Heat-conducting and insulating composite high polymer material containing expanded graphite subjected to in-situ surface coating and preparation method thereof

A technology of composite materials and expanded graphite, which is applied in the field of polymer materials, can solve the problems of inability to effectively improve thermal conductivity, inability to build thermal conduction paths, uneven EG dispersion, etc., achieve good thermal conductivity, reduce overall interface thermal resistance, and improve interface bonding force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

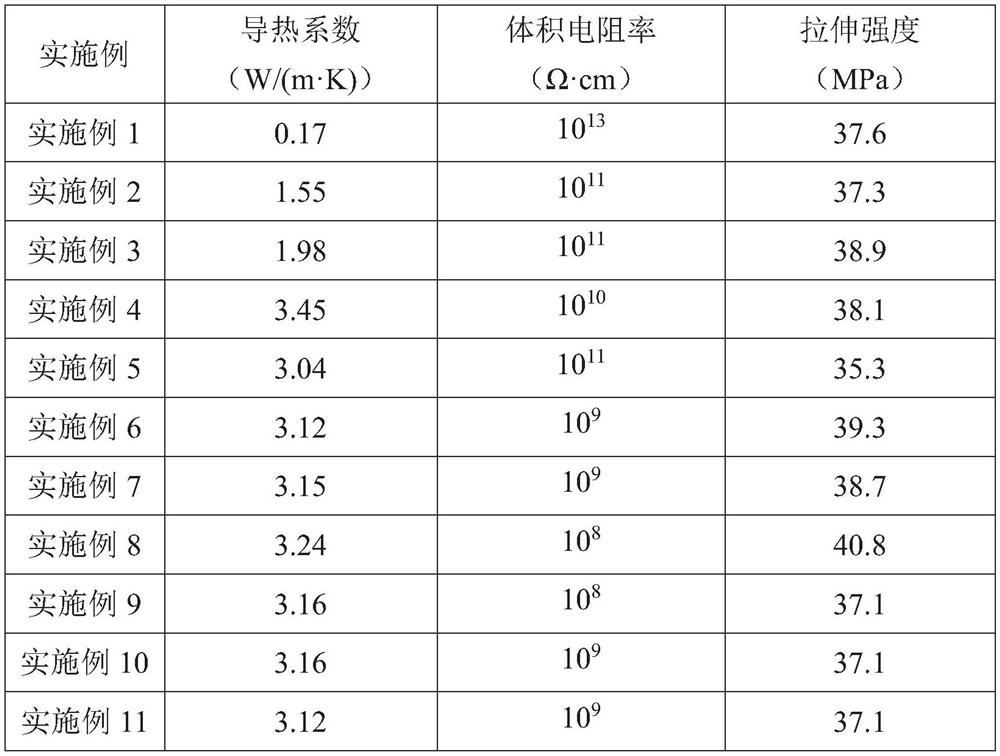

Examples

Embodiment 1

[0043] Embodiment 1 is the preparation of the VMQ material without adding EG, and the specific process is as follows:

[0044] (1) The configured VMQ was hot-pressed on a flat vulcanizer for 15 minutes under the conditions of 150° C. and 120 MPa, and finally cold-pressed under the condition of 100 MPa for 5 minutes to obtain the final thermally conductive composite material.

Embodiment 2

[0046] (1) Mix EG (5wt%) and configured VMQ (95wt%) at room temperature to form a uniformly dispersed suspension.

[0047] (2) The suspension was hot-pressed on a flat vulcanizer under the conditions of 150° C. and 120 MPa for 15 minutes, and finally cold-pressed under the condition of 100 MPa for 5 minutes to obtain a thermally conductive composite material.

Embodiment 3

[0049] (1) Disperse 1.4g of EG powder in 200ml of absolute ethanol, then add 40ml of deionized water and 30ml of NH 4 Oh. After magnetic stirring for 30 min, a uniformly dispersed suspension was obtained.

[0050] (2) Add 3.5ml TEOS to the above suspension, and continue magnetic stirring for 6h to obtain a reaction suspension.

[0051] (3) The reaction suspension was vacuum filtered and washed several times with ethanol and deionized water to remove excess SiO 2 particles, to obtain EG-SiO 2 .

[0052] (4) EG-SiO 2 (5 wt%) and formulated VMQ (95 wt%) were mixed at room temperature to form a homogeneously dispersed suspension.

[0053] (5) The suspension was hot-pressed on a flat vulcanizer under the conditions of 150° C. and 120 MPa for 15 minutes, and finally cold-pressed under the condition of 100 MPa for 5 minutes to obtain a thermally conductive composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com