A kind of preparation method of highly flat fiber

A flat fiber, high-level technology, applied in fiber processing, wet spinning, stretch spinning, etc., can solve the problems of affecting fiber plasticity, not meeting the environmental protection requirements of energy saving and emission reduction, and consuming a lot of manpower and material resources, etc., to achieve fiber cross-section The shape is controllable and the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

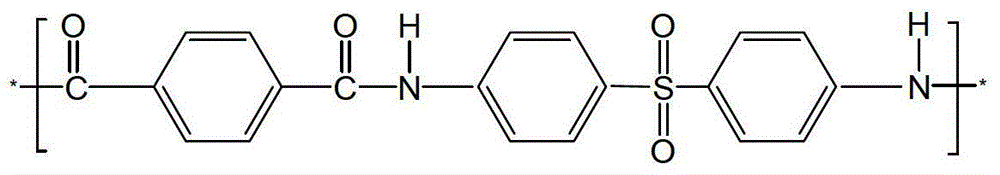

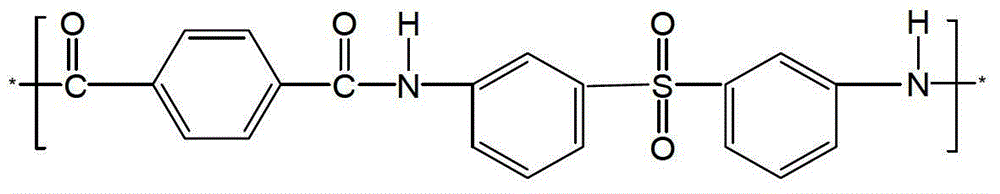

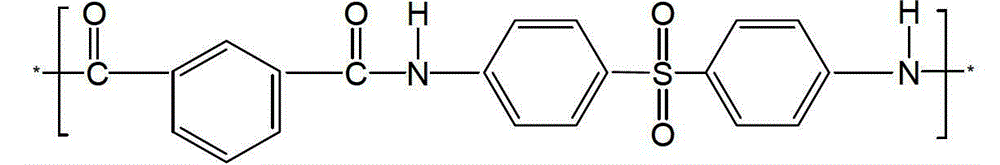

Image

Examples

Embodiment 1

[0043] Preparation method of highly flat polyacrylonitrile fiber:

[0044] Polyacrylonitrile homopolymer with a viscosity average molecular weight of 4.4×10 4 .

[0045] The composition of the polymer solution is: 25wt% polyacrylonitrile homopolymer, 75wt% dimethylacetamide; the apparent viscosity of the spinning solution at 40°C is 110Pa·s. The polymer solution is extruded through an elliptical spinneret hole with a major axis of 0.7mm and a ratio of major to minor axis of 5, and then enters the first coagulation bath with a temperature of 20°C, a concentration of 40wt% dimethylacetamide and the remainder of water. The residence time in the coagulation bath is 20s, the draw ratio of the spinneret is 2 times, and the solvent content in the coagulation bath filaments is 40wt%; Coagulation and stretching in the second coagulation bath of water for 2 times; then drawing in boiling water at 100°C, and drying and stretching at 100°C for 1.01 times to prepare highly flat polyacryl...

Embodiment 2

[0052] Preparation method of highly flat polyacrylonitrile fiber:

[0053] Acrylonitrile copolymer: the first monomer is polyacrylonitrile with a content of 85wt%; the second monomer is methyl acrylate with a content of 7wt%; the third monomer is itaconic acid with a content of 8wt%. The viscosity average molecular weight is 6.5×10 4 .

[0054] The composition of the polymer solution is: 30wt% acrylonitrile copolymer, 70wt% dimethylformamide; the apparent viscosity of the spinning solution at 40°C is 320Pa·s. The polymer solution is extruded through an inline spinneret hole with a length of 0.8mm and an aspect ratio of 2, and then enters the first coagulation bath with a temperature of 20°C, a concentration of 40wt% dimethylformamide and the rest of water, and is coagulated The residence time in the bath is 80s, the draw ratio of the spinneret is 6 times, and the solvent content in the silk strands exiting the coagulation bath is 25wt%; Coagulate and stretch 2.6 times in th...

Embodiment 3

[0061] Preparation method of highly flat polyacrylonitrile fiber:

[0062] Acrylonitrile copolymer: the first monomer is polyacrylonitrile with a content of 88wt%; the second monomer is methyl methacrylate with a content of 7wt%; the third monomer is sodium propylene sulfonate with a content of 5wt%. The viscosity average molecular weight is 2.5×10 5 .

[0063] The composition of the polymer solution is: 5wt% acrylonitrile copolymer, 95wt% dimethyl sulfoxide; the apparent viscosity of the spinning solution at 40°C is 270Pa·s. The polymer solution is extruded through an elliptical spinneret hole with a major axis of 0.2mm and a ratio of major to minor axis of 8, and then enters the first coagulation bath with a temperature of 0°C, a concentration of 50wt% dimethyl sulfoxide and the rest of water. The residence time in the coagulation bath is 50s, the draw ratio of the spinneret is 10 times, and the solvent content in the silk strands exiting the coagulation bath is 28wt%; Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com