A preparation method of flame-retardant modified graphene and its modified thermoplastic elastomer

A thermoplastic elastomer and graphene technology, which is applied in the field of flame retardant material preparation, can solve the problems of difficulty in achieving the flame retardant level of composite materials, restricting the popularization and application of graphene, and poor dispersion of graphene, so as to reduce secondary pollution and the scope of application Broadening and reducing the effect of reunion tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

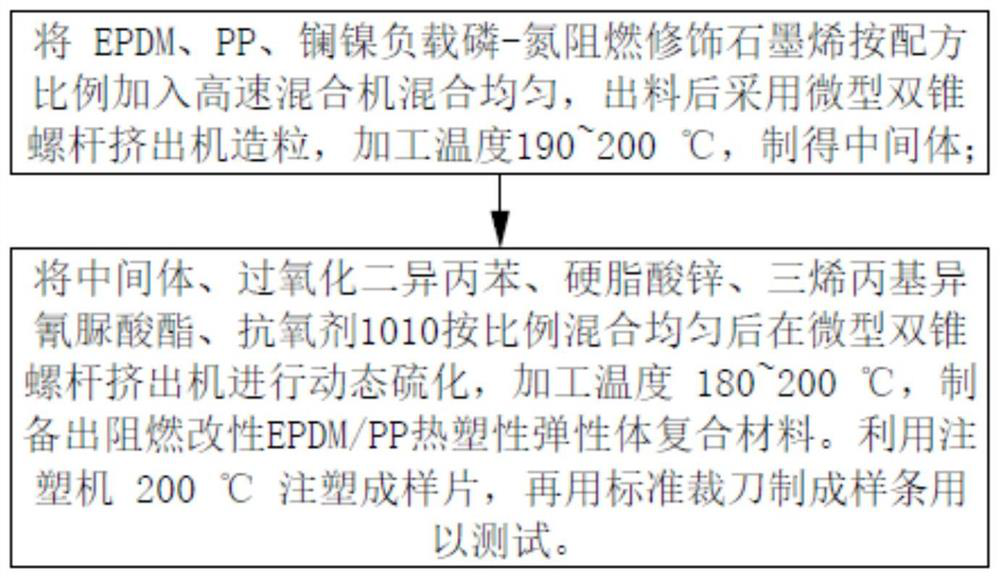

Examples

preparation example Construction

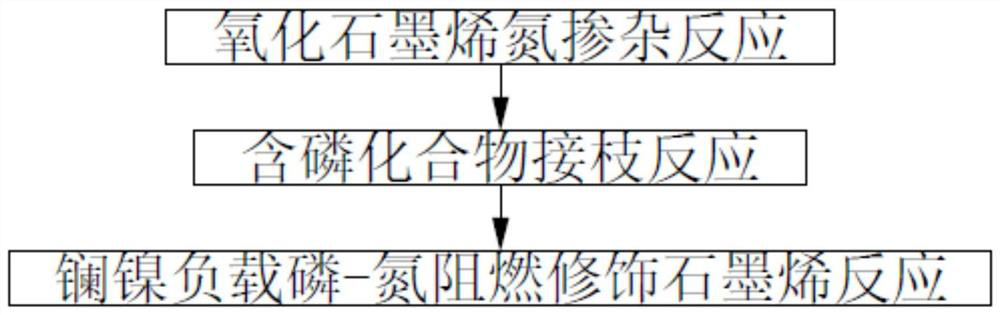

[0025] The invention provides a preparation method of flame-retardant modified graphene and its modified thermoplastic elastomer, which improves the expansion and flame-retardant efficiency of phosphorus-nitrogen flame-retardant modified graphene, and helps to improve the mechanical properties, electrical conductivity and resistance of substrate materials. Combustibility, solve the dispersion problem of graphene in the process of processing, give full play to its nano-enhanced effect, please refer to figure 1 ,

[0026] The preparation method of this flame-retardant modified graphene comprises the steps:

[0027] S1: Graphene oxide nitrogen doping reaction: Graphene oxide, 1,3,5-triazine and dimethylformamide are mixed in a certain mass ratio, and the above mixture is transferred to a reactor lined with polytetrafluoroethylene, Under nitrogen protection, heat to 80°C-150°C, stir for 2-10 hours, add distilled water to filter after the reaction, and then vacuum filter and dry t...

Embodiment 1

[0035]Add 1 gram of GO, 5 grams of 1,3,5-triazine and 20 grams of DMF into a beaker and stir evenly, then transfer to a reaction kettle with a Teflon liner, protect with nitrogen, heat to 80°C, and stir for 10 hours ; Add distilled water to filter after the reaction, and then vacuum filter and dry to obtain the product nitrogen-doped GO with a yield of 92.6%;

[0036] Add 1 gram of nitrogen-doped GO, 0.5 gram of dimethyl chlorophosphate and 20 grams of ethyl acetate into a three-necked flask with a magnetic stirring device, stir and react at 10°C for 6 hours, filter after the reaction, and use methanol After washing for several times, and then vacuum drying at 60°C for 12 hours, the product organophosphorus-grafted nitrogen-doped GO was obtained with a yield of 90.7%;

[0037] Add 1 g of PN-GO powder, 3 g of Ni(NO3)3·6H2O and 2 g of La(NO3)3·6H2O to 150 g of methanol, and ultrasonically disperse at room temperature for 1 hour to obtain a suspension. Add 6 grams of 2-methylimi...

Embodiment 2

[0039] 1 gram of GO, 1 gram of 1,3,5-triazine and 10 grams of DMF were added into a beaker and stirred evenly, then transferred to a reaction kettle with a Teflon liner, protected by nitrogen, heated to 150°C, and stirred for 2 hours ; Add distilled water to filter after the reaction, and then vacuum filter and dry to obtain the product nitrogen-doped GO with a yield of 78.7%;

[0040] Add 1 gram of nitrogen-doped GO, 0.1 gram of dimethyl chlorophosphate and 10 grams of acetonitrile into a three-necked flask with a magnetic stirring device, stir and react at 80°C for 2 hours, filter after the reaction, and wash with methanol times, and then vacuum-dried at 60°C for 12 hours to obtain the product organophosphorus-grafted nitrogen-doped GO with a yield of 84.3%;

[0041] Add 1 g of PN-GO powder, 10 g of Ni(NO3)3·6H2O and 5 g of La(NO3)3·6H2O to 2000 g of methanol, and ultrasonically disperse at room temperature for 1 hour to obtain a suspension, in the above suspension Add 50 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com