Waterproof and windproof elastic fabric and preparation method thereof

An elastic fabric, waterproof and windproof technology, applied in the direction of light fastness fiber, improved handle fiber, textile material treatment, etc., can solve the problems of high toxicity, difficult degradation, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

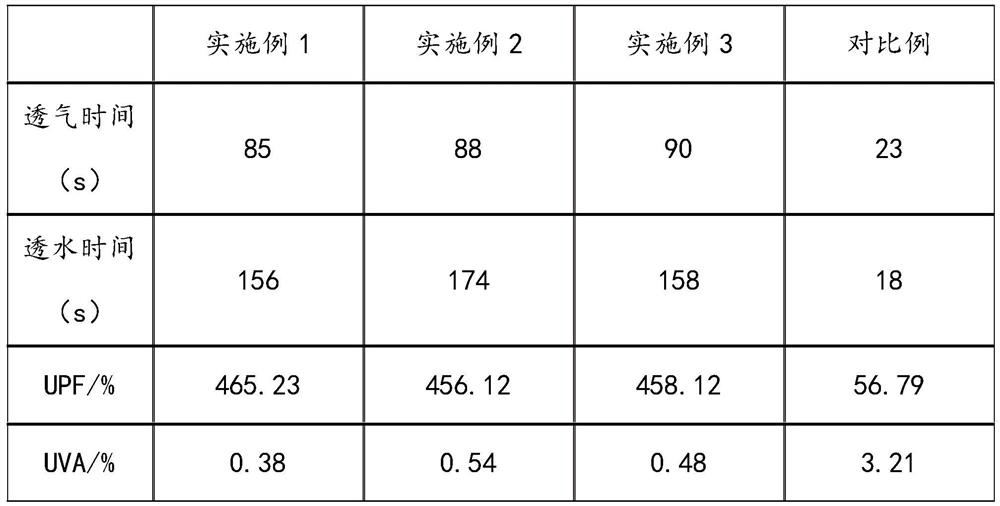

Examples

Embodiment 1

[0032] An elastic fabric with waterproof and windproof performance, comprising the following raw materials in parts by weight:

[0033] 30 parts of polyester fiber, 10 parts of spandex elastic fiber, 4 parts of bamboo charcoal fiber, 5 parts of cotton fiber, 50 parts of modified emulsion;

[0034] This waterproof and windproof elastic fabric is made by the following steps:

[0035] Step A1, weaving process: making polyester fibers and spandex elastic fibers into warp yarns through a twisting process of 5 twists / cm, making bamboo charcoal fibers and cotton fibers into wefts through a twisting process of 5 twists / cm Silk, and use the twill weave method of warp and weft interweaving on the loom to weave elastic fabric blanks;

[0036] Step A2, dyeing treatment: add the elastic fabric blank prepared in step A1 into the dye vat, add dye, soak and dye at 98°C for 40 minutes, then put the elastic fabric into the dye vat without dye, rinse twice, and dry to obtain the fabric semi-fi...

Embodiment 2

[0054] An elastic fabric with waterproof and windproof performance, comprising the following raw materials in parts by weight:

[0055] 35 parts of polyester fiber, 12 parts of spandex elastic fiber, 5 parts of bamboo charcoal fiber, 7 parts of cotton fiber, 60 parts of modified emulsion;

[0056] This waterproof and windproof elastic fabric is made by the following steps:

[0057] Step A1, weaving process: polyester fibers and spandex elastic fibers are made into warp yarns through a twisting process of 6 twists / cm, and bamboo charcoal fibers and cotton fibers are made into wefts through a twisting process of 6 twists / cm Silk, and use the twill weave method of warp and weft interweaving on the loom to weave elastic fabric blanks;

[0058] Step A2, dyeing treatment: add the elastic fabric blank prepared in step A1 into the dye vat, add dye, soak and dye at 100°C for 50 minutes, then put the elastic fabric into the dye vat without dye, rinse twice, and dry to obtain the fabric...

Embodiment 3

[0076] An elastic fabric with waterproof and windproof performance, comprising the following raw materials in parts by weight:

[0077] 40 parts of polyester fiber, 15 parts of spandex elastic fiber, 6 parts of bamboo charcoal fiber, 10 parts of cotton fiber, 70 parts of modified emulsion;

[0078] This waterproof and windproof elastic fabric is made by the following steps:

[0079] Step A1, weaving process: making polyester fibers and spandex elastic fibers into warp yarns through 7 twists / cm twisting process, making bamboo charcoal fibers and cotton fibers into wefts through 7 twists / cm twisting processes Silk, and use the twill weave method of warp and weft interweaving on the loom to weave elastic fabric blanks;

[0080] Step A2, dyeing treatment: add the elastic fabric blank prepared in step A1 into the dye vat, add dye, soak and dye at 110°C for 60 minutes, then put the elastic fabric into the dye vat without dye, rinse 3 times, and dry to obtain the fabric semi-finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com