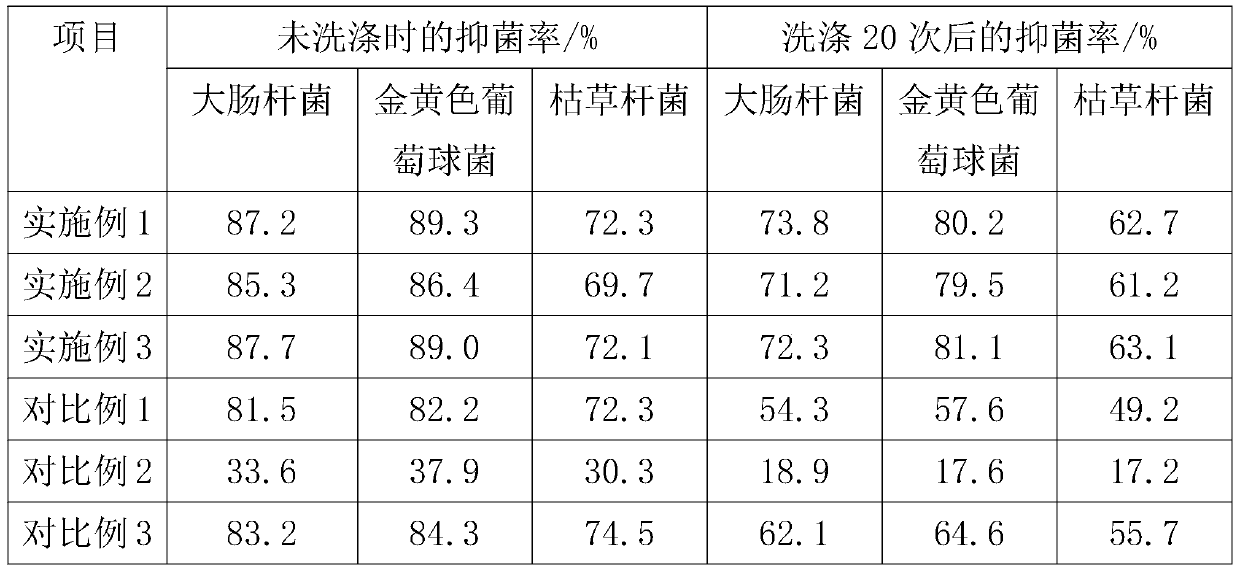

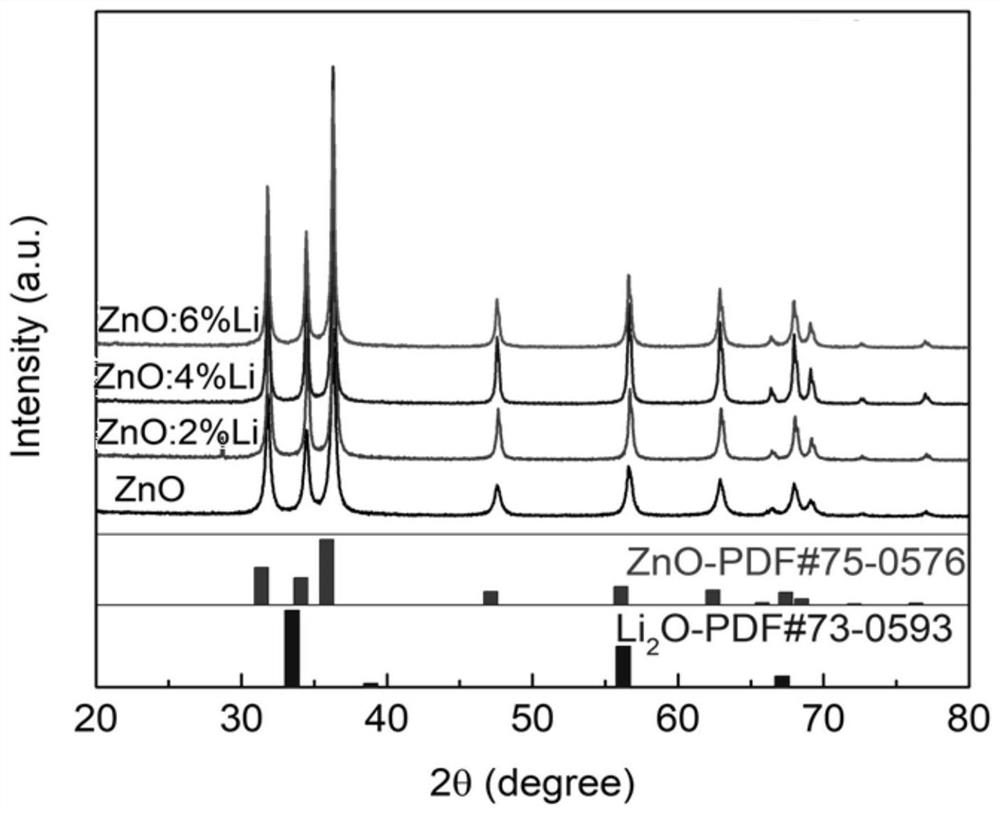

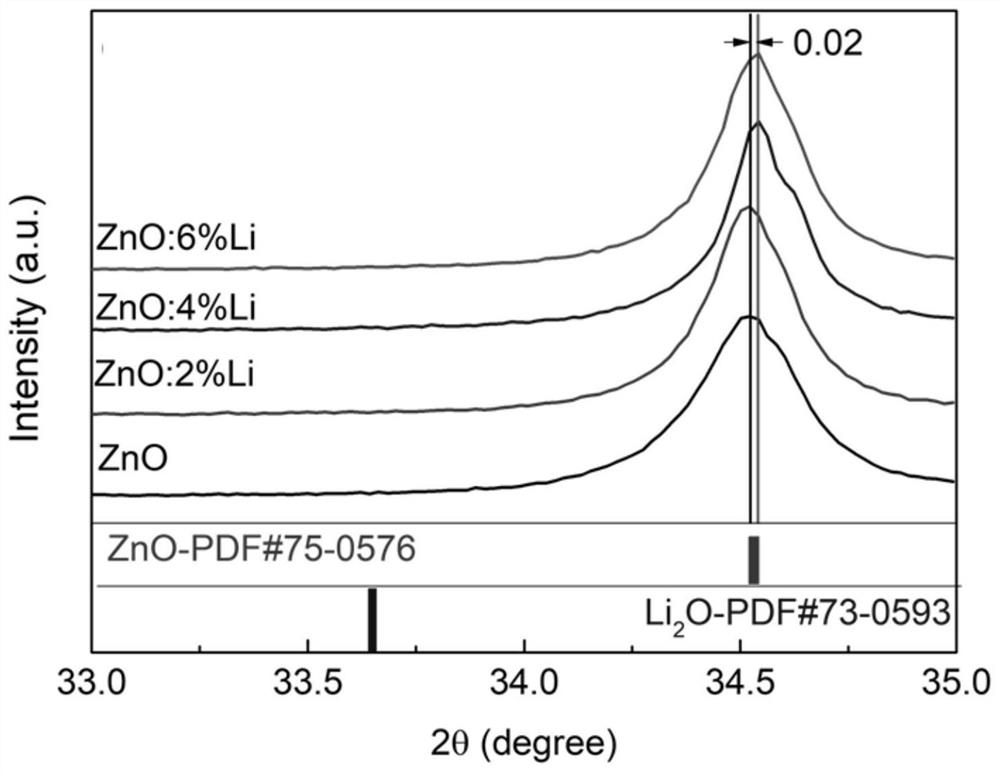

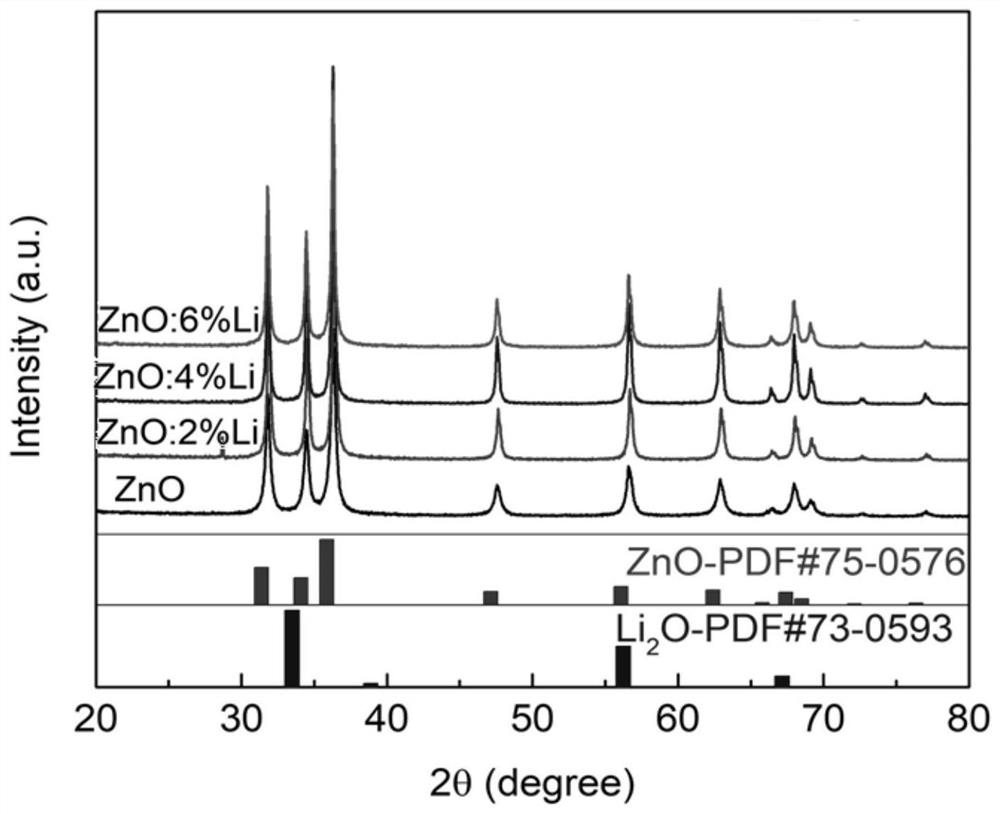

The invention discloses a preparation method of a metal ion doped modified silver zinc oxide electric contact material, and relates to a preparation method of an electric contact material. The invention aims to solve the problems of poor wettability between zinc oxide and a silver substrate and short electric contact life caused by easy agglomeration of zinc oxide during preparation of the existing silver zinc oxide electric contact material. The method comprises the following steps: preparing lithium metal doped zinc oxide powder by a self-propagating combustion method, and mixing metal ion doped zinc oxide powder with silver powder to obtain mixed powder; primarily pressing the mixed powder to obtain a blank; primarily sintering the blank to obtain a sintered blank; re-pressing the sintered blank; and re-sintering. The doping of metal ions can improve the wettability between the zinc oxide and the silver substrate and solve the problem that the zinc oxide is easy to agglomerate; and high-energy ball-milling mixed powder is combined to ensure high-efficiency densification of the material, improve the second-phase dispersion effect and improve the electric contact performance. The preparation method of the invention is suitable for preparing the silver zinc oxide electric contact material.

Owner:HARBIN INST OF TECH

Method for improving the impact resistance of thin-wall flame-retardant wire cable material

InactiveCN108342027AHigh tensile strengthImprove flame retardant performancePlastic/resin/waxes insulatorsPliabilityCopolymer

The invention belongs to the technical field of flame-retardant wire and cable processing, in particular to a method for improving the impact resistance of a thin-wall flame-retardant wire cable material. The preparation method comprises the following steps: preparing a nano calcium carbonate composite material, preparing materials, mixing the raw materials, granulating and aging. Compared with the prior art, the preparation method has the following advantages that the preparation of the nano calcium carbonate composite material reduces the agglomeration tendency, the middle material is compounded with acrylonitrile-butadiene-styrene copolymer and then is compounded with high-polymerization-degree ammonium polyphosphate at the same time, so that the tensile strength and the flame retardancy of the obtained composite material are obviously improved, the resin raw materials with different performances are cooperated, and then aging is carried out after the electric wire and the cable material are prepared, and a sample strip with the thickness of 0.6 mm is produced, detection is carried out, and the surface of the wire rod after mechanical scraping is not white, the acid and alkali resistance is good, the flexibility and impact resistance are relatively good, the environment-friendly and flame-retardant effects are achieved, and poisonous black smoke cannot be generated during combustion, and the flexibility and processability are good.

Owner:铜陵市远维线缆有限公司

High-shading polypropylene composition and preparation method thereof

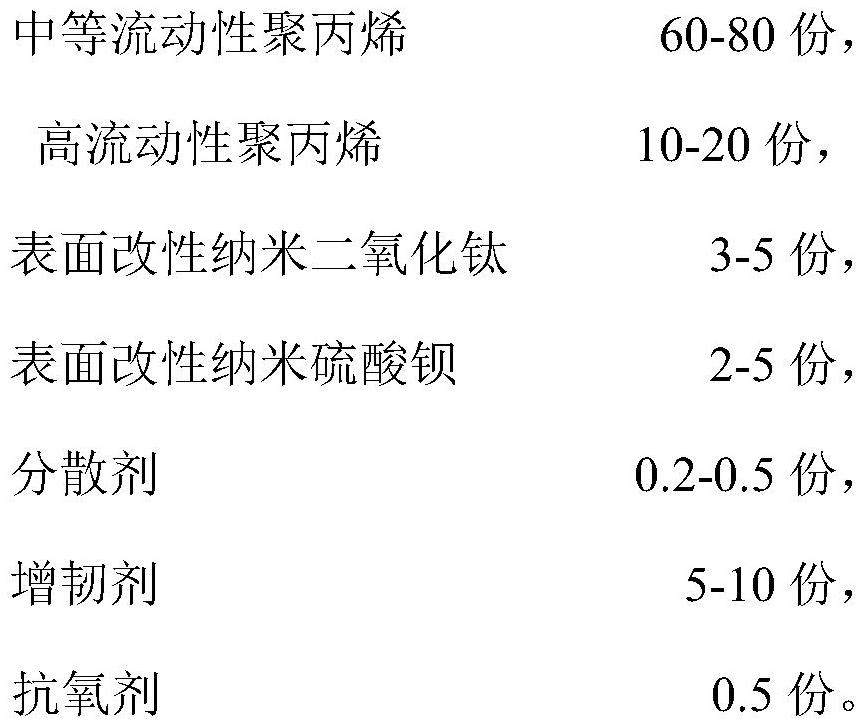

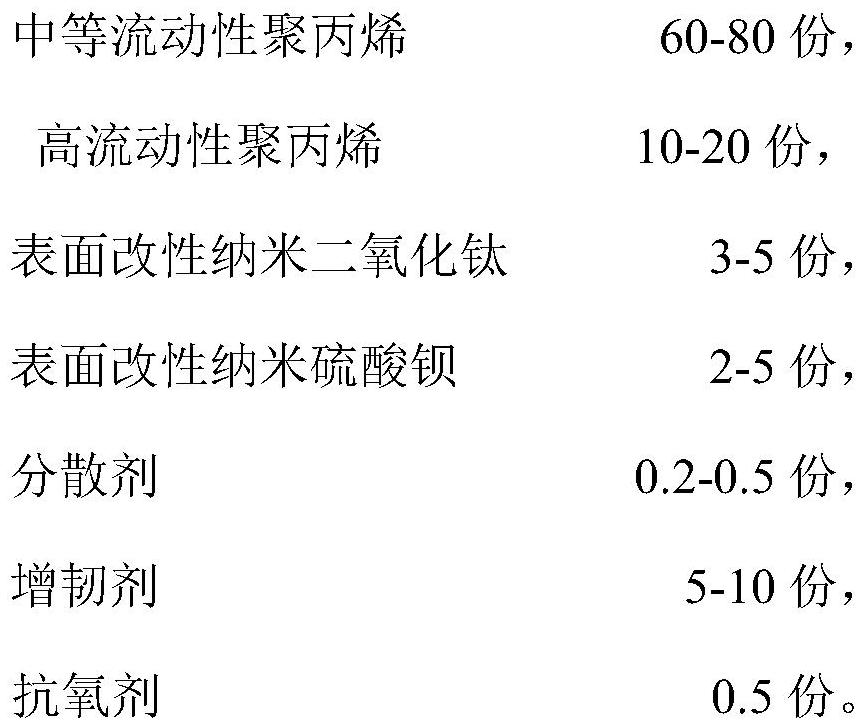

The invention discloses a high-shading polypropylene composition and a preparation method thereof. The polypropylene composition is prepared from the following components in parts by mass: 60-80 parts of medium-flowability polypropylene, 10-20 parts of high-flowability polypropylene, 3-5 parts of surface modified nano titanium dioxide, 2-5 parts of surface modified nano barium sulfate, 0.2-0.5 part of a dispersing agent, 5-10 parts of a toughening agent and 0.5 part of an antioxidant. Compared with the traditional titanium dioxide filled modified polypropylene, the polypropylene composition provided by the invention has the advantages that the addition amount of the surface modified nano titanium dioxide and the surface modified nano barium sulfate is small, the material density is small, and the polypropylene composition is more in line with the development trend of light weight of automobiles; under the action of the high-fluidity polypropylene, the mechanical property and the surface gloss of the material are obviously improved, and the comprehensive performance is excellent; in addition, under the combined action of the surface modified nano titanium dioxide and the surface modified nano barium sulfate, the material has a better shading effect.

Owner:HEFEI GENIUS NEW MATERIALS

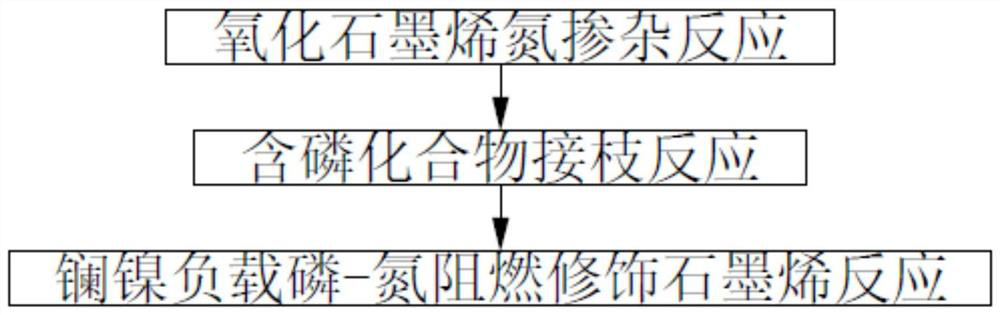

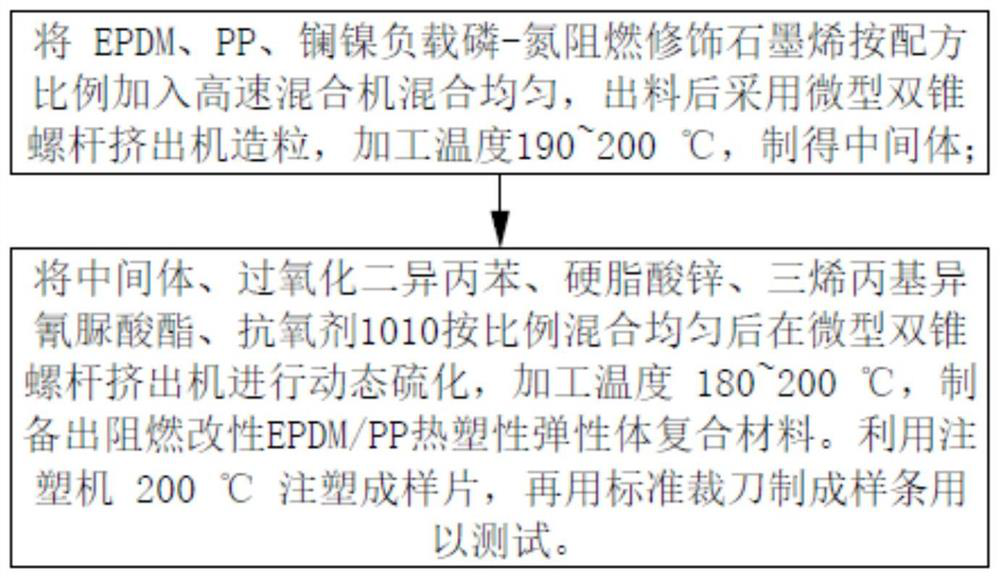

A preparation method of flame-retardant modified graphene and its modified thermoplastic elastomer

ActiveCN111892750BReduce the propensity to reuniteSolving Dispersion ProblemsElastomerDoped graphene

Owner:TAIZHOU UNIV

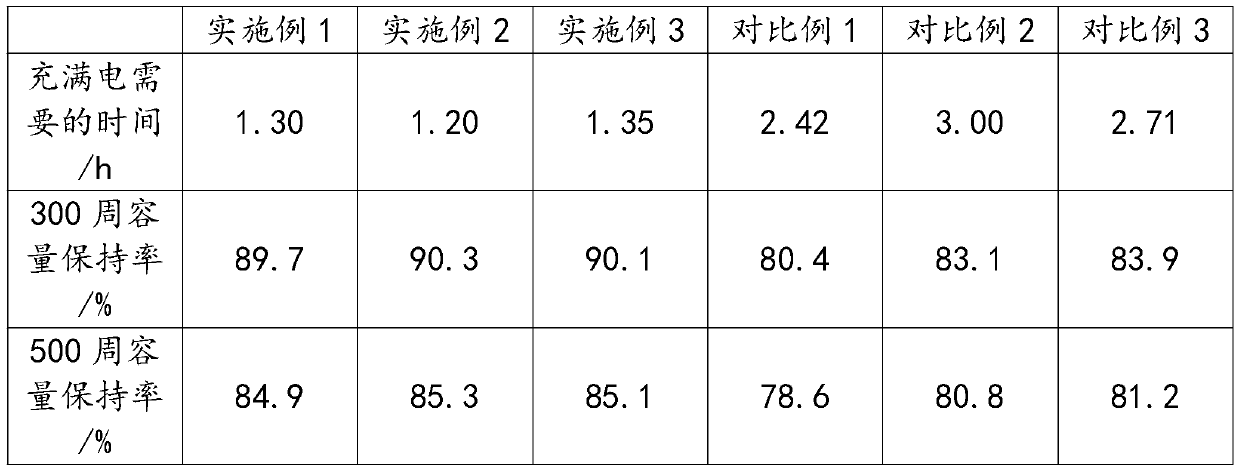

Lithium ion battery capable of being rapidly charged and preparation method of lithium ion battery

InactiveCN110212198AGood mechanical propertiesRelief volumeMaterial nanotechnologyFinal product manufactureAluminium-ion batteryElectrical battery

The invention discloses a lithium ion battery capable of being rapidly charged and a preparation method of the lithium ion battery. The lithium ion battery comprises a positive electrode, a negative electrode, a diaphragm inserted between the positive electrode and the negative electrode, and an organic electrolyte; the particle size D50 of an active material of the positive electrode is 3.1-8.1 microns; the particle size D50 of an active material of the negative electrode is 11.5-17.5 microns; the positive electrode surface density of the positive electrode is 357-373g / m<2>; and the negativeelectrode surface density of the negative electrode is 179-187g / m<2>. The lithium ion battery has good high-current rapid charging performance; the lithium precipitation of the battery is not caused;and the cycle life of the battery is not influenced. In addition, 1.3-1.7mol / L of LiPF6 is used as a lithium salt, and a modified carbon nanotube is used as a conductive agent, so that the high-current rapid charging performance can be further improved, and the final charging time is shortened by 55-60%.

Owner:合肥众禾动力新能源科技有限公司

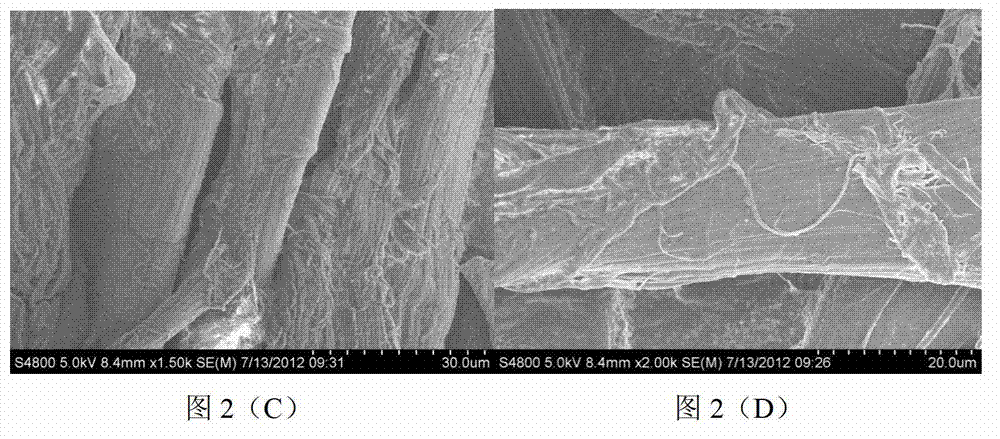

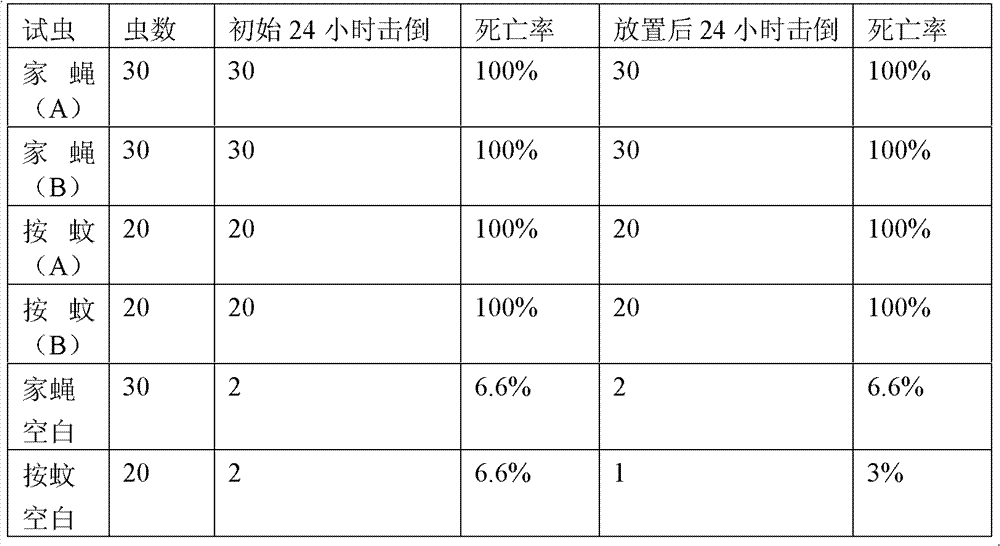

Domestic controlled-release insecticidal composition

ActiveCN102499239BReduce dosageImprove the distribution patternBiocideAnimal repellantsBetainePalygorskite

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

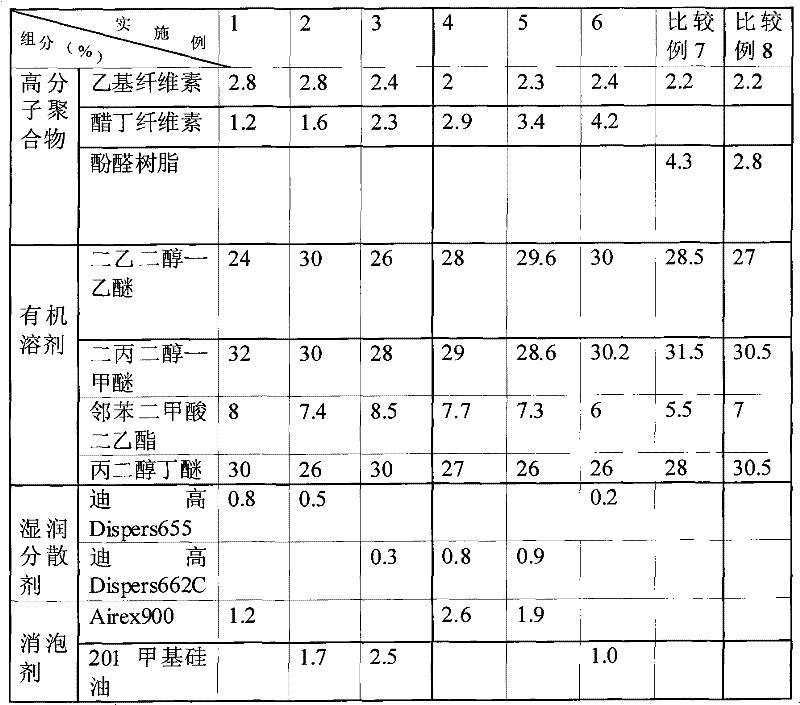

Organic adhesive for aluminum paste of silicon solar cells and preparation method thereof

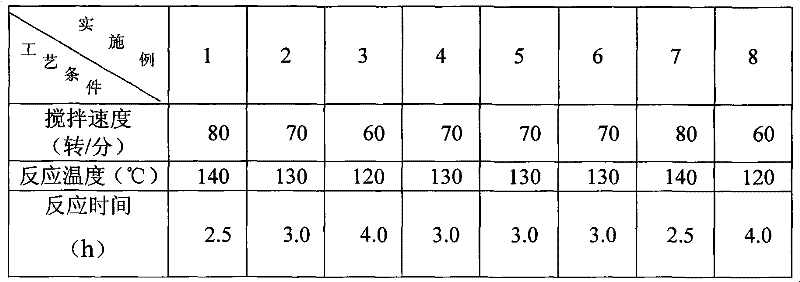

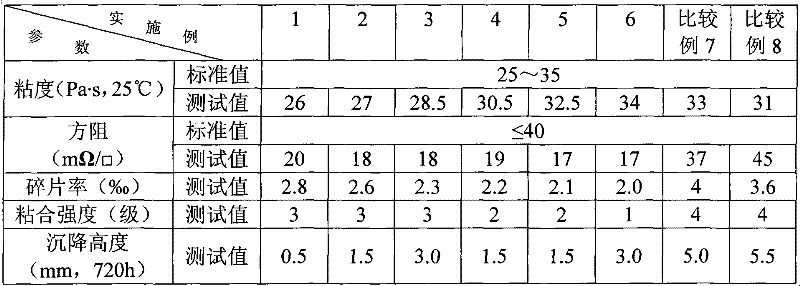

ActiveCN101555394BImprove adhesionImprove toughnessFinal product manufactureCellulose adhesivesOrganic solventAdhesive

The invention provides organic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The organic adhesive comprises the following components by the weight part: 23% of ethyl cellulose, 1% to 5% of cellulose acetate butyrate, 88% to 94% of organic solvent, 0.2% to 1% of wetting dispersant and 1% to 3% of defoamer with the total amount being 100%. The preparation method comprises the following steps: putting the components into a reaction kettle; heating the components up to the temperature of 120 to 140 DEG C while stirring at the speed of 60 to 80 RPM and holding at a constant temperature for 2 to 4 hours to ensure that the components in the reaction kettle can be evenly stirred and subjected to complete reaction; and cooling the reactant and filtering the reactant with mesh to obtain the final product of the organic adhesive. The aluminum paste prepared from the organic adhesive has the advantages that the dispersibility or the suspensibility thereof is high, the aluminum paste does not laminate or precipitate after long-time storage and the aluminum paste can be uniformly coated so that the solid powder in the dried aluminum powder has the advantages of high adhesive strength and low stress generated on silicon chips.

Owner:WUXI RUXING TECH DEV +1

Modified heavy calcium carbonate used for louver blade and preparation method thereof

InactiveCN107936620AIncrease spacingReduce the propensity to reunitePigment treatment with non-polymer organic compoundsCalcium carbonateRicinoleic acid

The invention relates to the field of calcium carbonate, and discloses modified heavy calcium carbonate used for a louver blade. The modified heavy calcium carbonate is prepared from the following rawmaterials in parts by weight: 100 parts of heavy calcium carbonate, 0.5 to 1 part of sodium cetyl sulfate, 0.5 to 1 part of sodium stearate and 1 to 1.5 parts of ricinoleic acid. The objective of theinvention is to provide low-agglomeration modified heavy calcium carbonate used for the louver blade.

Owner:英德市日昇矿业有限公司

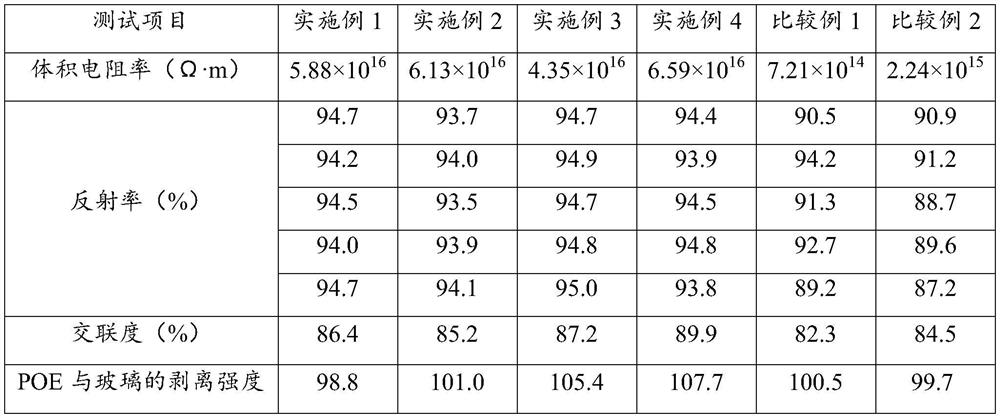

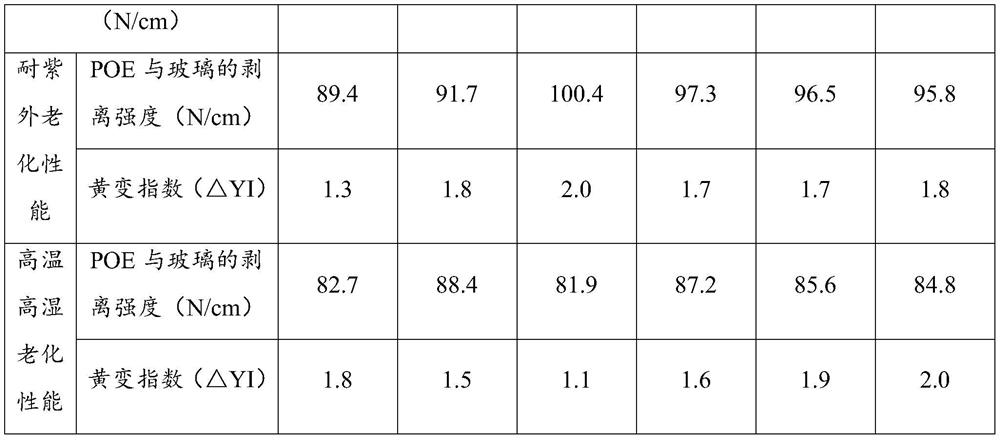

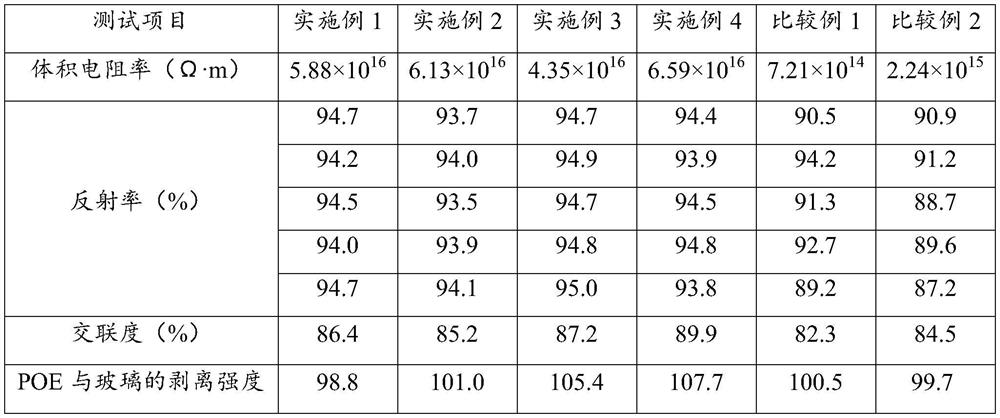

POE packaging adhesive and preparation method thereof

ActiveCN112175547AHigh volume resistivityReduce the propensity to reuniteNon-macromolecular adhesive additivesMasterbatchPolymer science

The invention relates to the technical field of packaging adhesives, in particular to a POE packaging adhesive and a preparation method thereof. The POE packaging adhesive is mainly prepared from thefollowing raw materials in parts by weight: 100 parts of POE resin, 10-30 parts of master batch, 1-2.5 parts of a cross-linking agent, 0.8-2 parts of an assistant cross-linking agent, 0.2-1 part of atackifier, 0.2-0.8 part of an ultraviolet absorbent and 0.1-0.8 part of an antioxidant, wherein the master batch is mainly prepared from the following components in percentage by mass: 30%-60% of modified titanium dioxide and 40%-70% of POE resin. By introducing the modified titanium dioxide filler and adopting specific raw material composition and proportion, the adhesive film has higher volume resistivity which can reach 1*10<16> omega.m or more, the tendency of agglomeration of titanium dioxide particles is reduced through modification treatment of titanium dioxide, the dispersion uniformity is good, and the prepared POE packaging adhesive is uniform in reflectivity and beneficial to improvement of the working efficiency of assemblies.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +2

Poe encapsulation glue and preparation method thereof

ActiveCN112175547BHigh volume resistivityReduce the propensity to reuniteNon-macromolecular adhesive additivesMasterbatchUv absorbance

The invention relates to the technical field of packaging glue, in particular to a POE packaging glue and a preparation method thereof. POE encapsulant is mainly prepared from the following raw materials in parts by weight: 100 parts of POE resin, 10 to 30 parts of masterbatch, 1 to 2.5 parts of crosslinking agent, 0.8 to 2 parts of auxiliary crosslinking agent, and 0.2 parts of tackifier ~1 part, 0.2-0.8 part of ultraviolet absorber and 0.1-0.8 part of antioxidant; the masterbatch is mainly made of 30%-60% of modified titanium dioxide and 40%-70% of POE resin by mass percentage. In the present invention, by introducing modified titanium dioxide filler and adopting specific raw material composition and ratio, the adhesive film has a higher volume resistivity, which can reach 1×10 16 Ω·m or more; the modification of titanium dioxide reduces the tendency of titanium dioxide particles to agglomerate, the dispersion uniformity is good, and the reflectance of the prepared POE encapsulant is uniform, which helps to improve the working efficiency of the module.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +2

A kind of rubber composition containing white carbon black modified polyamine dispersant and its application

Owner:RACHEM CHINA CO LTD +1

Method for modifying nanometer alumina particles by using inorganic nonmetal or metal elements

InactiveCN102127323BProper electronegativityEvenly dispersedMaterial nanotechnologyInorganic pigment treatmentHydrolysateNano hybrid

The invention relates to a method for modifying nanometer alumina particles by using inorganic nonmetal or metal elements. Nanometer alumina prepared by adopting an aerosol process in Dupont Company is used as a nanometer doped and modified high polymer material so as to improve the corona resistance performance, which achieves a great success; and an inorganic nanometer hydride polyimide film with corona resistance, namely a Kapton100CR film, is prepared and is always in a leading level in the world in recent twenty years. The method for modifying nanometer alumina particles by using inorganic nonmetal or metal elements comprises the following steps of: 1, fully dissolving a hydrocarbyloxy compound M[OR]n of the inorganic nonmetal or metal elements in toluene to obtain partial hydrolysate; 2, carrying out hydrolysis reaction on aluminum isopropoxide; and 3, adding the hydrolysate obtained through the reaction in the step 1 to a modified gamma-Al2O3 nanometer alumina particle dispersion obtained in the step 2. The method is used for modifying high polymer materials.

Owner:HARBIN UNIV OF SCI & TECH

Spherical iron phosphate and its preparation method and application

ActiveCN107986253BWeakened molecular forcesReduce the propensity to reuniteCell electrodesSecondary cellsLithium iron phosphateDiffusion pathway

The invention discloses spherical iron phosphate and a preparation method and application thereof. The preparation method comprises the following steps: adding a disperser into iron-phosphorus mixed liquor containing iron ion and phosphate anion, thus obtaining mixed liquor A; under a heating condition, adding urea into the mixed liquor A to regulate a pH value, and continuously heating to obtainmixed liquor B containing crystal-form iron phosphate; filtering the mixed liquor B, adding a filter cake into water to prepare mixed liquor C, atomizing the mixed liquor C by a spray gun, leading into a roasting furnace, and roasting at a temperature of 550 to 750 DEG C to obtain the spherical iron phosphate. The spherical iron phosphate is pure in crystalline phase, good in crystallinity, spherical in shape, uniform in grain fineness distribution and high in tap density, and can serve as a precursor for synthesizing spherical lithium iron phosphate with high tap density; the spherical iron phosphate can eliminate microscopic composition difference caused by different diffusion paths in a reaction, so as to generate the lithium iron phosphate with a uniform structure, and thus the performance of the lithium iron phosphate is improved.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Method for preparing sustained-release insecticide microcapsule by using supercritical fluid technology

ActiveCN102499238BCoated evenlyImprove uniformityBiocideAnimal repellantsCelluloseAdditive ingredient

The invention discloses a method for preparing a sustained-release insecticide microcapsule by using a supercritical fluid technology. A composition prepared with the method comprises ingredients, such as cellulose, attapulgite, essence, a betaine ampholytic surface active agent and the like. The method comprises the following steps of: compounding the above ingredients; and further evenly covering particles with a supercritical impact micro-granule wrapping method. With the method, the agglomeration tendency which easily appears when the common means are adopted is lightened so as to improvethe evenness of the microcapsule. Meanwhile, the method also has the universal advantages of the traditional supercritical wrapping method. The composition prepared with the method has a good insecticidal effect and an obvious sustained-release effect.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Insecticidal and bactericidal organic fertilizer and preparation method thereof

InactiveCN110283012ADark Green Bactericidal SpectrumBroad spectrumExcrement fertilisersSolid/semi-solid fertilisersConcentration gradientSoil quality

The invention discloses an insecticidal and bactericidal organic fertilizer. The organic fertilizer comprises organic fertilizer particles in a core layer and a microcapsule shell layer covering the core layer; the microcapsule shell layer contains a bactericide, and the bactericide has a certain concentration gradient in the microcapsule shell layer from inside to outside in the thickness direction of the microcapsule shell layer. The prepared insecticidal and bactericidal organic fertilizer can be slowly released into soil and has the effect of continuously improving the soil quality and crop quality for a long time. In addition, because the microcapsule shell layer contains the bactericide with the concentration gradient, the fertilizer has a good insecticidal and bactericidal effect, the use amount of the bactericide is also reasonable, and the situation is avoided that since bactericide residues remain in the soil, pollution is caused to the soil and the environment, and a toxic effect is generated on crops in the next season. The invention also discloses a preparation method of the insecticidal and bactericidal organic fertilizer.

Owner:徐悦阳

Powder dispersion method for magnetron sputtering coating

InactiveCN107955937ALower surface energyReduce the propensity to reuniteVacuum evaporation coatingSputtering coatingSurface energyMetallurgy

The invention relates to a powder dispersion method for magnetron sputtering coating. The powder dispersion method comprises the step that a certain ratio of large particle powder with a large particle size and a small specific surface area is incorporated into a powder base material with the small particle size and the large specific surface area for magnetron sputtering coating. Under the traditional mechanical vibration dispersion conditions, the powder dispersion method can effectively reduce surface energy of an entire system, reduce an agglomeration tendency of the powder base material,and can improve the dispersion effect of the powder base material through the impact of the large particle powder and the agglomerate powder base material, thereby achieving the uniform coating. Afterthe coating is completed, the large particle powder is removed by screening to obtain a coated product. The particle size of the powder base material is 0.1-150[mu]m, the particle size of the large particle powder is 200[mu]m-2mm, and a mass ratio of the powder base material to the large particle powder is (5-20):1.

Owner:SHANGHAI LANGYI NEW MATERIAL TECH CO LTD

Modified ground calcium carbonate for louver slats and preparation method of modified ground calcium carbonate

InactiveCN107987560AGood combinationIncrease spacingPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsSodium stearateCetyl sulfate

The invention relates to the field of calcium carbonate and discloses modified ground calcium carbonate for louver slats. Modified ground calcium carbonate is prepared from raw materials in parts by weight as follows: 100 parts of ground calcium carbonate, 0.5-1 part of sodium cetyl sulfate, 1-2 parts of sodium stearate and 0.5-1 part of a siloxane coupling agent. The invention aims to provide low-agglomerated modified ground calcium carbonate for the louver slats.

Owner:英德市日昇矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com