A molybdenum-antimony brominated graphene oxide modified ABS composite flame retardant material and preparation method thereof

An antimony brominated oxide and composite flame retardant technology is applied in the field of molybdenum-antimony brominated graphene oxide modified ABS composite flame retardant material and its preparation, which can solve the problems of the influence of polymer mechanical properties and processability, etc. Secondary pollution, low price, and the effect of improving smoke suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

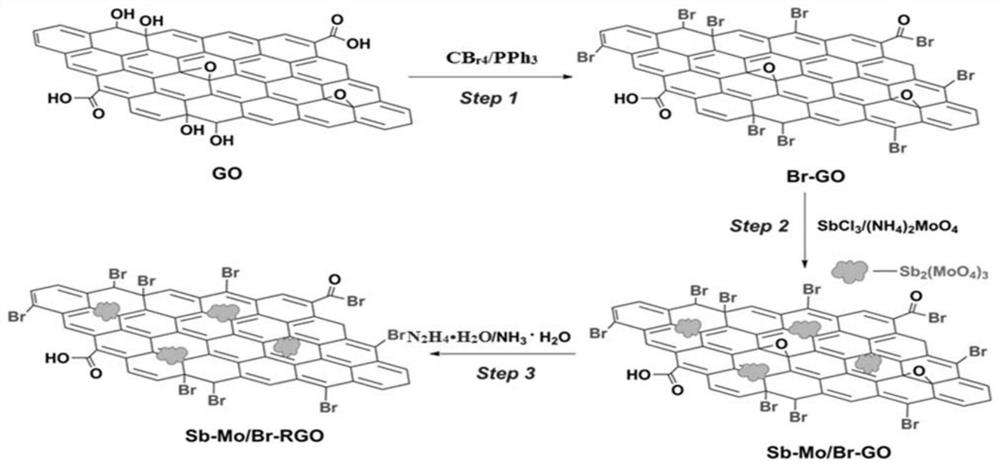

[0025] The synthesis of Sb-Mo / Br-RGO mainly consists of three steps, such as figure 1 Shown:

[0026] The first step is the bromination of graphene oxide.

[0027] Graphene oxide (GO) was prepared by the modified Hummers method, and dried under vacuum at room temperature for more than one week in a phosphorus pentoxide atmosphere. Weigh 250mg of graphene oxide, put it into a 100mL dry flask with a magnetic stirring bar, add 15g of carbon tetrabromide and 3g of triphenylphosphine, after the addition is complete, raise the temperature to 150°C, and stir for 5 hours at the same time, and wait for the reaction mixture to cool to After room temperature, 30 ml of ethanol was added to the solution. The reaction mixture was filtered, washed with methanol three times, and then dried in vacuum to obtain brominated graphene (Br-GO).

[0028] The second step is to load antimony molybdate on Br-GO.

[0029] Add 1.0g of Br-GO into 100mL of deionized water, ultrasonically disperse at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com