Dry spraying-wet spinning method for manufacturing aramid III fiber

A dry spray and fiber technology, applied in dry spinning, wet spinning, etc., can solve problems such as the inability to effectively control the flow rate of the coagulating liquid in a wide range, the short coagulation time of the fiber trickle, and the slow coagulation time of the fiber trickle. Aramid III fiber molecular chain structure, excellent fiber properties and appearance quality, the effect of optimizing polymer macromolecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A dry jet-wet spinning method for manufacturing aramid III fibers, the process steps are as follows:

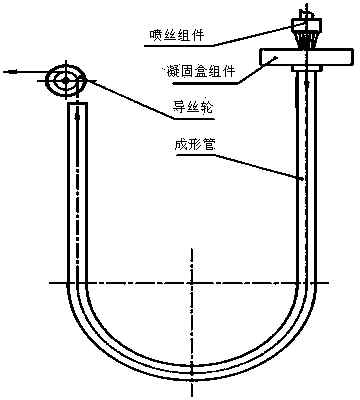

[0041] A. The temperature of the filtered and defoamed spinning stock solution is 26°C. After being extruded through the spinneret to form a thin stream, it enters the coagulation solution through a layer of 10mm air layer;

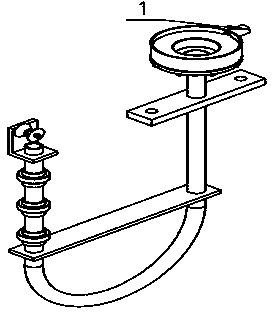

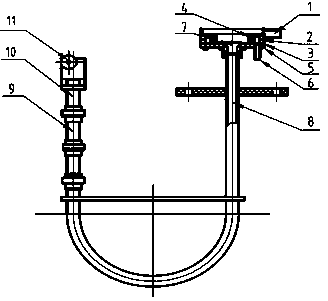

[0042]B. The thin stream extruded from the spinneret is fully solidified in the coagulation forming device to obtain primary fibers; the coagulation forming device includes two parts: a coagulation plate and a U-shaped coagulation tube. The extruded stream is rapidly pre-solidified in the coagulation plate, and then enters the U-shaped After fully extracting the solvent in the coagulation tube, aramid III primary fibers are formed;

[0043] The coagulation bath is a mixture of methanol and water, wherein the content of methanol is 30%; the temperature of the coagulation bath is controlled at 35°C, the residence time of the fiber in the coagulation...

Embodiment 2

[0052] A dry jet-wet spinning method for manufacturing aramid III fibers, the process steps are as follows:

[0053] A. After filtering and degassing, the temperature of the spinning stock solution is 30°C. After being extruded through the spinneret to form a thin stream, it enters the coagulation solution through a layer of 15mm air layer;

[0054] B. The thin stream extruded from the spinneret is fully solidified in the coagulation forming device to obtain primary fibers; the coagulation forming device includes two parts: a coagulation plate and a U-shaped coagulation tube. The extruded stream is rapidly pre-solidified in the coagulation plate, and then enters the U-shaped After fully extracting the solvent in the coagulation tube, aramid III primary fibers are formed;

[0055] The coagulation bath is a mixed solution of N,N-dimethylacetamide and water, wherein the content of N,N-dimethylacetamide is 37%; the temperature of the coagulation bath is controlled at 30°C, and the...

Embodiment 3

[0064] A dry jet-wet spinning method for manufacturing aramid III fibers, the process steps are as follows:

[0065] A. The temperature of the filtered and defoamed spinning stock solution is 35°C, and after being extruded through the spinneret to form a thin stream, it enters the coagulation solution through a layer of 20mm air layer;

[0066] B. The thin stream extruded from the spinneret is fully solidified in the coagulation forming device to obtain primary fibers; the coagulation forming device includes two parts: a coagulation plate and a U-shaped coagulation tube. The extruded stream is rapidly pre-solidified in the coagulation plate, and then enters the U-shaped After fully extracting the solvent in the coagulation tube, aramid III primary fibers are formed;

[0067] The coagulation bath is a mixed solution of ethanol and water, wherein the content of ethanol is 50%; the temperature of the coagulation bath is controlled at 25°C, the residence time of the fiber in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com