Preparation method for low-viscosity high-hydroxyl-value polymer surface enhancer used for paper

A surface enhancer, viscosity and high hydroxyl value technology, applied in the direction of enhancer addition, papermaking, paper coating, etc., can solve the problems of poor stability and low crosslinking density of acrylic resin, and achieve increased crosslinking density and steric hindrance , to ensure the effect of long-term storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

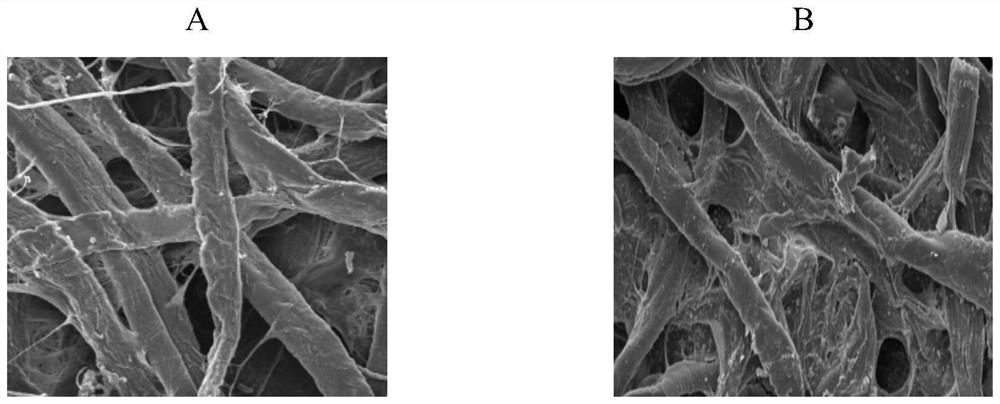

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a low-viscosity high-hydroxyl value polymer surface enhancer for paper, comprising the following steps:

[0033] 1) In parts by weight, add 25 parts of diethylene glycol dimethyl ether dispersion medium into the reactor, and heat to 120-140°C.

[0034] 2) Mix the soft vinyl monomer, hard vinyl monomer, hydroxyl-containing vinyl monomer, glycidyl methacrylate and isobornyl methacrylate in a weight ratio of 20:54:14:1:3 Mixing was performed to prepare a monomer mixed liquid A.

[0035]3) Weigh 69 parts of monomer mixture A, add 1.1-1.4 parts of dibenzoyl peroxide and 0.08-0.15 parts of tert-butyl peroxybenzoate double-initiator system, mix well and slowly add double-initiator system , the dropping time is 2 to 4 hours, and then the heat preservation reaction is continued for 60 to 90 minutes to form a polymer core.

[0036] 4) Weigh 17-69 parts of monomer mixture A, add 3 parts of acrylic acid monomer, 0.5-1.5 parts of diben...

Embodiment 1

[0048] 1) In parts by weight, add 25 parts of diethylene glycol dimethyl ether dispersion medium into the reactor, and heat to 120°C.

[0049] 2) Soft vinyl monomer butyl acrylate, hard vinyl monomer methyl methacrylate, hydroxyl-containing vinyl monomer hydroxypropyl acrylate, glycidyl methacrylate and isobornyl methacrylate 20:54:14:1:3 weight ratio was mixed to prepare monomer mixture A.

[0050] 3) Weigh 69 parts of monomer mixture A, add 1.1 parts of dibenzoyl peroxide and 0.8 parts of tert-butyl peroxybenzoic acid double initiator system, mix well and slowly add the double initiator system dropwise, the dropping time for 2 hours, and then continue to keep warm for 60 minutes to form a polymer core.

[0051] 4) Weigh 17 parts of monomer mixture A, add 3 parts of acrylic acid monomer, 0.5 part of dibenzoyl peroxide, and 0.05 part of tert-butyl peroxybenzoate, and mix well to prepare monomer mixture B.

[0052] 5) Gradually drop the monomer mixture solution B into the pol...

Embodiment 2

[0058] 1) In parts by weight, add 25 parts of diethylene glycol dimethyl ether dispersion medium into the reactor, and heat to 125°C.

[0059] 2) Soft vinyl monomer butyl methacrylate, hard vinyl monomer methyl methacrylate, hydroxyl-containing vinyl monomer hydroxypropyl acrylate, glycidyl methacrylate and methacrylate isoborneol The esters were mixed in a weight ratio of 20:54:14:1:3 to obtain a monomer mixture A.

[0060] 3) Weigh 69 parts of monomer mixture A, add 1.2 parts of dibenzoyl peroxide and 0.09 part of tert-butyl peroxybenzoic acid double initiator system, mix well and slowly add double initiator system, the time for adding for 3 hours, and then continue the incubation reaction for 70 minutes to form a polymer core.

[0061] 4) Weigh 21 parts of monomer mixture A, add 3 parts of acrylic acid monomer, 0.8 part of dibenzoyl peroxide, and 0.1 part of tert-butyl peroxybenzoate, and mix well to prepare monomer mixture B.

[0062] 5) Gradually drop the monomer mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com