White carbon black modified polyamine dispersant-containing rubber composition and applications thereof

A rubber composition and silica technology, applied in the rubber field, can solve the problems of weak rubber bonding force, limited improvement of silica dispersion, poor compatibility, etc. The effect of good silica dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Add 30g of polyamine (BASFLupasol WF) to a 250ml flask equipped with a stirring device, a thermometer and a reflux condenser, start stirring, and after the temperature rises to 60°C, add 90g of oleic acid dropwise to the flask. After the dropwise addition is completed, heat up to 90°C Stir at ~100°C for 10 minutes, sample A, gradually raise the temperature to 160°C and distill at atmospheric pressure for 60 minutes, and distill under reduced pressure until no fraction comes out to obtain the white carbon black modified polyamine dispersant, the pH of which is measured to be 8.02.

[0058] pH test: Dissolve 1g of white carbon black modified polyamine dispersant in 20ml of ethanol, and use Mettler FE20pH meter to measure.

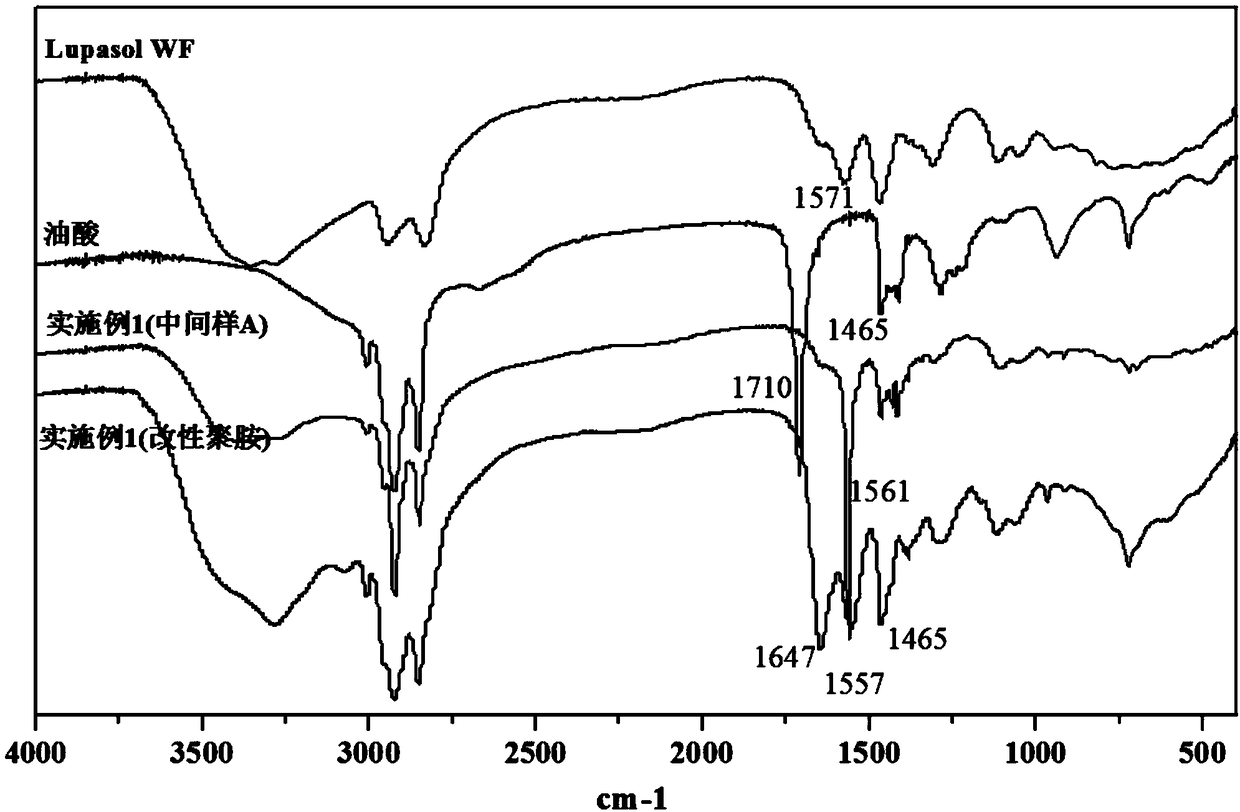

[0059] Characterized by Fourier transform infrared FT-IR, the white carbon black modified polyamine dispersant prepared by the present invention has amide structure (1647cm -1 ) generation, see attached figure 1 (1561cm -1 It is the characteristic st...

Embodiment 2-3

[0061] Except for changing the amount of organic carboxylic acid and polyamine Lupasol WF, the preparation process of the silica-modified polyamine dispersant in Example 1 was repeated. The specific parameter conditions are shown in Table 1.

[0062]

Embodiment 4

[0064] White carbon black adsorption test:

[0065] 1) Take by weighing 1g of the silica-modified polyamine dispersant prepared in Example 1-3 in a long-necked beaker, add 100ml of ethanol to dissolve;

[0066] 2) After the silica-modified polyamine dispersant is completely dissolved, add 20g of powdered silica VN3;

[0067] 3) Using IKAT25 disperser, stirring and dispersing at 3000rpm;

[0068] 4) Take a sample from the dispersion system and filter it with a suction filter bottle;

[0069] 5) Wash the suction filter cake with ethanol, and then suction filter, repeating 3 times;

[0070] 6) Dry the filter cake at 110°C to constant weight, and cool it to room temperature in a desiccator to obtain adsorbed white carbon black;

[0071] 7) Sample TGA test. The results are shown in Table 2.

[0072] TGA test: TGA / DSC1 thermogravimetric analyzer from Mettler Company, sample size is about 10mg, 70ul ceramic crucible, N2 atmosphere, temperature rise 20°C / min.

[0073] A blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com