Multifunctional cutting machine

A cutting machine, multi-functional technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of increased distance, reduced cutting efficiency, simple structure and insufficient functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

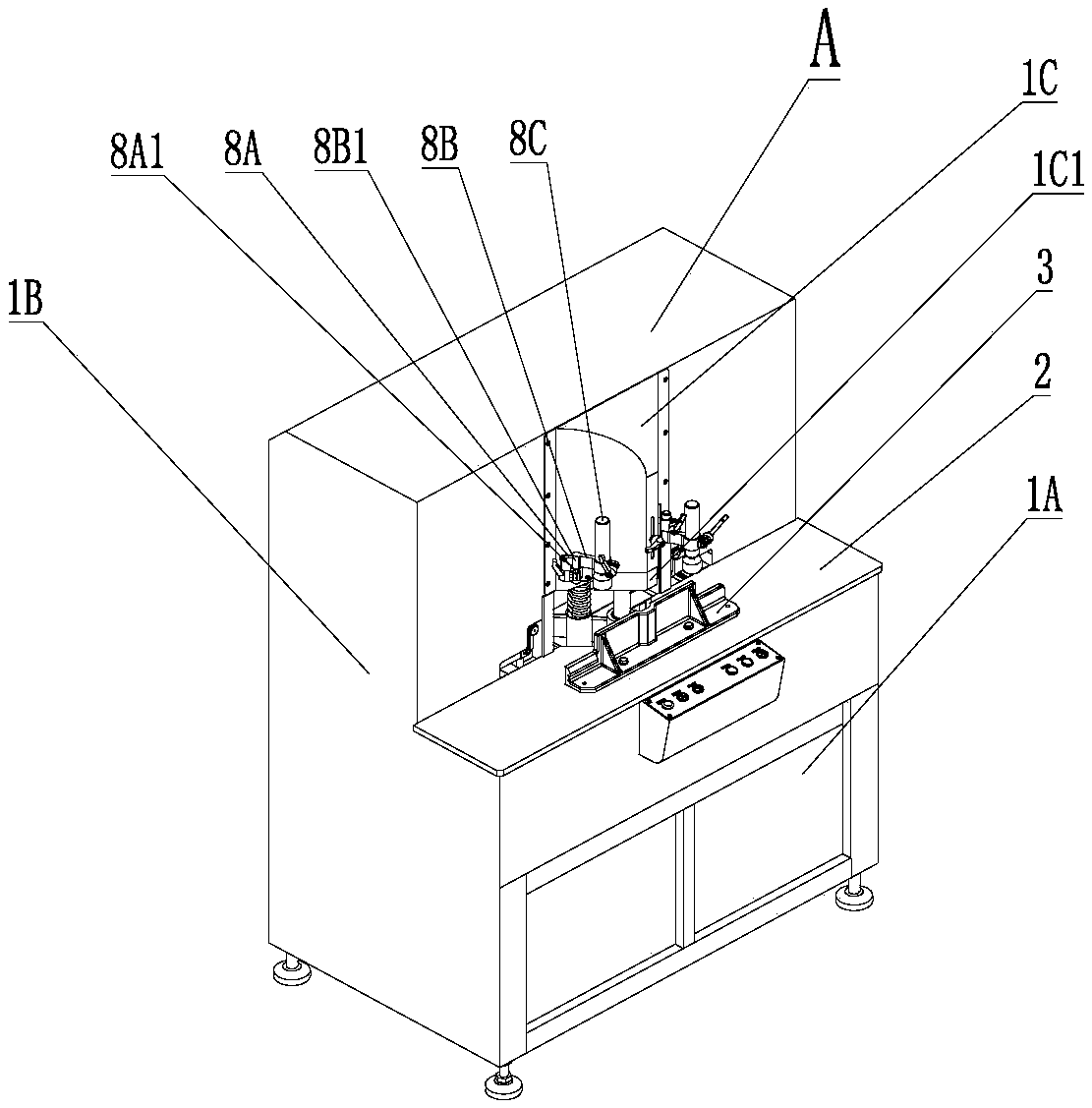

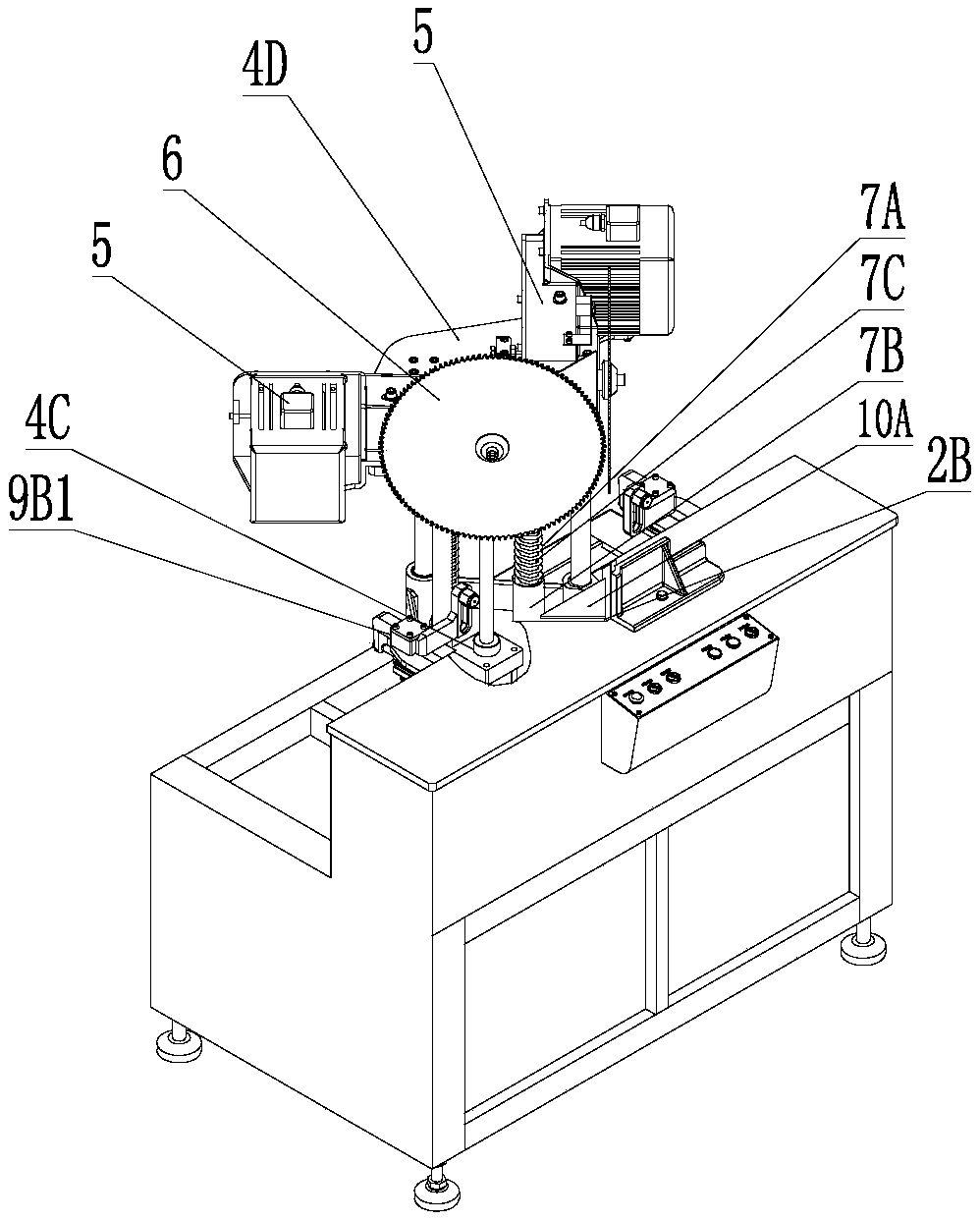

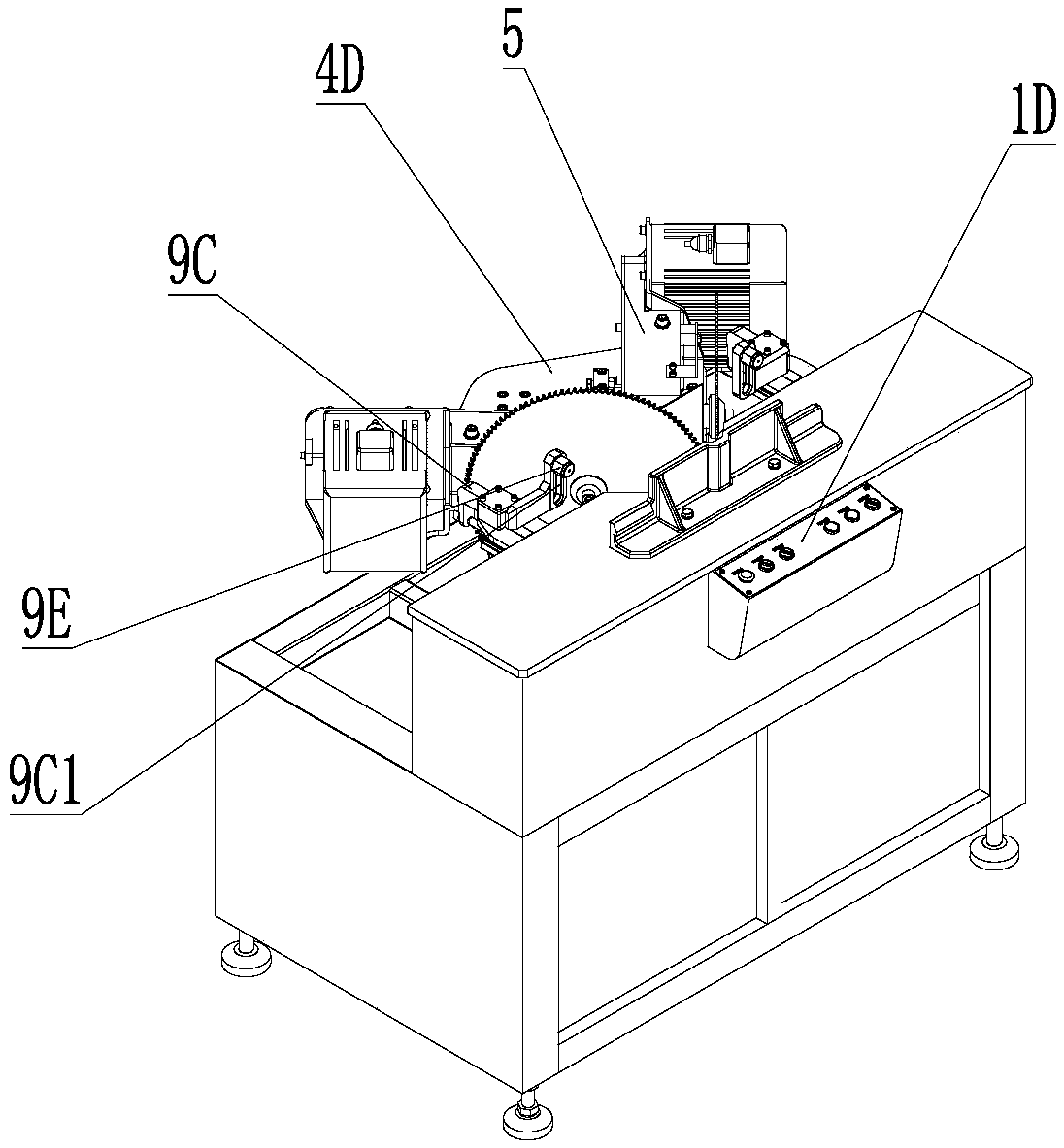

[0051] see figure 1 , figure 2 , image 3 , Figure 4 , Embodiment 1 is a cutting machine A with two power assemblies and two saw blades placed on a lifting mechanism, and simultaneously displays the shape of the whole machine, lifting mechanism, elastic device, swing vertical pressing device, horizontal pressing device, The remaining material falling delay device, the vertical section of the remaining material falling guide trough, the small lifting shield, etc. are placed on the front of the frame 1A. The front part of the cutting machine is removed from the coaming plate 1B, the shield 1C, and the small lifting shield 1C1 to show that the lifting guide seat 4A is vertically placed in the rear portion 1A1 of the workbench 2 frame with its guide post hole 4A1, and the lifting guide The column 4B is placed in the guide column hole 4A1 of the lifting guide seat, and the lifting plate 4D is connected to the upper part of the lifting guide column 4B. The cylinder 4C1 in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com