Lithium ion battery capable of being rapidly charged and preparation method of lithium ion battery

A lithium-ion battery and fast charging technology, applied in the field of lithium-ion batteries, can solve the problems of inability to withstand high current fast charging, the impact of cycle life, shorten battery life and other problems, achieve good electrochemical performance, alleviate volume shrinkage expansion and structure Collapse, the effect of increasing the liquid-solid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

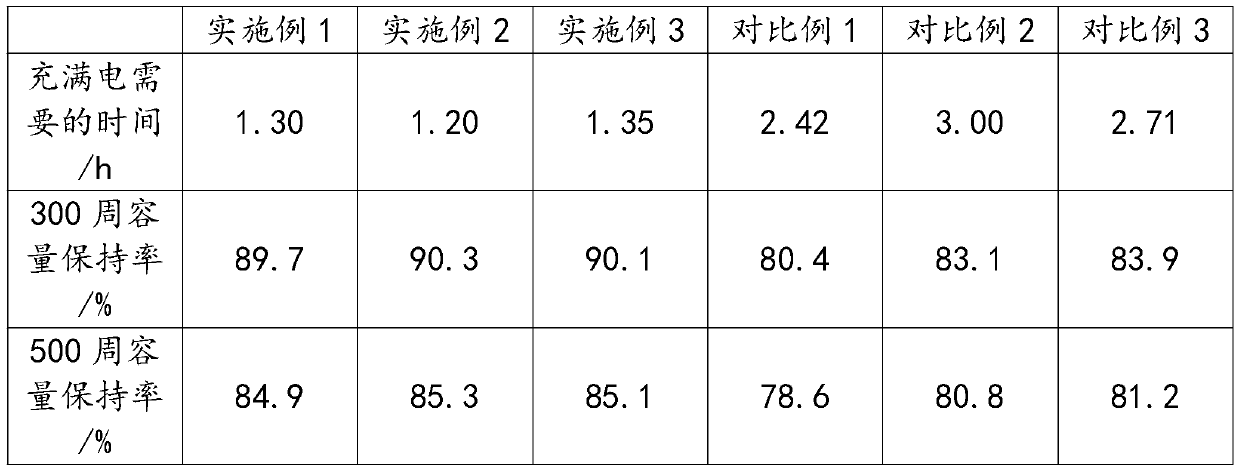

Examples

Embodiment 1

[0045] A rapidly chargeable lithium-ion battery, comprising a positive electrode, a negative electrode, and a diaphragm inserted between the positive electrode and the negative electrode, and an organic electrolyte;

[0046] The active material of the positive electrode is lithium manganate, the particle size D50 of the active material of the positive electrode is 3.1 microns, and the positive electrode surface density of the positive electrode is 357g / m 2 ;

[0047] The active material of the negative electrode is graphite, the particle size D50 of the active material of the negative electrode is 11.5 microns, and the negative surface density of the negative electrode is 179g / m 2 ;

[0048] Both positive and negative electrodes use modified carbon nanotubes as conductive agents;

[0049] The lithium salt in the organic electrolyte is LiPF 6 , and its concentration is 1.3mol / L.

Embodiment 2

[0051] A rapidly chargeable lithium-ion battery, comprising a positive electrode, a negative electrode, and a diaphragm inserted between the positive electrode and the negative electrode, and an organic electrolyte;

[0052] The active material of the positive electrode is lithium manganate, the particle size D50 of the active material of the positive electrode is 5.6 microns, and the positive electrode surface density of the positive electrode is 362g / m 2 ;

[0053] The active material of the negative electrode is graphite, the particle diameter D50 of the active material of the negative electrode is 14.5 microns, and the negative surface density of the negative electrode is 183g / m 2 ;

[0054] Both positive and negative electrodes use modified carbon nanotubes as conductive agents;

[0055] The lithium salt in the organic electrolyte is LiPF 6 , and its concentration is 1.5mol / L.

Embodiment 3

[0057] A rapidly chargeable lithium-ion battery, comprising a positive electrode, a negative electrode, and a diaphragm inserted between the positive electrode and the negative electrode, and an organic electrolyte;

[0058] The active material of the positive electrode is lithium manganate, the particle size D50 of the active material of the positive electrode is 8.1 microns, and the positive electrode surface density of the positive electrode is 373g / m 2 ;

[0059] The active material of the negative electrode is graphite, the particle diameter D50 of the active material of the negative electrode is 17.5 microns, and the negative surface density of the negative electrode is 187g / m 2 ;

[0060] Both positive and negative electrodes use modified carbon nanotubes as conductive agents;

[0061] The lithium salt in the organic electrolyte is LiPF 6 , and its concentration is 1.7mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com