Preparation method of metal ion doped modified silver zinc oxide electric contact material

A technology of electrical contact materials and metal ions, applied in the manufacture of oxide conductors, non-metallic conductors, cables/conductors, etc., can solve problems such as poor wettability, easy agglomeration of zinc oxide, electrical contact life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

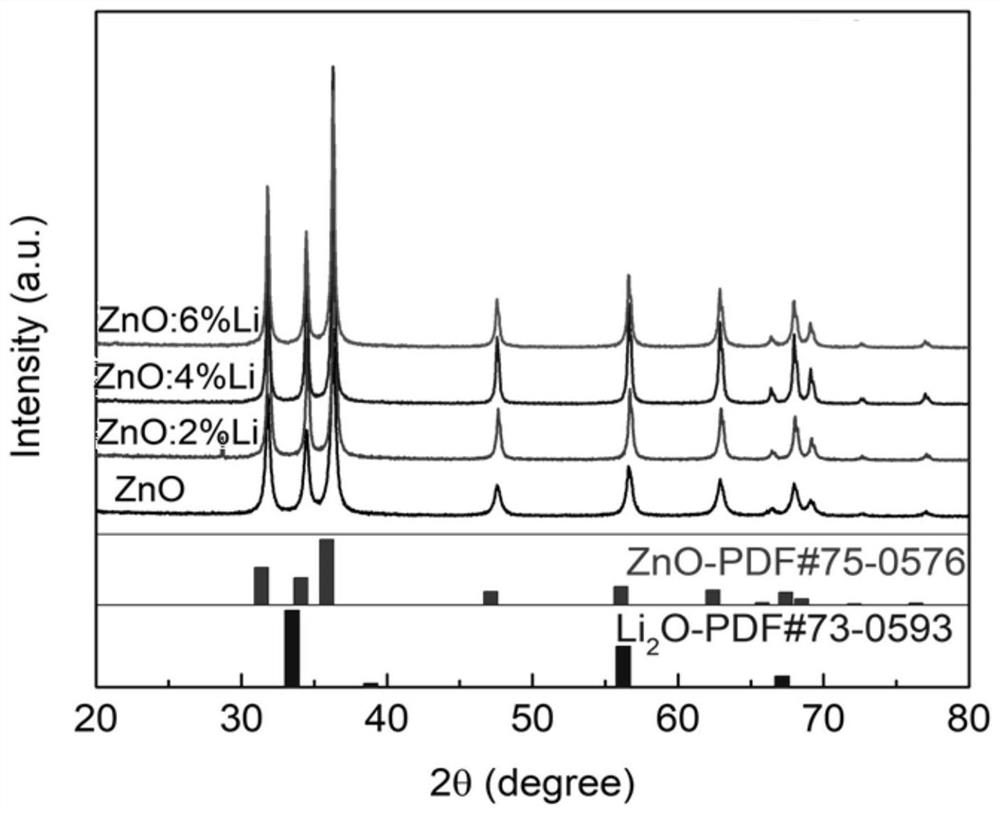

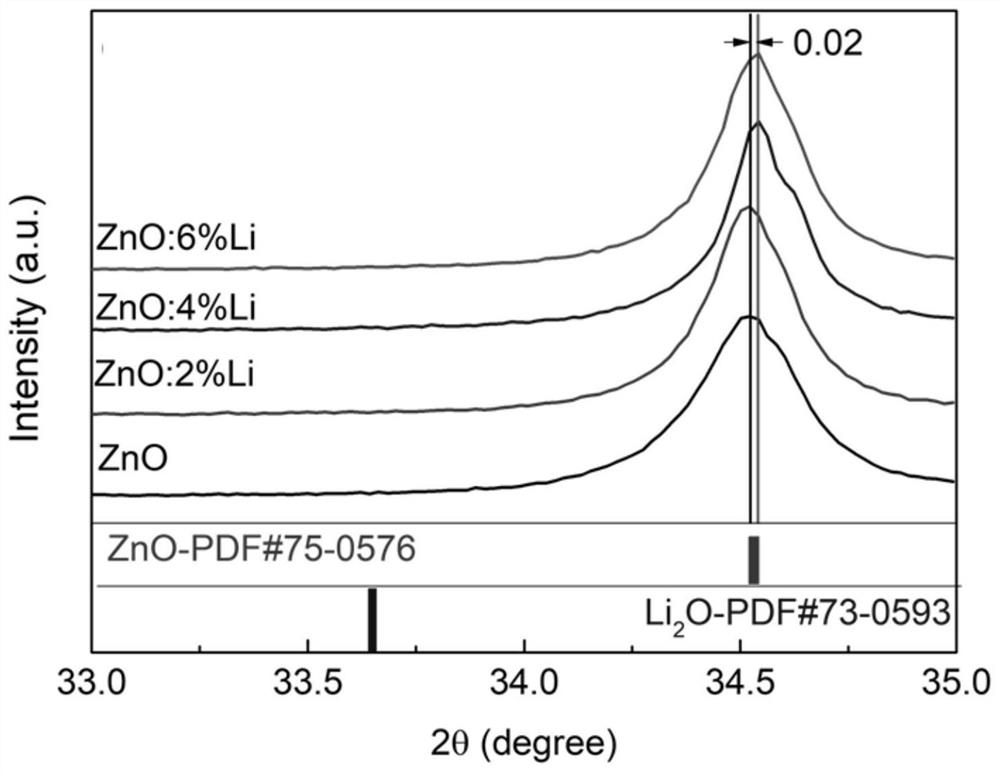

Image

Examples

specific Embodiment approach 1

[0035] Specific implementation mode 1: The preparation method of the metal ion doped modified silver zinc oxide electrical contact material in this implementation mode is carried out according to the following steps:

[0036] Step 1: preparing lithium metal-doped zinc oxide powder by self-propagating combustion method;

[0037] Dissolve zinc nitrate, organic fuel and nitrate of doping elements in deionized water, and then mix with magnetic stirring for 30 minutes, and then heat to self-propagating combustion at 400-500°C to obtain metal ion-doped zinc oxide powder;

[0038] The doping element is lithium or silver;

[0039] Step 2: using a high-energy ball mill to mix metal ions to dope zinc oxide powder and silver powder to obtain a mixed powder;

[0040] In the mixed powder, the content of metal ion-doped zinc oxide powder is 8-15wt.%.

[0041] The process of using a high-energy ball mill to mix metal ions doped with zinc oxide powder and silver powder is as follows: the ba...

specific Embodiment approach 2

[0055] Embodiment 2: This embodiment differs from Embodiment 1 in that the ratio of the mass of zinc nitrate to the volume of deionized water in Step 1 is 2.89 g: 50 mL.

specific Embodiment approach 3

[0056] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the organic fuel described in step 1 is made by mixing glycine and urea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com