Melt-blown polypropylene material as well as preparation method and application thereof

A melt-blown polypropylene and polypropylene technology, applied in the field of melt-blown polypropylene materials and their preparation, can solve the problem that masks cannot block droplet bacteria aerogels, masks are difficult to fit on the wearer's face, and melt-blown nonwovens Cloth feels hard and other problems, to achieve the effect of improving air permeability, easy to fully stretch, and delicate hand feeling

Active Publication Date: 2020-08-18

JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

View PDF5 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, in the process of preparing melt-blown non-woven fabrics for the existing melt-blown polypropylene materials, due to the high requirements for the particle filtration efficiency of melt-blown non-woven fabrics (the BFE of disposable medical surgical masks is required in the YY0469-2011 standard up to 95%), while satisfying the requirements of high-efficiency melt-blown non-woven fabrics, there are melt-blown non-woven fabrics that feel hard, and the cloth surface is hard and brittle, which will cause the mask prepared by it to wear. The cloth surface is broken and the mask is difficult to fit the wearer's face effectively

Moreover, for women and children, due to their small face area, this problem will be more severe, which will directly lead to the inability of masks to block droplets, bacteria, aerogels, etc. during use, threatening People's life and health during the epidemic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

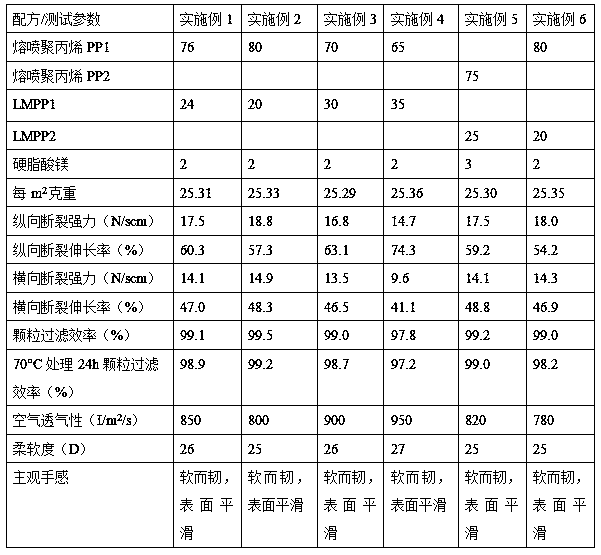

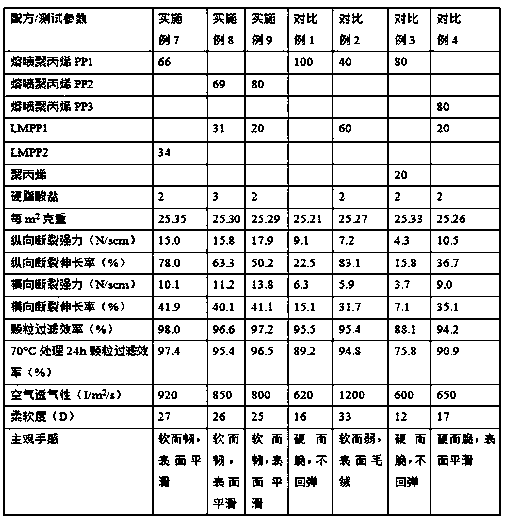

Embodiment and comparative example

[0043] According to the ratio in Table 1, after weighing each component in proportion, mix each component uniformly through a high-speed mixer, and then melt and extrude through a twin-screw extruder at 160~180°C, granulate, and dry Obtain melt-blown polypropylene material;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a melt-blown polypropylene material as well as a preparation method and application thereof. The melt-blown polypropylene material is prepared from the following components inparts by weight: 65-80 parts of melt-blown polypropylene, 20-35 parts of low-isotacticity polypropylene and 2-3 parts of stearate. According to the invention, low isotacticity polypropylene LMPP and melt-blown polypropylene are blended; the hand feeling of the melt-blown non-woven fabric can be effectively improved; the prepared melt-blown non-woven fabric has the advantages of being soft in handfeeling, high in strength, high in toughness and the like; meanwhile, the particle filtering efficiency and air permeability of the melt-blown non-woven fabric can be improved, and the material has wide application prospects in preparation of high-filtering and low-resistance female / child masks which are required to be perfectly attached to the face.

Description

technical field [0001] The invention belongs to the field of polymer materials, and in particular relates to a melt-blown polypropylene material and a preparation method and application thereof. Background technique [0002] Melt-blown non-woven fabric is the key filter material in disposable medical surgical masks, medical N95 masks and other products, while melt-blown non-woven fabrics mainly use polypropylene as raw material, after feeding-melt extrusion-fiber formation-fiber cooling- It is prepared by processes such as netting-reinforcement into cloth. The diameter of the fibers formed by melt-blown can reach 1-5 microns, with many voids, fluffy structure, and good wrinkle resistance. These ultra-fine fibers with unique capillary structure increase the number and surface area of fibers per unit area, thus making melt-blown nonwovens Cloth has excellent filterability, shielding, heat insulation and oil absorption. It can be used in air and liquid filter materials, iso...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/12C08L27/18C08K13/06C08K9/12C08K3/08C08K3/22C08K3/36C08J3/22D04H1/56B01D39/08B01D46/00

CPCB01D39/083B01D46/0001B01D46/0028C08J3/226C08J2323/12C08J2423/12C08K2003/0806C08K2003/2296C08K2201/003C08K2201/011C08L23/12C08L2205/025C08L2205/03D04H1/56C08L27/18C08K13/06C08K9/12C08K3/08C08K3/36C08K3/22

Inventor 丁明笃杨友强刘乐文杨霄云付大炯陈平绪叶南飚王爱东简思强尹朝清程文建

Owner JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com