Preparation method of predispersed clay-aramid pulp flocculation masterbatch

A technology of aramid pulp and clay, applied in the field of high-performance polymer structural material manufacturing, can solve problems such as difficult dispersion, easy mutual entanglement, high electrostatic tendency, etc., achieve good compatibility and adhesion, and simplify preparation Process flow, reduce the effect of agglomeration tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

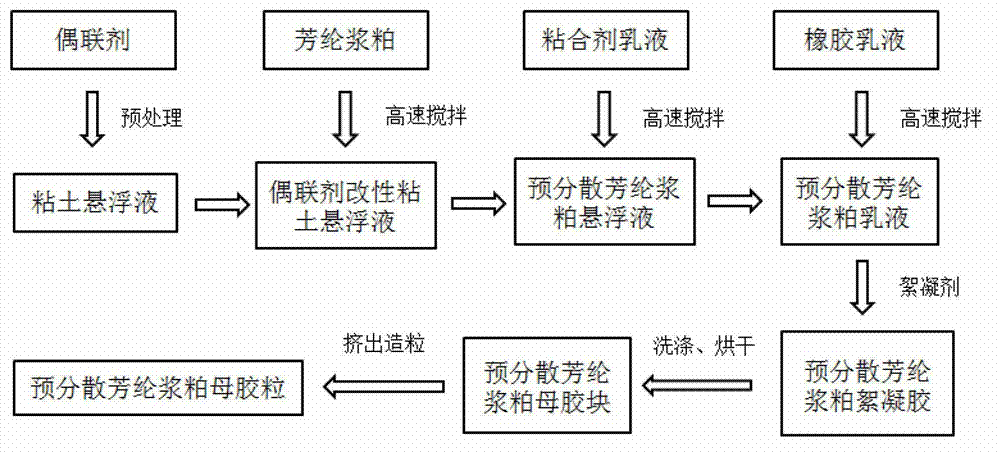

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 40 parts by mass of aramid pulp, 6 parts by mass of montmorillonite, 1 part by mass of KH560 coupling agent, 1 part by mass of water-soluble epoxy resin, 50 parts by mass of natural latex (60% solid content), 50 parts by mass of flocculation 2 parts by mass of calcium chloride (configured as a 2% aqueous solution).

[0034] (2) Mix clay with deionized water, stir for 30 minutes at a dispersion speed of 100r / min, then add KH560 coupling agent and continue stirring for 30 minutes;

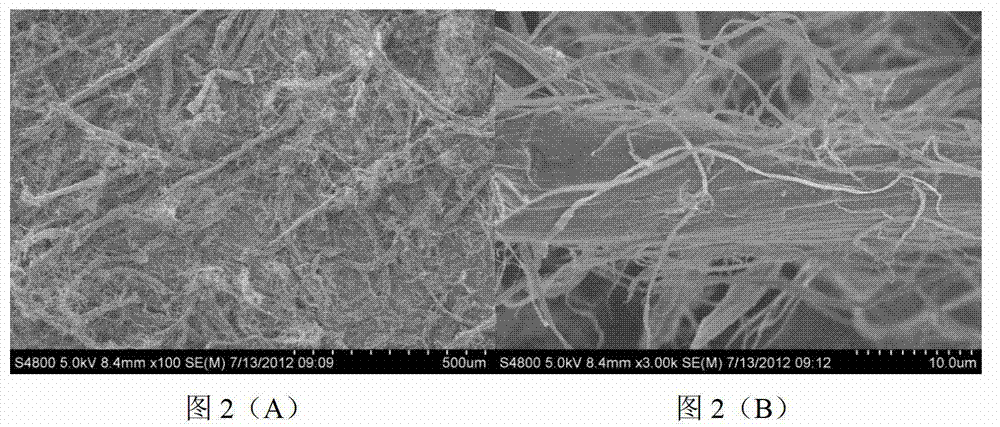

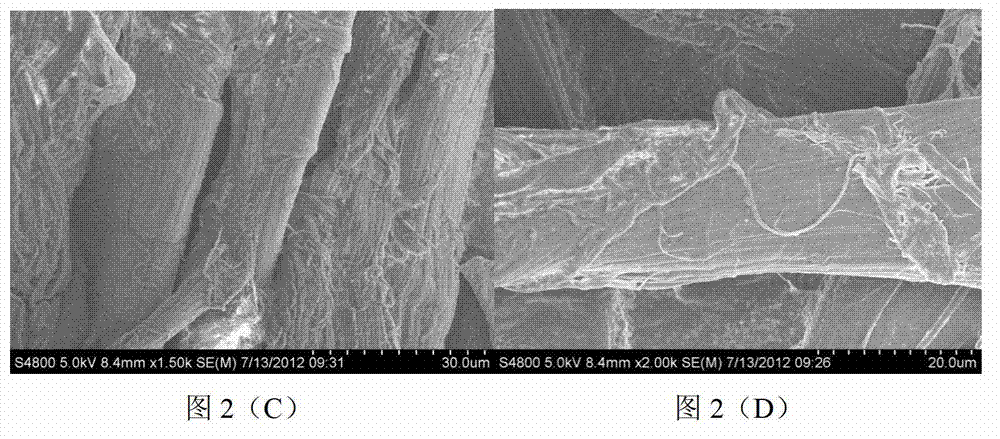

[0035] (3) Mix the clay suspension obtained in step (2) with aramid pulp, and pretreat it until the aramid pulp microfibers are fully stretched at a stirring speed of 200 / min in the water phase, and are flocculent without spherical lumps or reunion phenomenon, forming an effective isolation;

[0036] (4) Add water-soluble epoxy resin to the mixed solution obtained in step (3), and further stir until there is no agglomeration;

[0037] (5) After adding natural latex to the aramid pulp...

Embodiment 2

[0041] (1) Weigh 40 parts by mass of aramid pulp, 6 parts by mass of montmorillonite, 1 part by mass of KH550 coupling agent, 1 part by mass of benzopyridine latex, 50 parts by mass of natural latex (solid content 60%), and flocculant 2 parts by mass of concentrated sulfuric acid (configured as a 2% sulfuric acid solution).

[0042] (2) Mix clay with deionized water, stir for 30 minutes at a dispersion speed of 100 r / min, then add KH550 coupling agent and continue stirring for 30 minutes;

[0043] (3) Mix the clay suspension obtained in step (2) with aramid pulp, and pretreat it until the aramid pulp microfibers are fully stretched at a stirring speed of 200 / min in the water phase, and are flocculent without spherical lumps or reunion phenomenon, forming an effective isolation;

[0044] (4) Add styrene-butadiene pyridine latex to the mixed solution obtained in step (3), and further stir until there is no agglomeration;

[0045] (5) After adding natural latex to the aramid pu...

Embodiment 3

[0049] (1) Weigh 40 parts by mass of aramid pulp, 6 parts by mass of montmorillonite, 1 part by mass of KH560 coupling agent, 1 part by mass of water-soluble epoxy resin, 50 parts by mass of styrene-butadiene latex (solid content 60%), 2 parts by mass of flocculant calcium chloride (configured into 2% aqueous solution);

[0050] (2) Mix clay with deionized water, stir for 30 minutes at a dispersion speed of 100 r / min, then add KH560 coupling agent and continue stirring for 30 minutes;

[0051] (3) Mix the clay suspension obtained in step (2) with aramid pulp, and pretreat for 1 hour under the stirring speed of the water phase at 200 / min. Pimple or reunion phenomenon, forming an effective isolation;

[0052] (4) Add water-soluble epoxy resin to the mixture obtained in step (3), and stir at a dispersion speed of 200 / min until there is no agglomeration;

[0053] (5) After adding styrene-butadiene latex to the aramid pulp suspension system obtained in step (4), under stirring, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com