Spherical iron phosphate and preparation method and application thereof

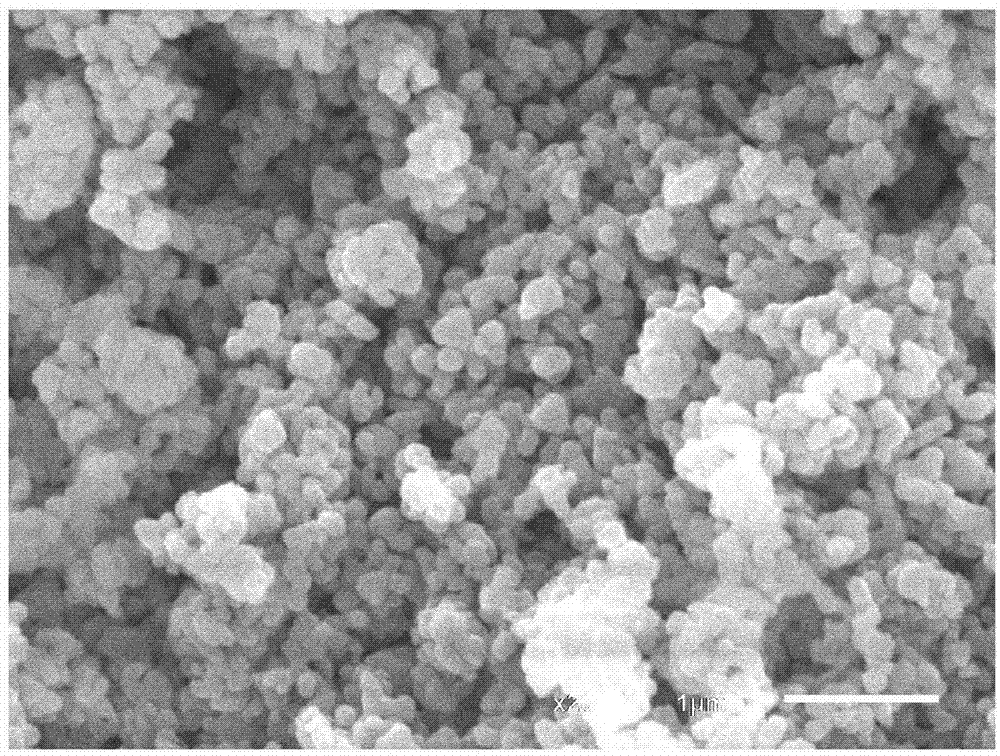

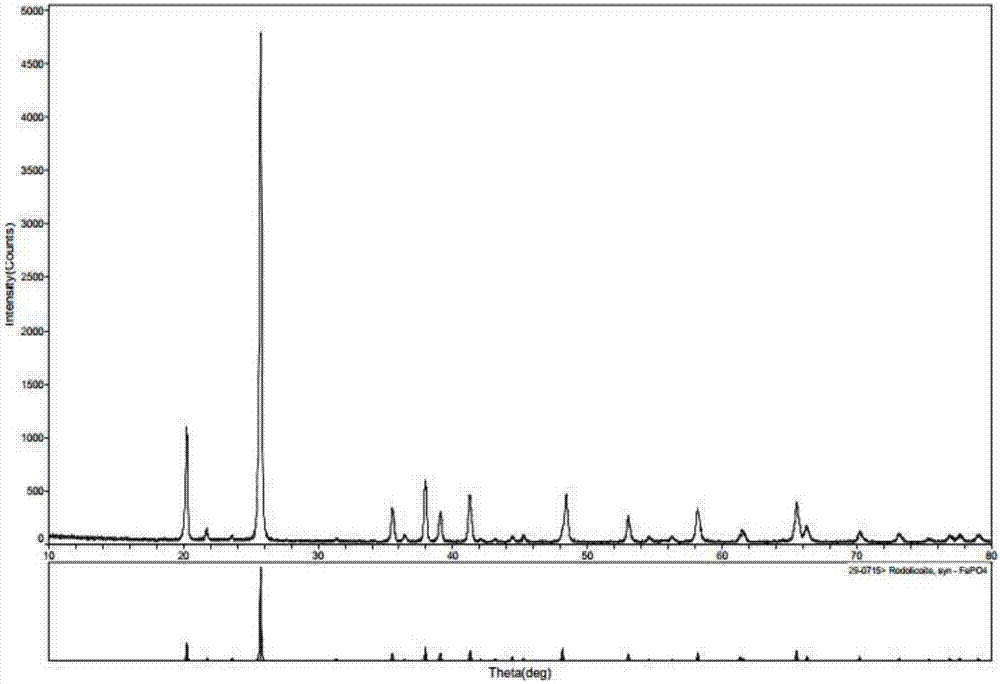

A ferric phosphate, spherical technology, applied in chemical instruments and methods, phosphorus compounds, structural parts, etc., can solve the problem of difficult control of ferric phosphate particle size, particle shape structure and particle size distribution, poor crystallinity of ferric phosphate, vibration Low density and other problems, to achieve the effect of eliminating the difference in microscopic components, good crystallinity, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of spherical iron phosphate of the present invention comprises the following steps:

[0035] (1) Add a dispersant to the iron-phosphorus mixed solution containing iron ions and phosphate ions to obtain mixed solution A;

[0036] (2) Under heating conditions, add urea to the mixed solution A obtained in step (1) to adjust the pH value, and continue heating to obtain mixed solution B comprising crystalline ferric phosphate;

[0037] (3) Filter the mixed solution B prepared in step (2), add the filter cake into water to prepare mixed solution C, atomize the mixed solution C with a spray gun and introduce it into a roasting furnace, and heat it at a temperature of 550-750°C Roasting to obtain spherical iron phosphate.

[0038] In the above preparation method of spherical ferric phosphate, the application of the dispersant as the crystal form control agent in step (1) can weaken the molecular force between particles, reduce the tendency of primary par...

Embodiment 1

[0057] (1) The iron-phosphorus mixed solution obtained by mixing the ferric sulfate solution with an iron ion concentration of 1mol / L and the ammonium dihydrogen phosphate solution with a phosphate ion concentration of 1mol / L according to the iron-phosphorus molar ratio of 1:1, at 55°C, Under the condition of rotating speed of 180r / min, polyvinyl alcohol with a fraction of 10% of iron-phosphorus mixed liquid was added, stirred for 5 minutes, and mixed liquid A was obtained;

[0058] (2) Under the conditions of heating at 60°C and a stirring rate of 360r / min, add urea with a concentration of 0.2mol / L to the mixed solution A obtained in step (1) to adjust the pH value to 2.0, continue heating to 85°C, and keep warm 120min, obtain the mixed solution B that comprises crystalline ferric phosphate, i.e. ferric phosphate slurry;

[0059] (3) The mixed solution B obtained in step (2) is repeatedly washed with pure water and press-filtered until the conductivity of the filtrate is less...

Embodiment 2

[0063] (1) The iron-phosphorus mixed solution obtained by mixing the ferric sulfate solution with the iron ion concentration of 0.5mol / L and the ammonium dihydrogen phosphate solution with the phosphate ion concentration of 0.5mol / L according to the iron-phosphorus molar ratio of 1: 1.15, at 55 ℃, under the condition of rotating speed of 360r / min, add polyvinyl alcohol with a fraction of 5% of the iron-phosphorus mixed liquid, and stir for 10 minutes to obtain the mixed liquid A;

[0064] (2) Under the conditions of heating at 70°C and a stirring rate of 600r / min, add urea with a concentration of 0.2mol / L to the mixed solution A obtained in step (1) to adjust the pH value to 1.0, continue heating to 95°C, and keep warm 50min, obtain the mixed solution B that comprises crystalline ferric phosphate, i.e. ferric phosphate slurry;

[0065] (3) The mixed solution B obtained in step (2) is repeatedly washed with pure water and press-filtered until the conductivity of the filtrate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com