Method for anaerobic-aerobiotic-microbial flocculation reinforced wastewater treatment

A technology of microbial flocculation and microbial flocculant, which is applied in the field of anaerobic-aerobic-biological flocculation enhanced treatment of wastewater, can solve problems such as difficult removal, insufficient carbon source, obstacles to wastewater treatment and resource utilization, etc., to achieve reduction of chroma and Effects of turbidity and improvement of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

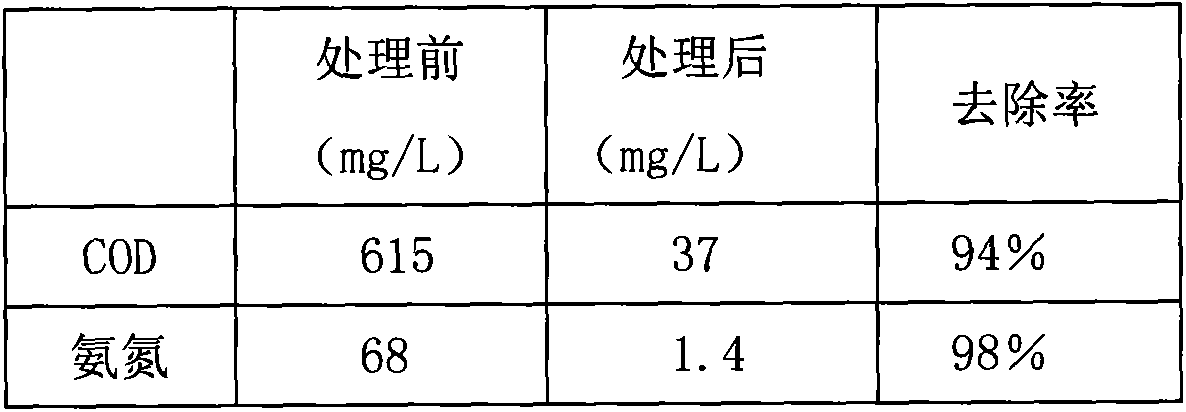

Embodiment 1

[0034] 1) The simulated wastewater to be treated in the laboratory first enters the regulating tank, and the aeration pipe is set to pre-aerate the wastewater to be treated, and the aeration intensity is 160m 3 / (h·m 3 ), using the pipe-through aeration method, each aeration pipe is composed of 3 groups of 45° air holes, so that the wastewater to be treated can be mixed evenly and its pH value can be adjusted to 6-8;

[0035] 2) Pass the wastewater treated in the regulating tank through the grid device to remove larger floating objects and impurities in the wastewater;

[0036] 3) Pump the effluent from 2) into the quick mixing tank, add flocculant PAC to the quick mixing tank for flocculation pre-sedimentation to effectively remove suspended solids and colloidal substances in the raw water, the optimal dosage of flocculant PAC is 180mg / L, stir rapidly at a speed of 220r / min for 5min, then stir slowly at a speed of 80r / min for 15min, then stop stirring and let it stand for 3...

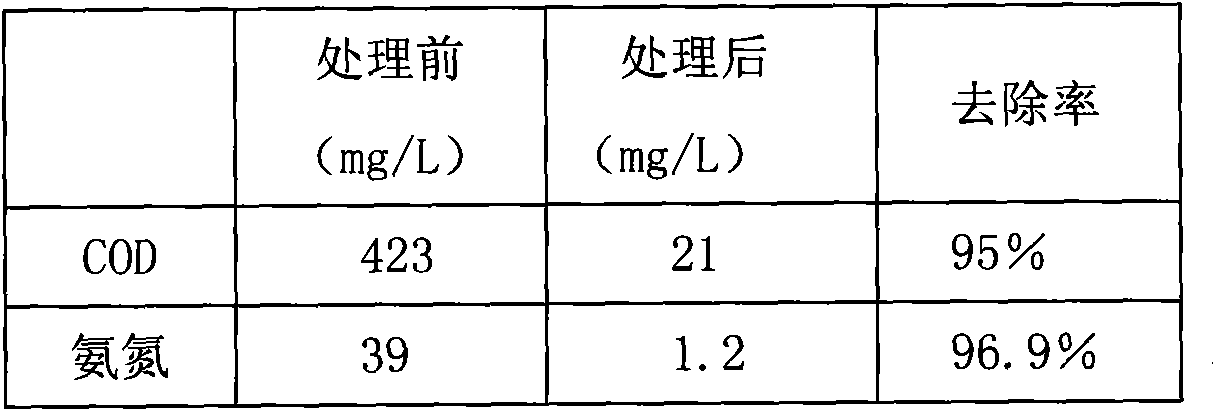

Embodiment 2

[0044]1) The simulated wastewater to be treated in the laboratory first enters the regulating tank, and the aeration pipe is set to pre-aerate the wastewater to be treated, and the aeration intensity is 165m 3 / (h·m 3 ), using the pipe-through aeration method, each aeration pipe is composed of 3 groups of 45° air holes, so that the wastewater to be treated can be mixed evenly and its pH value can be adjusted to 6-8;

[0045] 2) Pass the wastewater treated in the regulating tank through the grid device to remove larger floating objects and impurities in the wastewater;

[0046] 3) Pump the effluent from 2) into the quick-mixing tank, and add flocculant PAC to the quick-mixing tank for flocculation pre-sedimentation to effectively remove suspended solids and colloidal substances in the raw water. The optimal dosage of flocculant PAC is 185mg / L, stir rapidly at a speed of 220r / min for 5min, then stir slowly at a speed of 80r / min for 15min, then stop stirring and let it stand fo...

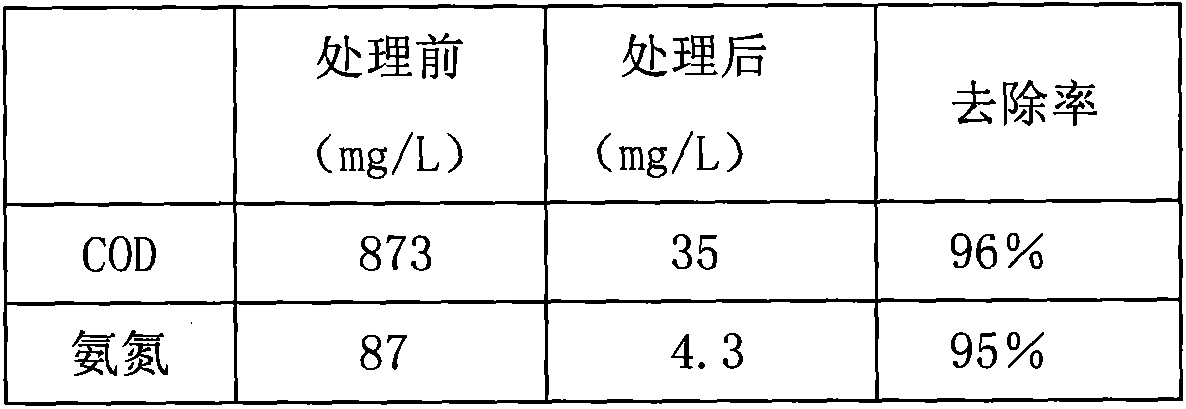

Embodiment 3

[0054] 1) The wastewater to be treated first enters the regulating tank, and the aeration pipe is set to pre-aerate the wastewater to be treated, and the aeration intensity is 170m 3 / (h·m 3 ), using the pipe-through aeration method, each aeration pipe is composed of 3 groups of 45° air holes, so that the wastewater to be treated can be mixed evenly and its pH value can be adjusted to 6-8;

[0055] 2) Pass the wastewater treated in the regulating tank through the grid device to remove larger floating objects and impurities in the wastewater;

[0056] 3) Pump the effluent from 2) into the quick mixing tank, and add flocculant PAC to the quick mixing tank for flocculation pre-sedimentation to effectively remove suspended solids and colloidal substances in the raw water. The optimal dosage of flocculant PAC is 190mg / L, stir rapidly at a speed of 220r / min for 5min, then stir slowly at a speed of 80r / min for 15min, then stop stirring and let it stand for 30min, discharge the floc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com