Method for destroying water-absorbing performance of sodium polyacrylate resin and method for recycling waste water-absorbing articles

A technology of sodium polyacrylate and water absorption performance, applied in the field of resource recycling and comprehensive utilization, can solve the problems of waste of water resources, increased treatment costs, surge in water consumption, etc., so as to reduce production and treatment costs, reduce single or insufficient raw materials, and reduce water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

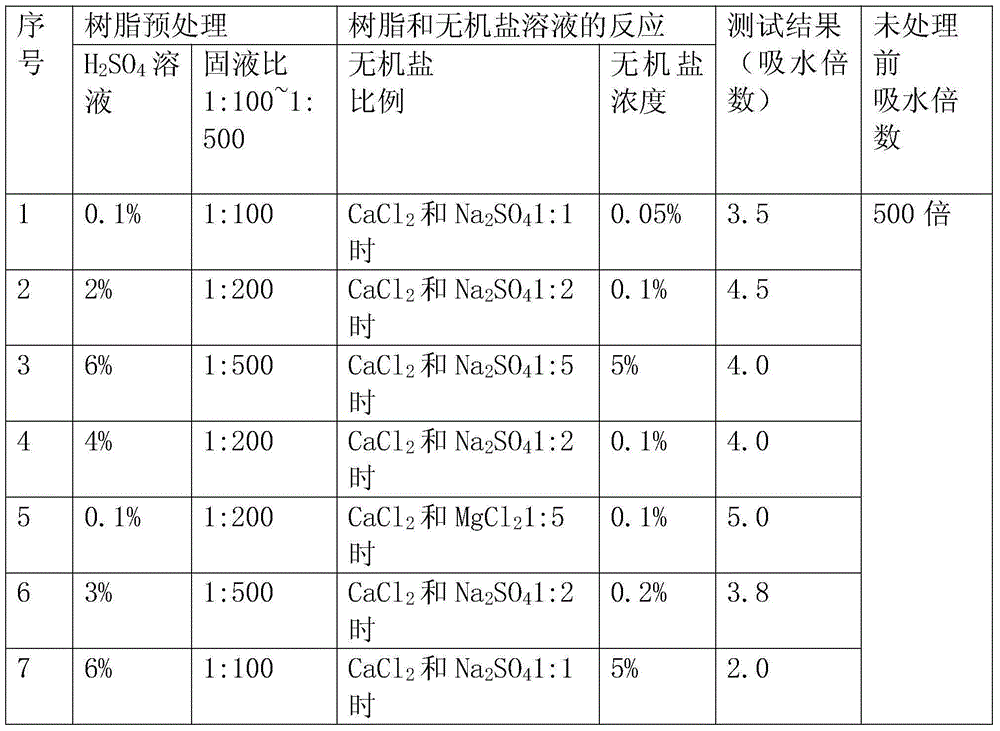

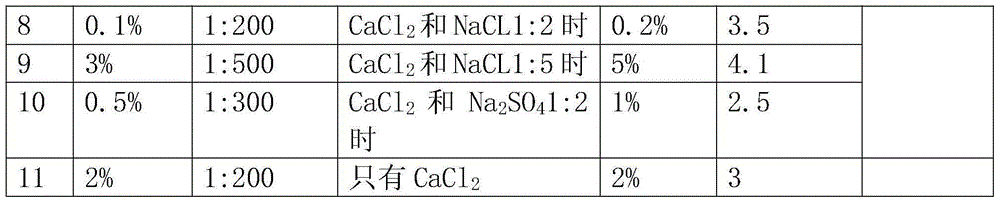

Examples

preparation example Construction

[0031] (1) Preparation of destruction fluid:

[0032] Take containing CaCl 2 Inorganic salt, make it into a solution with a concentration of 0.05% to 5%, and place it in a water bath at 30°C to 80°C for heat preservation to obtain an inorganic salt solution;

[0033] The inorganic salt includes main material CaCl 2 and auxiliary materials, wherein the auxiliary materials are Na 2 SO 4 , mixed in a ratio of 1:1 to 1:5 by mass ratio to obtain an inorganic salt;

[0034] In addition, the inorganic salt can also include the main material CaCl 2 And auxiliary material, wherein auxiliary material is any or composition in NaCl, FeCl3, MgCl2,

[0035] The main material and the auxiliary material are mixed according to the mass ratio of 1:1-1:5 to obtain the inorganic salt.

[0036] Wherein preferably, the CaCl 2 and Na 2 SO 4 The concentration of the mixed solution is 1% to 3%;

[0037] (2) Pretreatment of sodium polyacrylate resin:

[0038] Take the solid sodium polyacryla...

Embodiment 1

[0047] (1) Destruction reagent preparation: take CaCl 2 and Na 2 SO 4 The solids are mixed according to the ratio of 1:1, and the mixture is made into a solution with a concentration of 0.05%, and placed in a water bath at 50°C, and the solution is kept warm for 30 minutes:

[0048] (2) Pre-preparation of sodium polyacrylate resin: prepare 0.1% H 2 SO 4 Solution, take a laboratory triangle flask, after cleaning and drying, take sodium polyacrylate resin, add the prepared H 2 SO 4 The solution was stirred with a glass rod for 15 minutes at room temperature, left to stand for 30 minutes, filtered to obtain a pretreated resin, and set aside.

[0049] (3) Destruction of the water absorption of the resin: then slowly add the resin obtained by filtering in step (2) into the mixed solution in step (1) according to the solid-to-liquid ratio of 1:100, stir with a glass rod, let stand for 6 hours, and filter A treated resin is obtained.

[0050] (4) Inspection of water absorption...

Embodiment 2

[0053] (1) Destruction reagent preparation: take CaCl 2 and Na 2 SO 4 The solids were mixed according to the ratio of 1:2, and the mixture was made into a solution with a concentration of 0.1%, and placed in a water bath at 60°C, and the solution was kept warm for 30 minutes:

[0054] (2) Pre-preparation of sodium polyacrylate resin: prepare 0.1% H 2 SO 4 solution, take a laboratory triangular flask, after cleaning and drying, take sodium polyacrylate resin, add the prepared H 2 SO 4 The solution was stirred with a glass rod for 15 minutes at room temperature, left to stand for 30 minutes, filtered to obtain a pretreated resin, and set aside.

[0055] (3) Destruction of the water absorption of the resin: then slowly add the resin filtered in step (2) to the mixed solution in step (1) according to the solid-to-liquid ratio of 1:200, stir with a glass rod, let stand for 6 hours, and filter A treated resin is obtained.

[0056] (4) Inspection of water absorption performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com