Manufacture method for colored soft contact lenses

A soft contact lens and a production method technology, which can be applied to other household appliances, optical components, household appliances, etc., can solve the problems of lens power deterioration, oxide layer generation, unclearness, etc., so as to improve hydrophilicity and wear Safe and comfortable, preventing dry eyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] Example 2: Preparation of lens outer layer monomer (thermosetting)

[0044]

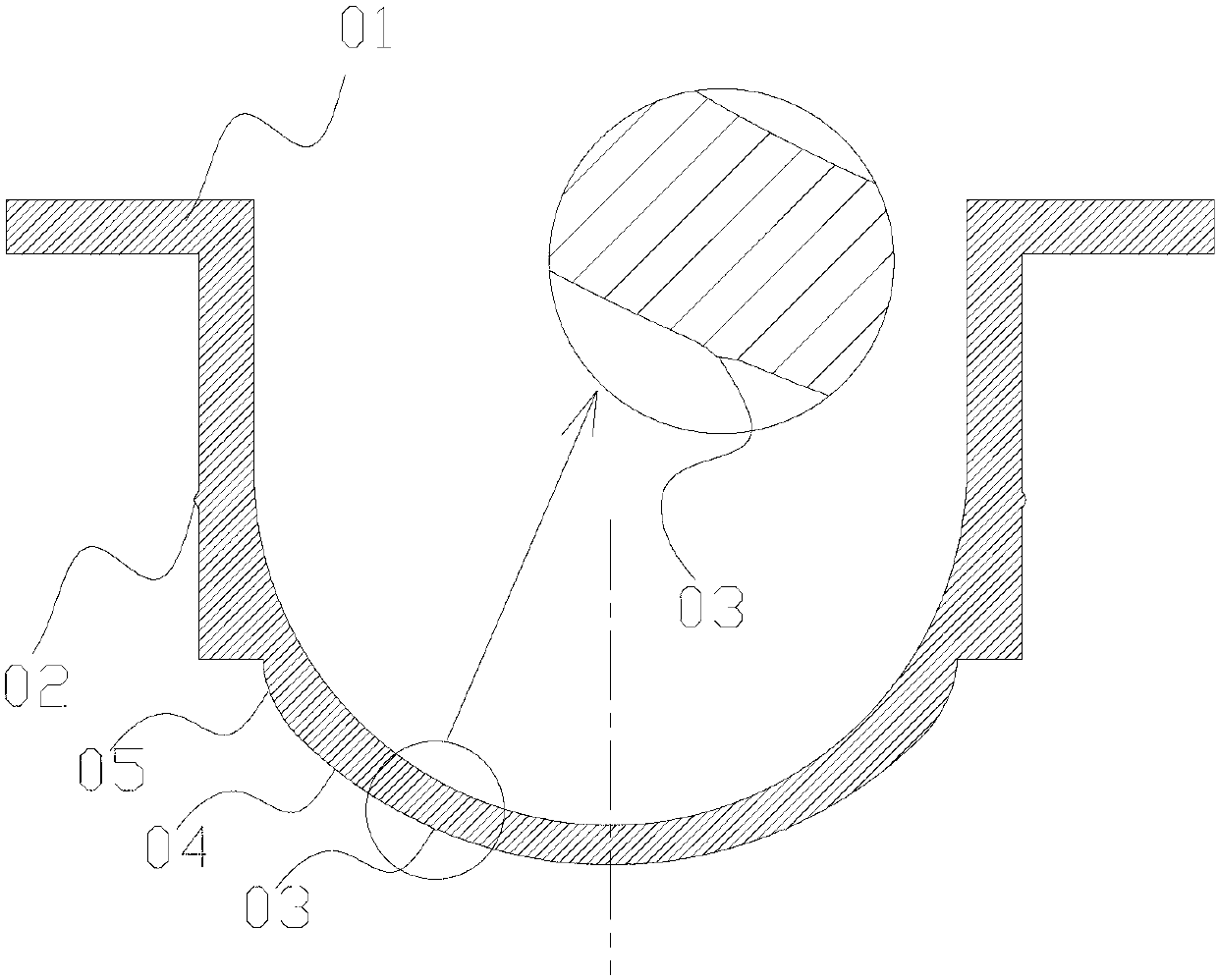

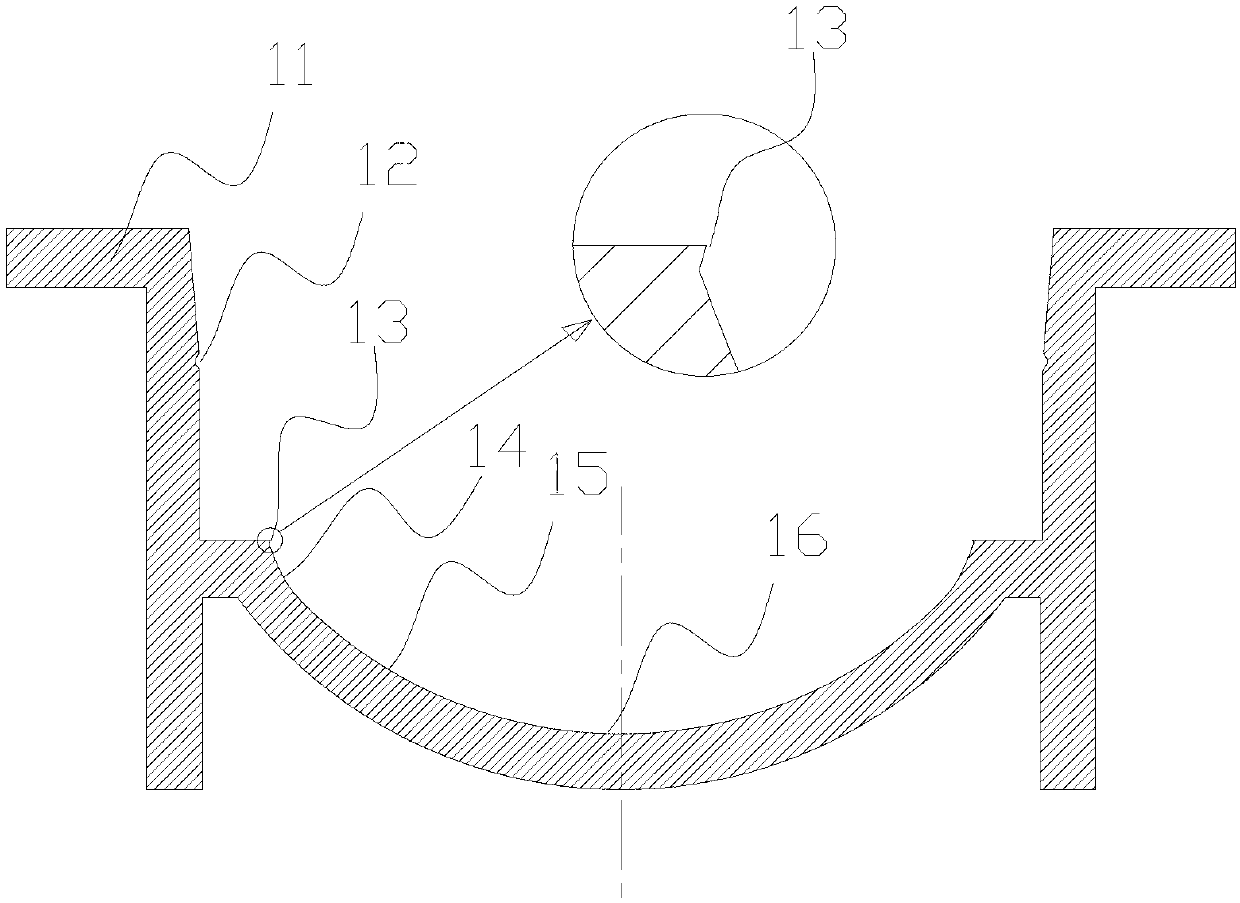

[0045] 3), the production of lens color layer: by Figure 5 As we know, use the pad printing method to transfer the ink on the steel plate pattern to the lower mold 11 with the outer layer material with a silicone head ( image 3 ), the pad printing range is above the outer layer 17 of the non-optical zone of the lens. Afterwards, the ink layer 19 is polymerized and cured by room temperature curing, light curing or thermal curing.

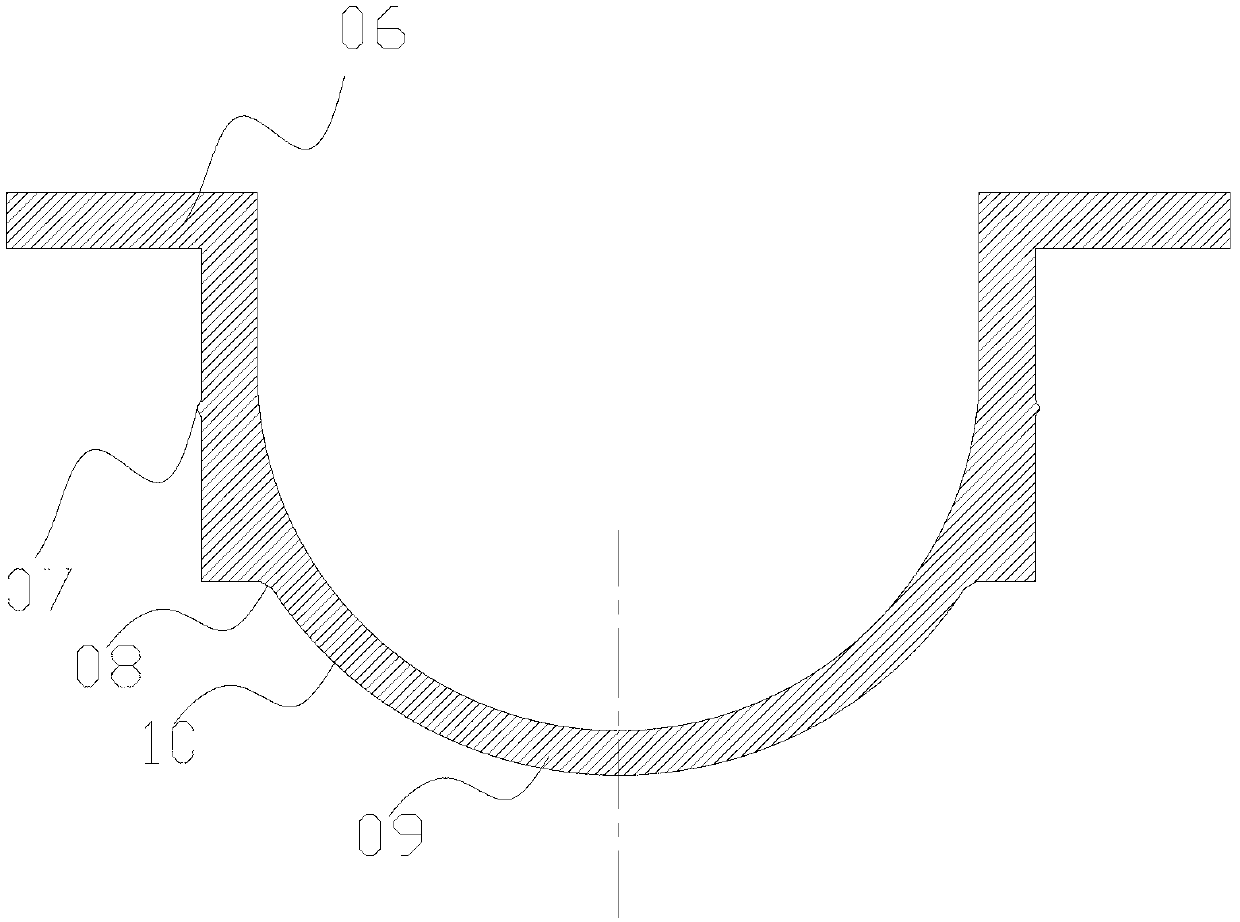

[0046] 4) The production of the inner surface layer of the lens: by Figure 6 , Figure 7 , Figure 8 It is known that the outer layer 17 with the lens non-optical zone ( Figure 5 ) and ink layer 19 ( Figure 5 ) into the lower mold 11 of the lens inner surface material 20, and cover it with the upper mold II06, that is, the upper mold II06 and the lower mold 11 cooperate, and the curved surface III08 of the upper mold II06 ( figure 2 ) and the male ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com