Biocompatible nano-conductive fiber and preparation method thereof

A nano-conductive and biocompatible technology, applied in the field of biocompatible nano-conductive fibers and their preparation, can solve the problems of difficult degradation or recycling of materials, and achieve the effects of reasonable distribution, reasonable formula and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

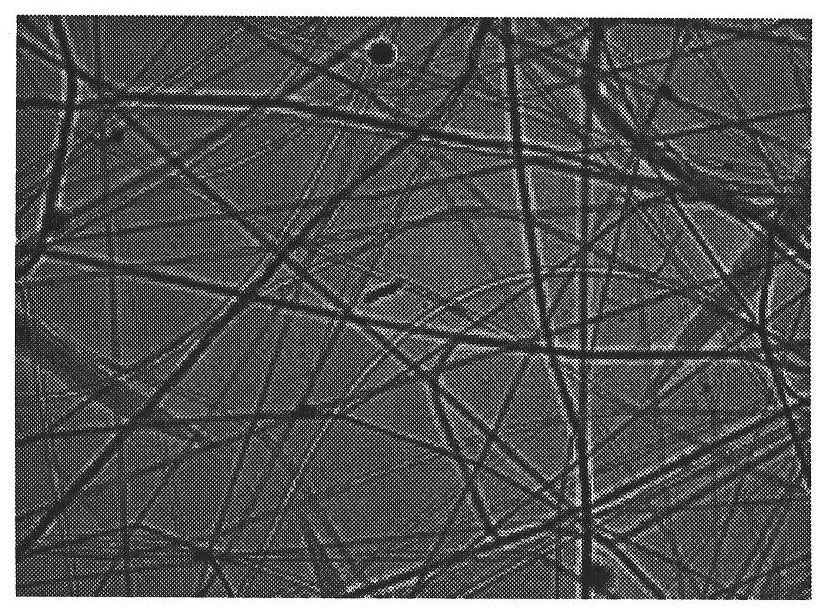

Examples

Embodiment 1

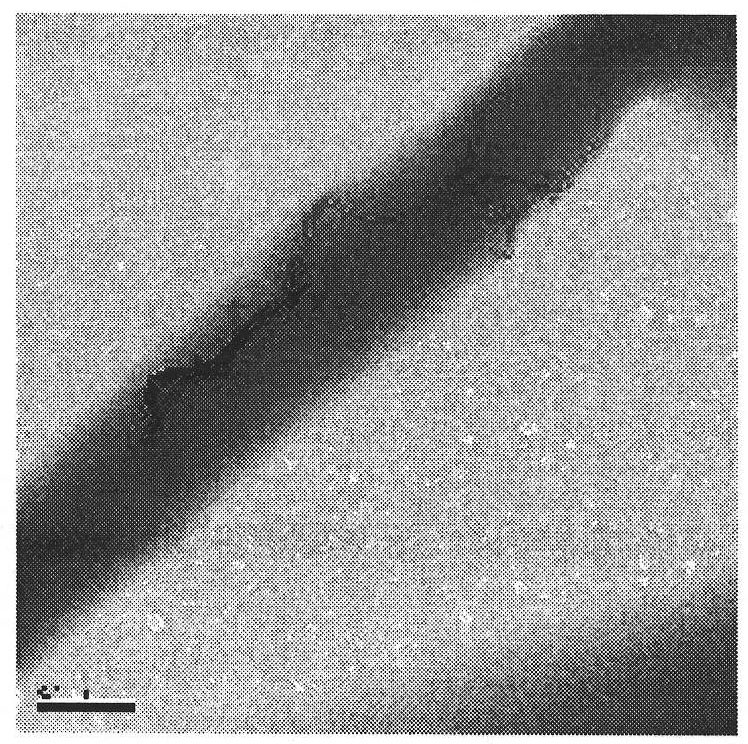

[0029] (1) Add 5 parts by mass of surface hydroxylated carbon nanotubes and 1 part by mass of sodium dodecylsulfonate to a sufficient amount of chloroform, ultrasonically disperse, and add 100 parts by mass after the carbon nanotubes are uniformly dispersed polylactic acid, then add chloroform and add dimethyl sulfoxide, configure ultrasonic dispersion again, and prepare a spinning solution with a concentration of 6.5wt%, wherein the mass ratio of chloroform to dimethyl sulfoxide is 3: 1.

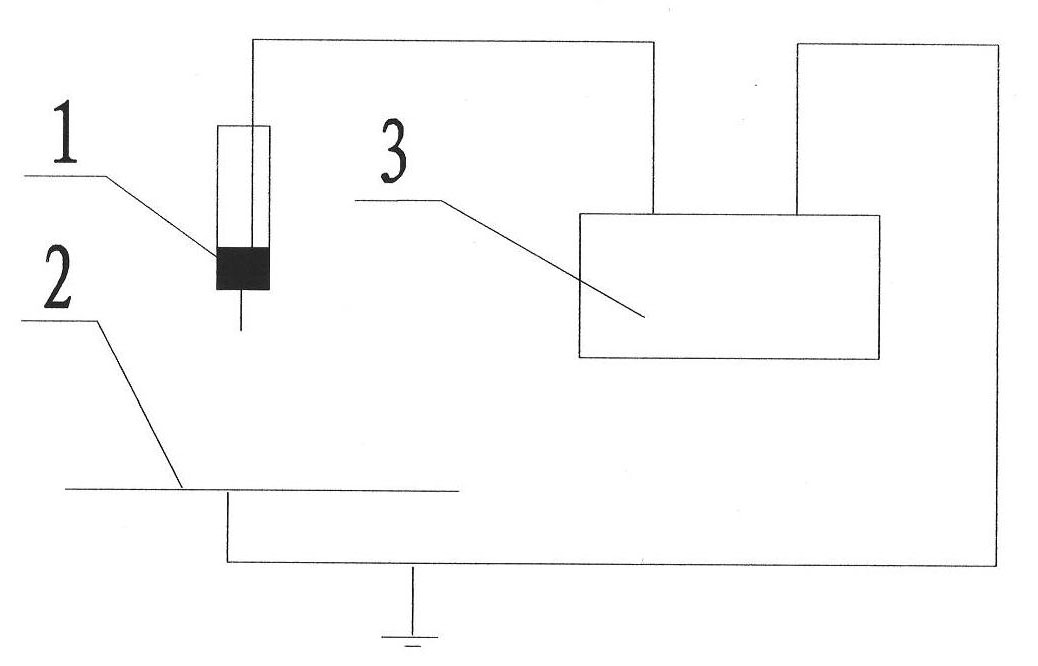

[0030] (2) Place the spinning solution prepared in step (1) in an electrospinning device, the distance between the spinneret and the receiving plate is 15cm, switch on the power supply and adjust the voltage to 20kV to start spinning, and obtain a biophase Compatible nano conductive fibers.

[0031] The mass ratio of the sum of the mass parts of chloroform and dimethyl sulfoxide to the sum of the mass parts of polylactic acid, carbon nanotubes and sodium dodecylsulfonate is 100:5-10.

[0...

Embodiment 2

[0035] (1) Add 10 parts by mass of surface hydroxylated carbon nanotubes and 1 part by mass of sodium dodecylsulfonate to a sufficient amount of chloroform, ultrasonically disperse, and add 100 parts by mass after the carbon nanotubes are uniformly dispersed polylactic acid, then add chloroform and add dimethyl sulfoxide, configure ultrasonic dispersion again, and prepare a spinning solution with a concentration of 6.5wt%, wherein the mass ratio of chloroform to dimethyl sulfoxide is 3: 1.

[0036] (2) Place the spinning solution prepared in step (1) in an electrospinning device, the distance between the spinneret and the receiving plate is 15cm, switch on the power supply and adjust the voltage to 20kV to start spinning, and obtain a biophase Compatible nano conductive fibers.

[0037]The mass ratio of the sum of the mass parts of chloroform and dimethyl sulfoxide to the sum of the mass parts of polylactic acid, carbon nanotubes and sodium dodecylsulfonate is 100:5-10.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com