Graphene surface dispersity modification method

A graphene surface, graphene technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve problems such as limited preparation conditions, low efficiency, and inability to meet mass production applications. , to achieve the effect of improving comprehensive performance, improving surface state, and improving interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using graphene as a reinforcing phase, add graphene to 1000ml of 1g / L dopamine hydrochloride solution, ultrasonically disperse it for 30 minutes, and then apply mechanical stirring for 24 hours. During the reaction process, pay attention to avoiding light to obtain polydopamine graphene solution, and then add 1mol / L CuSO to the polydopamine graphene solution 4 Solution 10ml, Cu 2+ Reduction, Cu nanoparticles were formed on the surface of graphene, and reacted for 4 hours under the action of mechanical stirring. After the polydopamine-reduced copper-modified graphene solution is obtained, the obtained solution is suction-filtered and dried. The polydopamine-reduced copper-modified graphene can be obtained.

Embodiment 2

[0022] Using graphene as a reinforcing phase, add graphene to 1000ml of 1g / L dopamine hydrochloride solution, ultrasonically disperse it for 30 minutes, and then apply mechanical stirring for 24 hours. During the reaction process, pay attention to avoiding light to obtain polydopamine graphene solution, and then add 1mol / L CuSO to the polydopamine graphene solution 4 Solution 20ml, Cu 2+ Reduction, Cu nanoparticles were formed on the surface of graphene, and reacted for 4 hours under the action of mechanical stirring. After the polydopamine-reduced copper-modified graphene solution is obtained, the obtained solution is suction-filtered and dried. The polydopamine-reduced copper-modified graphene can be obtained.

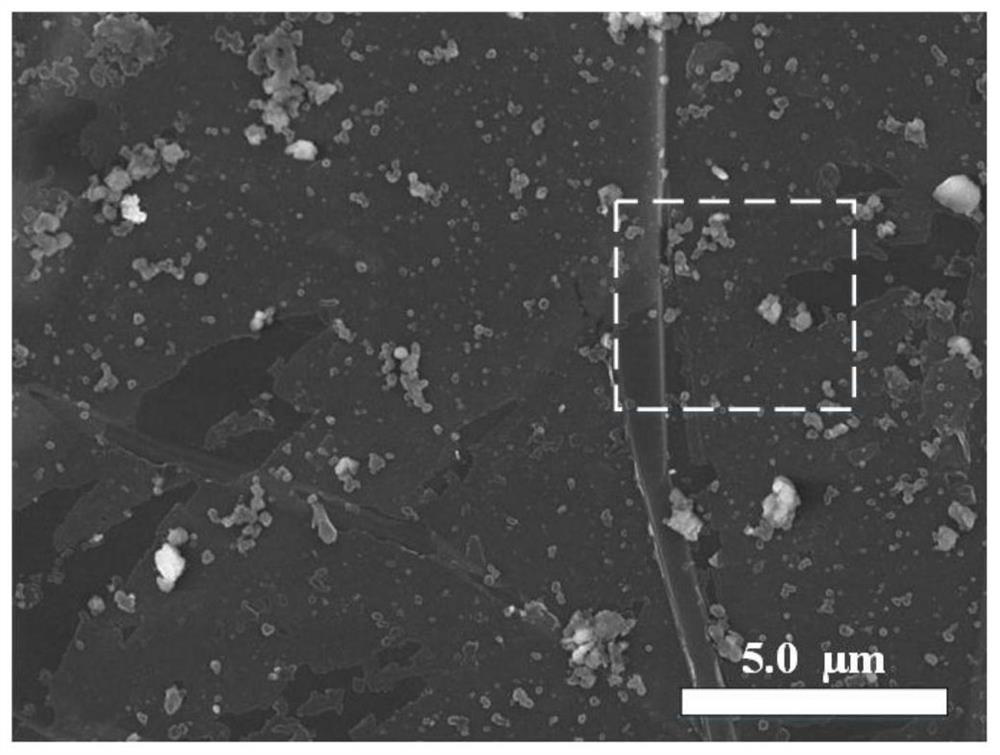

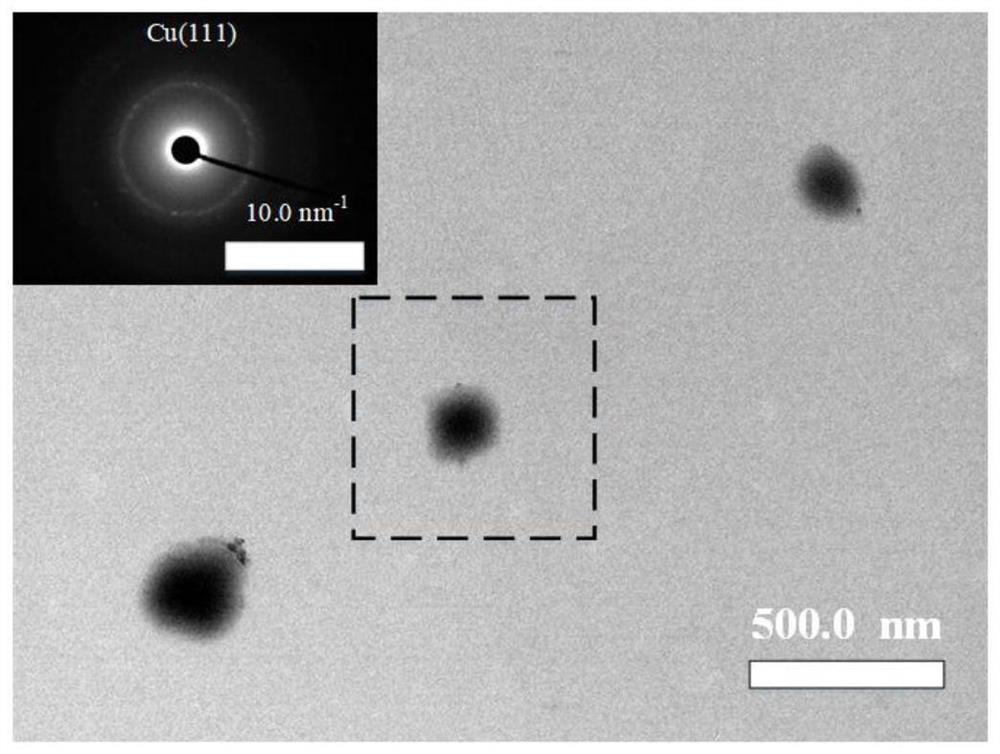

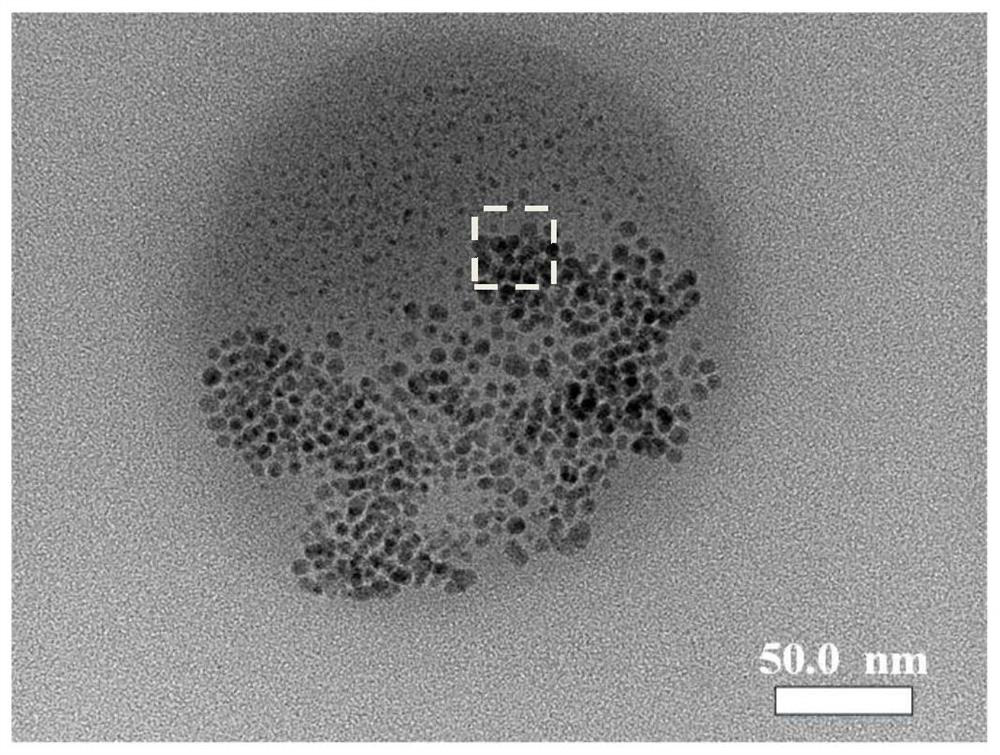

[0023] Add different content of CuSO 4 Cu nanoparticles-modified graphene with different densities can be obtained. figure 1 SEM image of copper-modified graphene reduced to polydopamine. From figure 1 It can be seen that its microscopic appearance shows that s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com