Method for modifying nanometer alumina particles by using inorganic nonmetal or metal elements

A technology of nano-alumina and metal elements, applied in the direction of nanotechnology, chemical instruments and methods, nanotechnology, etc. for materials and surface science, can solve the problem that it is difficult to flexibly adjust the chemical and physical structure of nano-alumina, and cannot be flexible Adjust the chemical and physical structure of nanoparticles, and it is difficult to further obtain nano-alumina particles, etc., to achieve the effects of improving compatibility, improving dielectric properties, and reducing the tendency of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

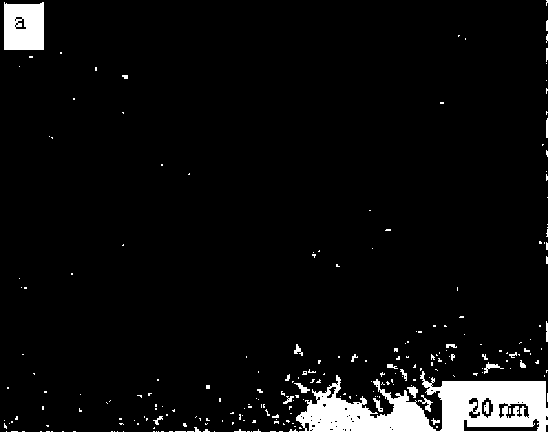

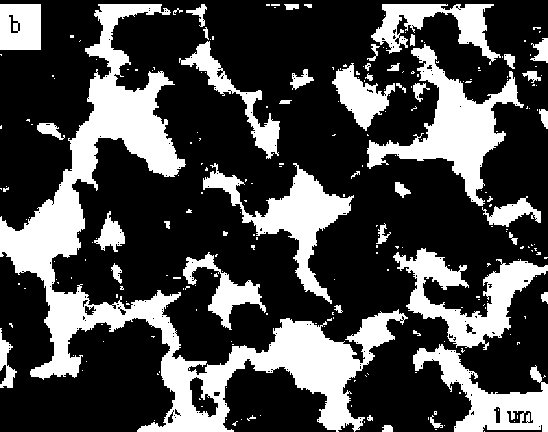

Image

Examples

Embodiment 1

[0019] A method for modifying nano-alumina particles with inorganic non-metal or metal elements. The method is divided into three steps. The first step is to fully dissolve the alkoxy compounds of non-metal or metal elements in toluene

[0020] M[OR]n obtained partial hydrolysis product; the second step, the hydrolysis reaction of aluminum isopropoxide; the third step, adding the hydrolyzate of the first step reaction to the second step reaction to obtain modified γ-Al 2 o 3 Nanodispersion.

Embodiment 2

[0022] The method for modifying nano-alumina particles with inorganic non-metal or metal elements described in embodiment 1, the first step described:

[0023] Fully mix and dissolve different metalloid or metal element alkoxy compounds M[OR]n in toluene, the concentration of solute in the solution is less than 15w%, add an appropriate amount of catalyst, acidic catalyst such as acetic anhydride, acetic acid, formic acid, methanesulfonate Acid, basic catalysts such as ammonia water, diethylamine, ethylenediamine, etc., the amount is controlled at 0.2-2% of the solute mass, and then slowly added dropwise to the solution in the temperature range of 40-80 ℃ and under ultrasonic conditions Deionized water (dropping water for more than 2 hours), the amount of water can be adjusted in the range of 0.1 to 1.5 times the molar amount of M[OR]n according to needs, and continue to stir ultrasonically for 2 hours. The reaction principle is as follows:

[0024] Ma[OR]n 1 The hydrolysis re...

Embodiment 3

[0033] The method for modifying nano-alumina particles with inorganic non-metal or metal elements described in embodiment 1 or 2, the second step described:

[0034] The reaction of aluminum isopropoxide, the reaction steps are the same as the first step reaction, the principle is as follows:

[0035] Hydrolysis reaction: Al(OC 3 h 7 ) 3 + 2H 2 o Al(OC 3 h 7 ) (OH) 2 + 2C 3 h 7 Oh

[0036] Adjusting the amount of dripping water can adjust the degree of hydrolysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com