Poe encapsulation glue and preparation method thereof

A packaging glue and resin technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem that the volume resistivity of POE packaging glue cannot meet the needs of special environments, and achieve improved work efficiency and high efficiency. The effect of volume resistivity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

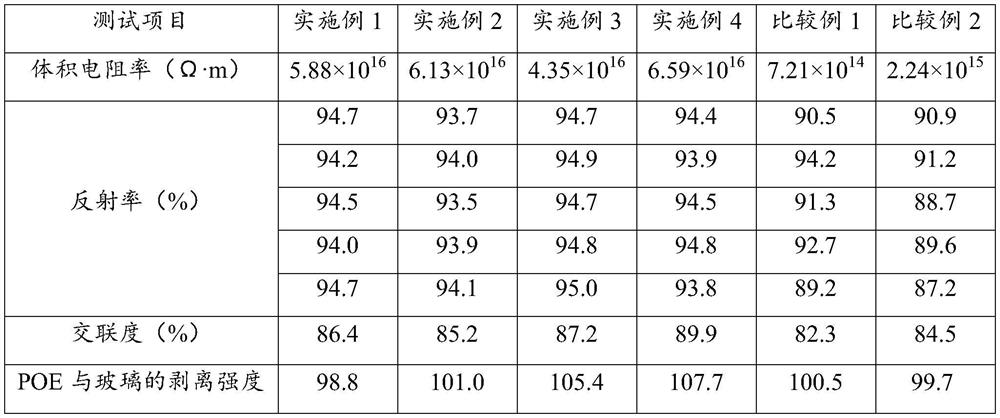

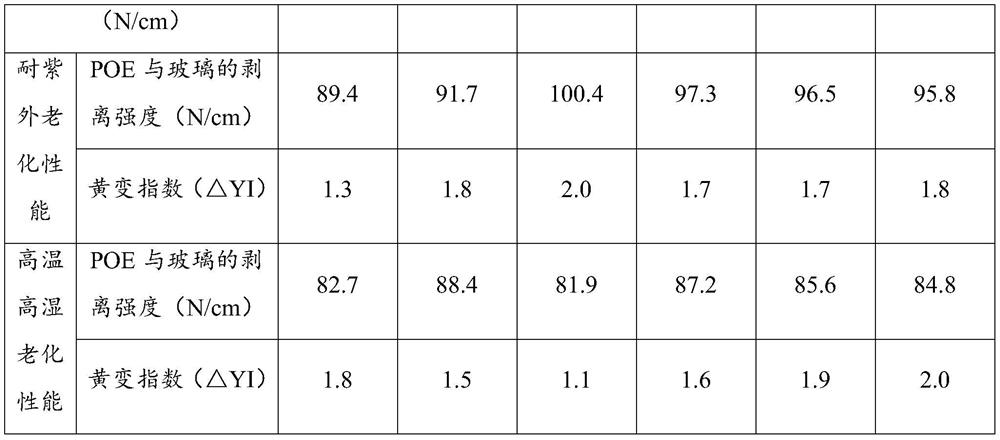

Examples

preparation example Construction

[0037] In a specific embodiment of the present invention, the preparation method of the modified titanium dioxide includes: mixing the modifying agent with the titanium dioxide, and reacting at 90-150° C. for 80-120 minutes.

[0038] As in different embodiments, in the preparation of the modified titanium dioxide, the reaction temperature can be 90°C, 100°C, 110°C, 120°C, 130°C, 140°C, 150°C, etc.; the reaction time can be 80min, 90min , 100min, 110min, 120min and so on.

[0039]In a specific embodiment of the present invention, the preparation method of the masterbatch includes: extruding and pelletizing the mixture of the modified titanium dioxide and the POE resin through a twin-screw extruder, each of the twin-screw extruders The section temperature is 80℃~90℃, 100℃~120℃, 120℃~130℃, 120℃~130℃, 120℃~130℃, 120℃~130℃, 120℃~130℃, 120℃~130℃ , 80 ℃ ~ 100 ℃.

[0040] As in different embodiments, among the raw materials of the POE encapsulant, the amount of masterbatch can be 10...

Embodiment 1

[0051] This embodiment provides a method for preparing POE encapsulation glue, including the following steps:

[0052] (1) Weigh stearic acid and titanium dioxide powder with a mass ratio of 8:100, stir and react at 120° C. for 100 min to obtain modified titanium dioxide.

[0053] (2) In parts by weight, take 60 parts of modified titanium dioxide prepared in step (1) and 40 parts of POE resin whose melt index is 5g / 10min, mix uniformly, extrude and draw through a twin-screw extruder Strips and pellets to obtain white masterbatch; the temperature of each section of the twin-screw extruder is 80°C, 100°C, 130°C, 130°C, 130°C, 130°C, 130°C, 130°C, 100°C.

[0054] (3) In parts by weight, take 100 parts of POE resins with a melt index of 5g / 10min, 18 parts of white master batches made in step (2), 1 part of tert-butyl peroxide 2-ethylhexyl carbonate Esters, 2 parts of triallyl cyanurate, 0.5 parts of γ-aminopropyltriethoxysilane, 0.2 parts of 2,4-dihydroxybenzophenone, 0.1 parts o...

Embodiment 2

[0056] This embodiment provides a method for preparing POE encapsulation glue, including the following steps:

[0057] (1) Weigh stearic acid, oleic acid and titanium dioxide powder with a mass ratio of 8:2:100, stir and react at 120° C. for 100 min to obtain modified titanium dioxide.

[0058] (2) In parts by weight, take 60 parts of modified titanium dioxide prepared in step (1) and 40 parts of POE resin with a melt index of 13g / 10min respectively, mix uniformly, extrude and draw through a twin-screw extruder Strips and pellets to obtain white masterbatch; the temperature of each section of the twin-screw extruder is 80°C, 100°C, 120°C, 120°C, 120°C, 120°C, 120°C, 120°C, 90°C.

[0059] (3) In parts by weight, take 100 parts of POE resins with a melt index of 13g / 10min, 18 parts of white master batches made in step (2), 1 part of tert-butyl peroxide 2-ethylhexyl carbonate Esters, 0.5 parts of 1,1-di(tert-butylperoxy)cyclohexane, 1.5 parts of trimethylolpropane trimethacrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com