Segment color yarn spinning device and segment color yarn spinning method

A technology of segment color and roving, which is applied in spinning machine, textile and papermaking, continuous winding spinning machine, etc., can solve the problem that the quality of yarn evenness needs to be improved, the quantitative adjustment and control of roving is not convenient, and the color of yarn single problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

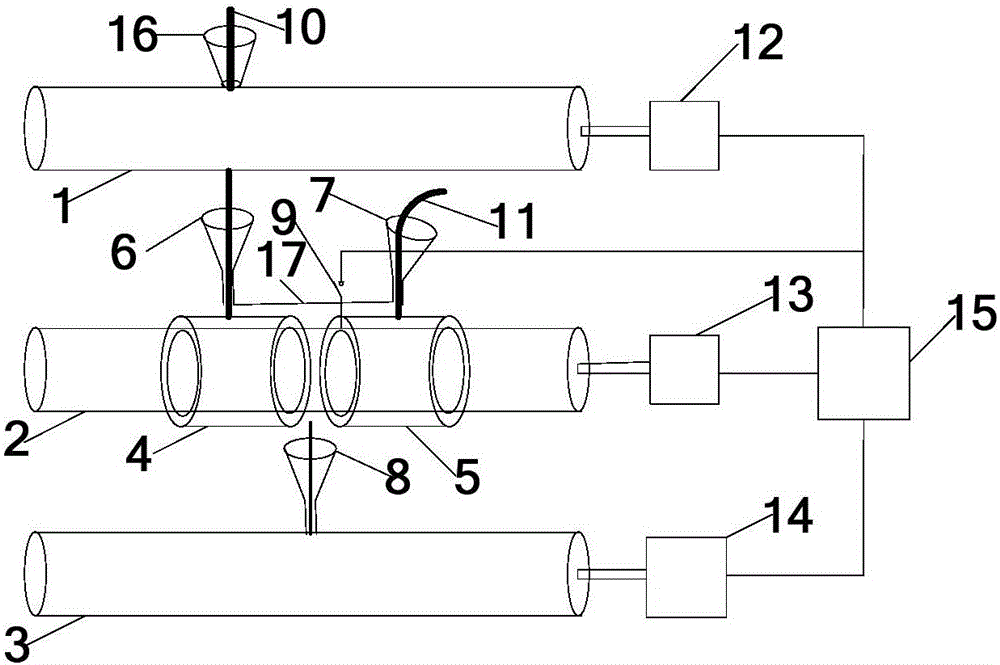

[0009] Depend on figure 1 As shown, a segment colored yarn spinning device includes a front roller 3, a middle roller 2 and a rear roller 1, the front roller 3 and the rear roller 1 are steel solid cylindrical structures with constant diameters, and the middle roller 2 includes a roller shaft , the roller shaft is a steel solid cylindrical structure with constant diameter, the first roller sleeve 4 and the second roller sleeve 5 are connected from left to right on the roller shaft, the first roller sleeve 4 and the second roller sleeve 5 have the same diameter And equal to the diameter of the front roller 3 and the rear roller 1, the first roller sleeve 4 is integrally connected with the roller shaft, the second roller sleeve is connected with the roller shaft through the bearing 5, and the bearing has two working states, including the open state and the closed state , the bearing is connected with the electromagnetic switch 9, and the working state of the bearing is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com