Patents

Literature

44results about How to "Fully bent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

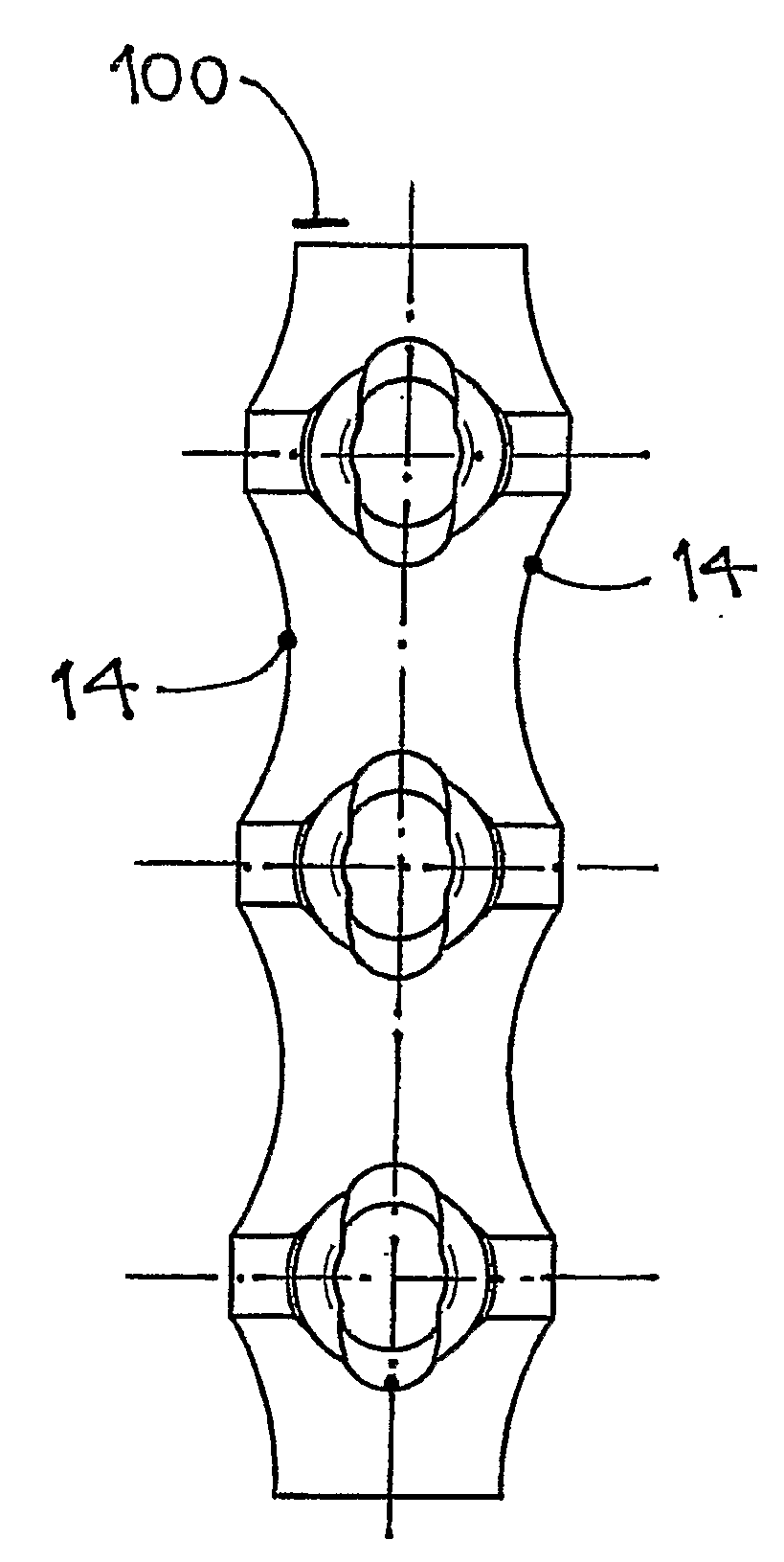

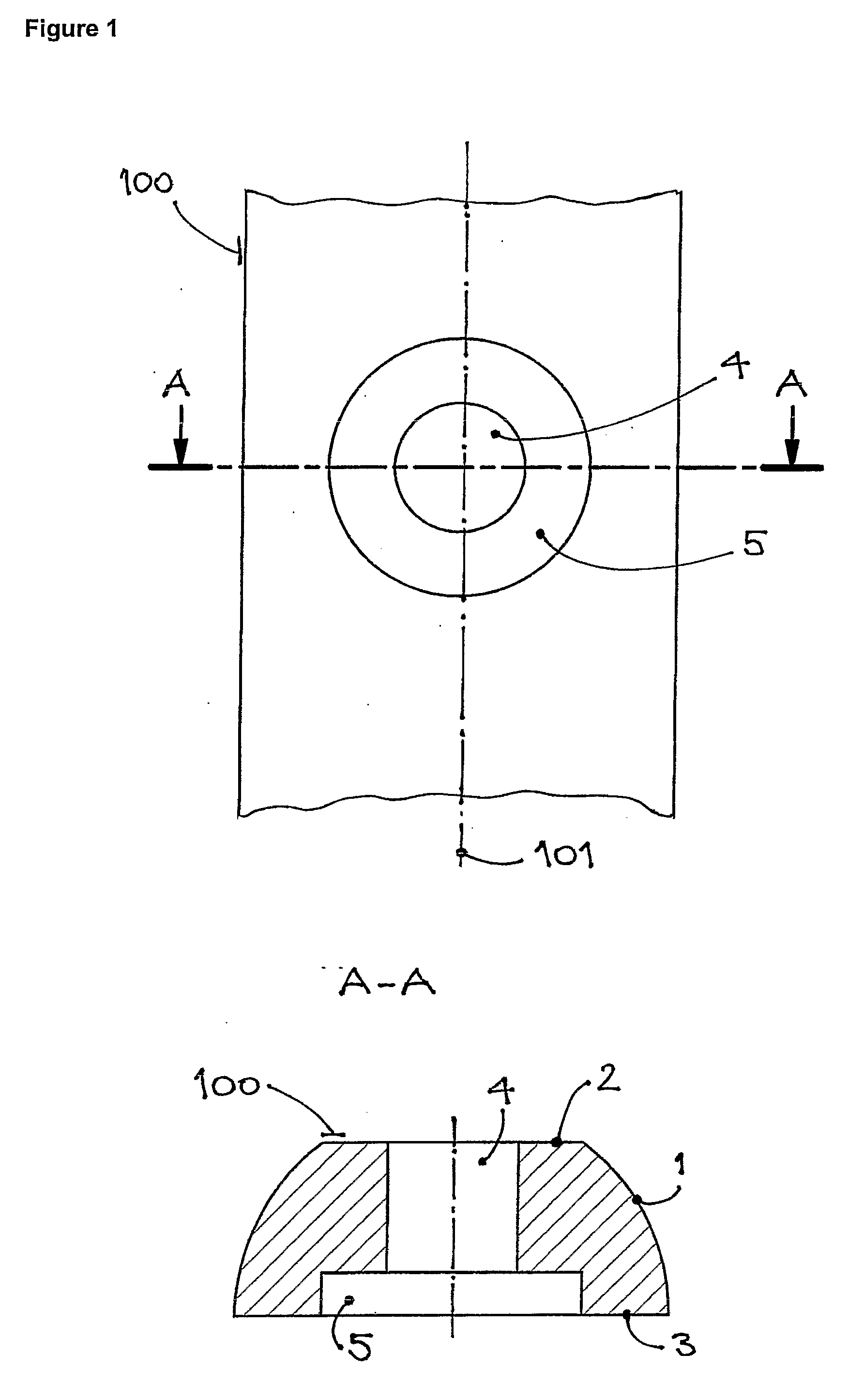

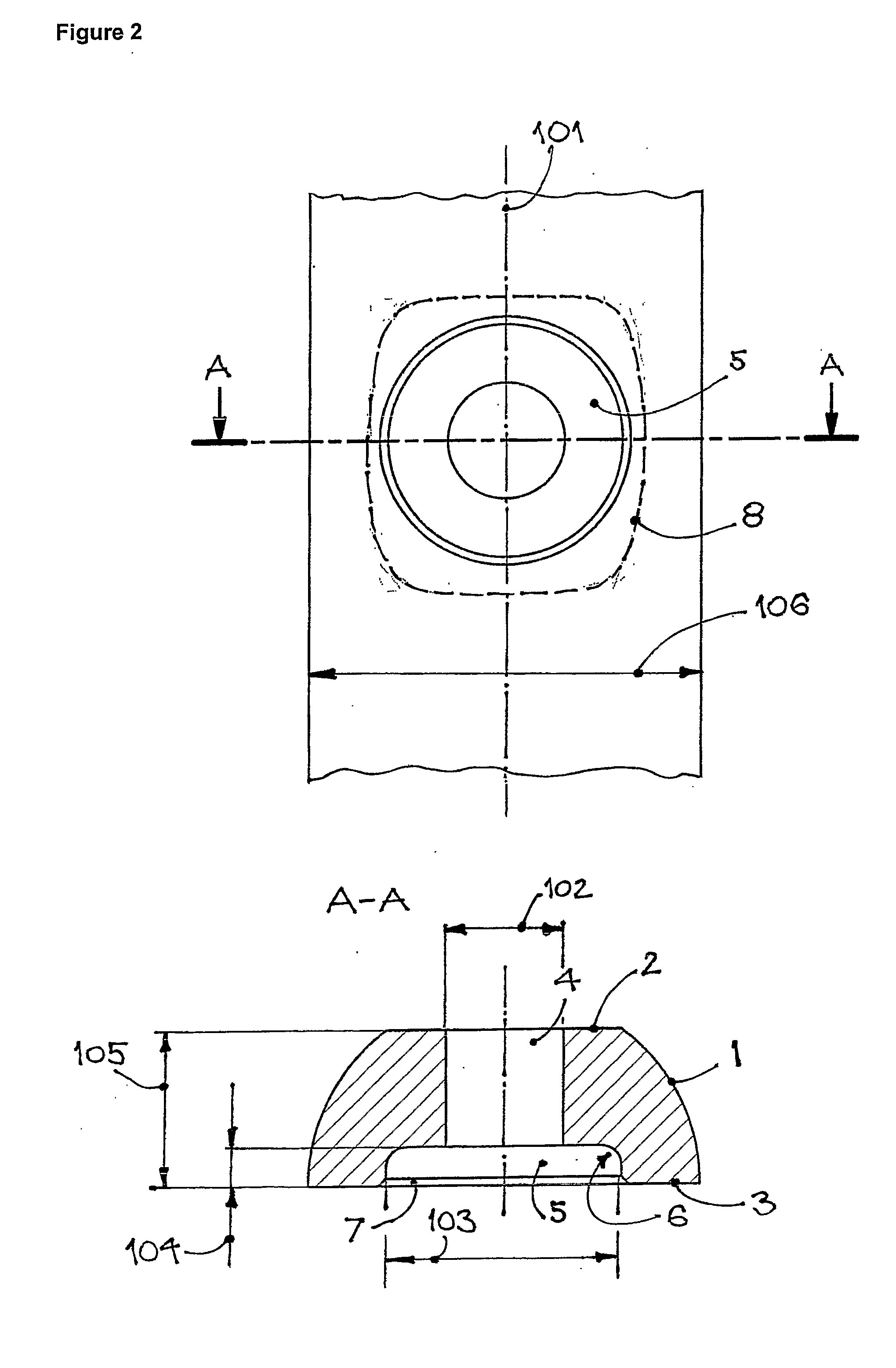

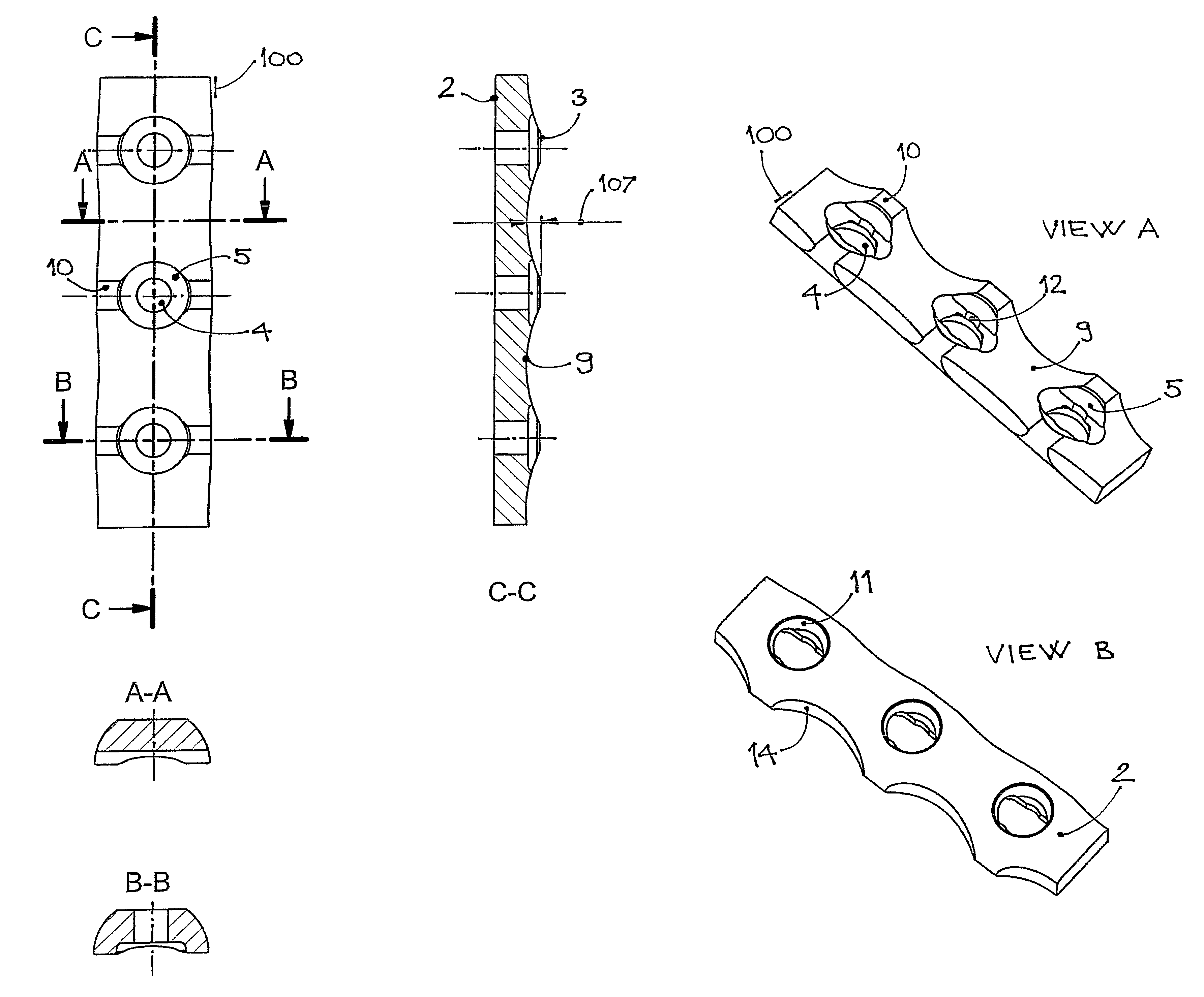

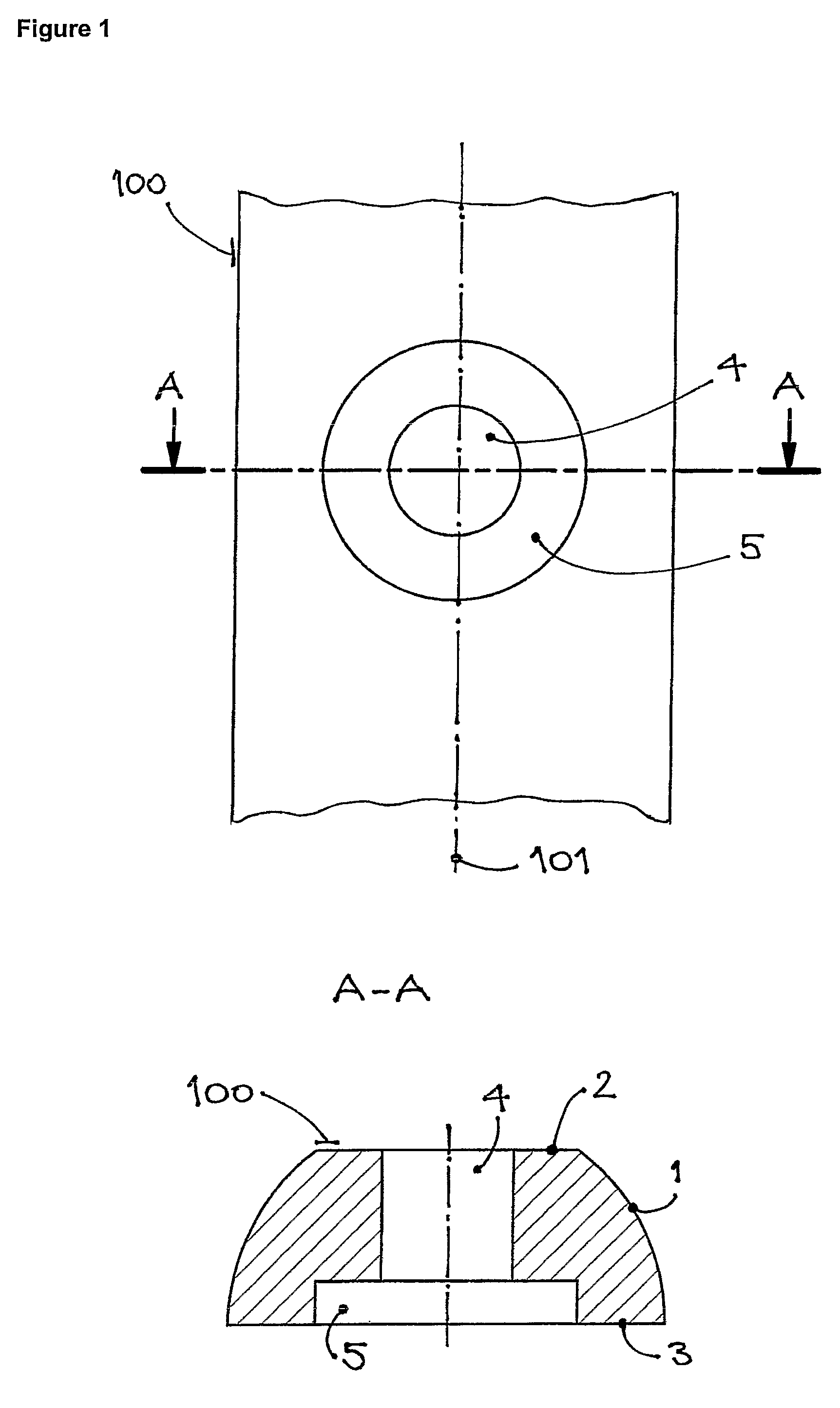

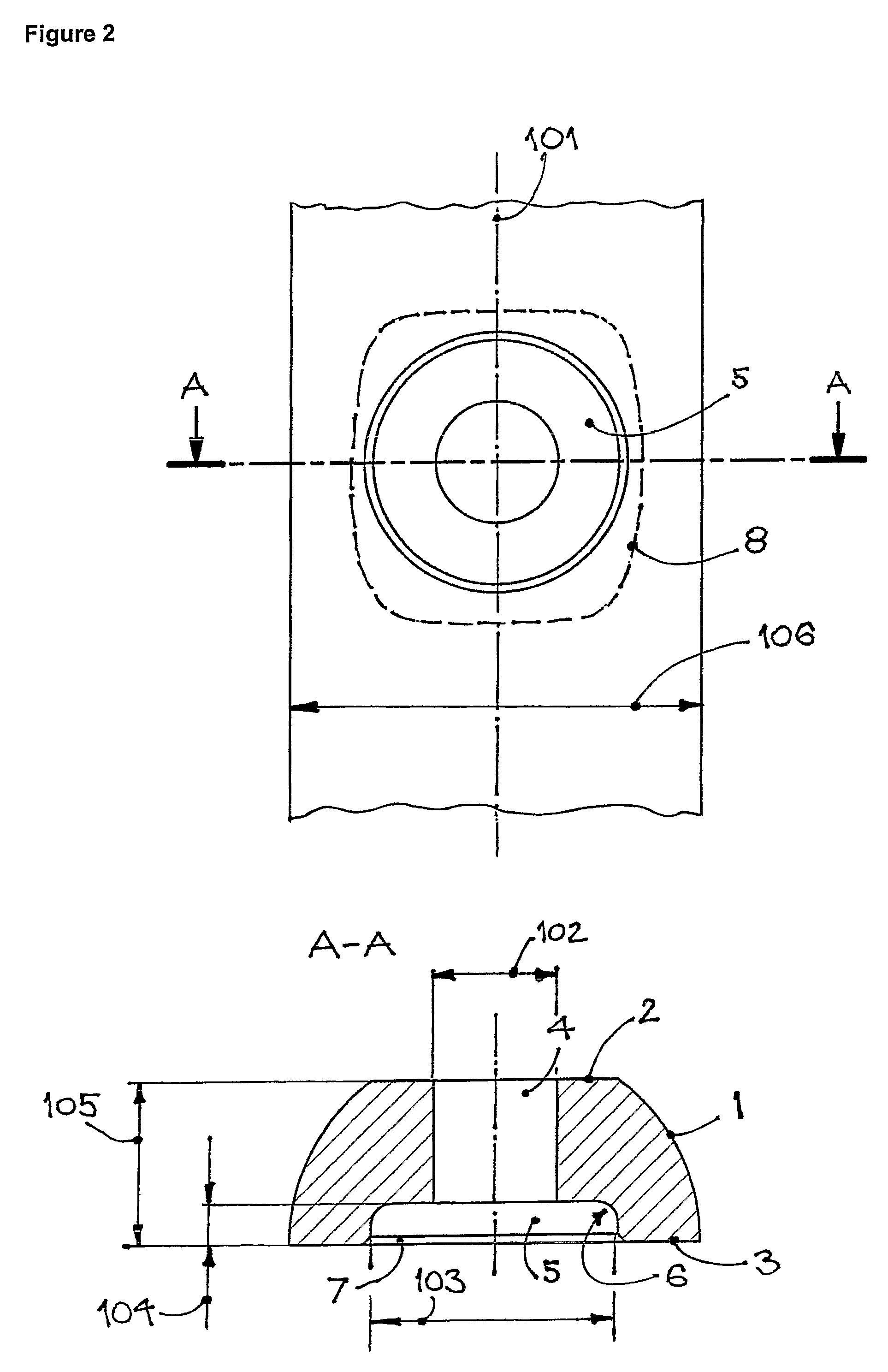

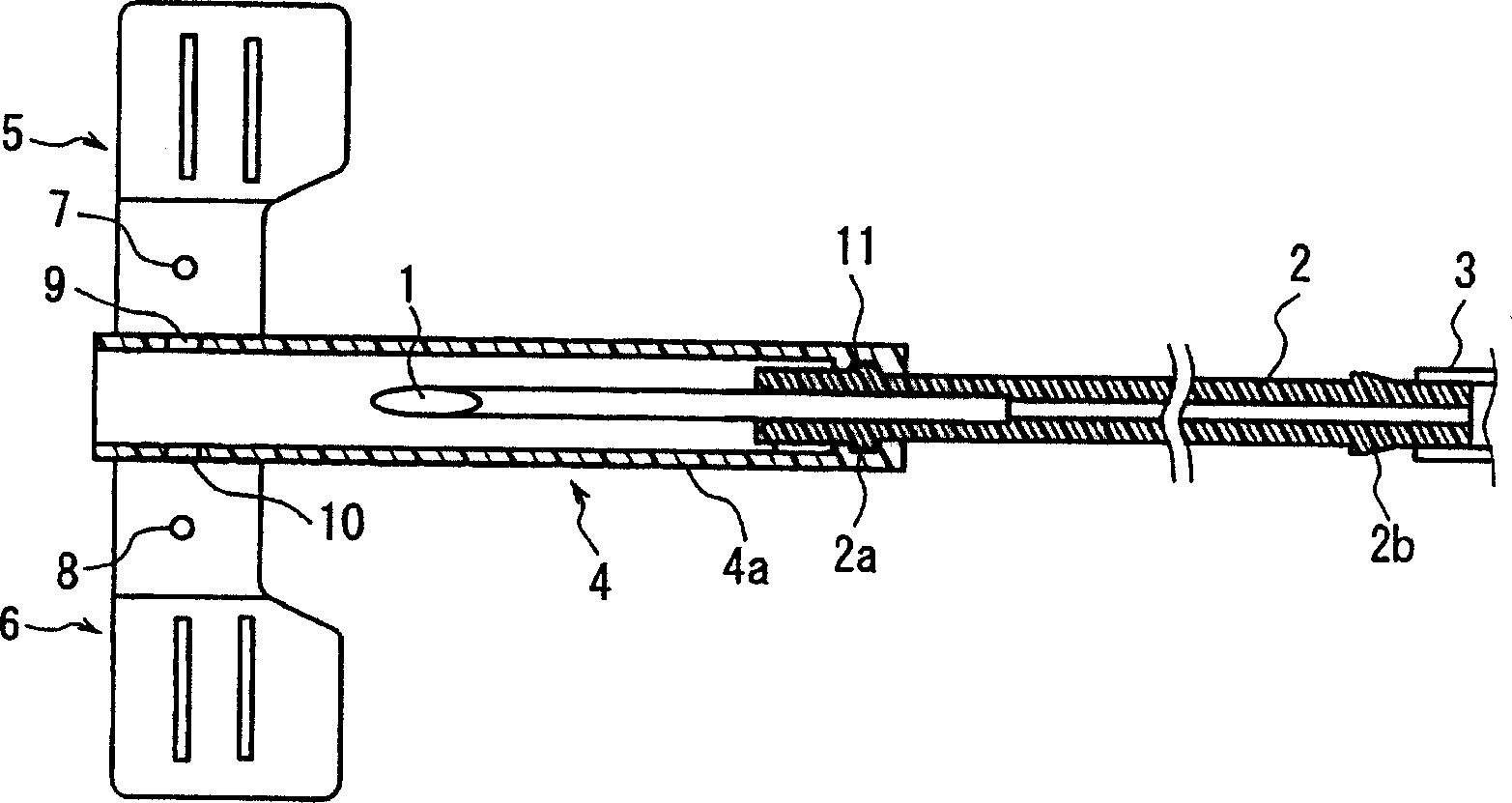

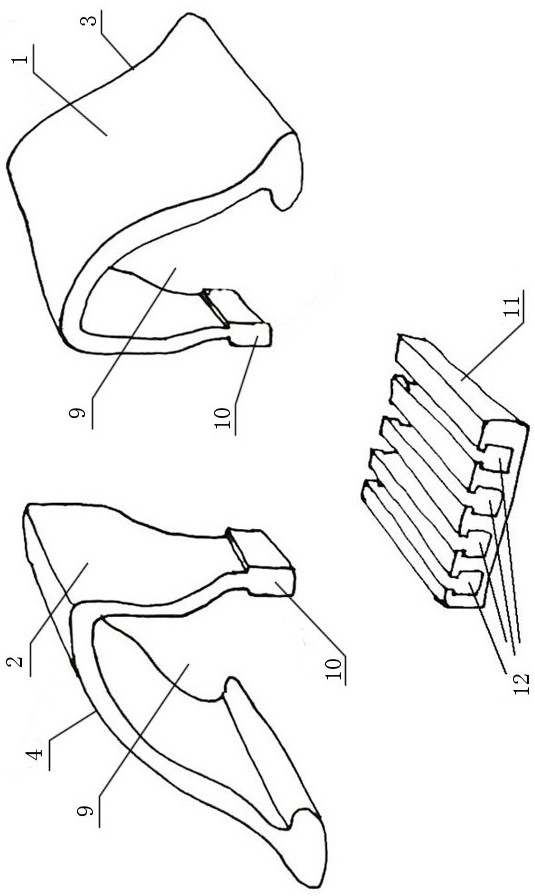

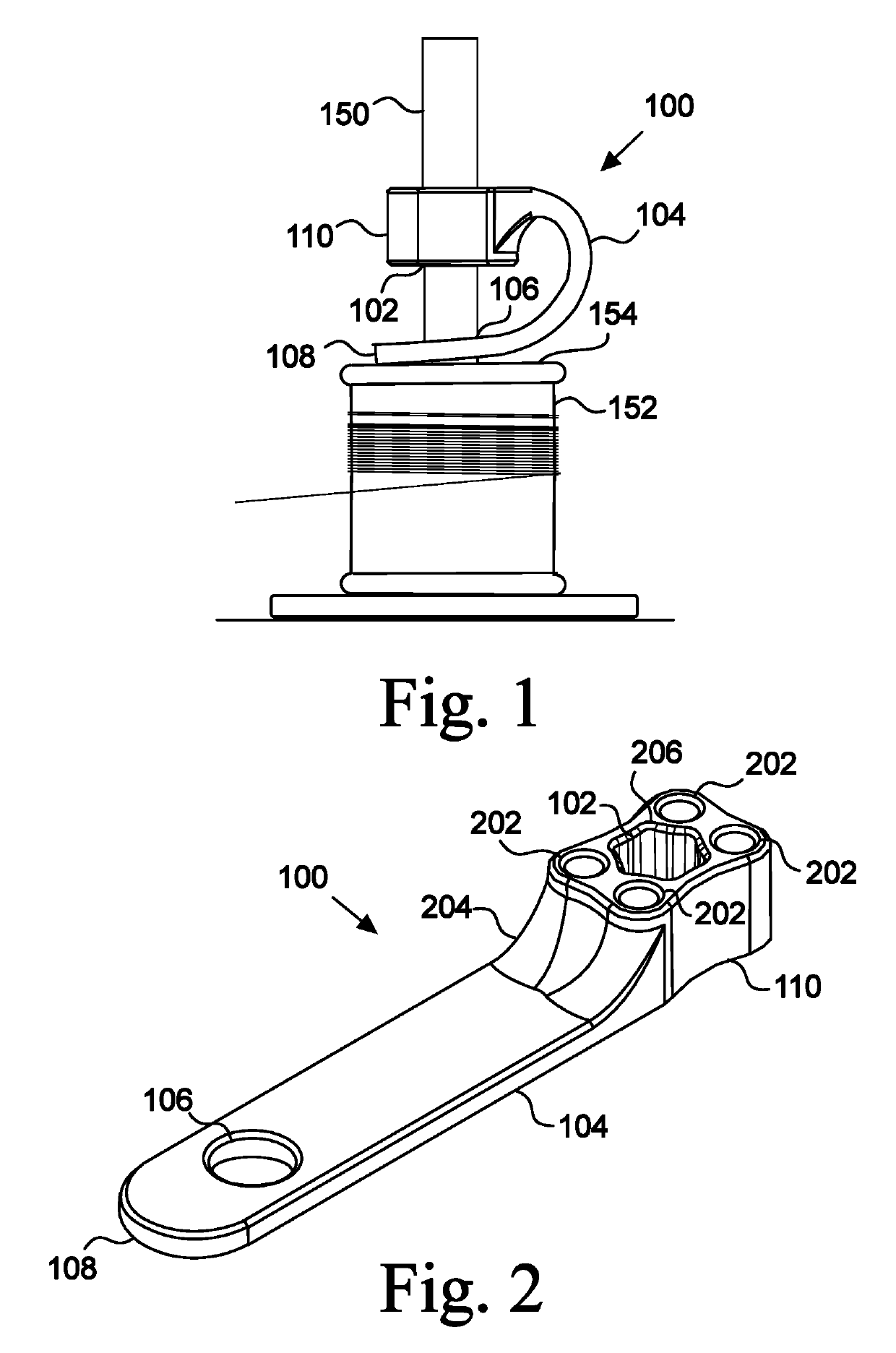

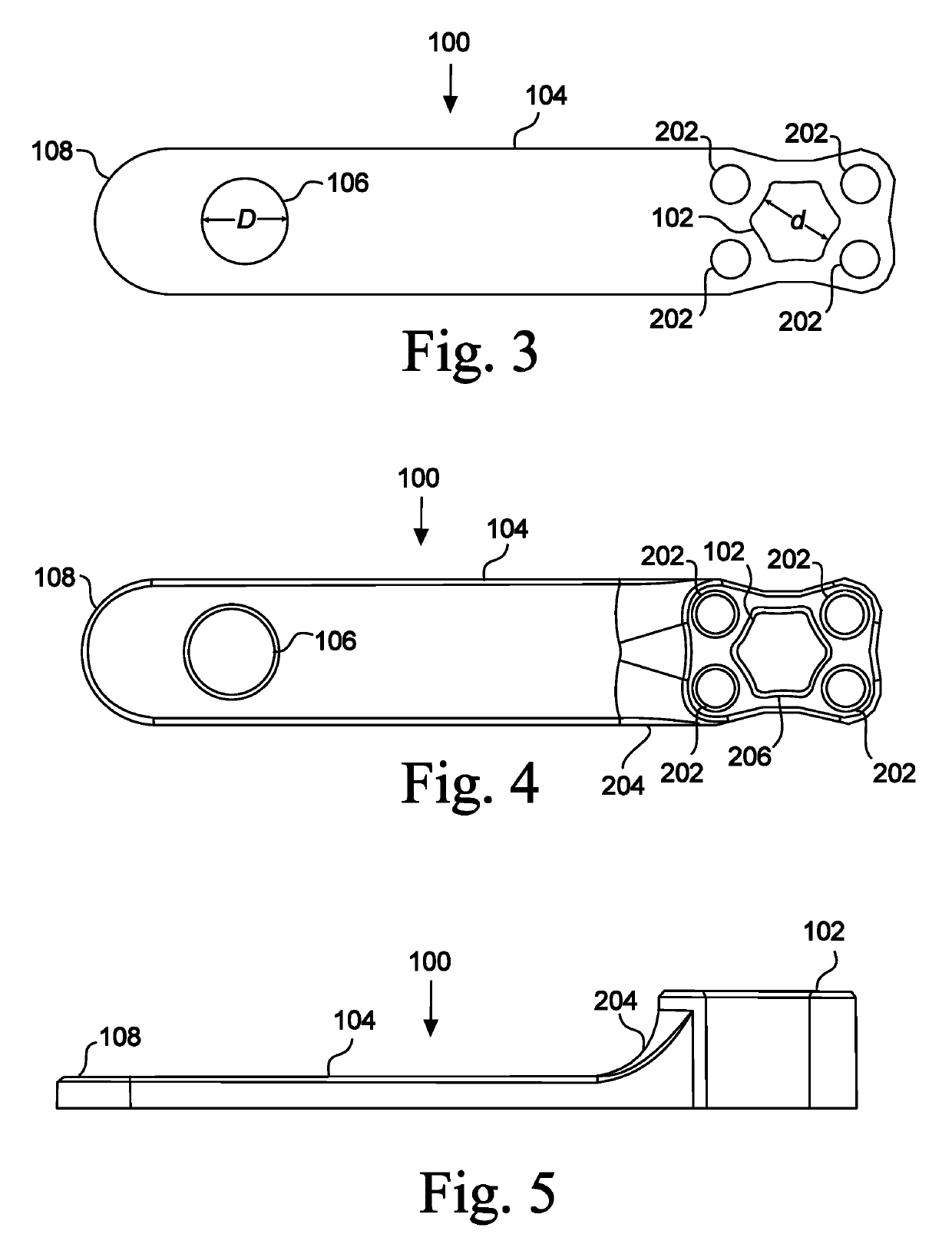

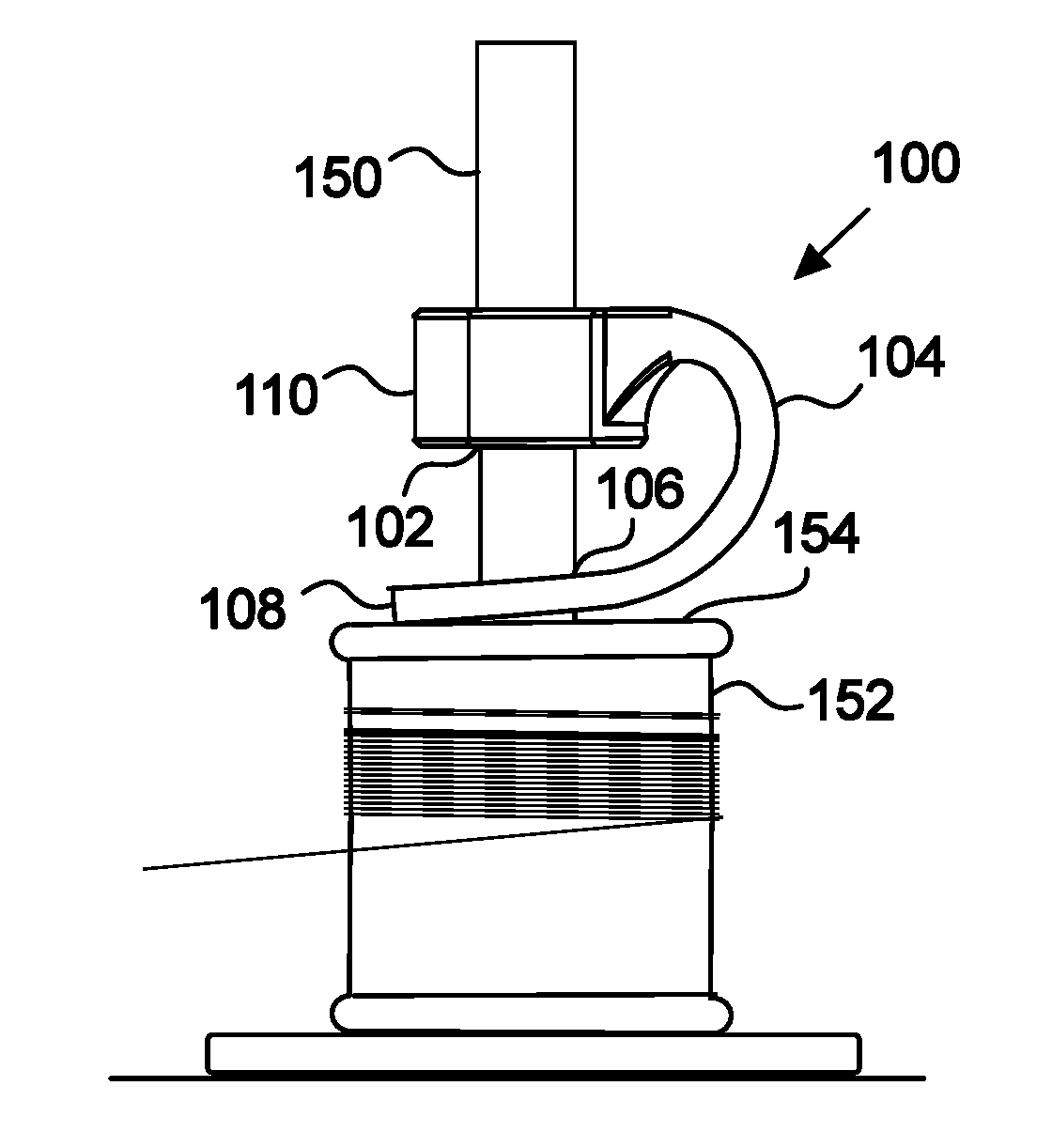

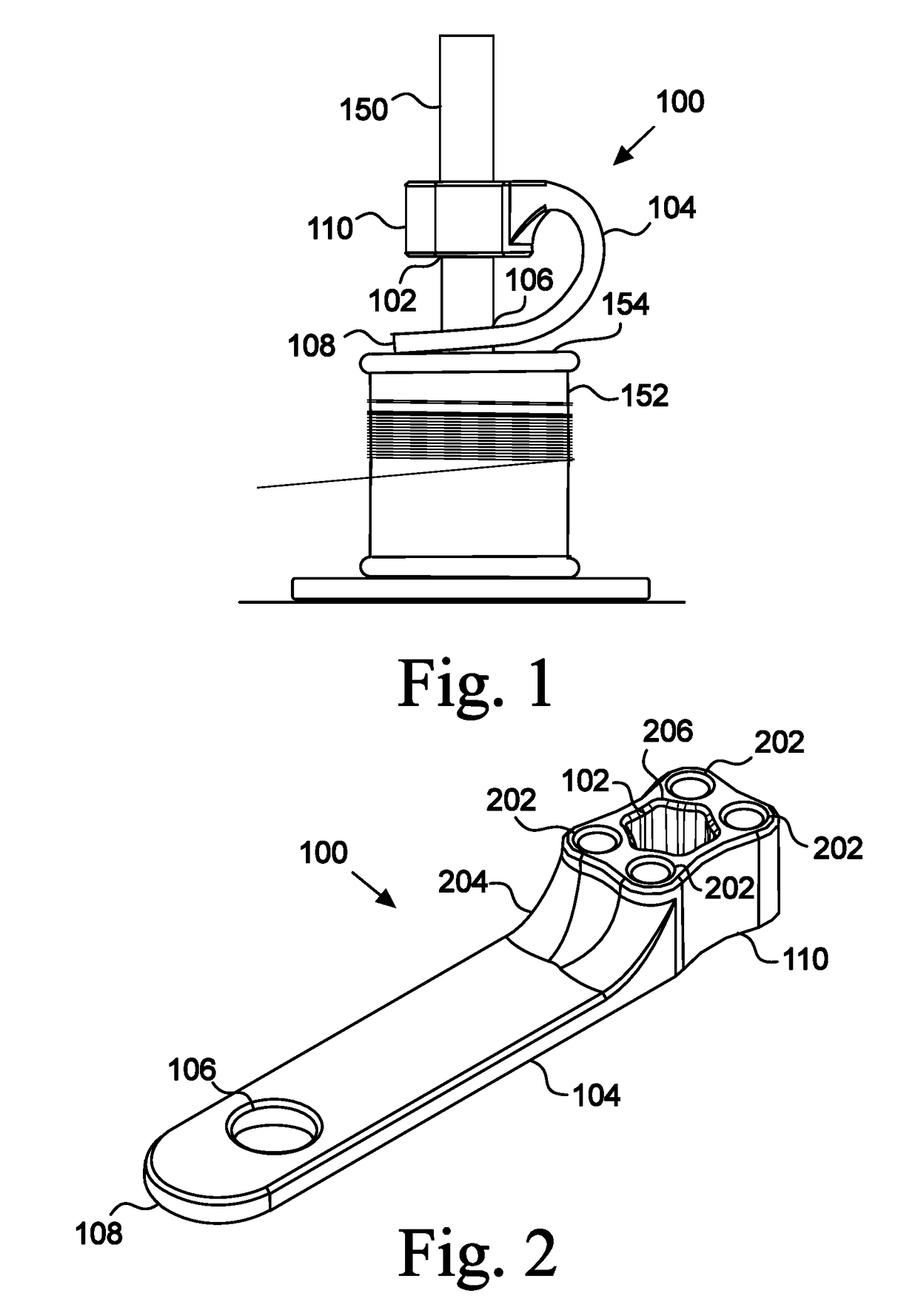

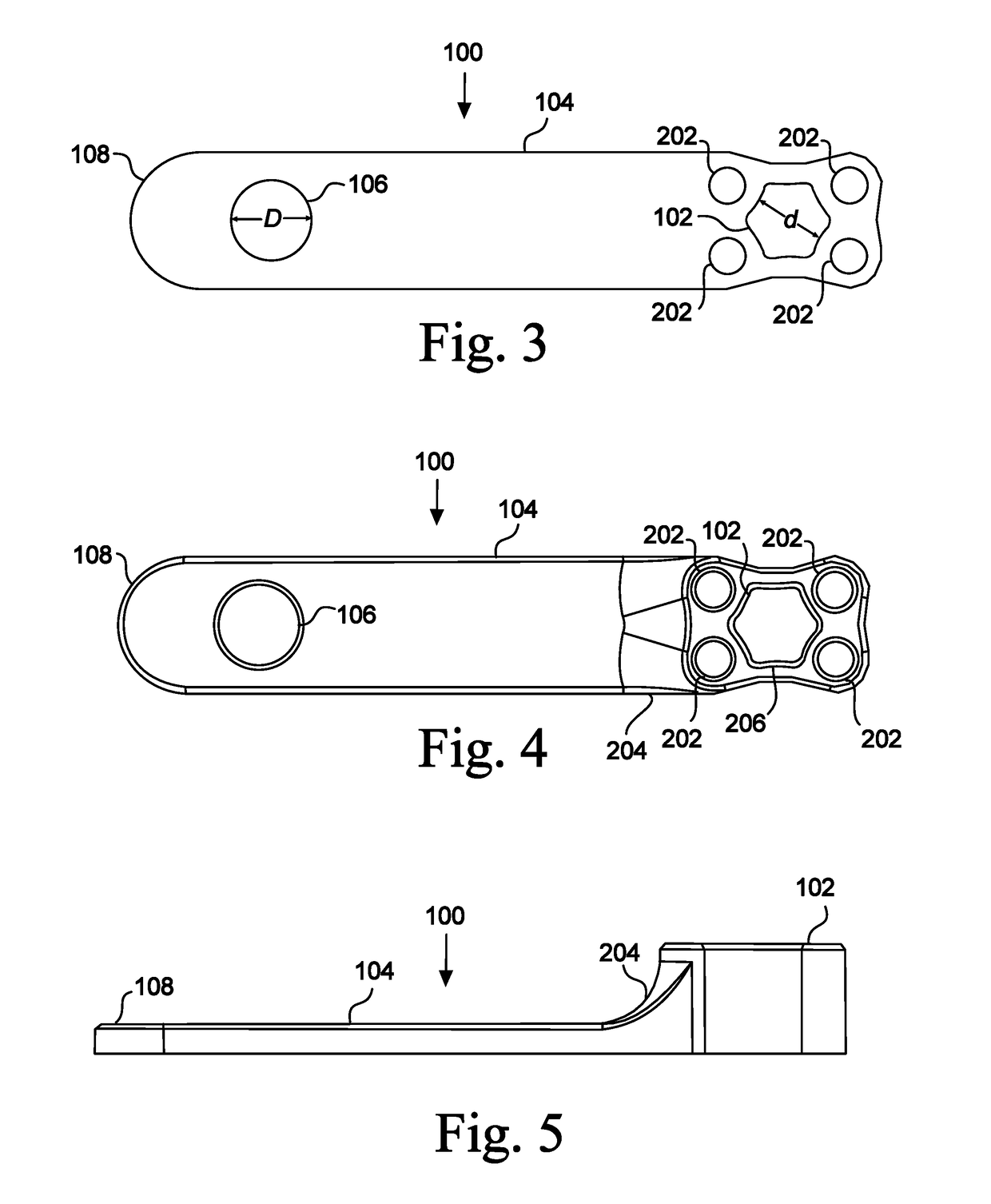

Plate and Screws for Treatment of Bone Fractures

ActiveUS20080200955A1Eliminate potential contactRelieve pressureSuture equipmentsLigamentsTransverse grooveEngineering

A plate for treatment of bone fractures with reduced potential contact to bone through a combination of annular recesses surrounding the screw holes at the lower, bone facing surface of the plate and transverse grooves between the holes, allows for use of locking as well as conventional bone screws. With the transverse grooves cut into the plate from the lower side, as well as from the sides, the strength of the plate at the span between the holes is lower than at the screw holes. The plate can be bent in both planes without undue deformation of the screw holes. Protection of the holes during bending is afforded by hole plugs, which may be provided pre-installed in order to reduce surgery time. Screw hole plugs may then be left in place in the holes not used for bone screws.

Owner:KYON

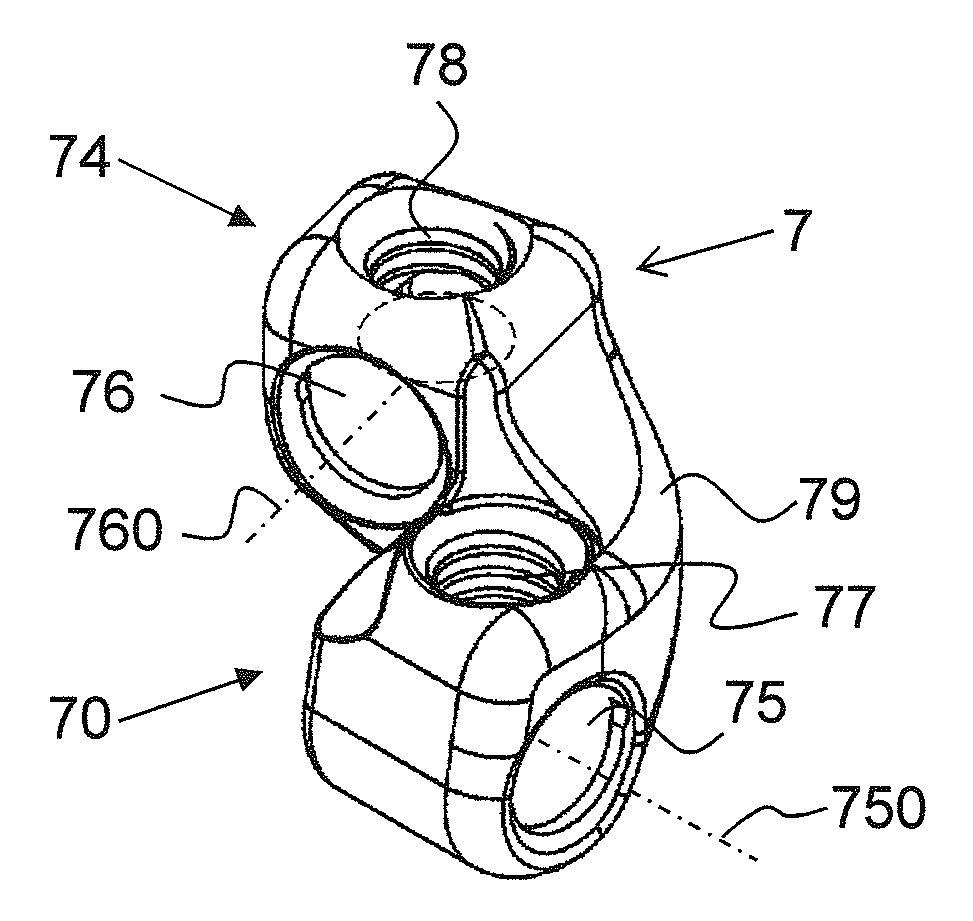

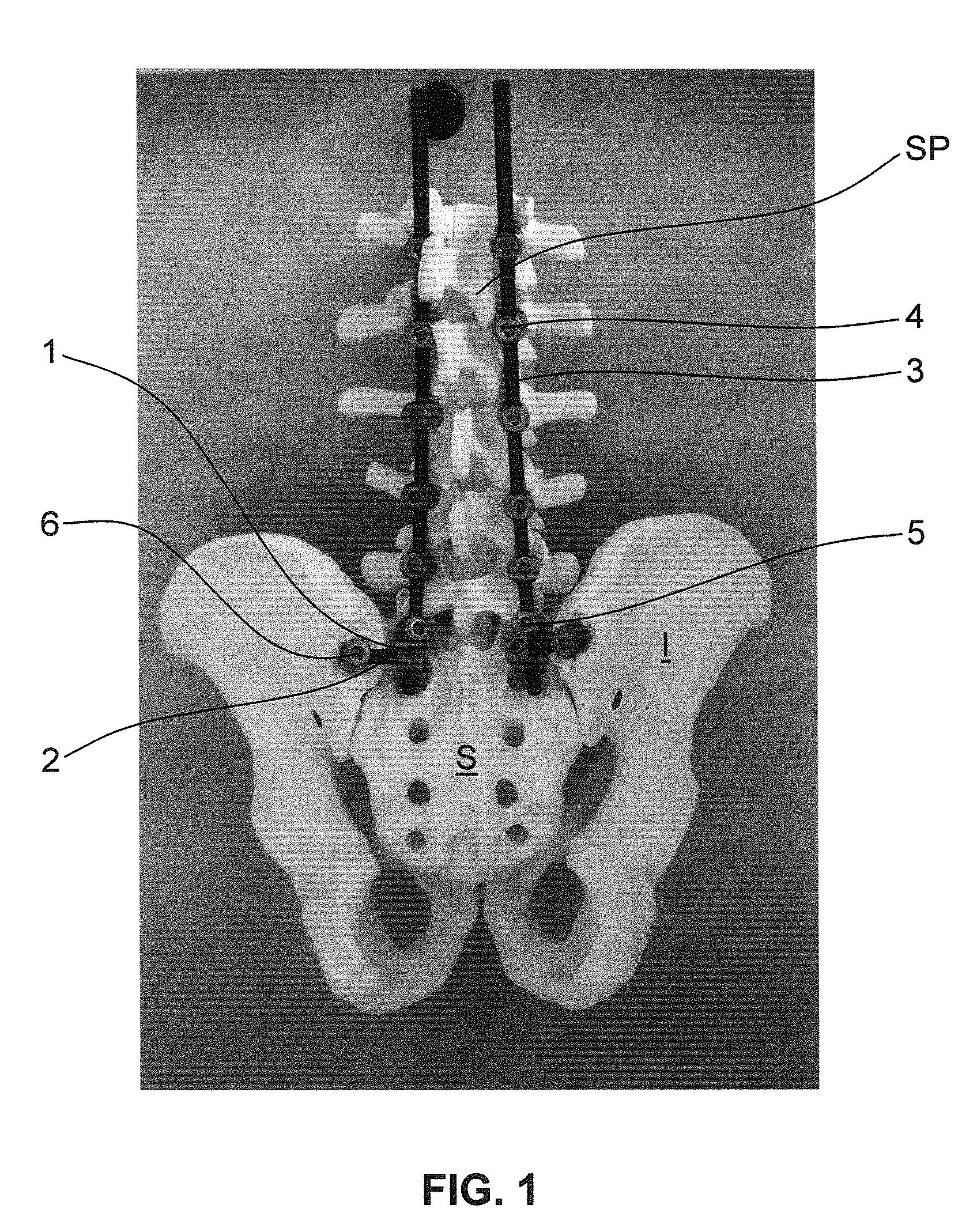

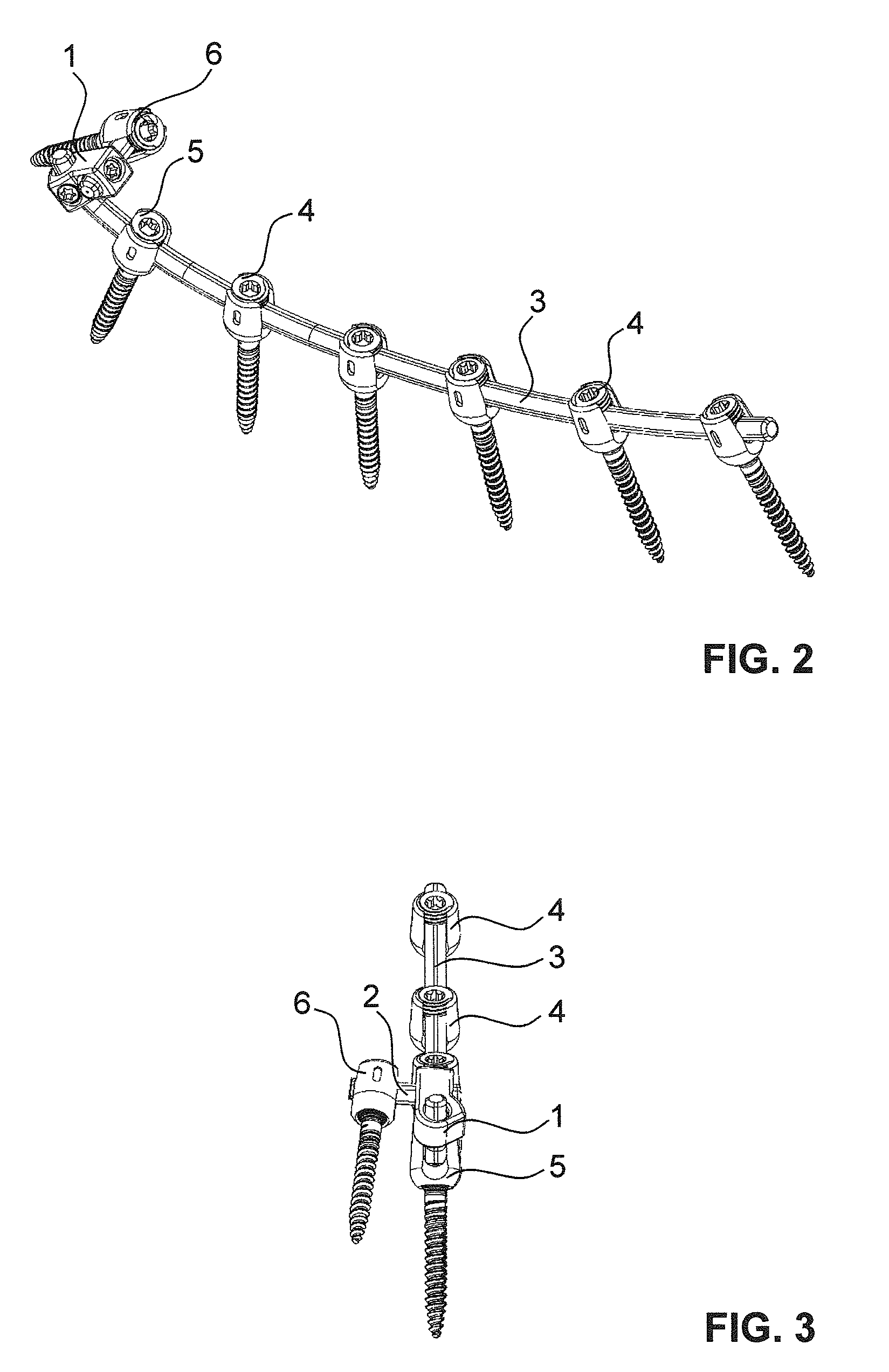

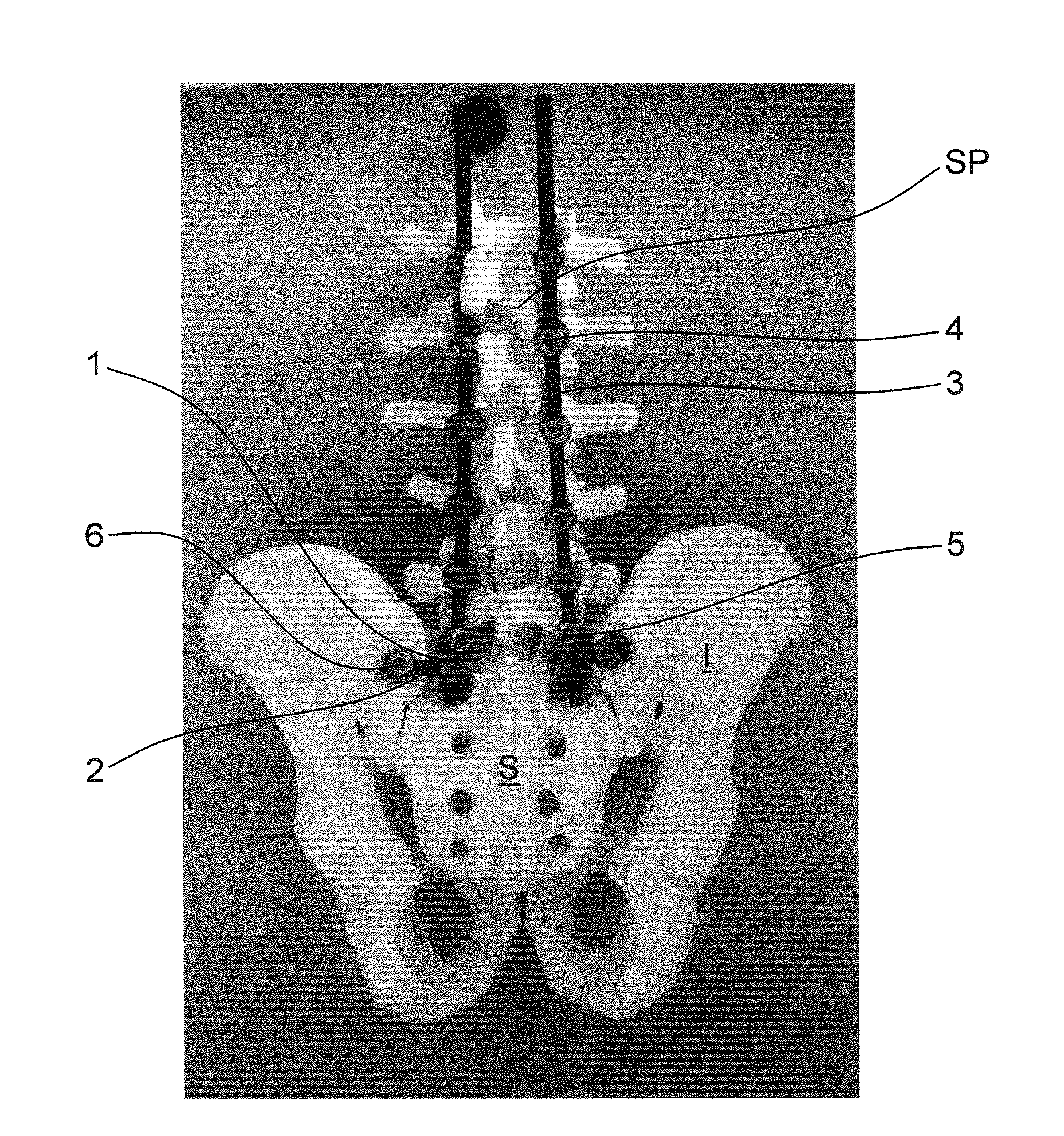

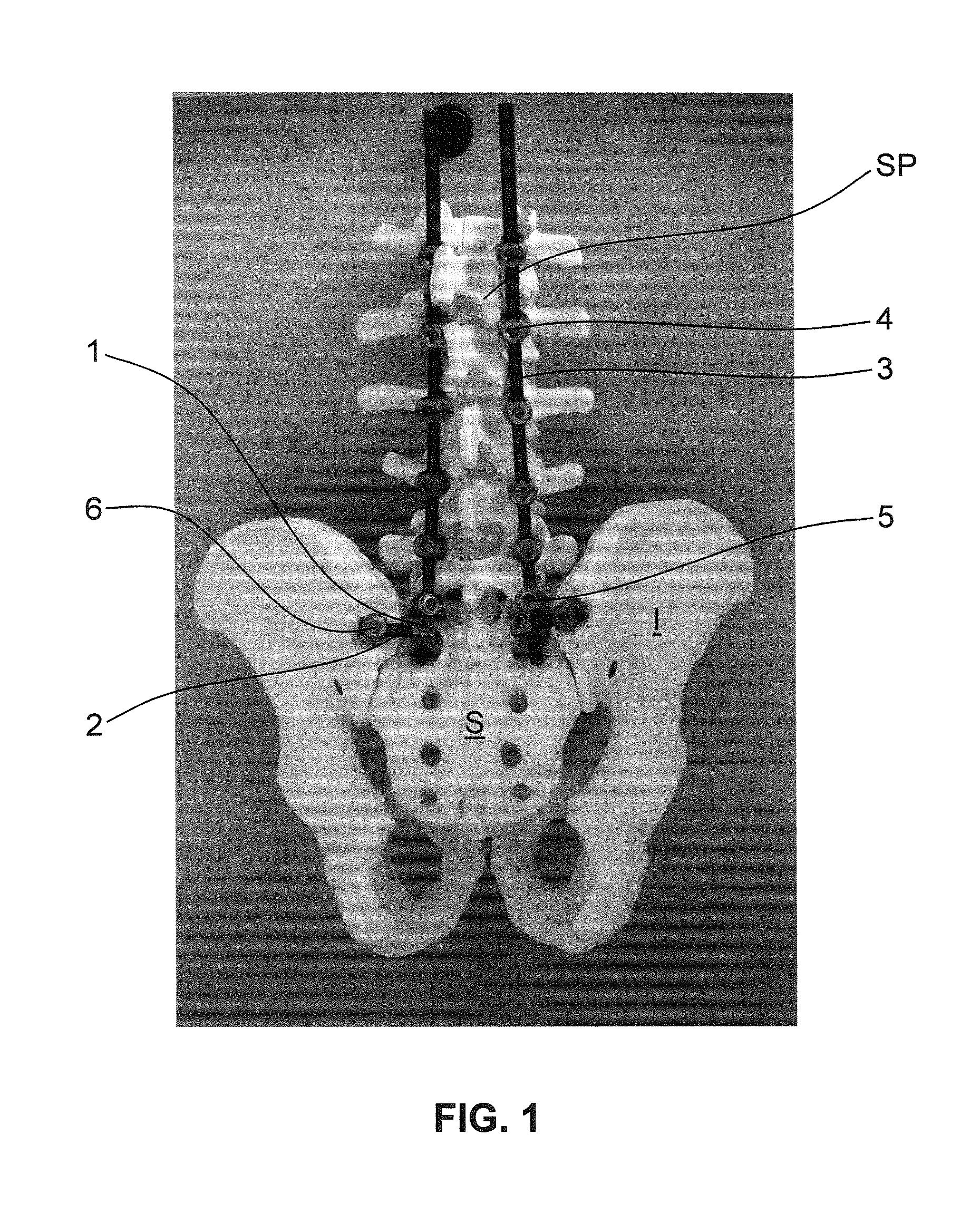

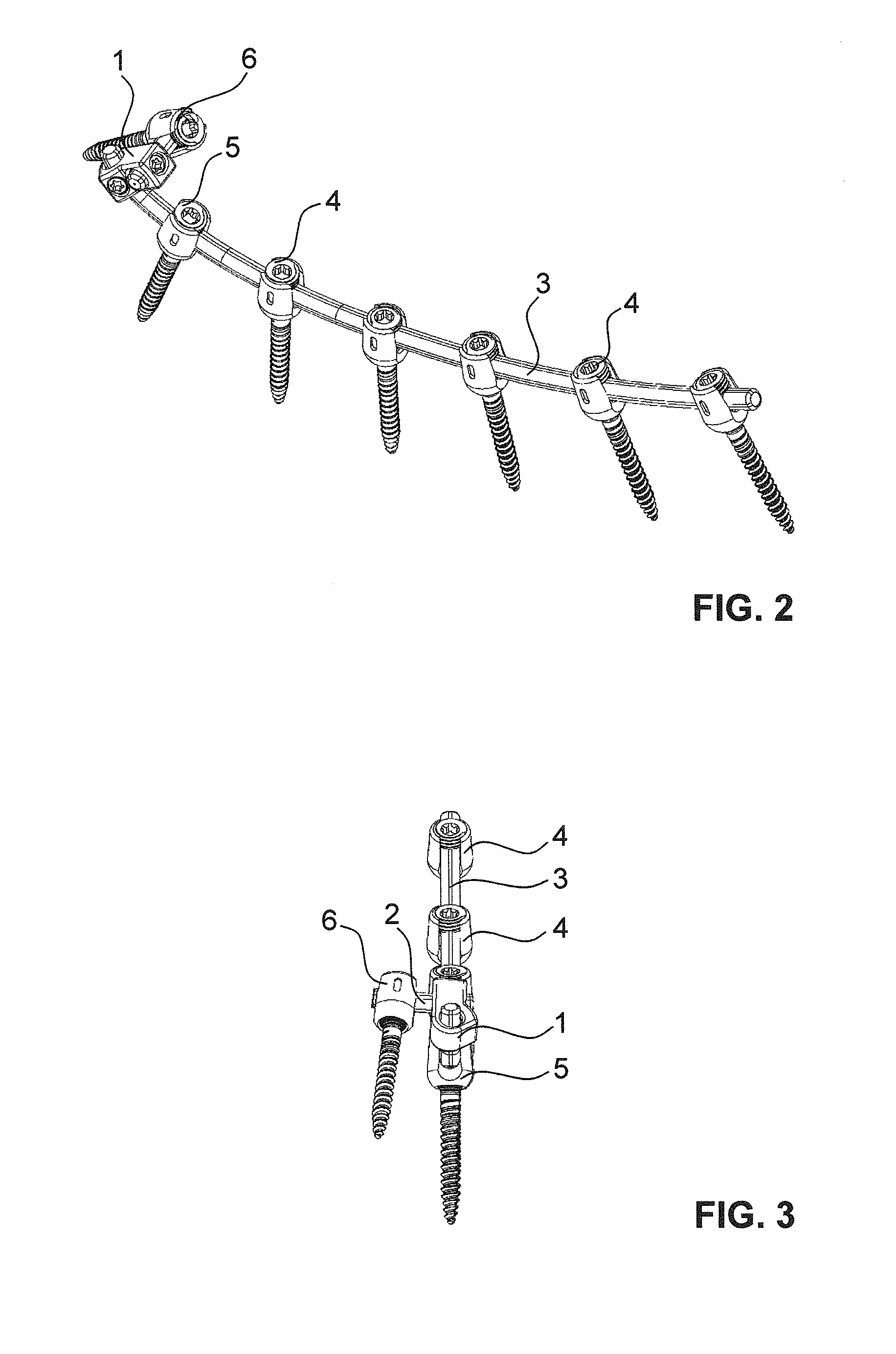

Iliac connector, connector head, spinal fixation system and method of stabilizing a spine

ActiveUS9561058B2Improve stabilityReduce distortionInternal osteosythesisJoint implantsSacrumBiomedical engineering

Owner:LIGNE

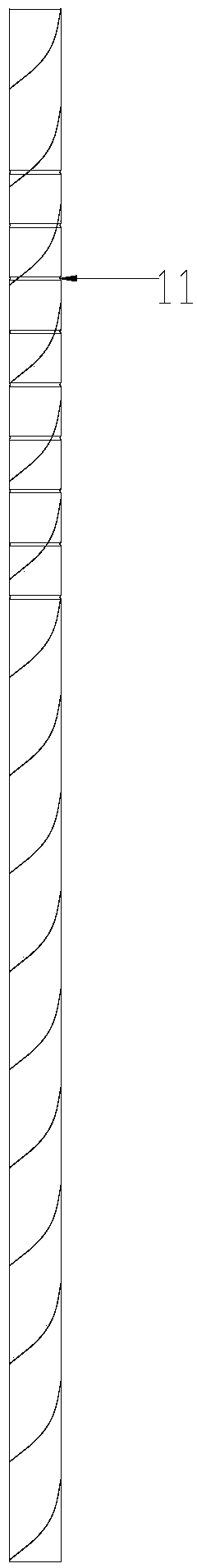

Paper straw with 90-degree elbow

PendingCN109431212ANot softenedFully bentSpecial paperPaper/cardboard articlesPulp and paper industryDrinking straw

The invention discloses a paper straw with a 90-degree elbow. The straw is formed by spirally overlapping and forming a paper strip body and cutting both ends, one end of the straw is uniformly pressed with 8-12 annular grooves, the paper strip body is composed of a first paper layer, a second paper layer and a third paper layer, it is ensured that the straw is not softened during use, a pluralityof the annular grooves with certain spacing are formed so that the straw fully bends to 90 degrees, the inner diameter of a straw bending zone is not significantly reduced, and the straw can be fullydegraded after use, do not cause white pollution, have low pressure on the environment, and can effectively replace plastic straws used in the market.

Owner:MENGTE COMMODITY CO LTD

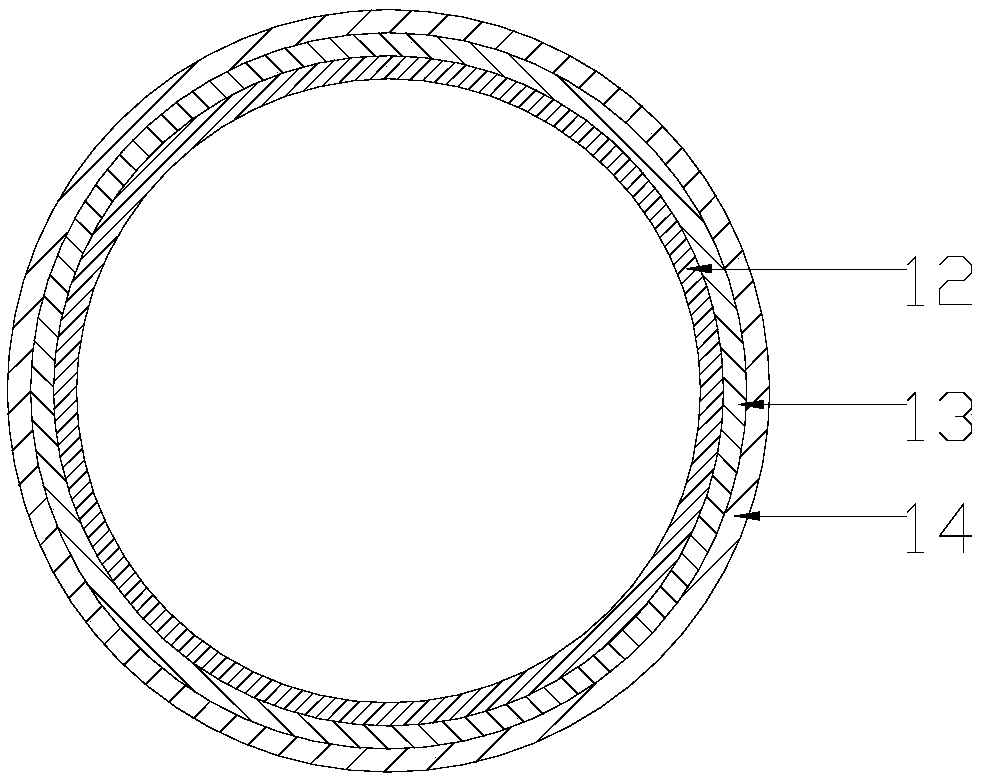

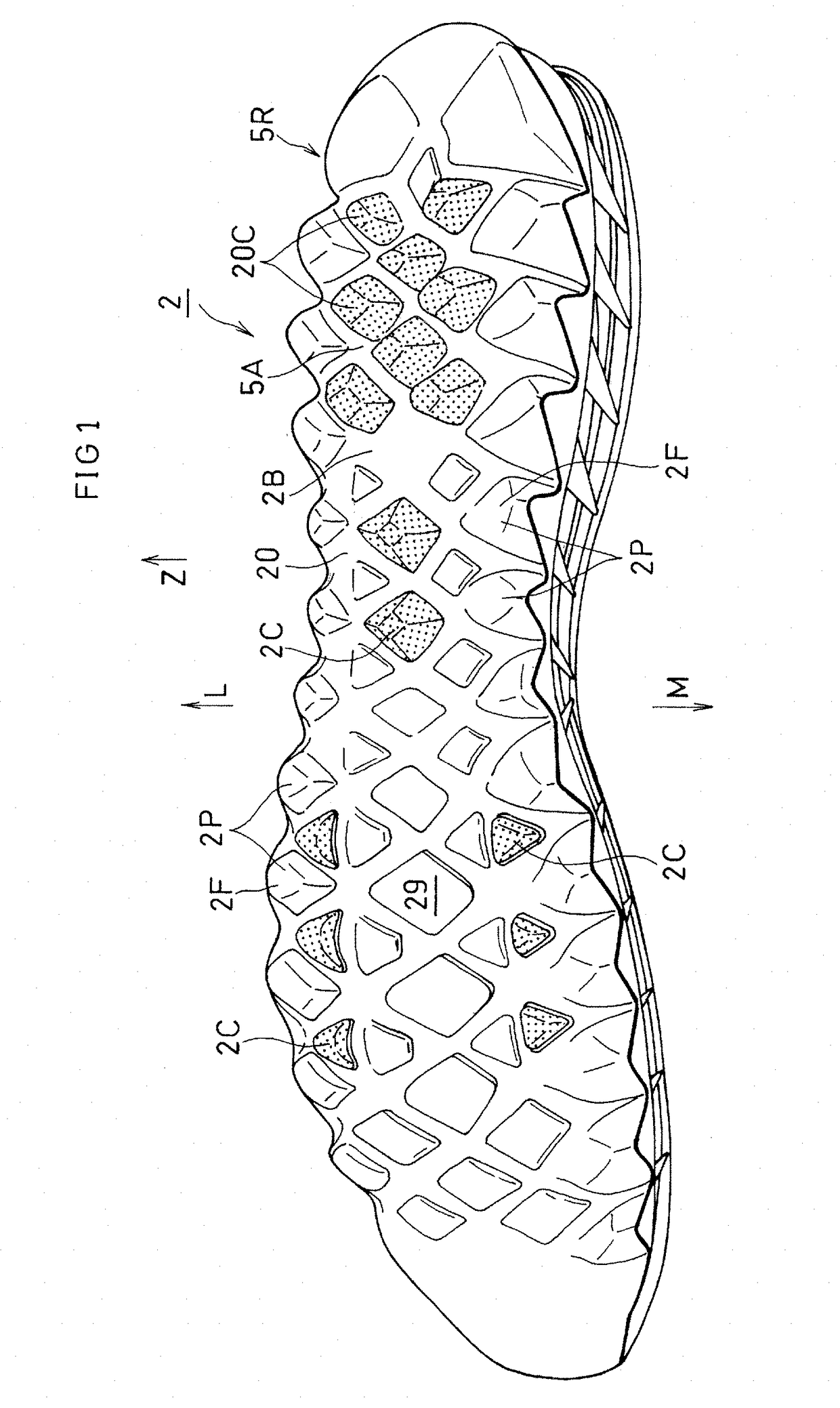

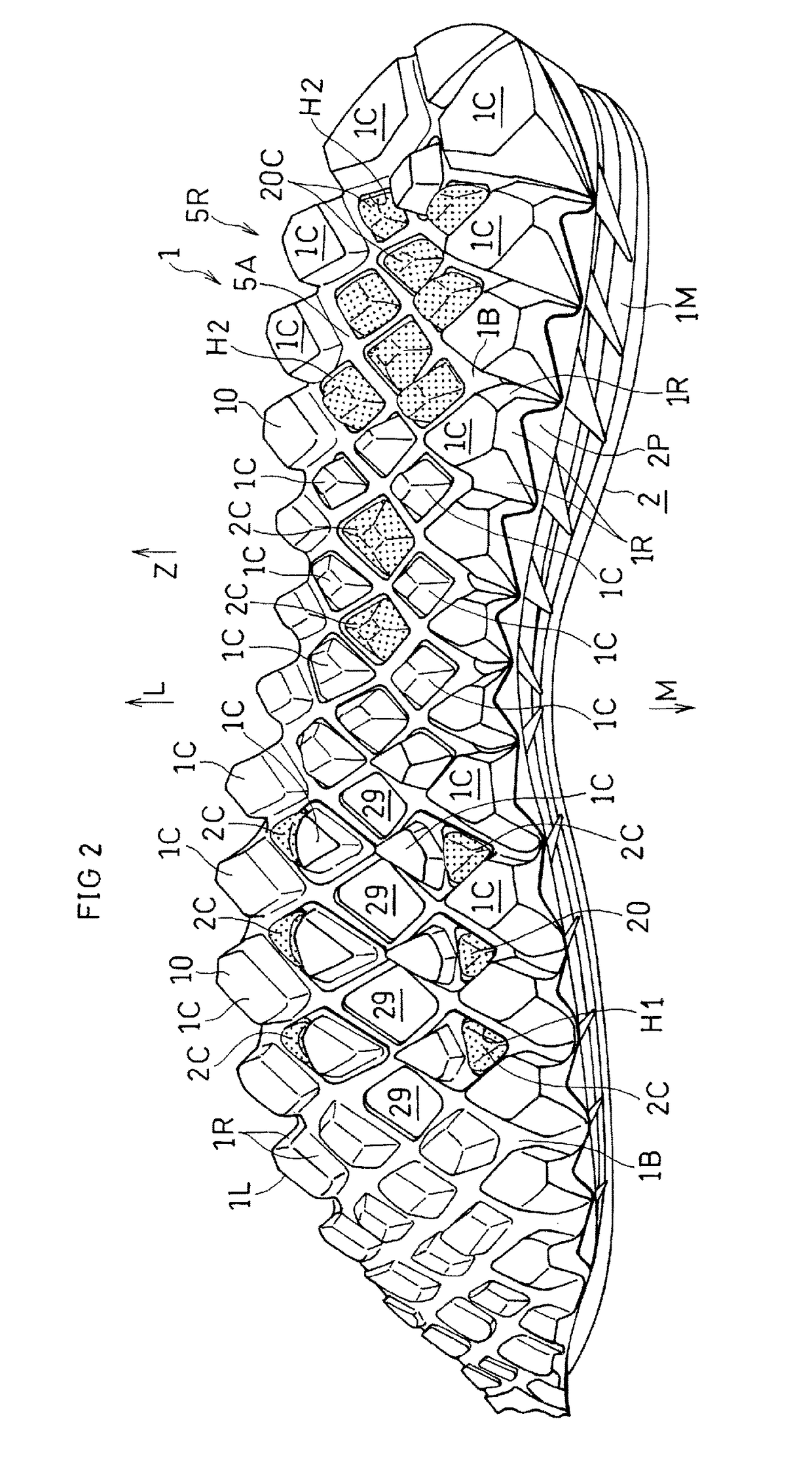

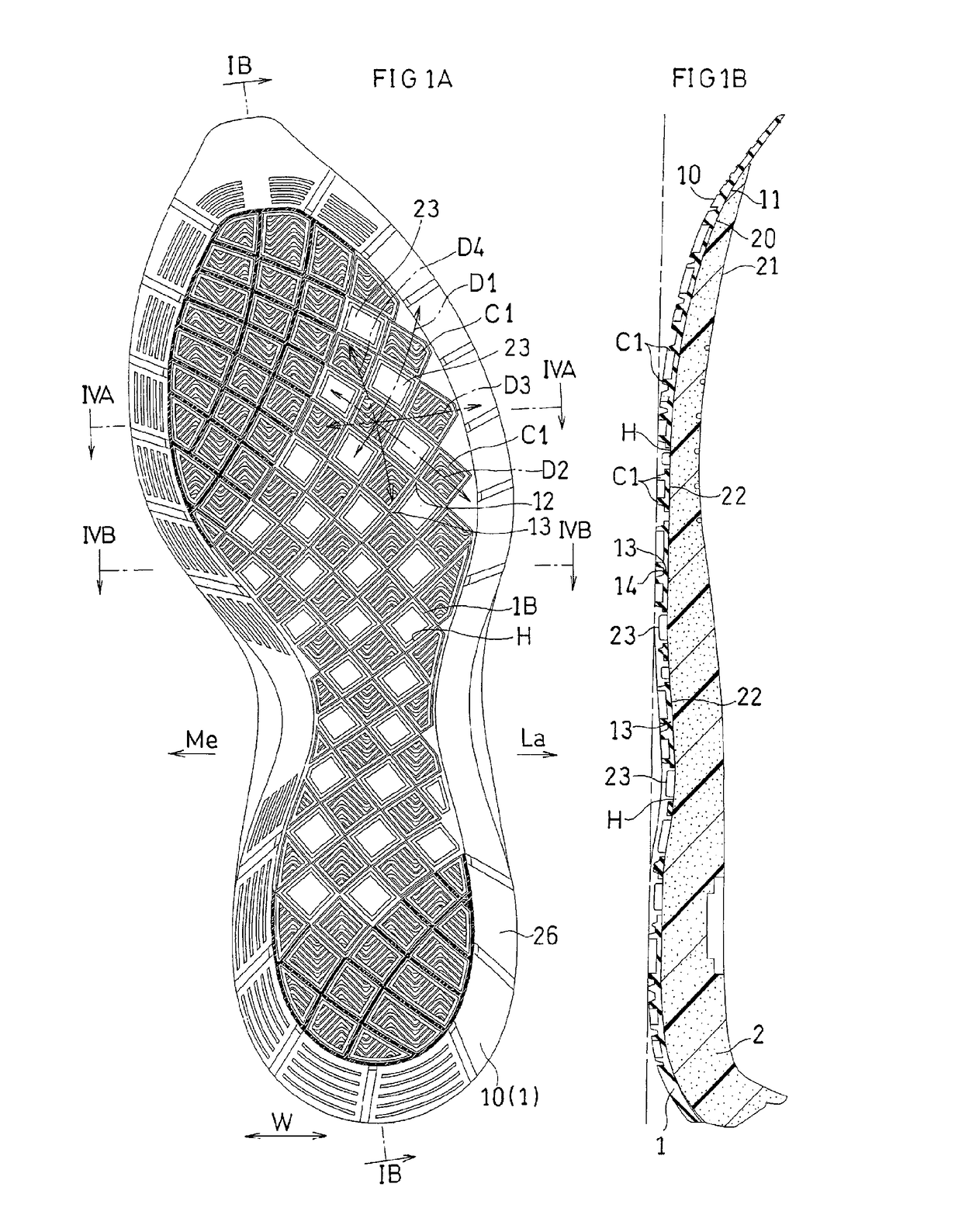

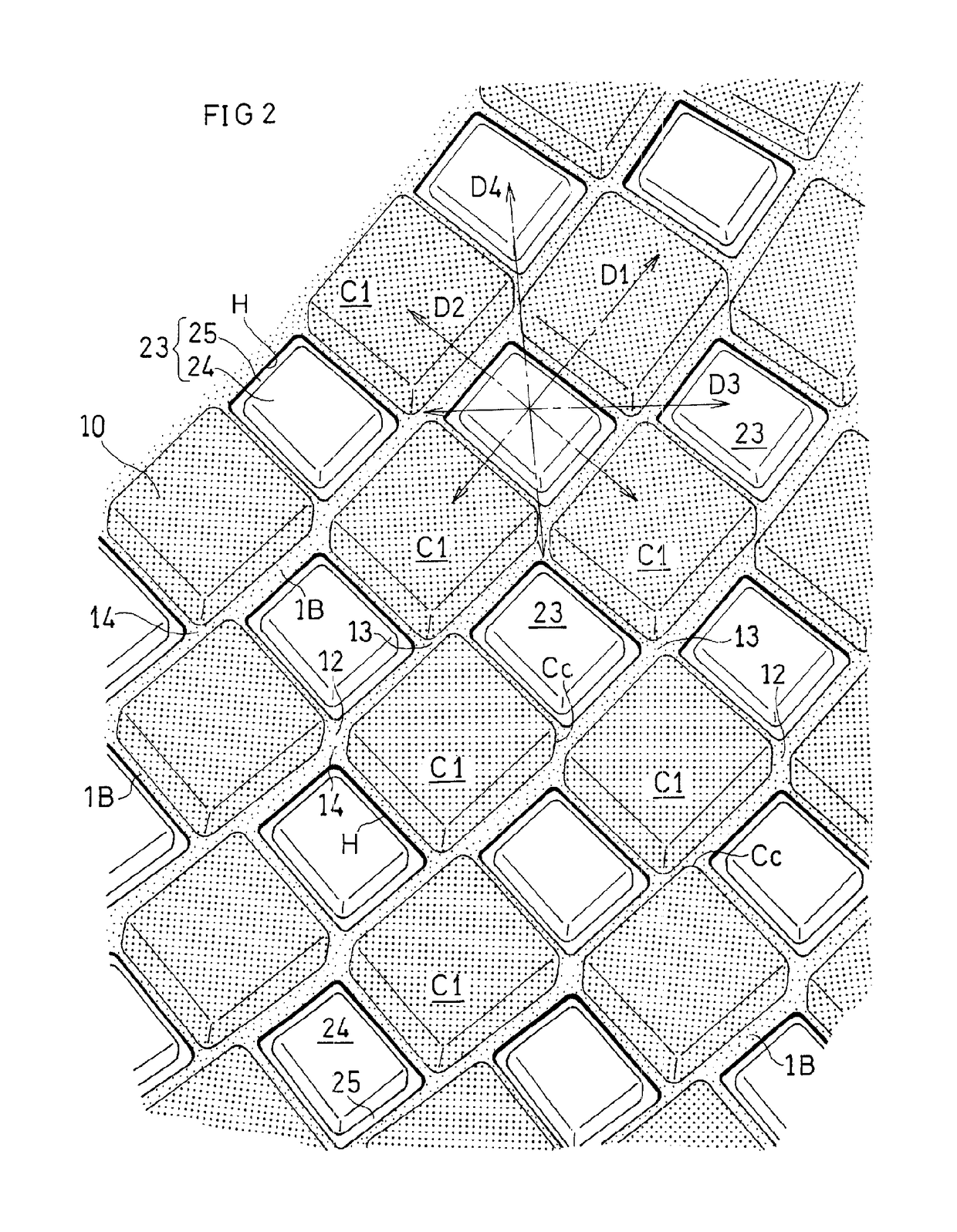

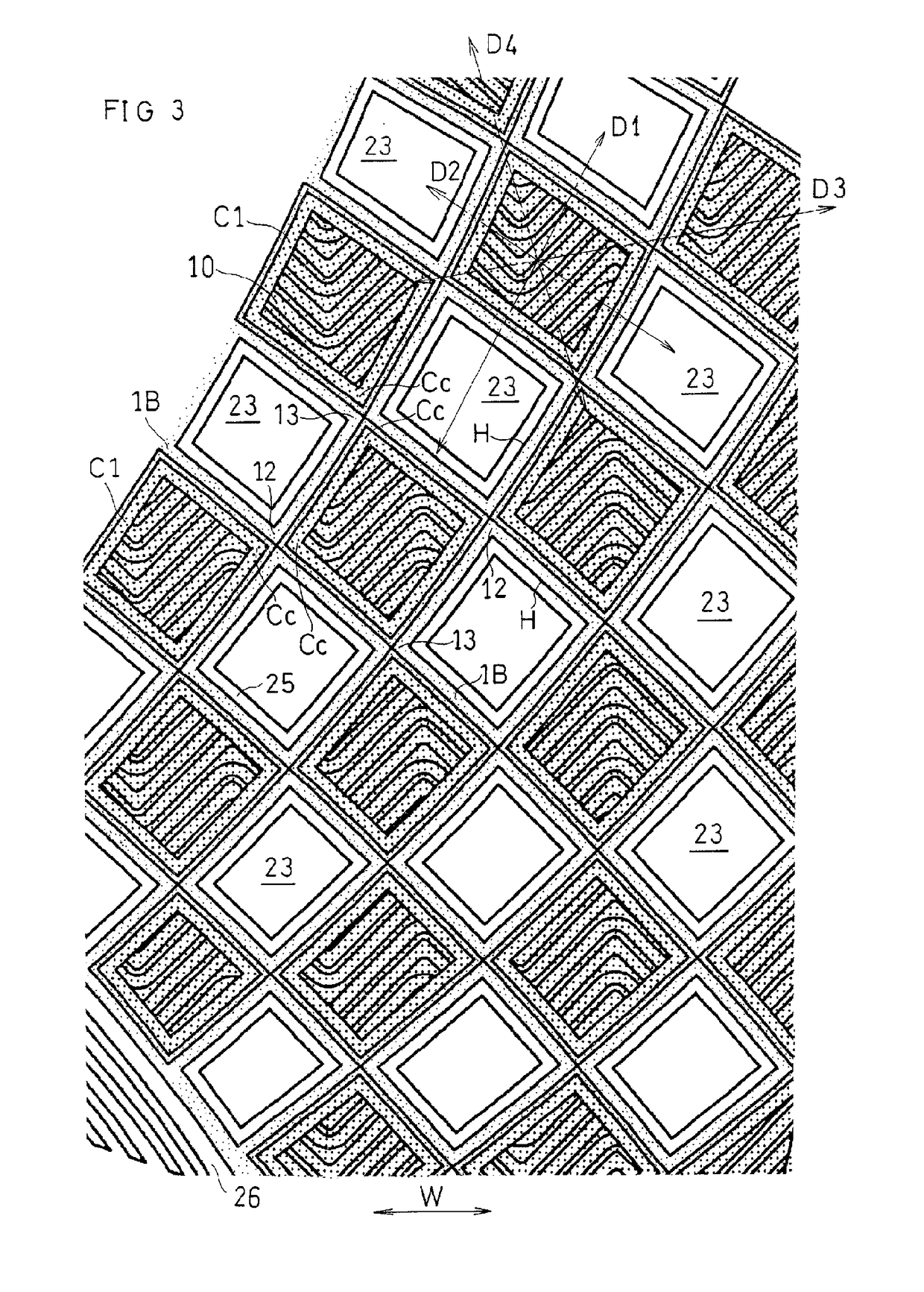

Shoe sole

ActiveUS9867427B2Improve bending performanceIncrease flexibilitySolesFasteningsConvex sideMechanical engineering

An outsole includes: a plate-like base; a plurality of first cleats protruding in the downward direction from the base to form the tread surface, wherein the plurality of first cleats are arranged in the longitudinal direction and in the transverse direction; and a concave surface recessed in the downward direction on the upper surface of each of the first cleats, wherein: the lower surface of the midsole includes a convex surface formed by a surface of a convex portion protruding in the downward direction from a base of the midsole; the concave surface and the convex surface are in contact with, and attached to, each other; and a distance from the tread surface in each of the first cleats to a top of the convex surface is greater than a thickness of the base.

Owner:ASICS CORP

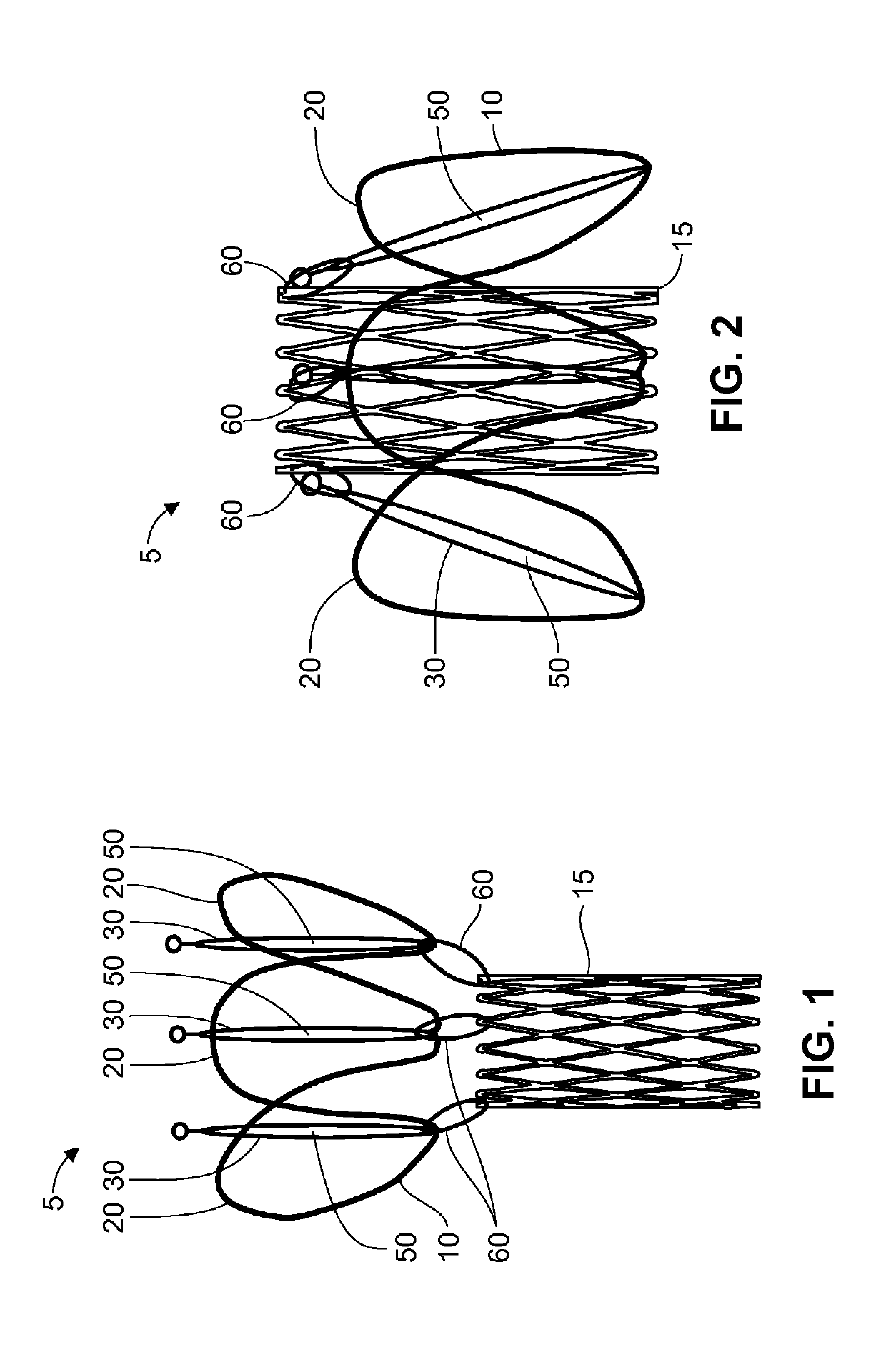

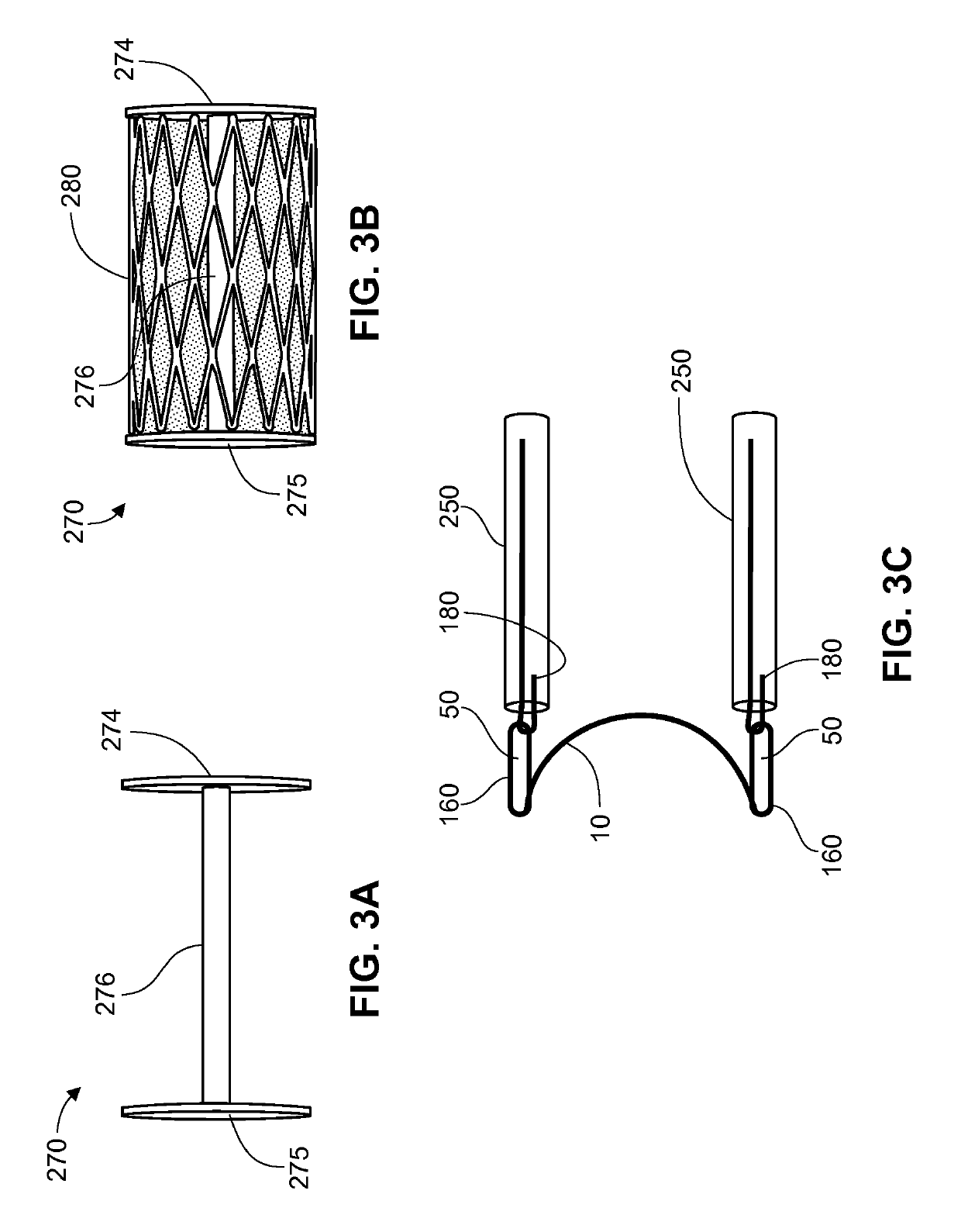

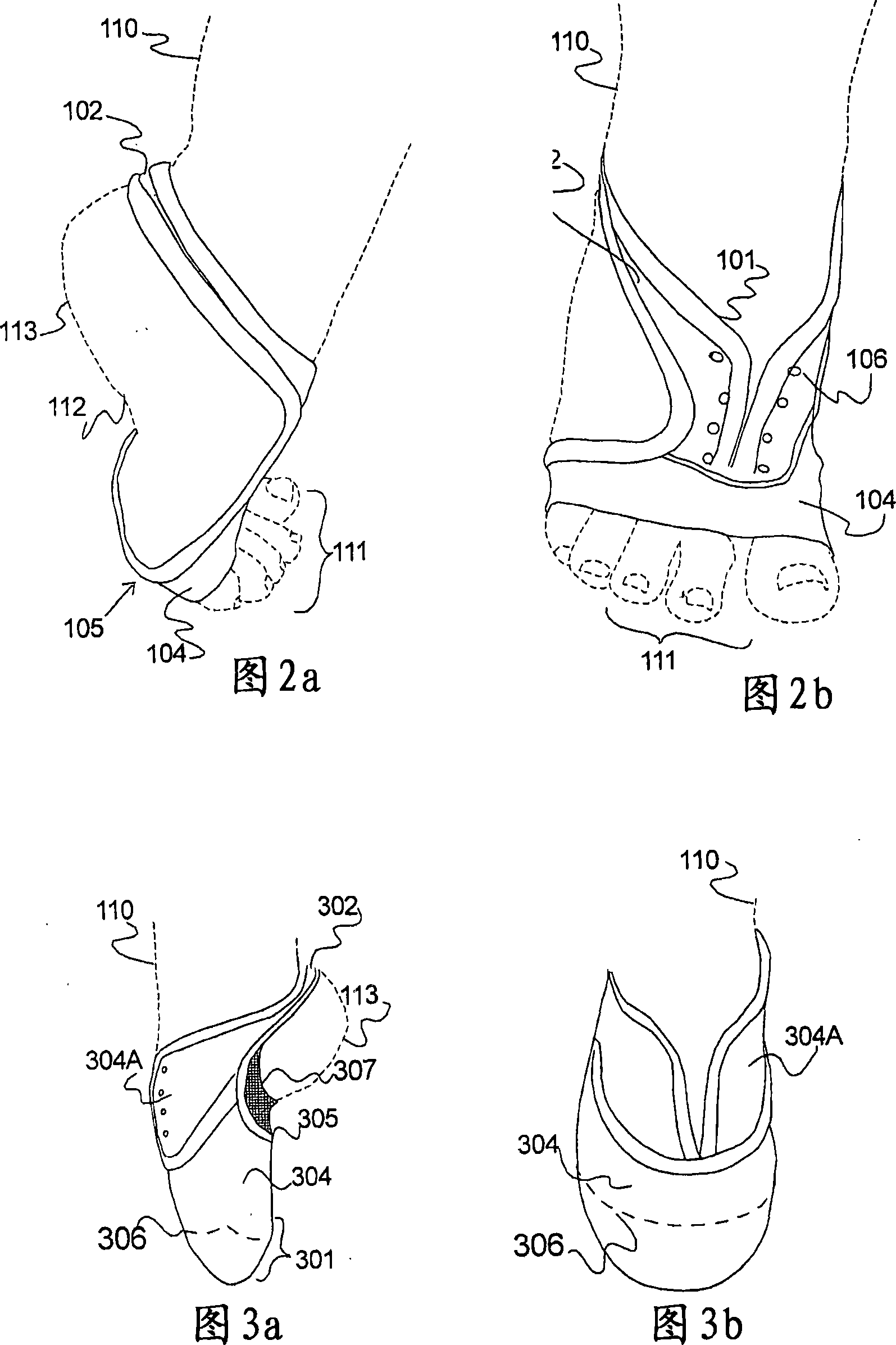

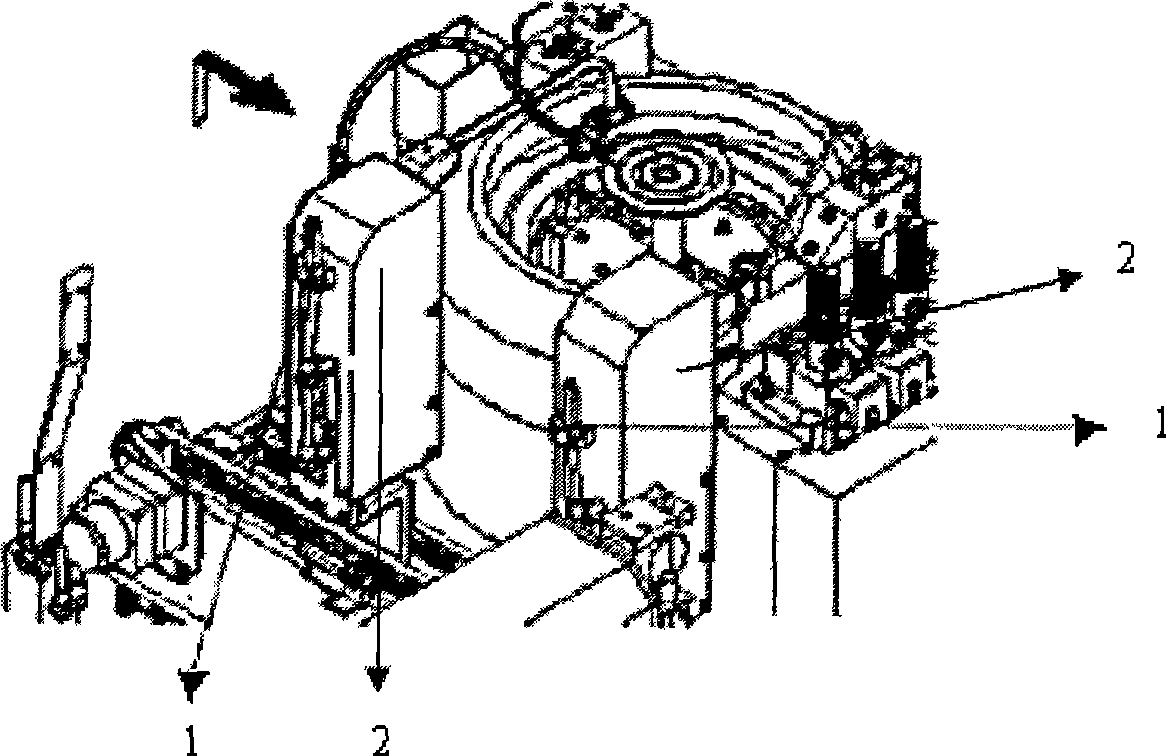

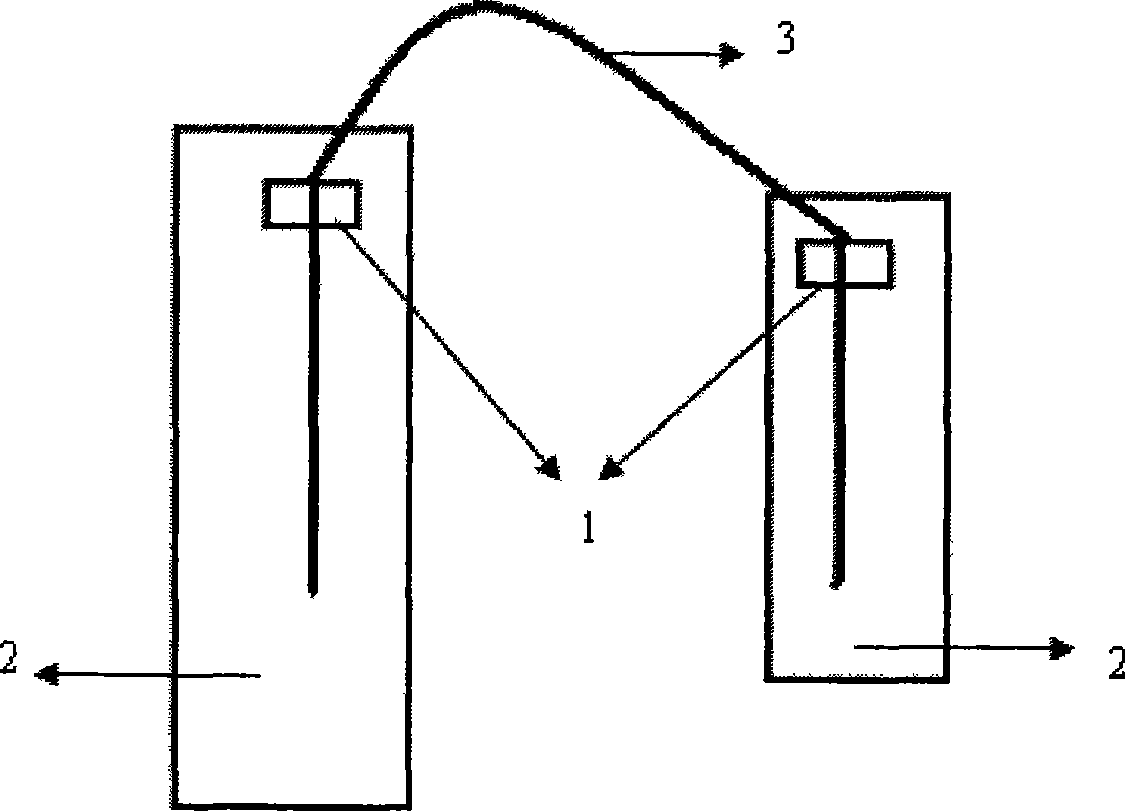

Iliac connector, connector head, spinal fixation system and method of stabilizing a spine

ActiveUS20130304128A1Improve stabilityReduce distortionInternal osteosythesisJoint implantsSacrumEngineering

An inventive iliac connector comprises a connector head (1) and a connecting rod (2) for connecting a sacrum (S) or a spine (SP) to an ilium (I). The connector head (1) has a first hole (15) for holding a spinal rod (3) and a second hole (16) for holding the connecting rod (2), wherein the connecting rod (2) is made of a material being more flexible than titanium. This iliac connector enables a stabilization of ilium, sacrum and spine and enables at the same time movement between ilium and sacrum.

Owner:LIGNE

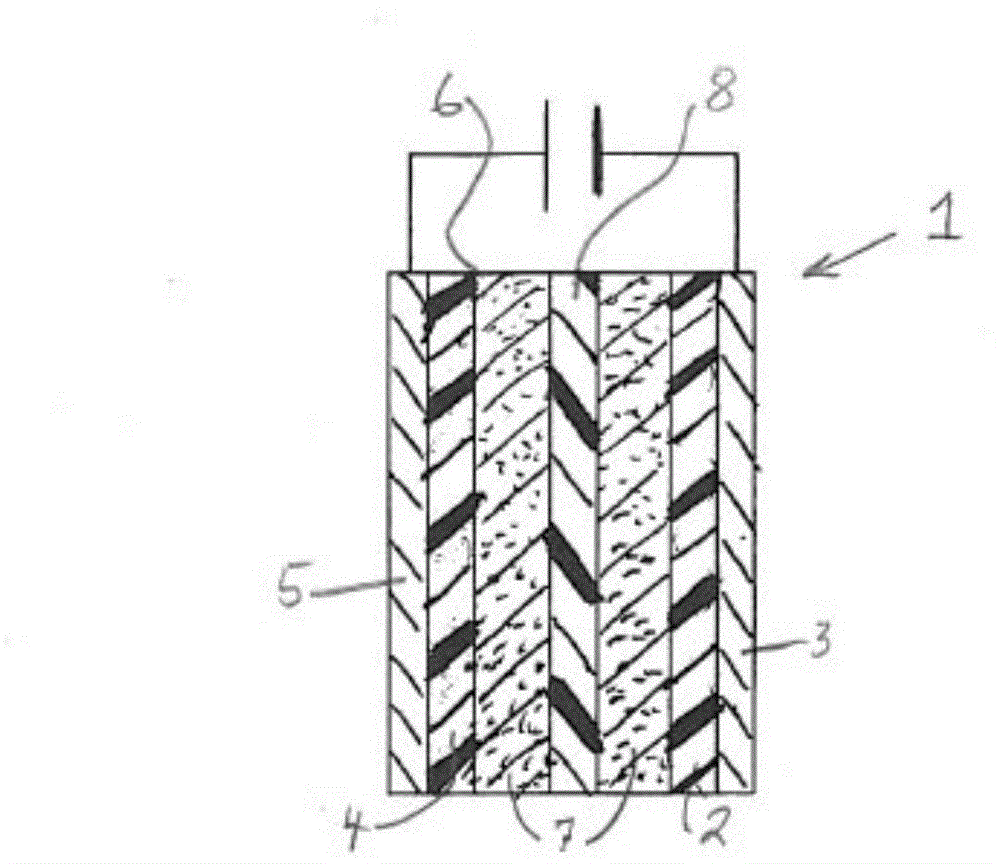

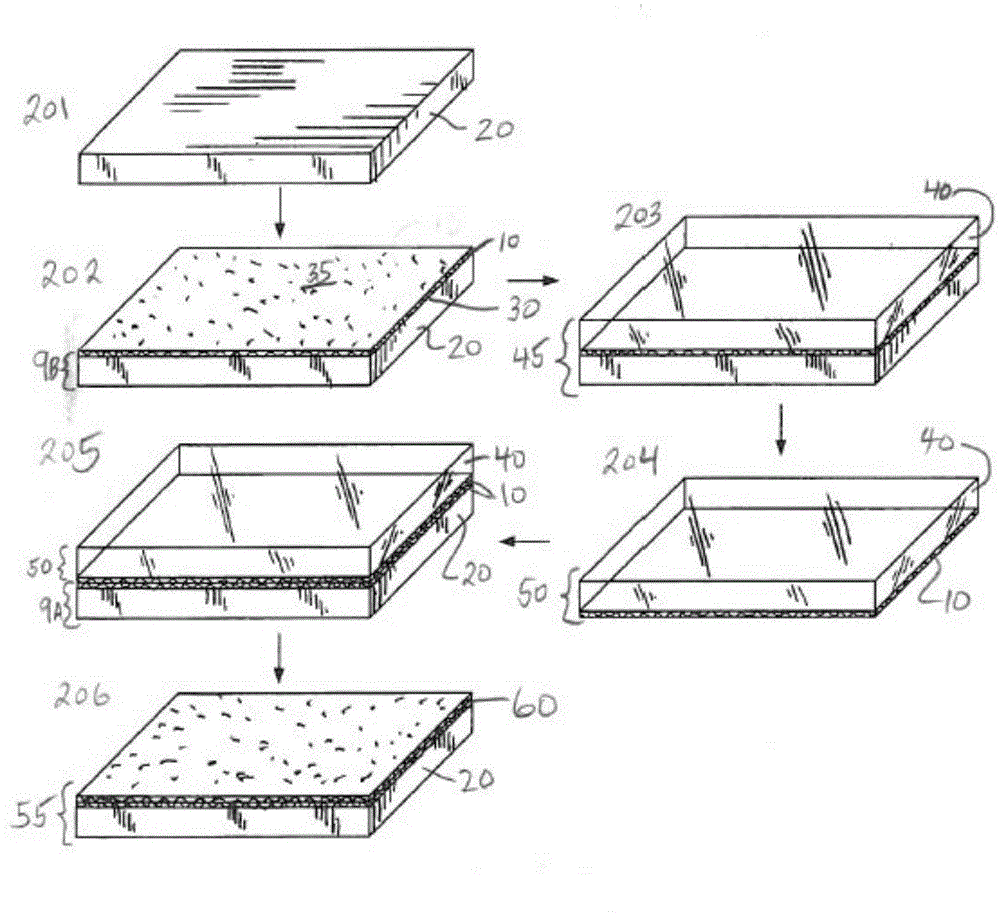

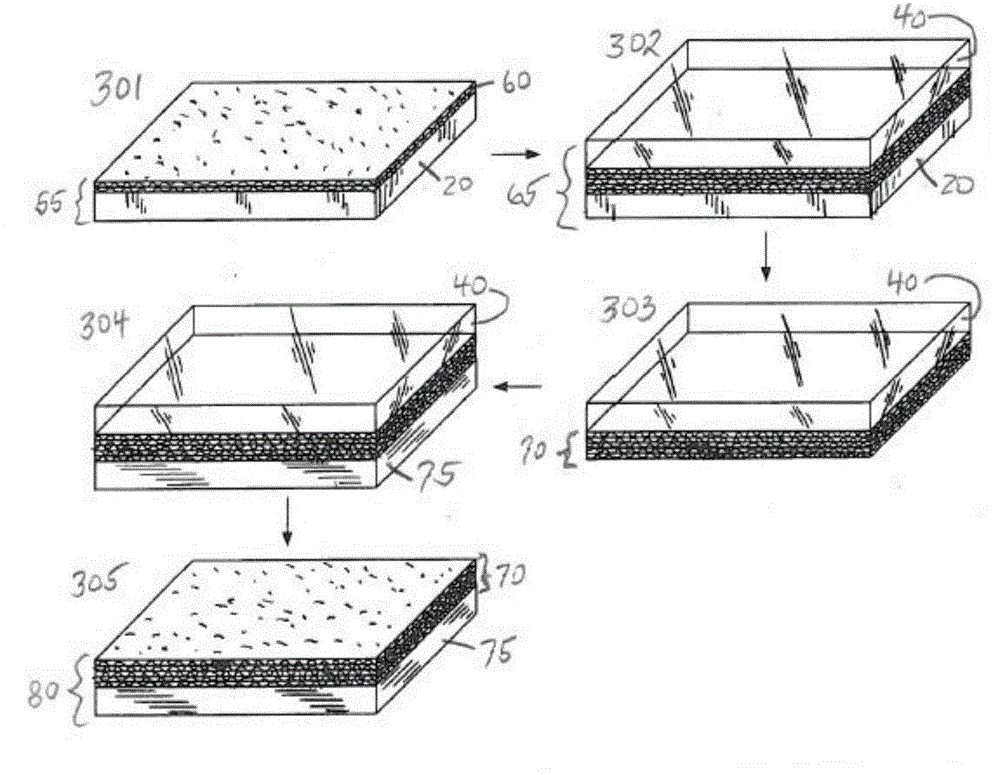

Method for preparing graphene substrate electrode and battery and super capacitor

ActiveCN105304860AImprove electrochemical performanceFully bentHybrid capacitor electrodesCell electrodesSupercapacitorOptoelectronics

The invention discloses a method for preparing a graphene substrate electrode and a battery and a super capacitor. The method comprises the steps as follows: (a) a first graphene thin film is formed on a first substrate; (b) a second graphene thin film is formed on a second substrate; (c) an anti-corrosion compound is applied to the second graphene thin film, and the second graphene thin film is covered to form an anti-corrosion coating; (d) the anti-corrosion coating is dried; (e) the second substrate is removed; (f) the second graphene thin film is arranged on the first graphene thin film and contacts the first graphene thin film to form a graphene thin film superposition layer; (g) the anti-corrosion coating is removed from the graphene thin film superposition layer; (h) the steps (b) to (g) are repeated, and the graphene thin film is further superposed on the superposition layer until the required thickness of the graphene thin film superposition layer is obtained; and (i) the first substrate is removed from the bottom of the graphene thin film superposition layer to form the electrode.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

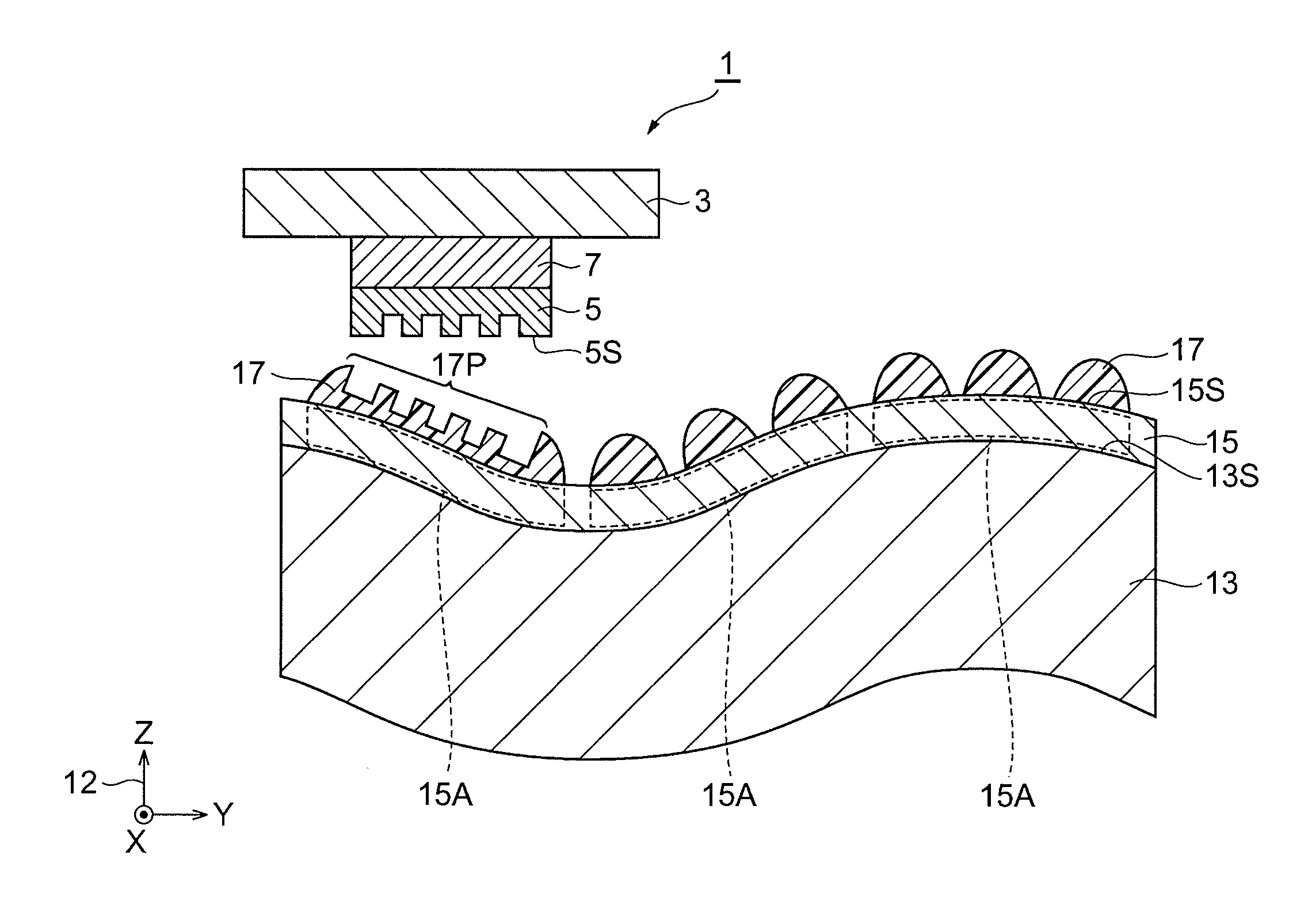

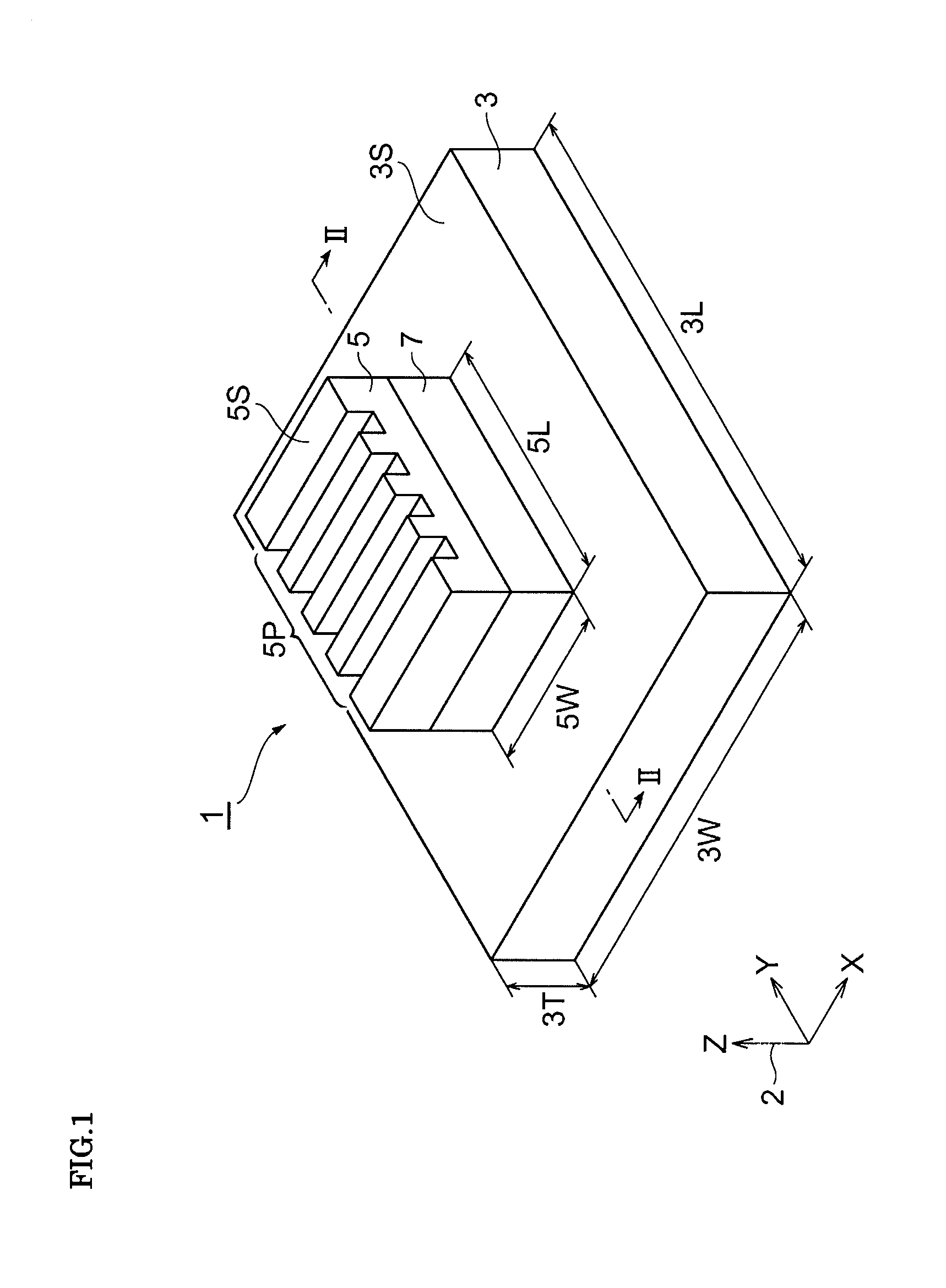

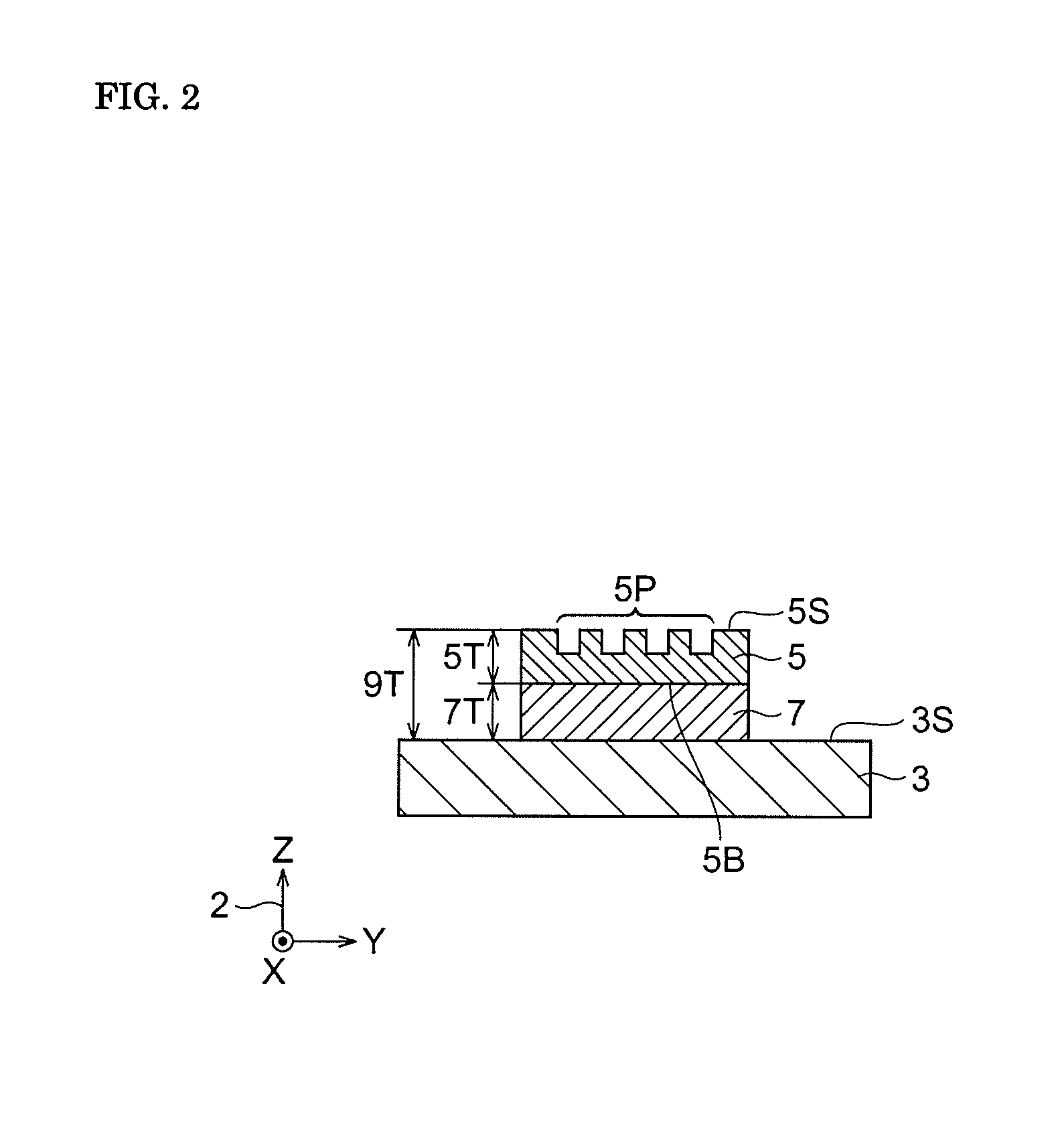

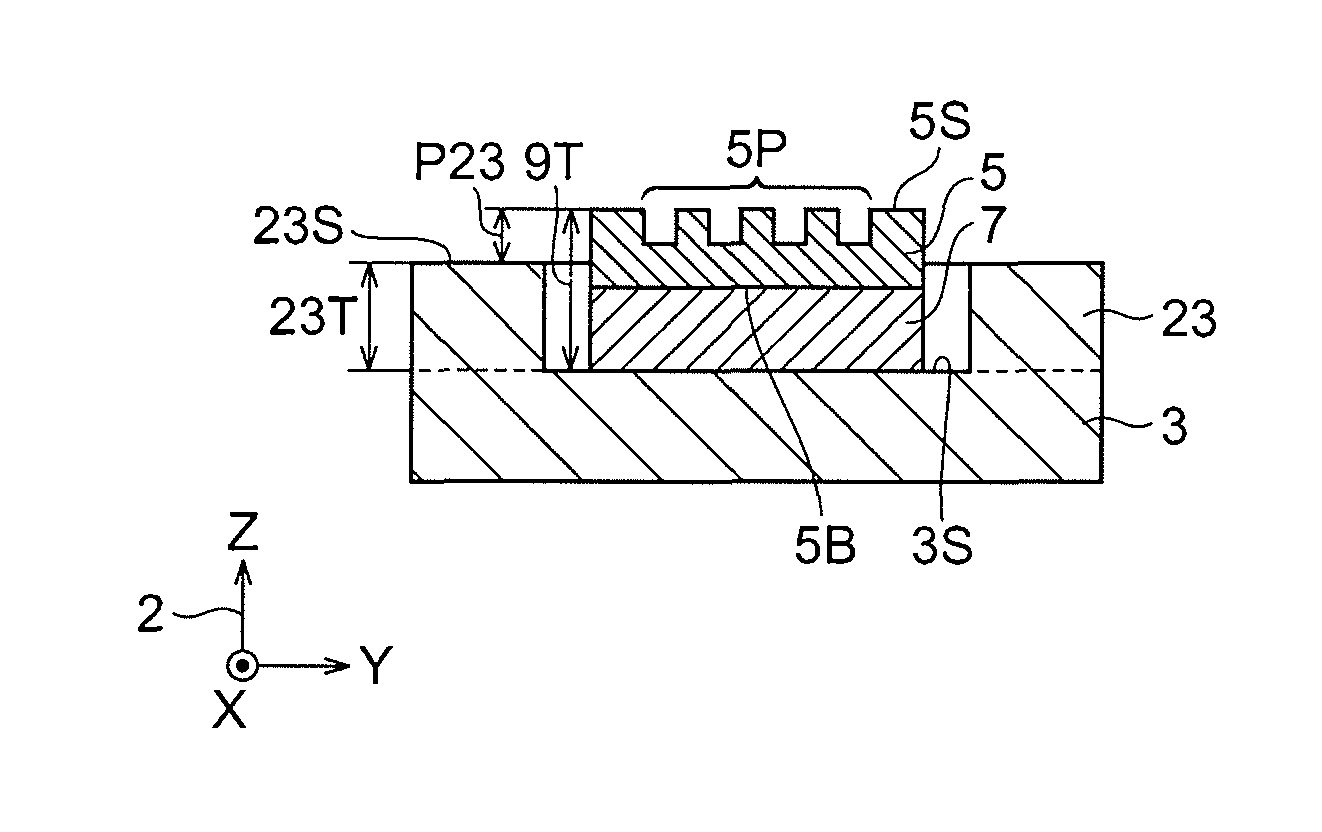

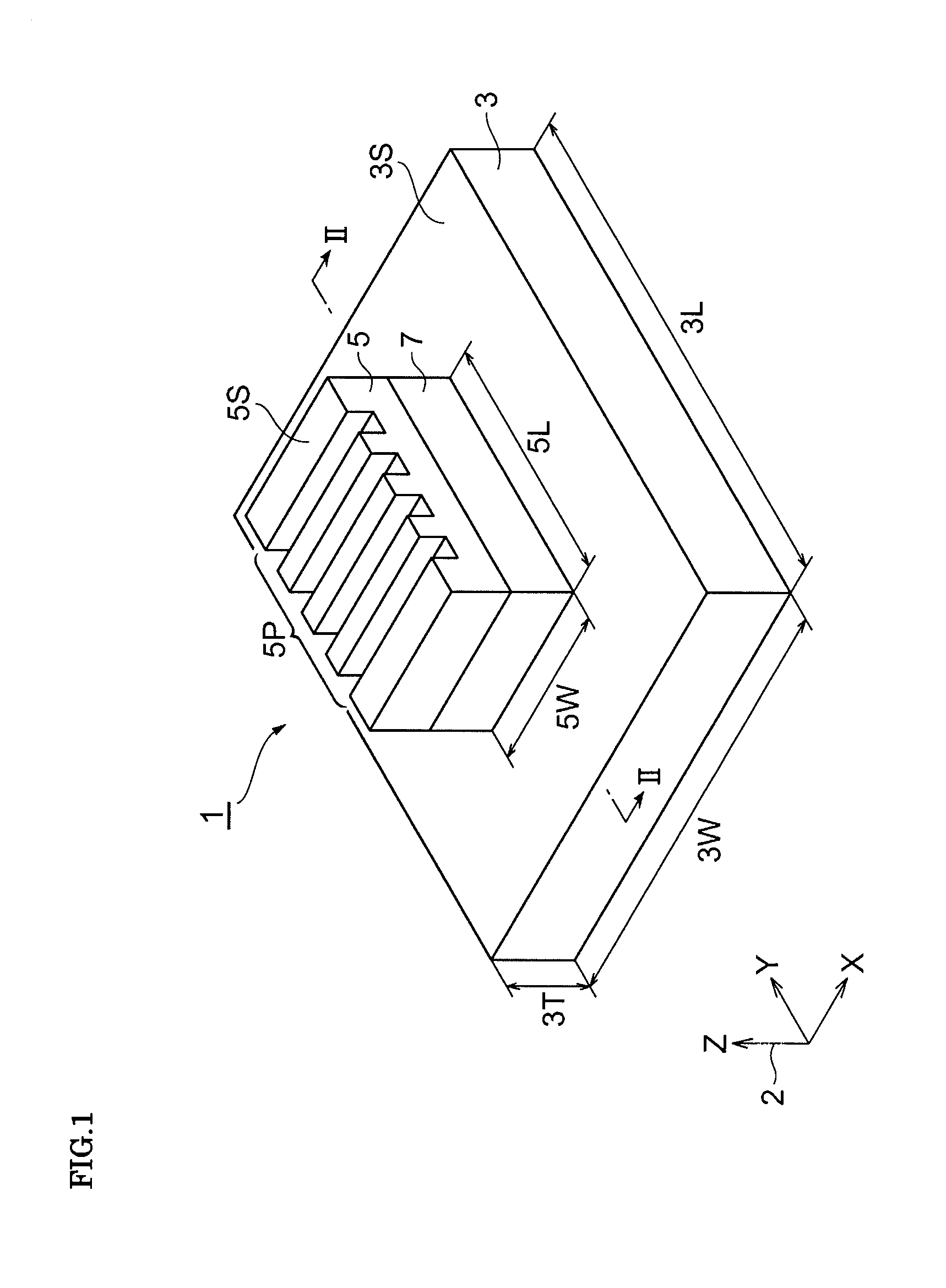

Nano-imprint mold

ActiveUS20120003348A1Reduce manufacturing costLow costConfectioneryNanoopticsElastomerMaterials science

A nano-imprint mold includes a mold base; mold body having a first surface and a second surface opposite the first surface; and an elastic body disposed between a surface of the mold base and the first surface of the mold body, the elastic body being composed of resin. The second surface of the mold body is provided with a nano-imprint pattern. In addition, the elastic body has a bulk modulus lower than a bulk modulus of the mold body.

Owner:SUMITOMO ELECTRIC IND LTD

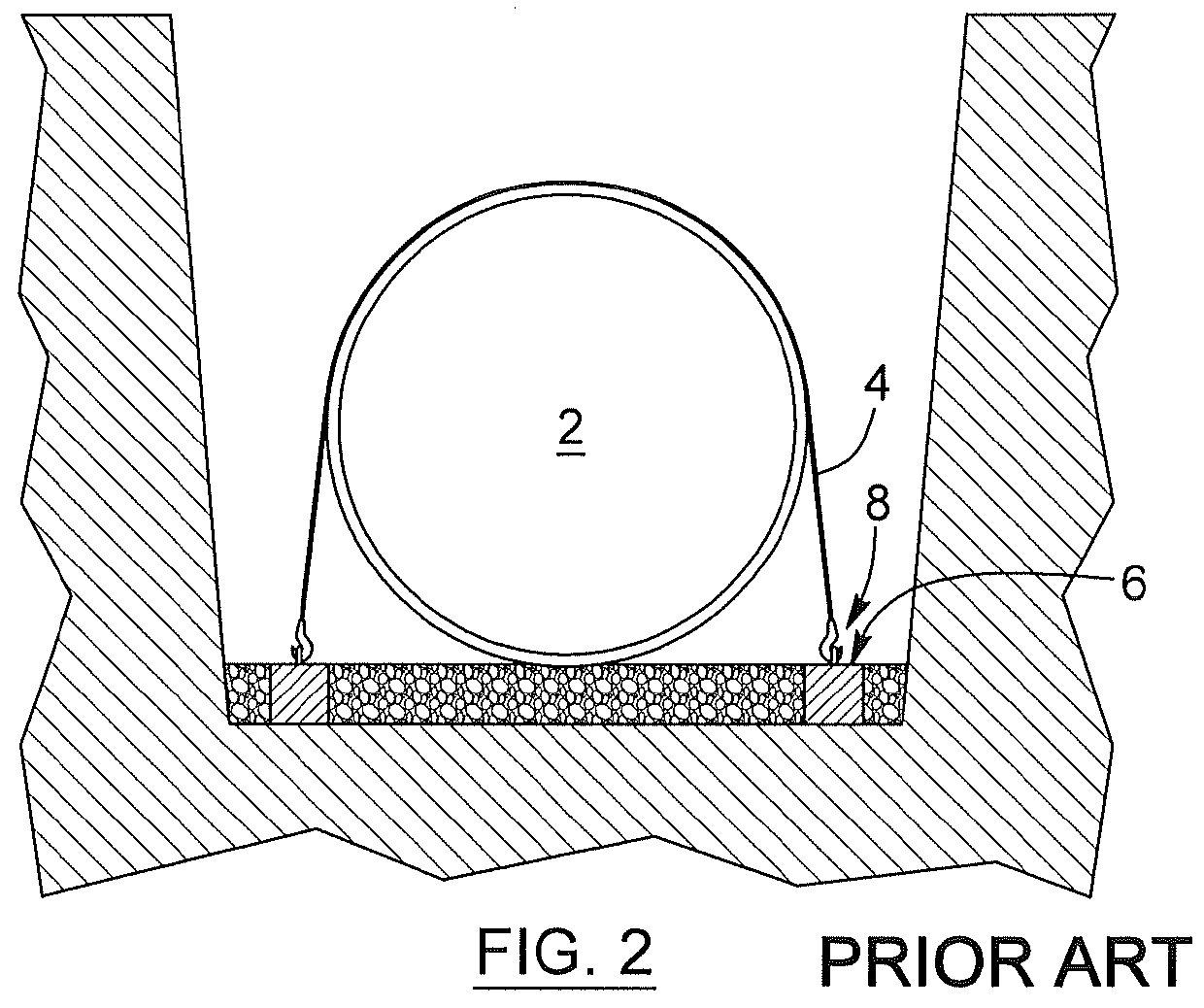

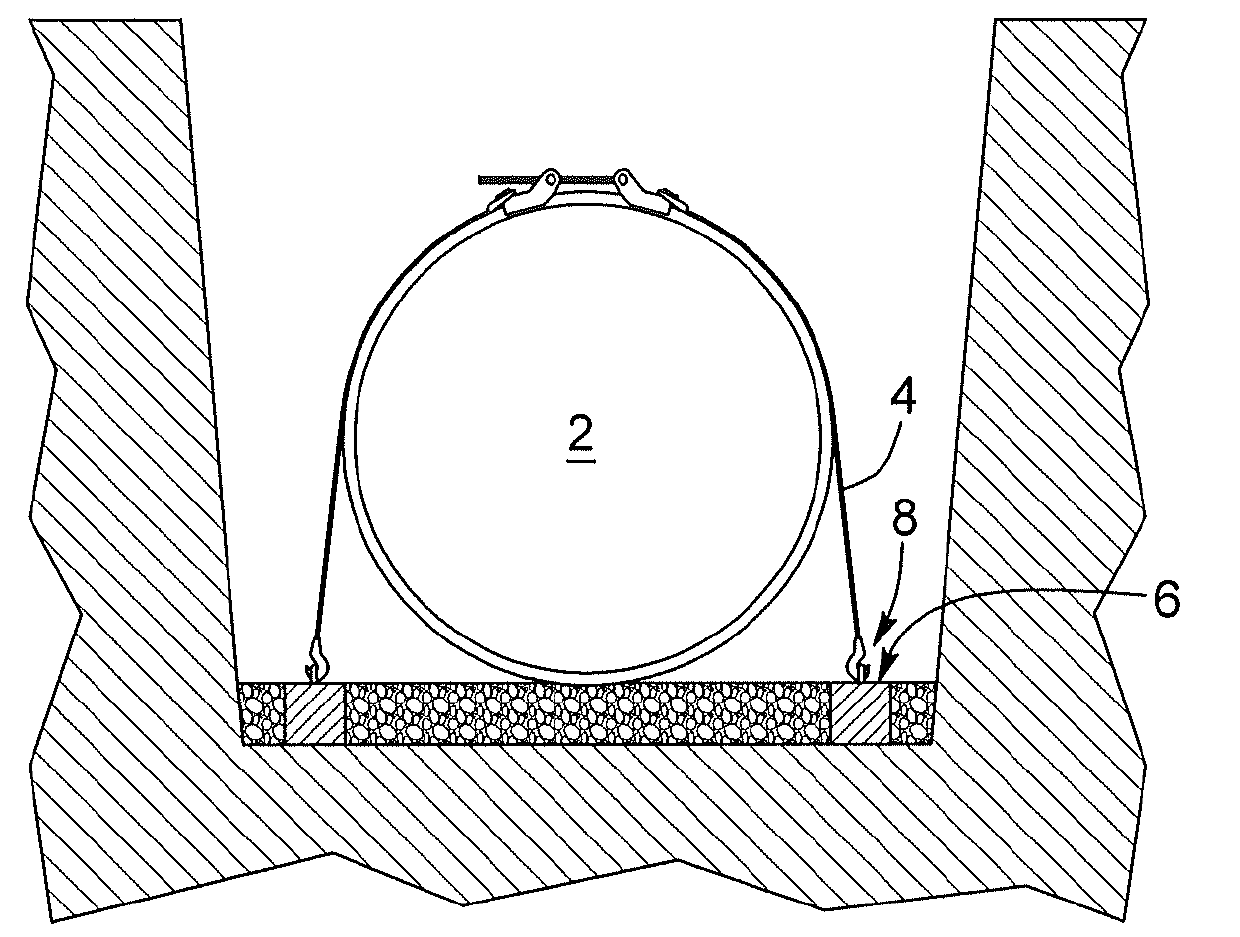

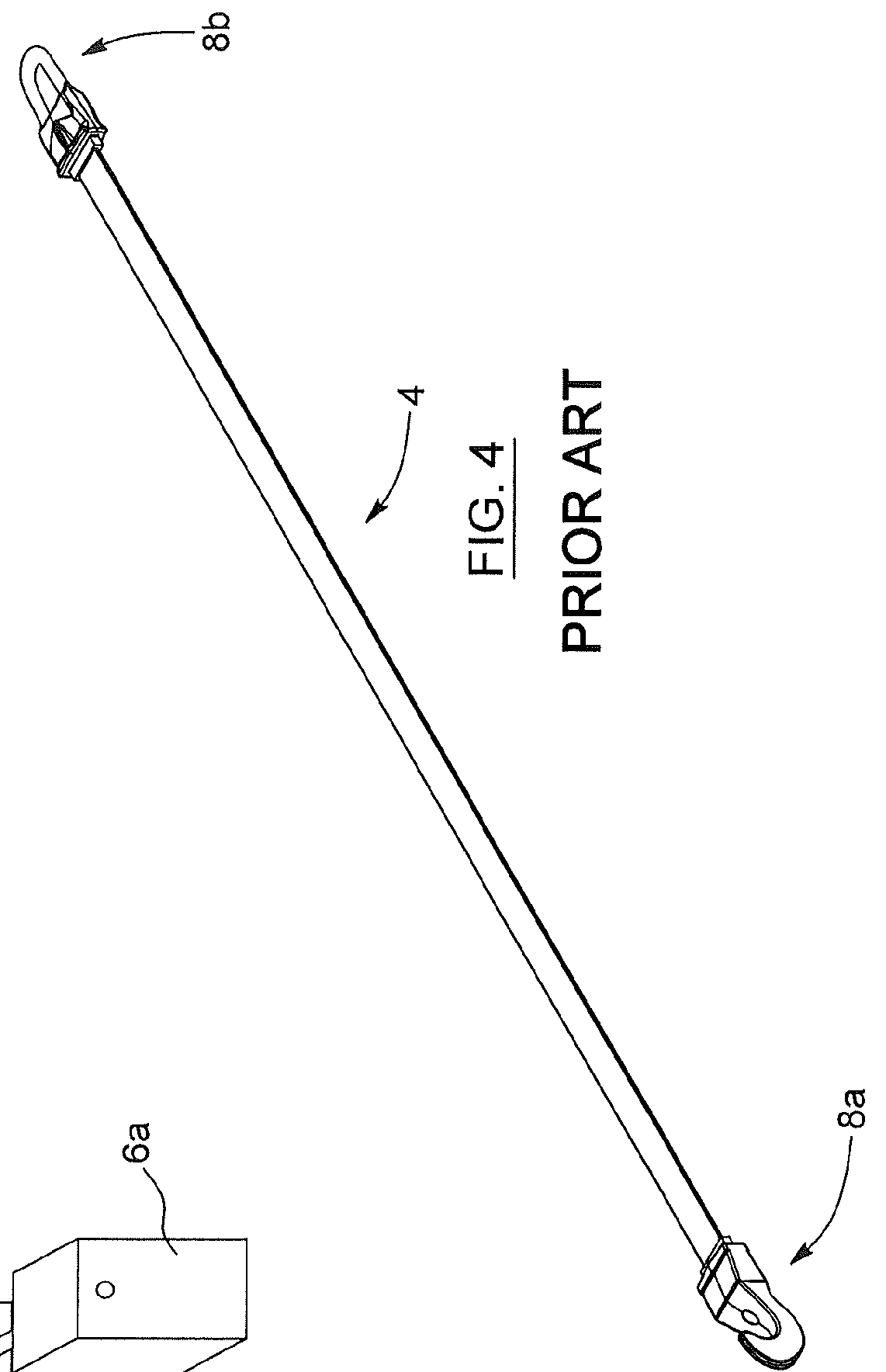

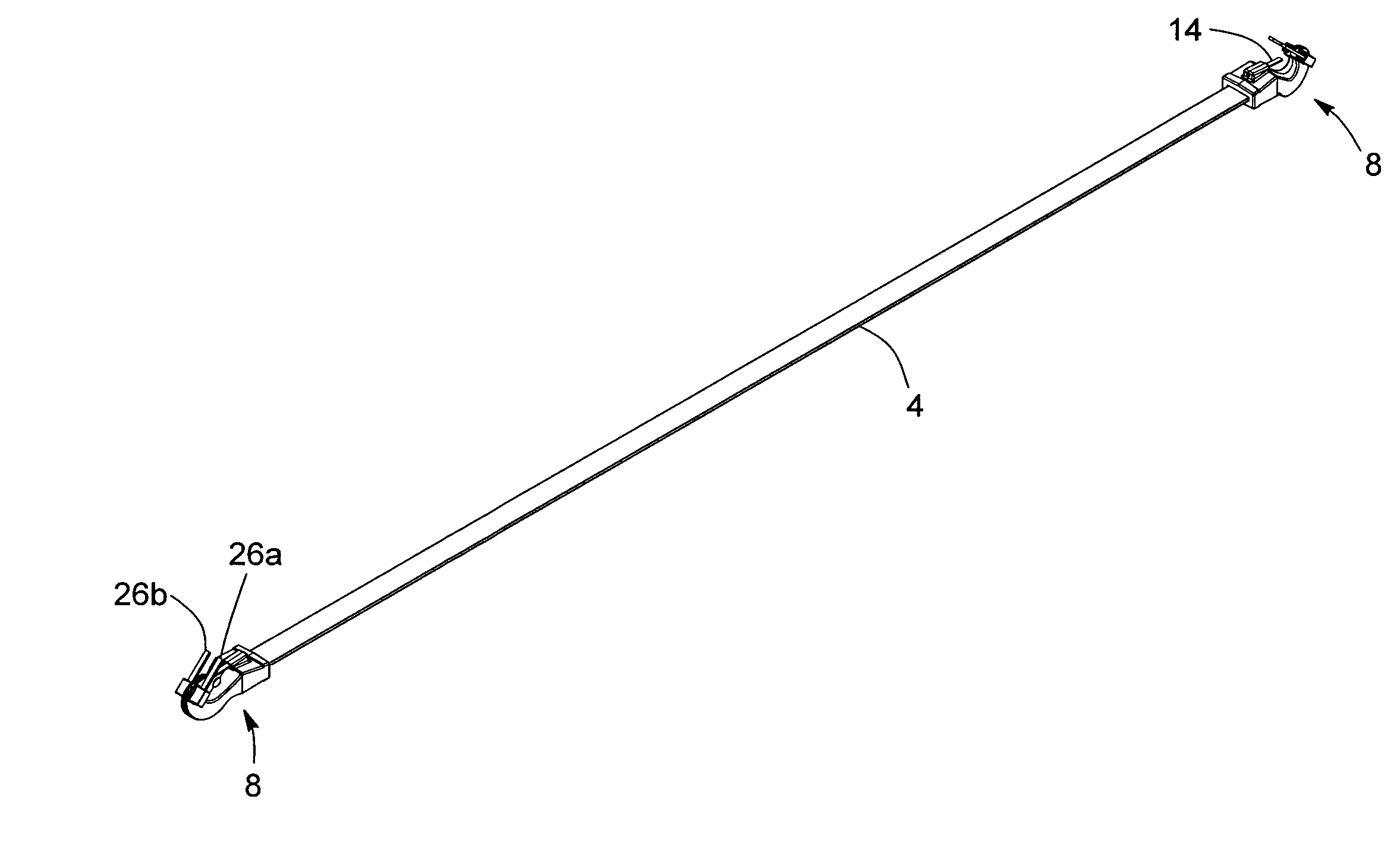

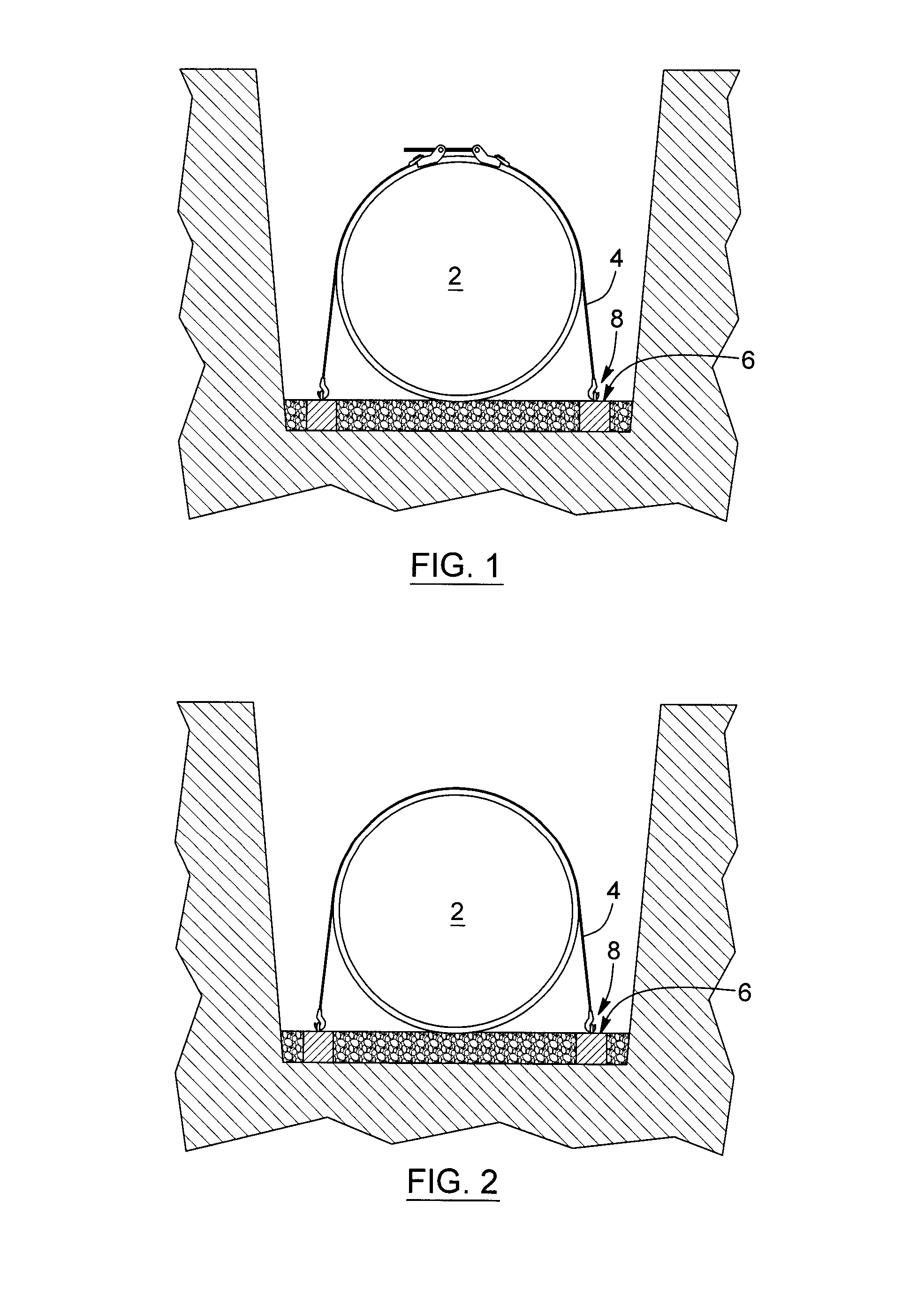

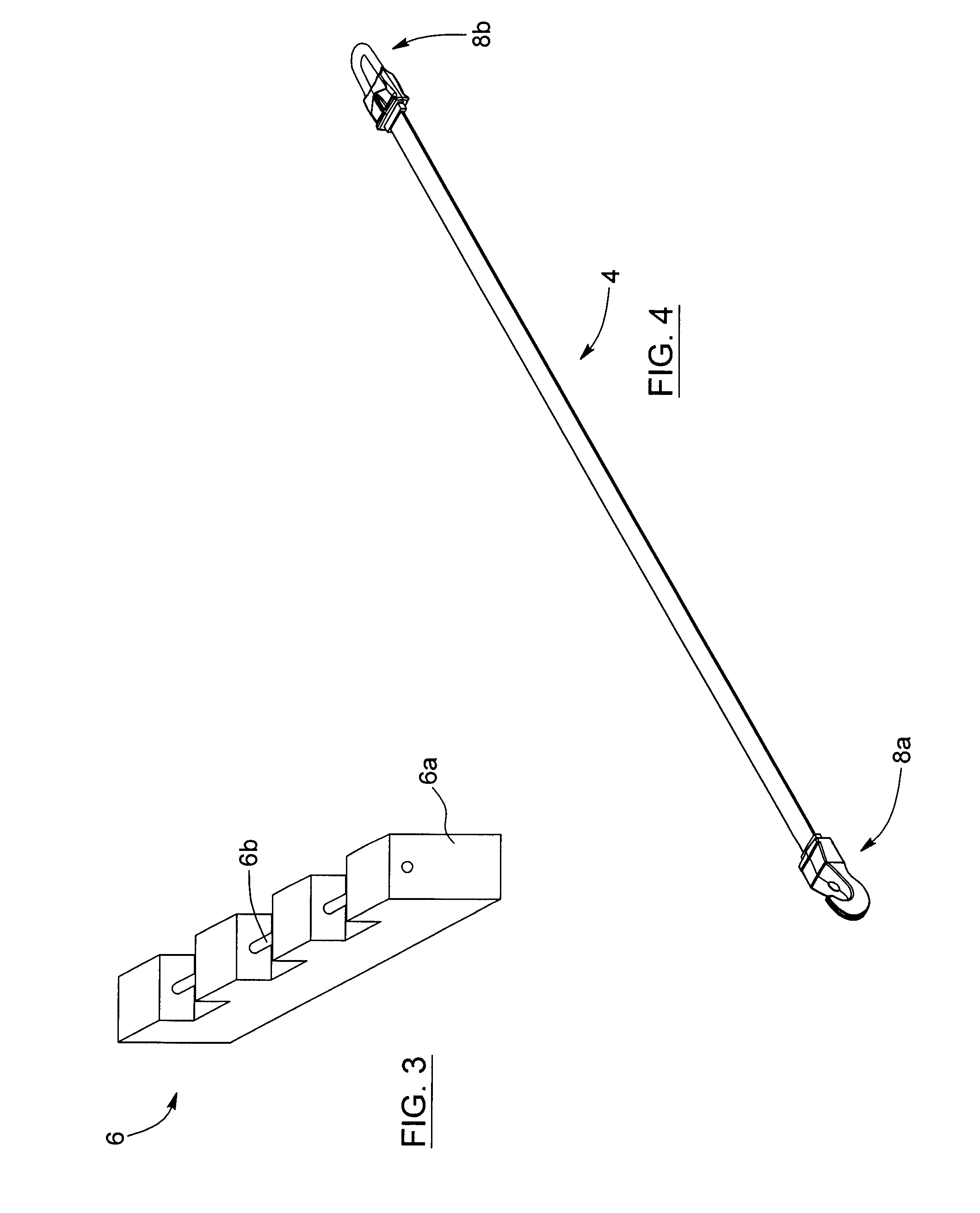

Hook with holding means and method for holding down underground tank with a strap

ActiveUS9228606B2Fully bentPreventing sufficient bendingLarge containersFurniture partsEngineeringMechanical engineering

A hook, a hold down strap and a method for holding down an underground tank. The hook includes a base portion connectable to the hold down strap; a curved portion extending from the base portion and defining a concave receiving area having an entrance sized and configured for receiving an anchor element. The hook includes at least one hooking aid member being a flexible member or an extension member. The flexible member extends across the entrance of the concave receiving area and is sized and configured to bend from a closed position to an open position such that, when the anchor element traverses the entrance, the flexible member bends from the closed position toward the concave receiving area to the open position, thus allowing the anchor element to enter the concave receiving area. The extension member extends from the curved portion beyond the entrance of the concave receiving area.

Owner:PULTRUSION TECHN

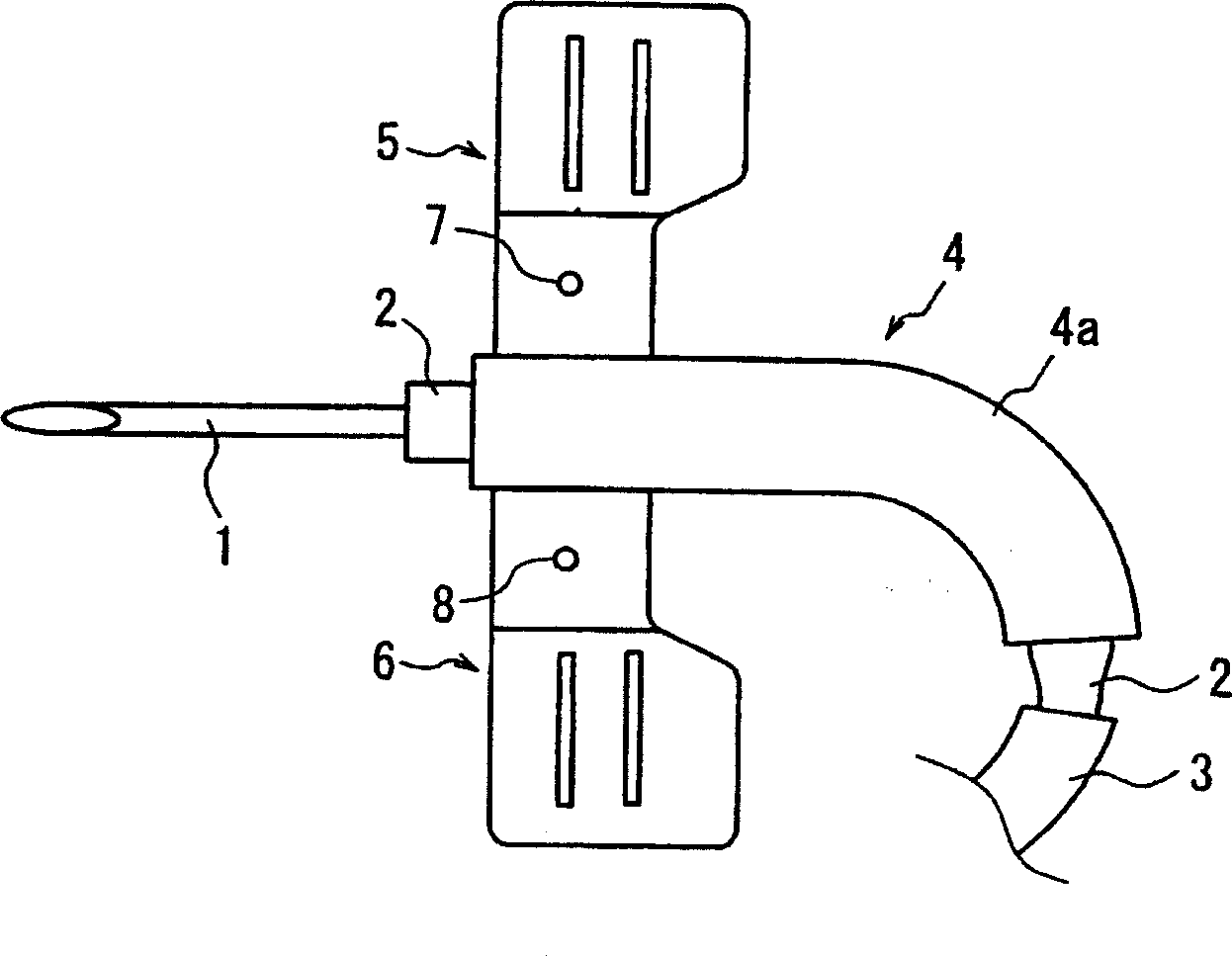

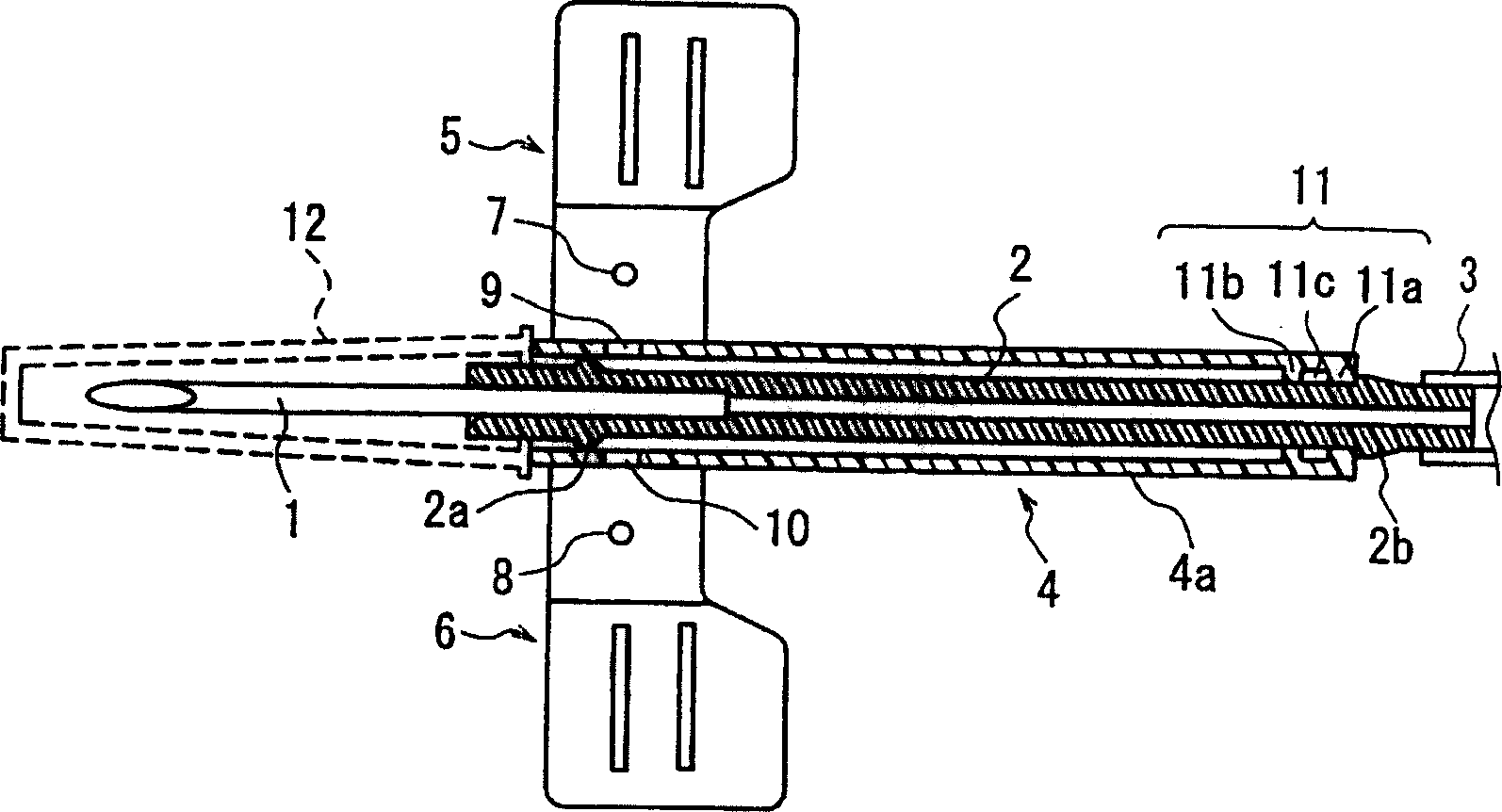

Medical needle device having shield with wings

InactiveCN1767868AShroud bendsFully bentGuide needlesInfusion needlesMedical deviceBiomedical engineering

Owner:JMS CO LTD

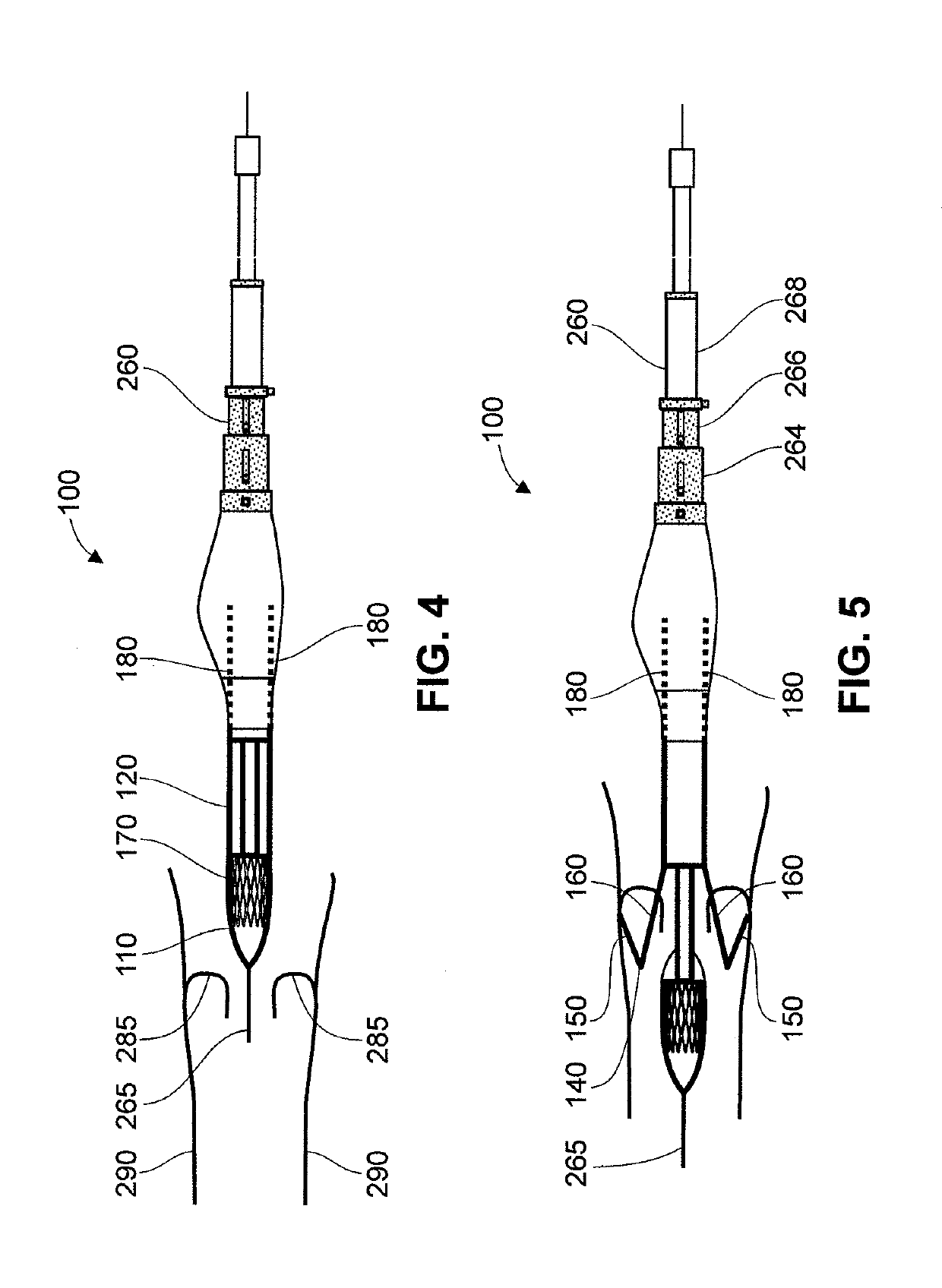

Sutureless valve prosthesis delivery device and methods of use thereof

ActiveUS10507104B2Reduce harmFully bentHeart valvesBlood vesselsMinimally invasive proceduresBiomedical engineering

Owner:JC MEDICAL INC

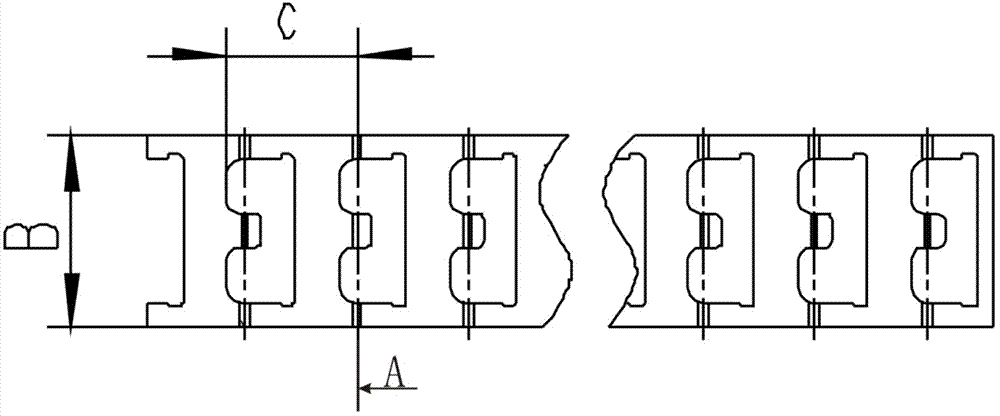

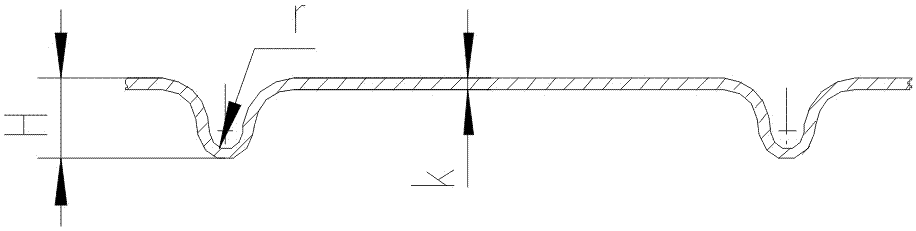

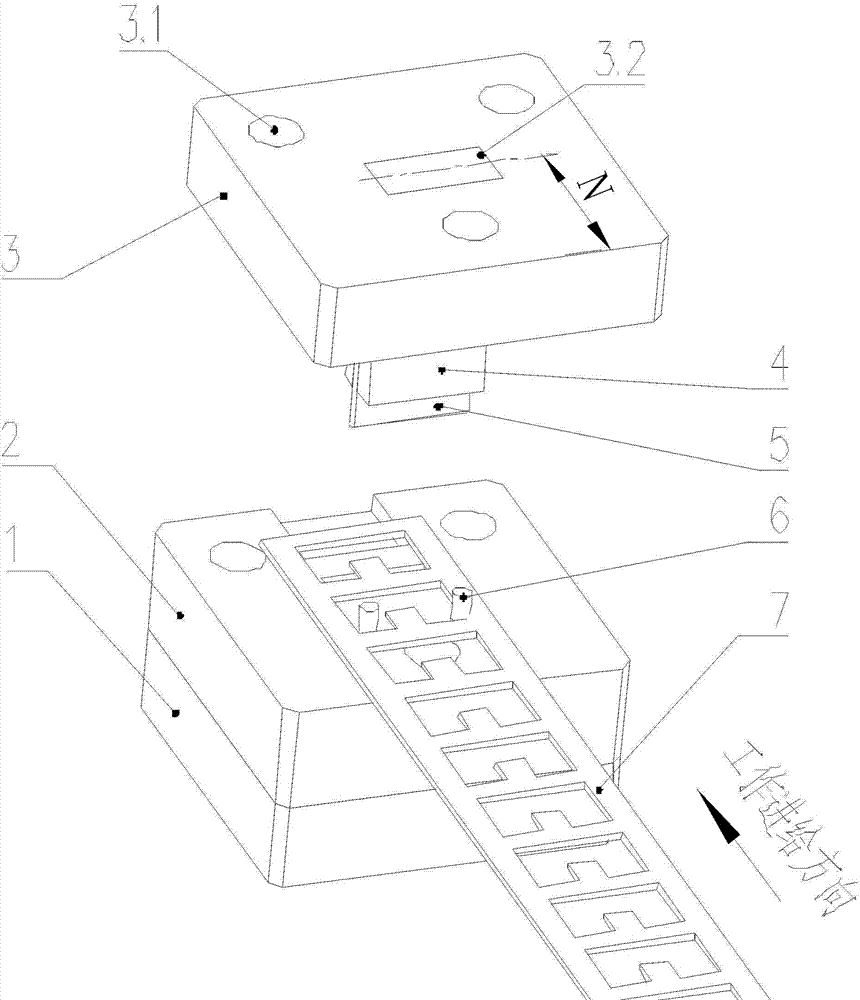

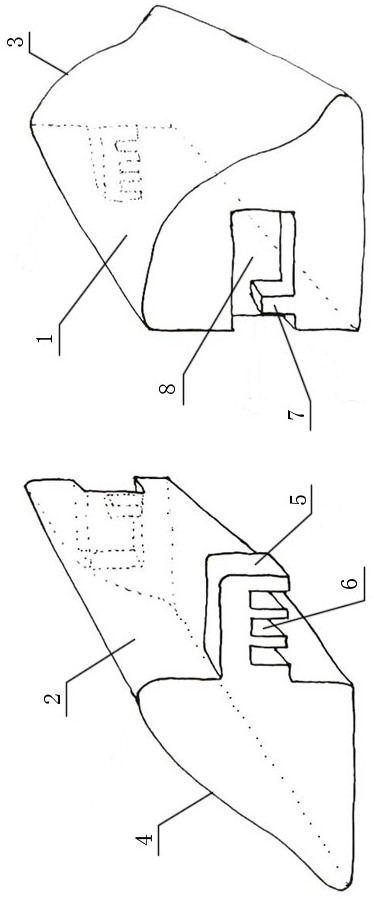

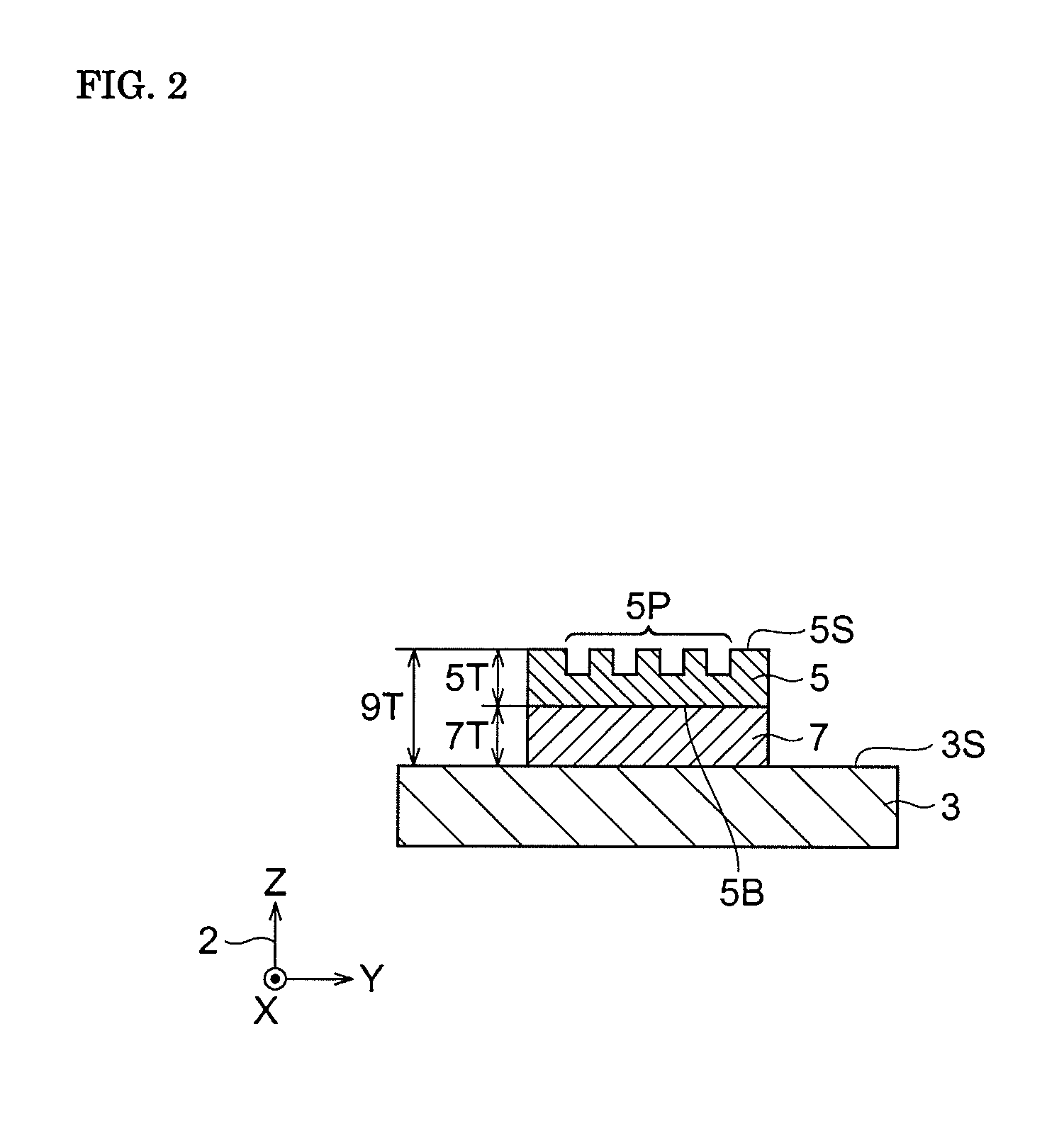

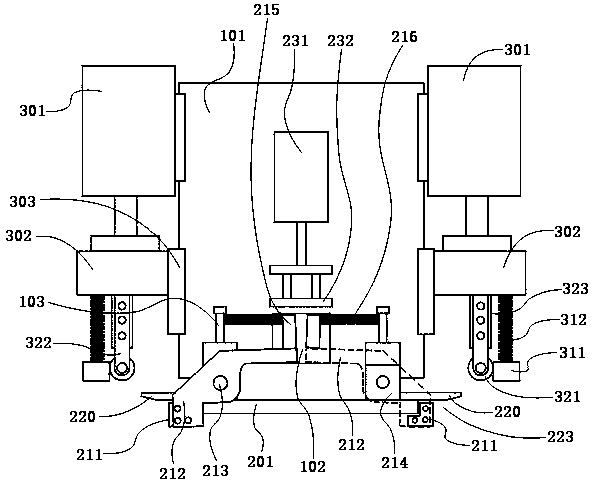

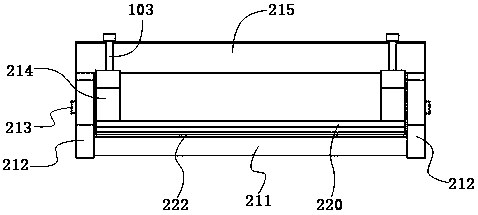

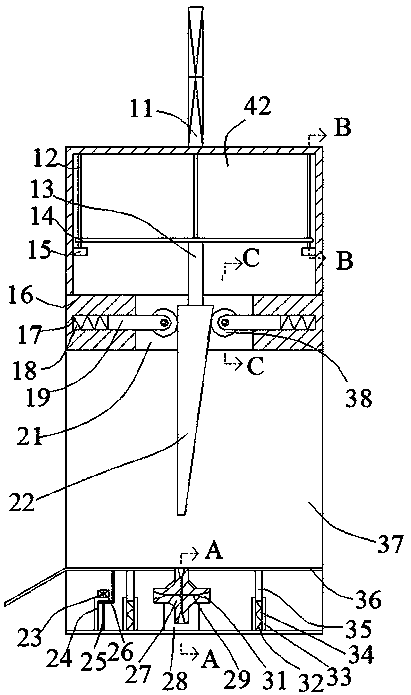

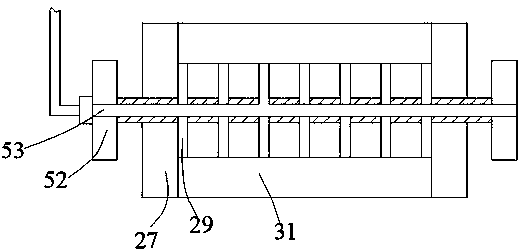

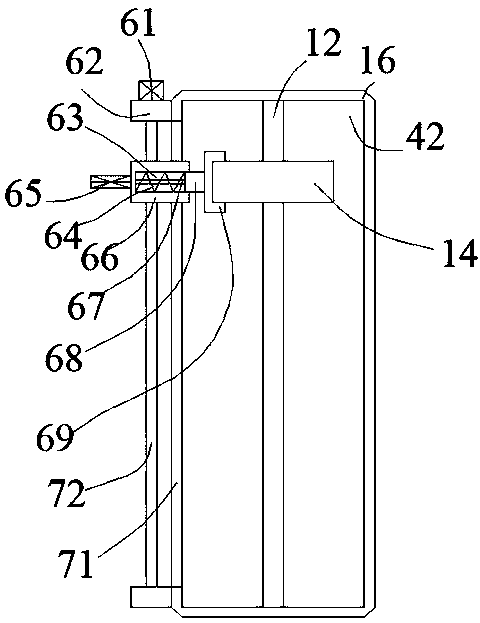

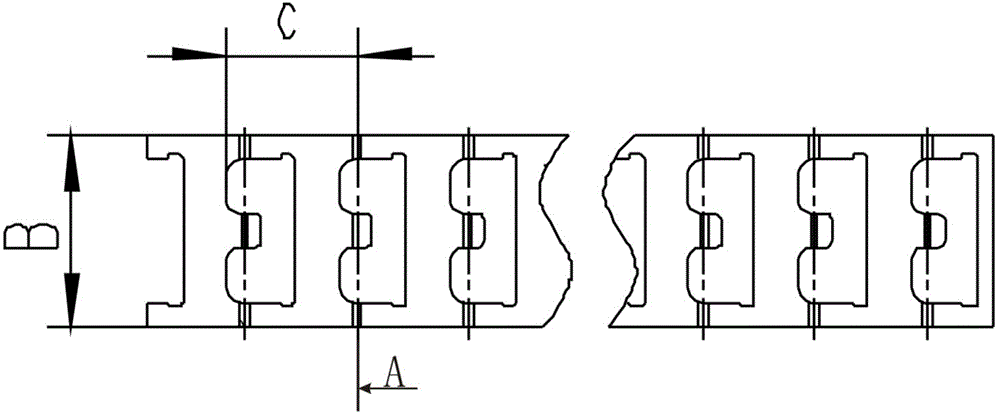

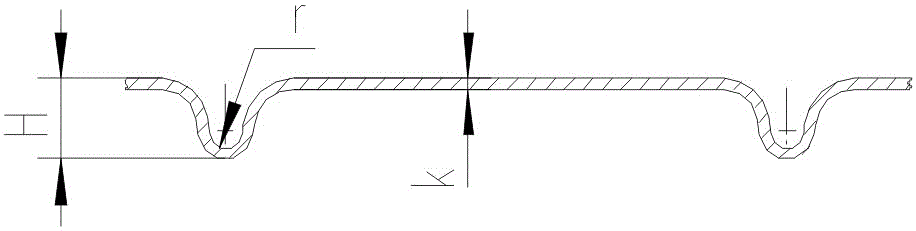

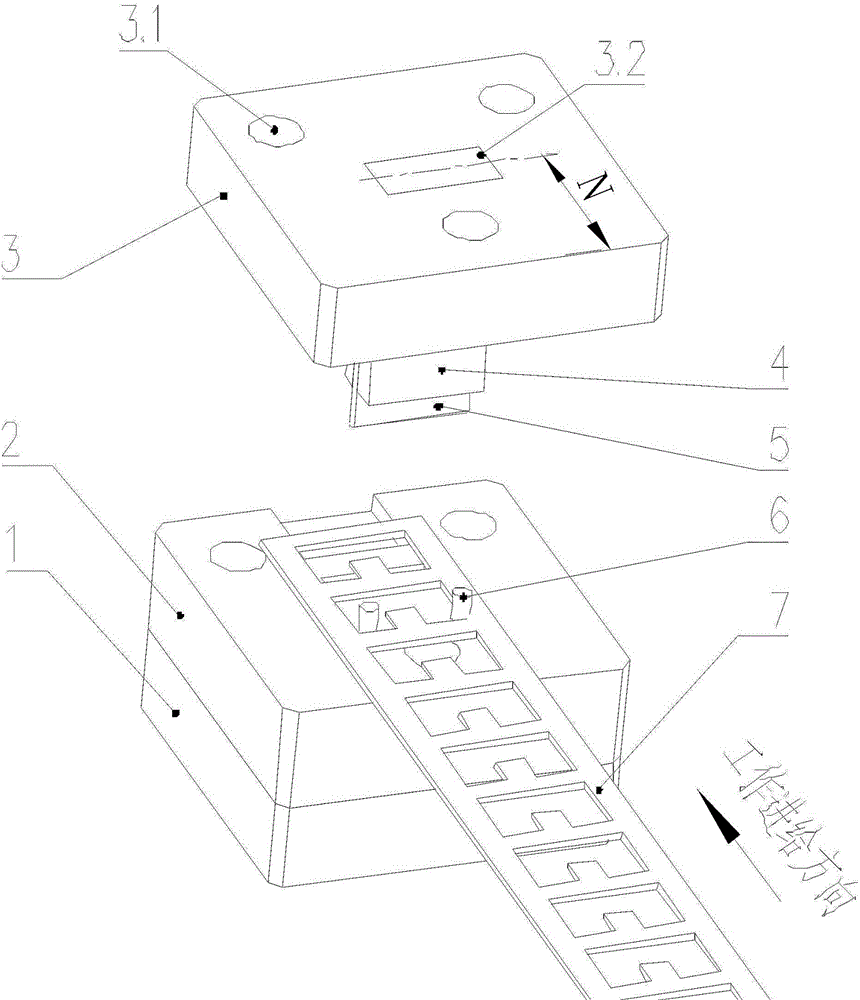

Method for bending wave spring with concave hole

The invention discloses a method for bending a wave spring with concave holes. The wave spring (7) to be bent has a width B and a thickness K and is provided with a plurality of concave holes; a pad plate (1) and a concave die (2) are fixed on a working table of a press machine through threaded through holes (8) of the concave die; a positioning pin (6) is installed inside a positioning pin hole (9); a convex die (3) is linked with a punching platform of the press machine through a threaded through holes (3.1) of the convex die; as N equals to M, a bending pressure head (5) can enter a bending groove (10); when the wave spring to be bent is positioned through the positioning pin, the punching platform moves downwards to bend the wave spring to be bent from the concave holes, and the bent parts of the wave spring meet the requirements of H and r; and the bent wave spring to be bent is taken out from the bending groove and moved to a discharge groove (11) so as to accomplish the bending process of the wave spring to be bent at one of the concave holes. The wave spring can be formed by repeating the bending process, the productivity is improved, and the rejection rate is reduced.

Owner:LUOYANG BEARING RES INST CO LTD

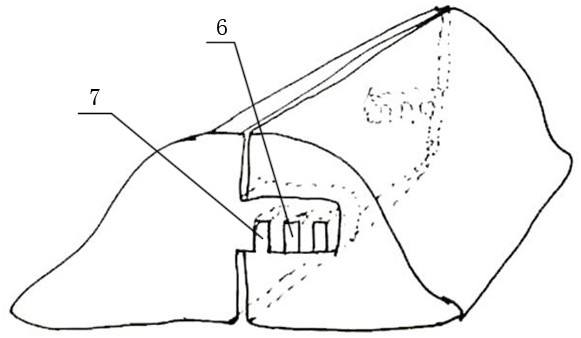

Combined cervical vertebra pillow

PendingCN111700454AAdjustable spacingAdjust and limit spacingPillowsMedical scienceHuman bodyCervical spondylosis

The invention relates to a combined cervical vertebra pillow, the pillow comprises a front half pillow and a rear half pillow which are arranged front and back, the rear end surface of the front halfpillow is opposite to the front end surface of the rear half pillow; the front end surface of the front half pillow is a neck and shoulder supporting curved surface for supporting the neck and shoulders of a human body; the rear end surface of the rear half pillow is an afterbrain supporting curved surface for supporting the afterbrain of a human body; the front half pillow and the rear half pillow are connected through a distance adjusting piece. The distance between the front half pillow and the rear half pillow can be adjusted and limited by changing the position of the movable connection;therefore, the neck and shoulder supporting curved surface and the afterbrain supporting curved surface are matched to form neck placing surfaces with different widths; the pillow is simple in structure, convenient to use, low in cost, capable of meeting the requirements of different people and different cervical spondylosis conditions, capable of meeting the requirements of cervical vertebra patients for sufficient bending of the cervical vertebra or horizontal stretching of the cervical vertebra in the change of the conditions, and convenient to apply and popularize.

Owner:洛阳轩尧健康科技有限公司

Hook with holding means and method for holding down underground tank with a strap

ActiveUS20140291471A1Fully bentPreventing sufficient bendingLarge containersFlexible elementsEngineeringMechanical engineering

A hook, a hold down strap and a method for holding down an underground tank. The hook includes a base portion connectable to the hold down strap; a curved portion extending from the base portion and defining a concave receiving area having an entrance sized and configured for receiving an anchor element. The hook includes at least one hooking aid member being a flexible member or an extension member. The flexible member extends across the entrance of the concave receiving area and is sized and configured to bend from a closed position to an open position such that, when the anchor element traverses the entrance, the flexible member bends from the closed position toward the concave receiving area to the open position, thus allowing the anchor element to enter the concave receiving area. The extension member extends from the curved portion beyond the entrance of the concave receiving area.

Owner:PULTRUSION TECHN

High tenacity low extensible nylon 6.6 cord

A two or three-ply nylon 6.6 cord having a breaking elongation of 8 to 12% and a minimum tenacity of 9 g / dtex is disclosed in the present invention. The two or three-ply nylon 6.6 cord is used as tire reinforcement, in particular as cap ply spirally wound on belt package with 0° to 5° to the equatorial plane of the radial pneumatic tire.

Owner:KORDSA TEKNIK TEKSTIL ANONIM SIRKETI

Nano-imprint mold

Owner:SUMITOMO ELECTRIC IND LTD

Shoe sole

Owner:ASICS CORP

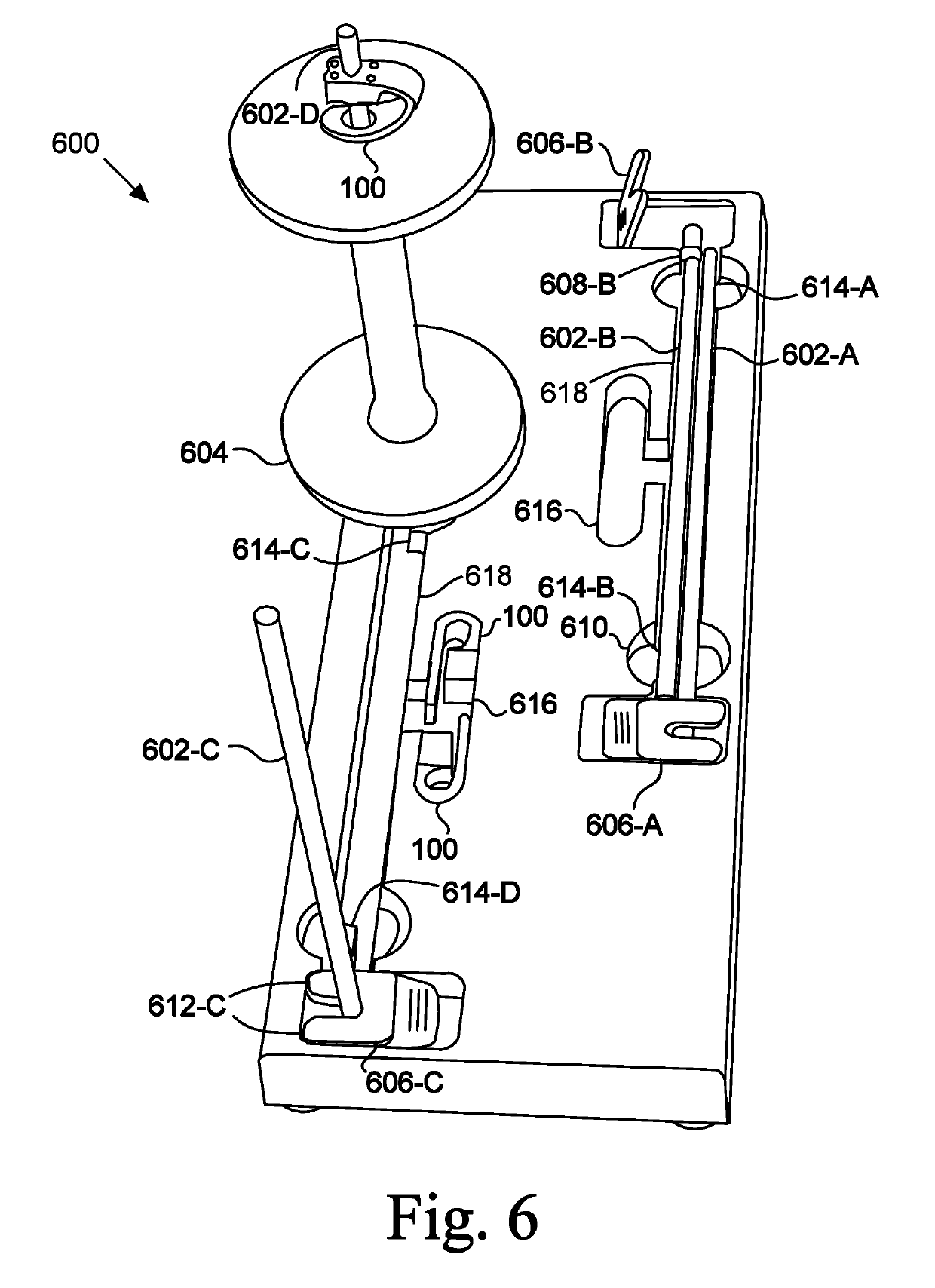

Quick-adjust tensioner

ActiveUS10427850B2Fine-tune braking torqueIncrease and decrease tensionFilament handlingFlexible elementsEngineering

Owner:AKERWORKS INC

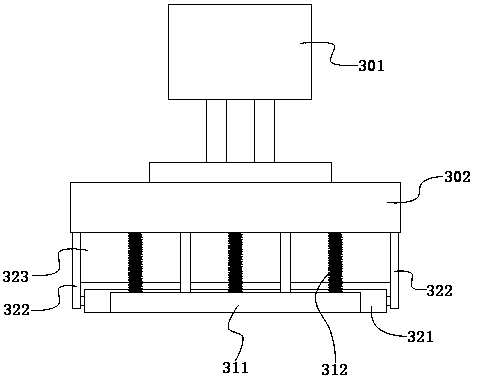

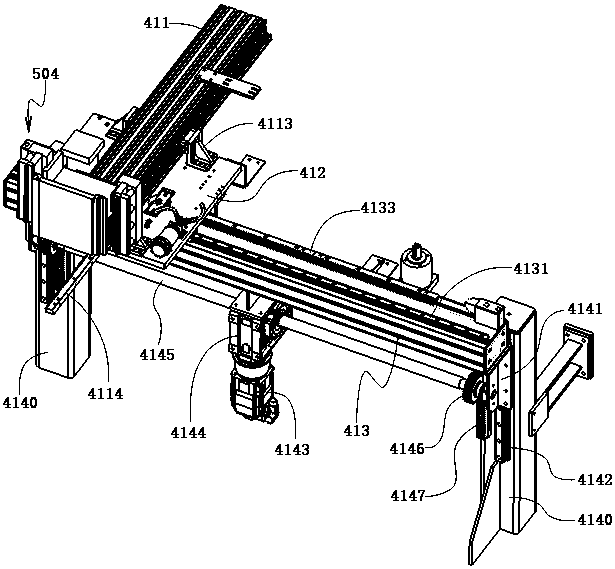

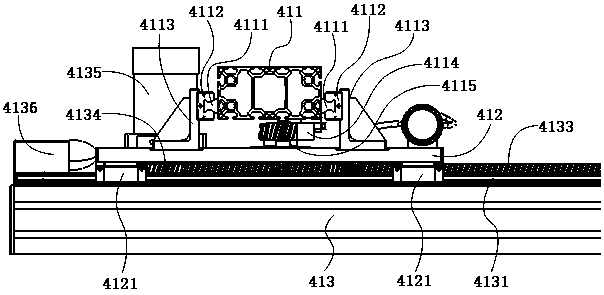

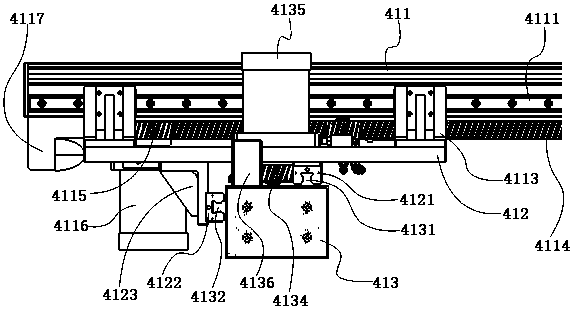

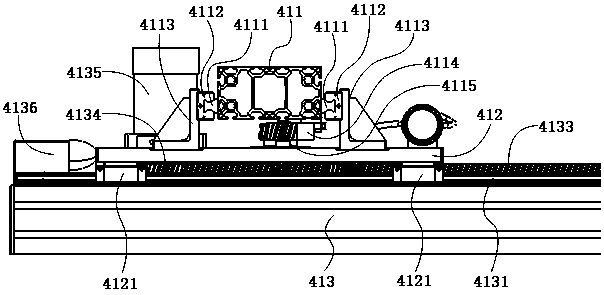

Double short side corner line riveting mechanism for liner of roller type refrigerator

PendingCN108580712ARealize bending rivetingImprove yieldHollow articlesEngineeringMechanical engineering

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Quick-adjust Tensioner

ActiveUS20180111732A1Fine-tune braking torqueIncrease and decrease tensionFilament handlingFlexible elementsBrake torqueEngineering

Owner:AKERWORKS INC

High tenacity low extensible nylon 6.6 cord

InactiveUS20180187344A1Increased durabilityEasy to handlePneumatic tyre reinforcementsYarnNylon 6Engineering

A two or three-ply nylon 6.6 cord having a breaking elongation of 8 to 12% and a minimum tenacity of 9 g / dtex is disclosed in the present invention. The two or three-ply nylon 6.6 cord is used as tire reinforcement, in particular as cap ply spirally wound on belt package with 0° to 5° to the equatorial plane of the radial pneumatic tire.

Owner:KORDSA TEKNIK TEKSTIL ANONIM SIRKETI

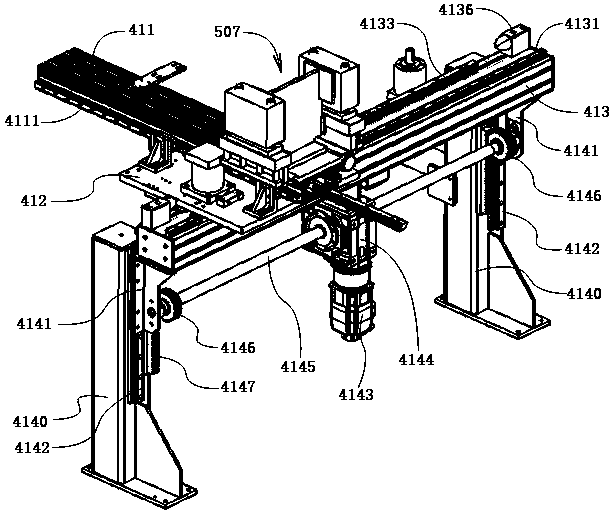

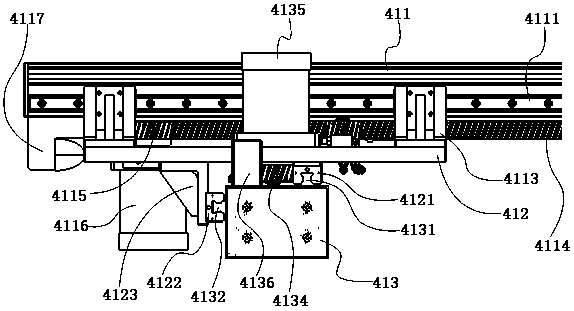

Turnover type refrigerator liner double-vertical edge angle line substep riveting mechanism

ActiveCN108176779ARealize bending rivetingImprove yieldProgramme-controlled manipulatorVertical edgeEngineering

The invention discloses a turnover type refrigerator liner double-vertical edge angle line substep riveting mechanism. The turnover type refrigerator liner double-vertical edge angle line substep riveting mechanism comprises a double-vertical edge riveting device and a mechanical arm mechanism. The mechanical arm mechanism comprises a mechanical arm that is horizontally translational and longitudinally retractable. The double-vertical edge riveting device is arranged at the front end of the mechanical arm, and comprises a vertical edge riveting bracket and two vertical straight-side riveting mechanisms which face opposite directions and are arranged on the vertical edge riveting bracket. Each straight-sided riveting mechanism comprises a straight-sided clamping opening mechanism and a straight-sided pressing plate bending mechanism. The straight-sided pressing plate bending mechanism comprises a straight-sided pressing plate die strip a straight-sided bending die strip and a straight-sided driving frame. The straight-sided bending die strip is located at the inner side of the straight-sided pressing plate die strip, and arranged at the front of the straight-sided driving frame through a turnover shaft at the top end, and is in parallel and close to the straight-sided pressing plate die strip. The turnover shaft is provided with a turnover gear. The turnover gear is meshed witha turnover gear connected with a turnover air cylinder. A clamping opening mounting plate is arranged at the front portion of the vertical edge riveting bracket, the straight-sided clamping opening mechanisms are arranged at the two sides of the clamping opening mounting plate. The turnover type refrigerator liner double-vertical edge angle line substep riveting mechanism improves the rate of finished products.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

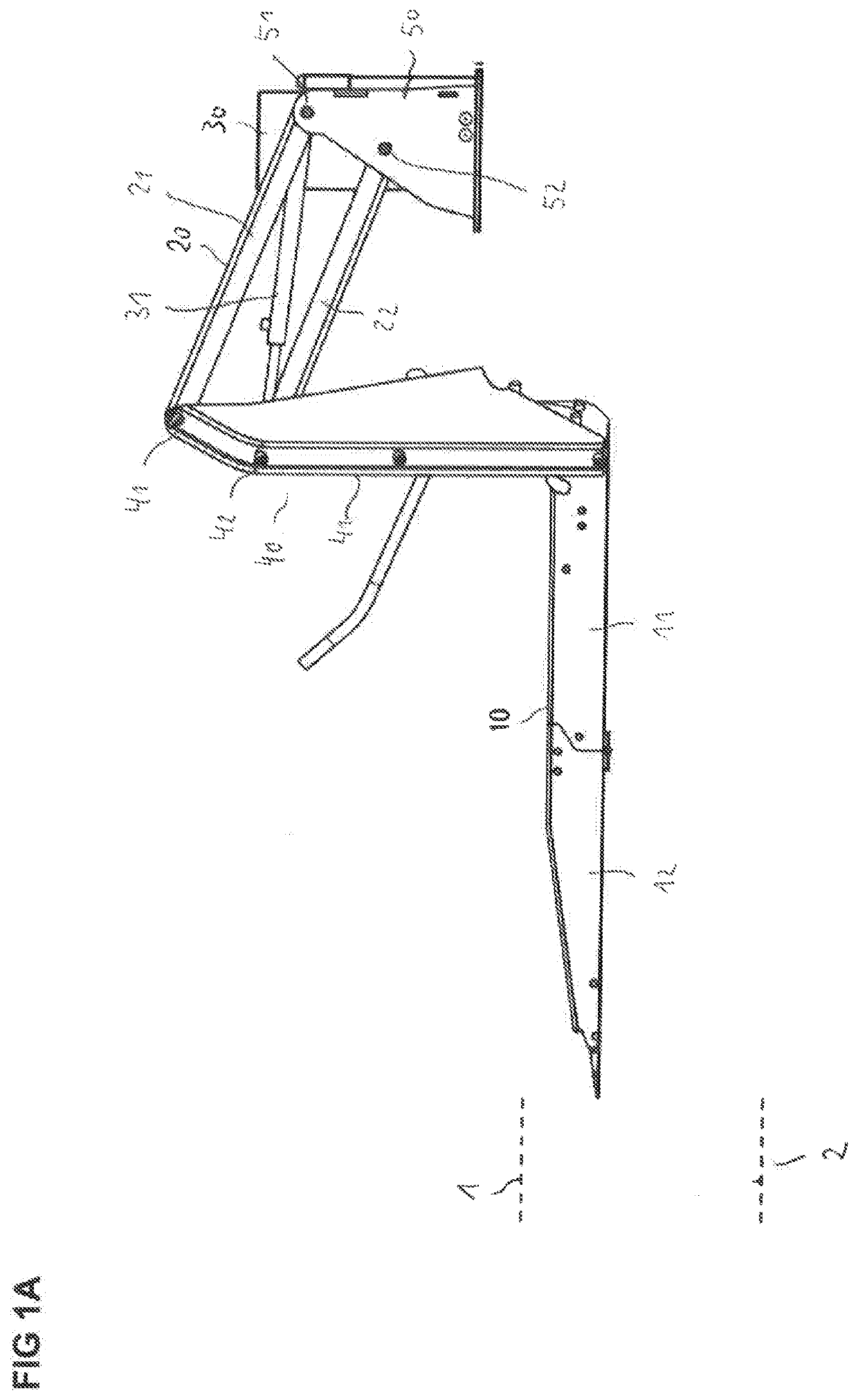

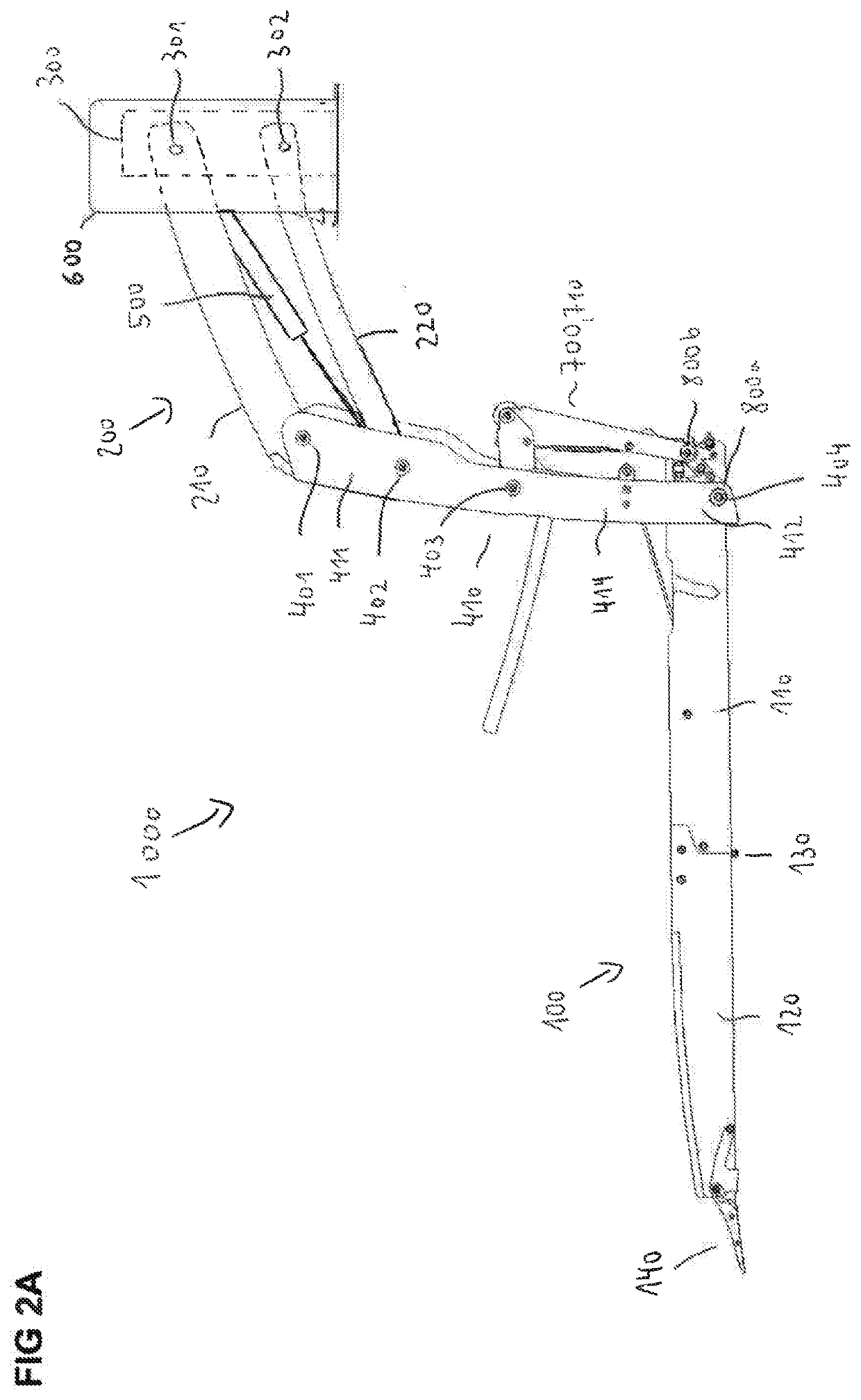

Wheelchair lift with high stability

ActiveUS20200093660A1High strength and stabilityHigh torsional force/momentAmbulance serviceEngineeringPhysical therapy

A wheelchair lift includes a platform assembly to receive a wheelchair, and a lifting assembly to move the platform assembly, a supporting plate to support the lifting assembly, and a supporting arm to support the platform assembly. The lifting assembly includes a pair of a first lifting arm and a second lifting arm. The first lifting arm has a bent shape along the longitudinal direction of the first lifting arm, and the second lifting arm has a bent shape along the longitudinal direction of the second lifting arm.

Owner:AUTOELEVATOR

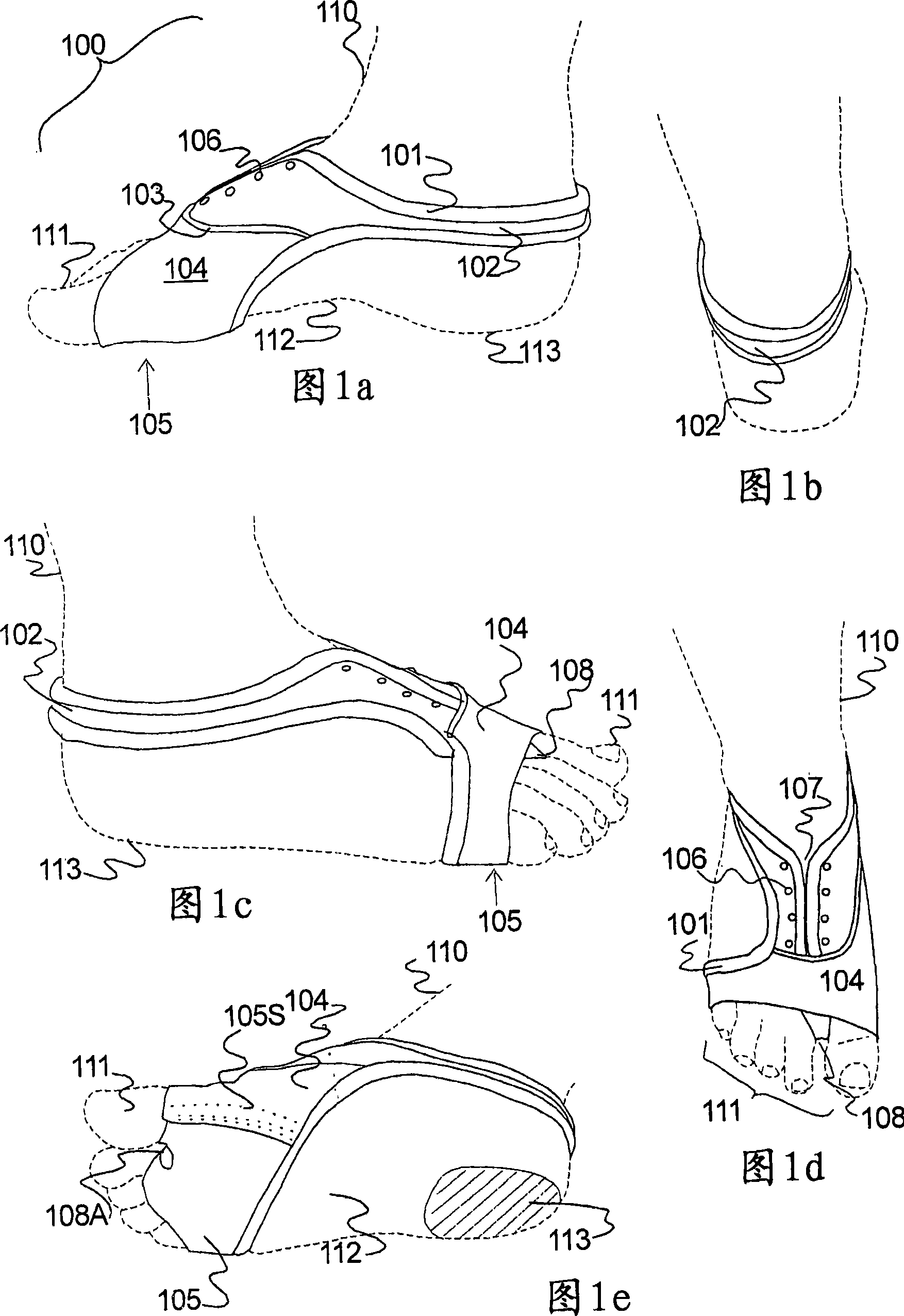

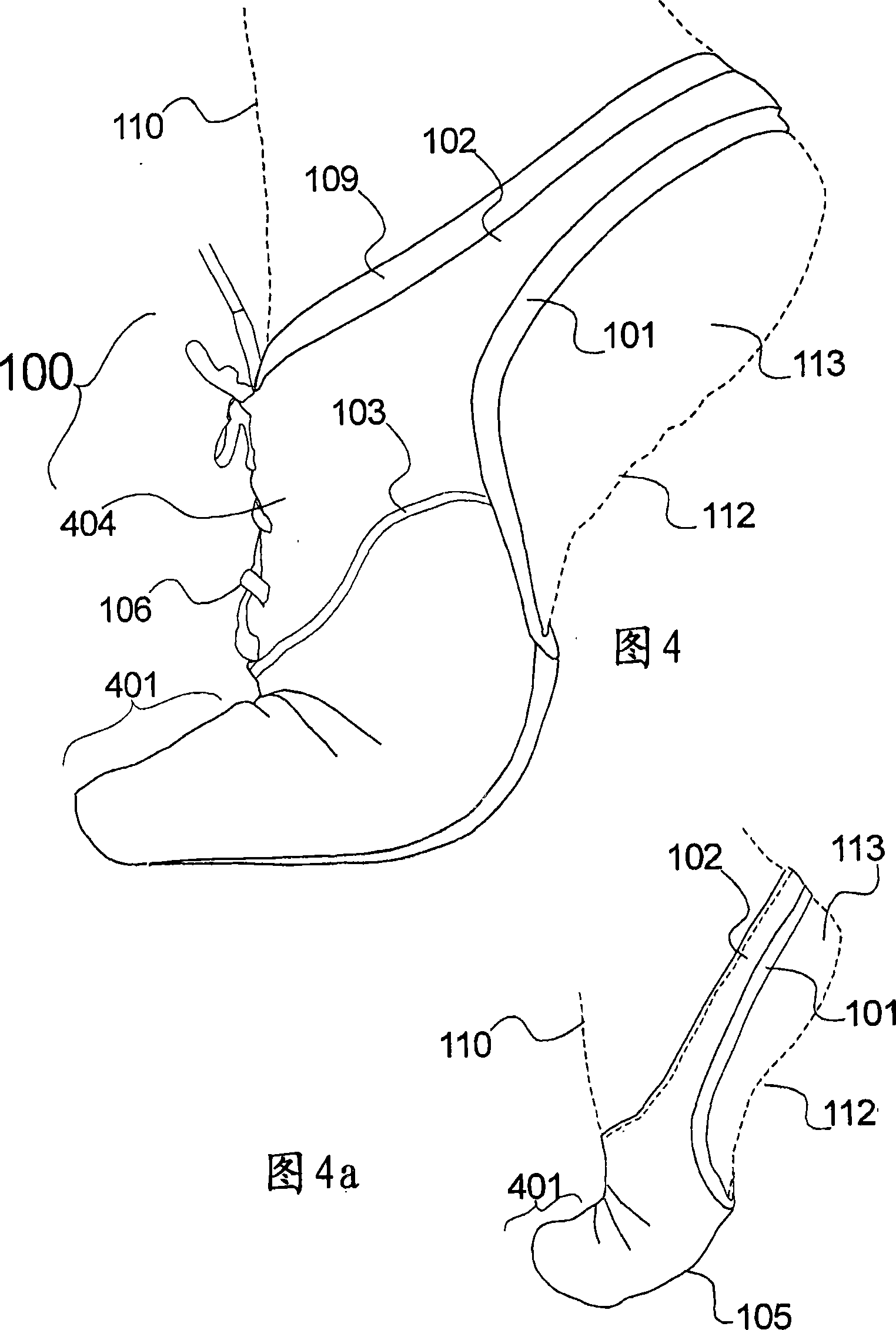

A shoe

InactiveCN101170919AAdvantages of industrial applicabilityImprove matchFootwearDorsal partsPhysical medicine and rehabilitation

A shoe (100) provides a sole (105) under the ball of the foot (110) but none below the arch (112) or heel (113). An upper (104) encircles the metatarsal bones and the distal end of the tarsals. An inelastic ankle band (102) shaped as ''C'' holds the shoe on the foot. Support is mainly longitudinal, includes over the arch, may be adjustable, and is provided without causing foot distortion. Sensation from exposed parts of the foot promotes kinaesthetic procedure for teaching and learning dance. Variations enclose the dorsal part of the foot, some enclose the toes, and one optio is a toe box for en pointe.

Owner:凯列·彼得雷亚·布罗德利

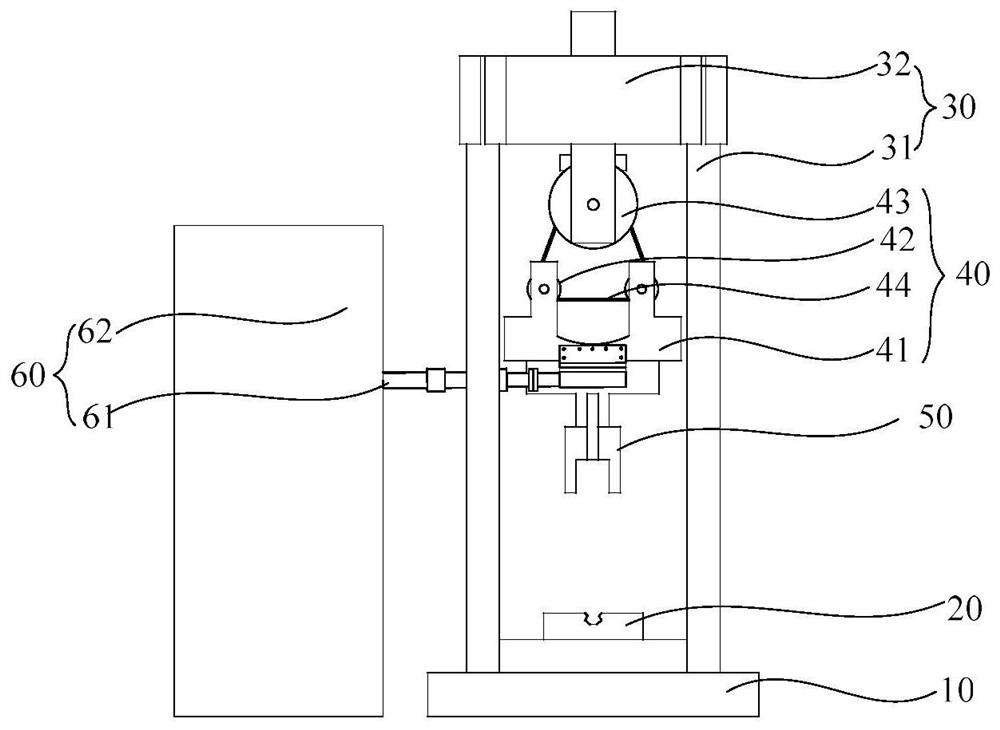

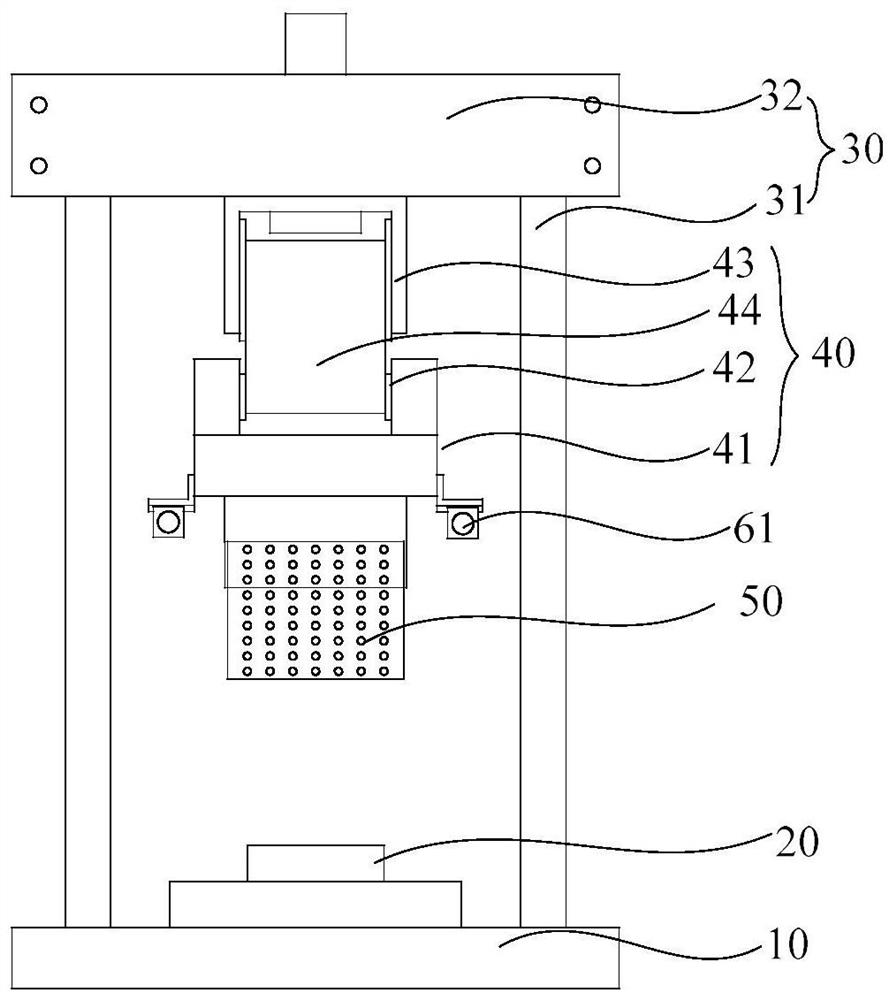

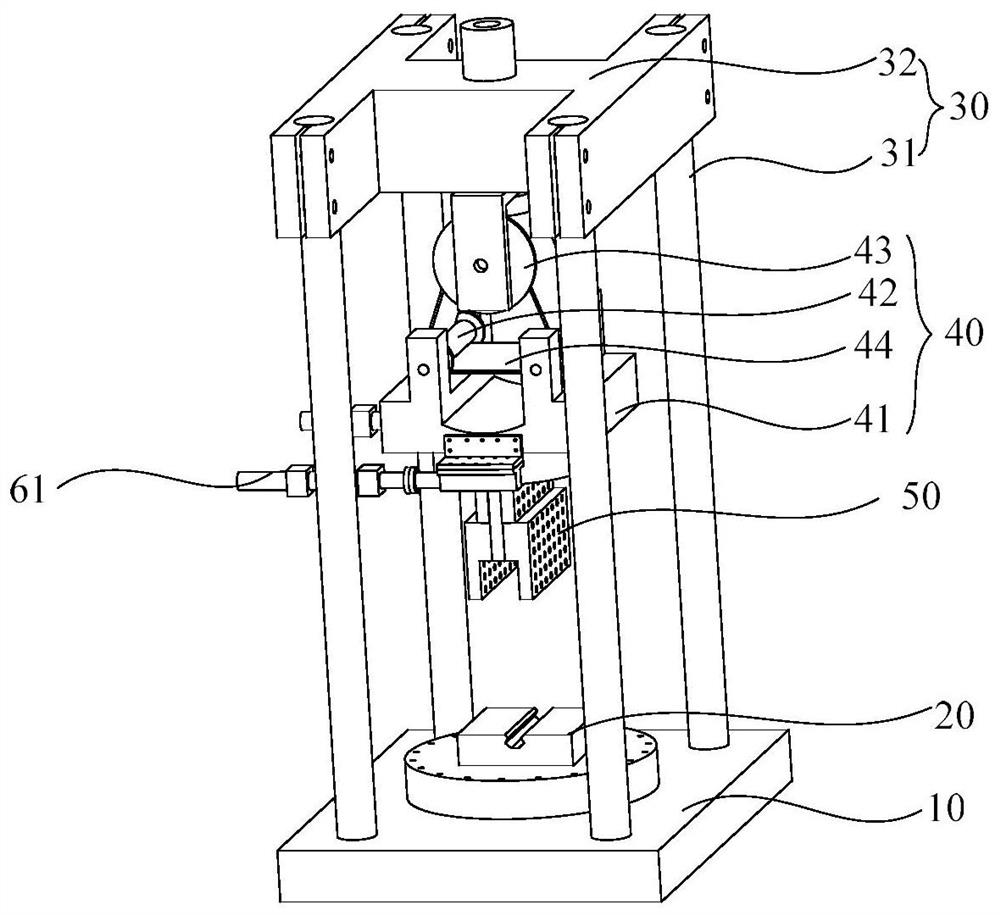

Low-cycle fatigue composite test device

InactiveCN113176088AAchieve bendingFully bentMachine part testingWind energy generationFatigue loadingPull force

The invention provides a low-cycle fatigue composite test device. The low-cycle fatigue composite test device comprises a base, a first chuck, a support, a lifting device, a rotating device, a horizontal moving device, a second chuck, a load applying device and a control device. The horizontal moving device is fixed to the rotating device and can move in the horizontal direction relative to the support. According to the load applying device, a horizontal pushing force or pulling force is applied to a blade through the horizontal moving device, the lifting device can apply a vertical pulling force and pressure to the blade, the rotating device can apply rotating forces in different directions to the blade, and an external force can be applied to the blade in multiple directions; and bending, twisting and multi-angle combined fatigue loading forms of the blade can be realized, and through the fatigue load and the strain distribution, the structural performance of the blade under the fatigue load can be evaluated. Therefore, the fatigue test can be fully performed on the blade.

Owner:HARBIN INST OF TECH

Metal sheet bending equipment

InactiveCN111266441AAvoid getting hurtEasy to useShaping toolsHydraulic cylinderStructural engineering

The invention discloses metal sheet bending equipment. The equipment comprises a box, a passing inner cavity is formed in the box in a penetrating mode, a penetrating inner cavity is formed in the upper end wall of the passing inner cavity in a communicating mode, a top inner cavity is formed in the upper end wall of the penetrating inner cavity in a communicating mode, a top hydraulic cylinder isfixedly arranged on the upper end face of the box, a bottom fixing rod located in the top inner cavity is arranged on the lower side of the top hydraulic cylinder in a power connection mode, an upperdie is fixedly arranged on the lower end face of the bottom fixing rod, side bosses are fixedly arranged in the end walls of the two sides of the top inner cavity in a symmetrical mode, a vertical rod is fixedly arranged between each side boss and the upper end wall of the top inner cavity, lifting mating plates are arranged on the outer surfaces of the vertical rods in a sliding mode, and the lifting mating plates are fixed with the bottom fixing rod. According to the equipment, the structure is simple, and the upper die and a lower die are subjected to oil lubrication, so that bending is efficient, and the service life of the equipment is prolonged; and meanwhile, a structure for preventing personnel from being injured is arranged so that the personnel can safely use the equipment.

Owner:王宏斌

Roller type refrigerator liner double-short-side corner line step-by-step riveting mechanism

The invention discloses a roller-type refrigerator liner double-short-side corner line step-by-step riveting mechanism. The mechanism comprises a double-short-side corner line riveting mechanism and amechanical arm mechanism. The mechanical arm mechanism comprises a transverse movable mechanical arm and a longitudinal telescopic mechanical arm. The double-short-side corner line riveting mechanismis installed at the front end of the mechanical arm, wherein the double-short-side riveting support comprises a short side riveting support and two horizontal edge riveting mechanisms arranged on theshort side riveting support, and the two horizontal edge riveting mechanisms are opposite to each other. The horizontal edge riveting mechanism comprises a straight edge clamping mechanism and a straight edge pressing plate bending mechanism. The straight edge pressing plate bending mechanism comprises a straight edge pressing plate mold strip, a straight edge bending mold strip and a straight edge driving frame. The straight edge pressing plate mold strip is installed below the straight edge driving frame through a spring column mechanism. The straight edge bending mold strip is a roller horizontally arranged and installed on a rolling shaft below the straight edge driving frame. The straight edge bending mold strip is located on the inner side of the straight edge pressing plate mold strip and clings to the inner side of the straight edge pressing plate mold strip. The straight edge clamping mechanism is located on the inner side of the straight edge bending mold strip. The straightedge driving frame is driven by a driving air cylinder to ascend and descend. According to the mechanism, the product rate of finished products is improved.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

Mechanical arm fixed block for light blockage coating machine

InactiveCN101434072AReduce tensionRelieve pressureLiquid surface applicatorsFlexible pipesRobotic armAgricultural engineering

The invention relates to a mechanical arm fixing block for a photoresist coating machine. The inner wall of the fixing block is a truncated cone shaped through hole and is used for receiving a pipeline; the fixing block is arranged at the middle part of a mechanical arm, and the longitudinal axis of the fixing block is intersected with that of the mechanical arm at an oblique angle. The adoption of a structure and a fixing mode of the mechanical arm fixing block can overcome dust caused by the loss of the pipeline in the prior art.

Owner:HEJIAN TECH SUZHOU

Method for bending wave spring with concave hole

The invention discloses a method for bending a wave spring with concave holes. The wave spring (7) to be bent has a width B and a thickness K and is provided with a plurality of concave holes; a pad plate (1) and a concave die (2) are fixed on a working table of a press machine through threaded through holes (8) of the concave die; a positioning pin (6) is installed inside a positioning pin hole (9); a convex die (3) is linked with a punching platform of the press machine through a threaded through holes (3.1) of the convex die; as N equals to M, a bending pressure head (5) can enter a bending groove (10); when the wave spring to be bent is positioned through the positioning pin, the punching platform moves downwards to bend the wave spring to be bent from the concave holes, and the bent parts of the wave spring meet the requirements of H and r; and the bent wave spring to be bent is taken out from the bending groove and moved to a discharge groove (11) so as to accomplish the bending process of the wave spring to be bent at one of the concave holes. The wave spring can be formed by repeating the bending process, the productivity is improved, and the rejection rate is reduced.

Owner:LUOYANG BEARING RES INST CO LTD

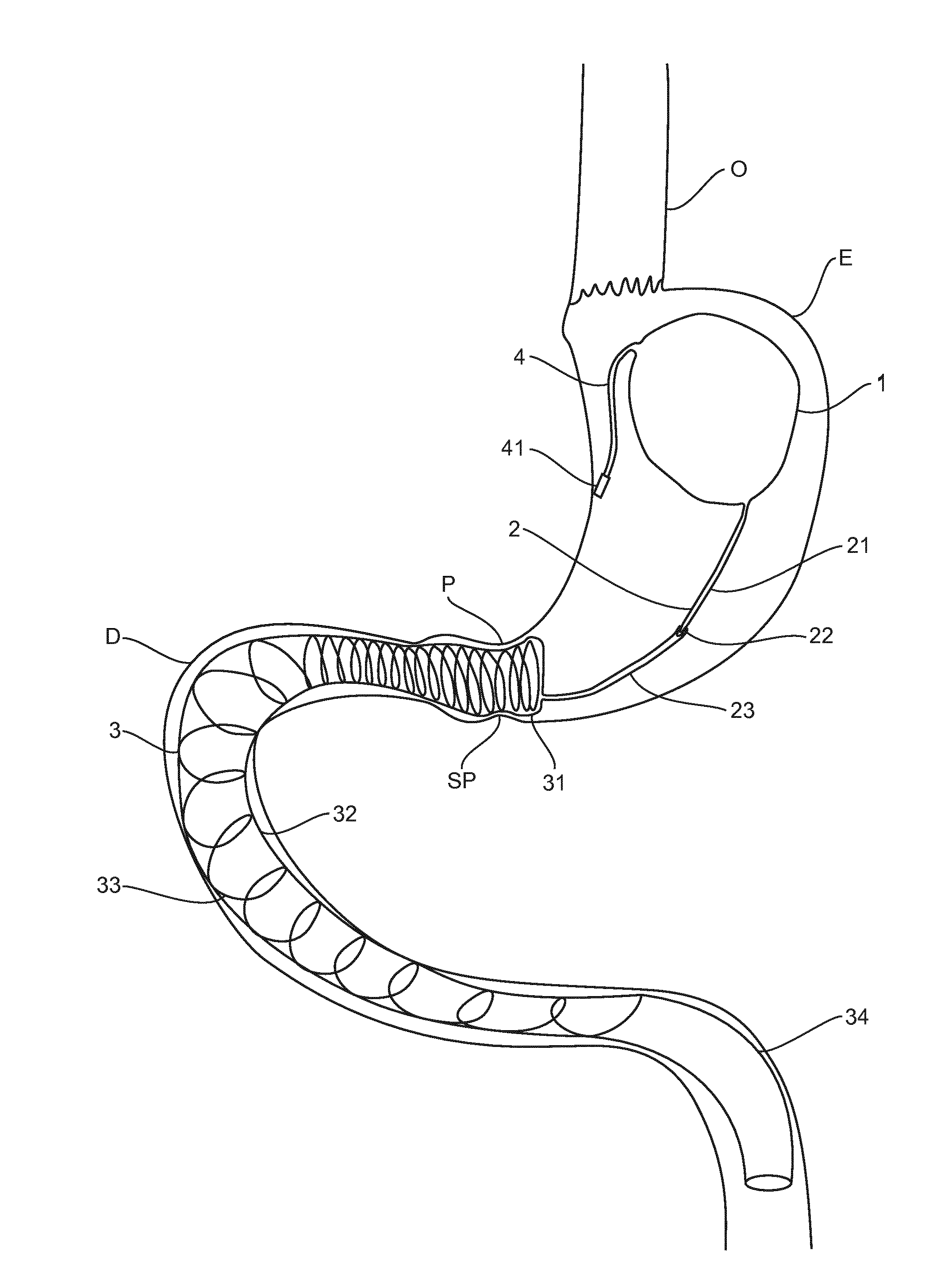

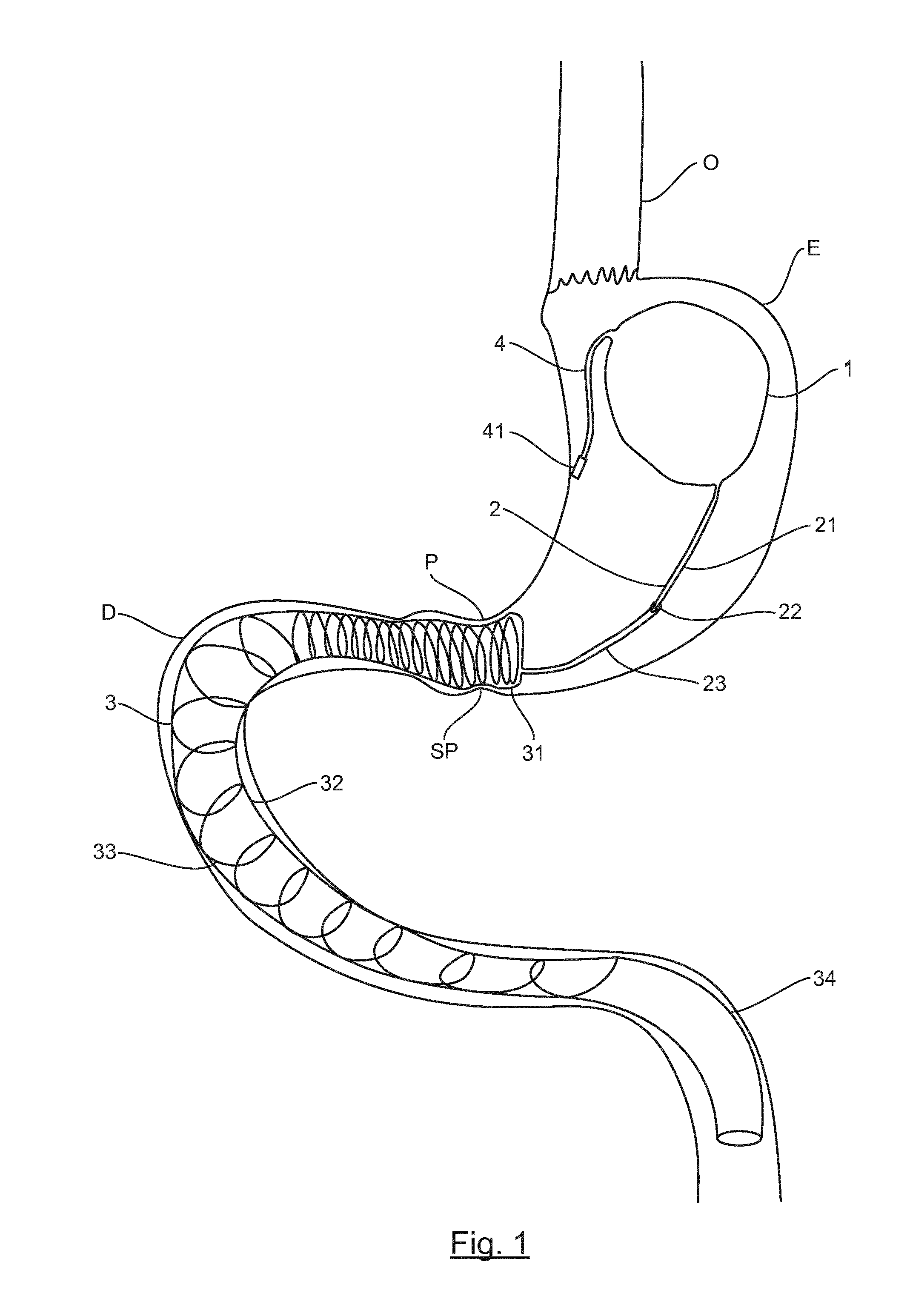

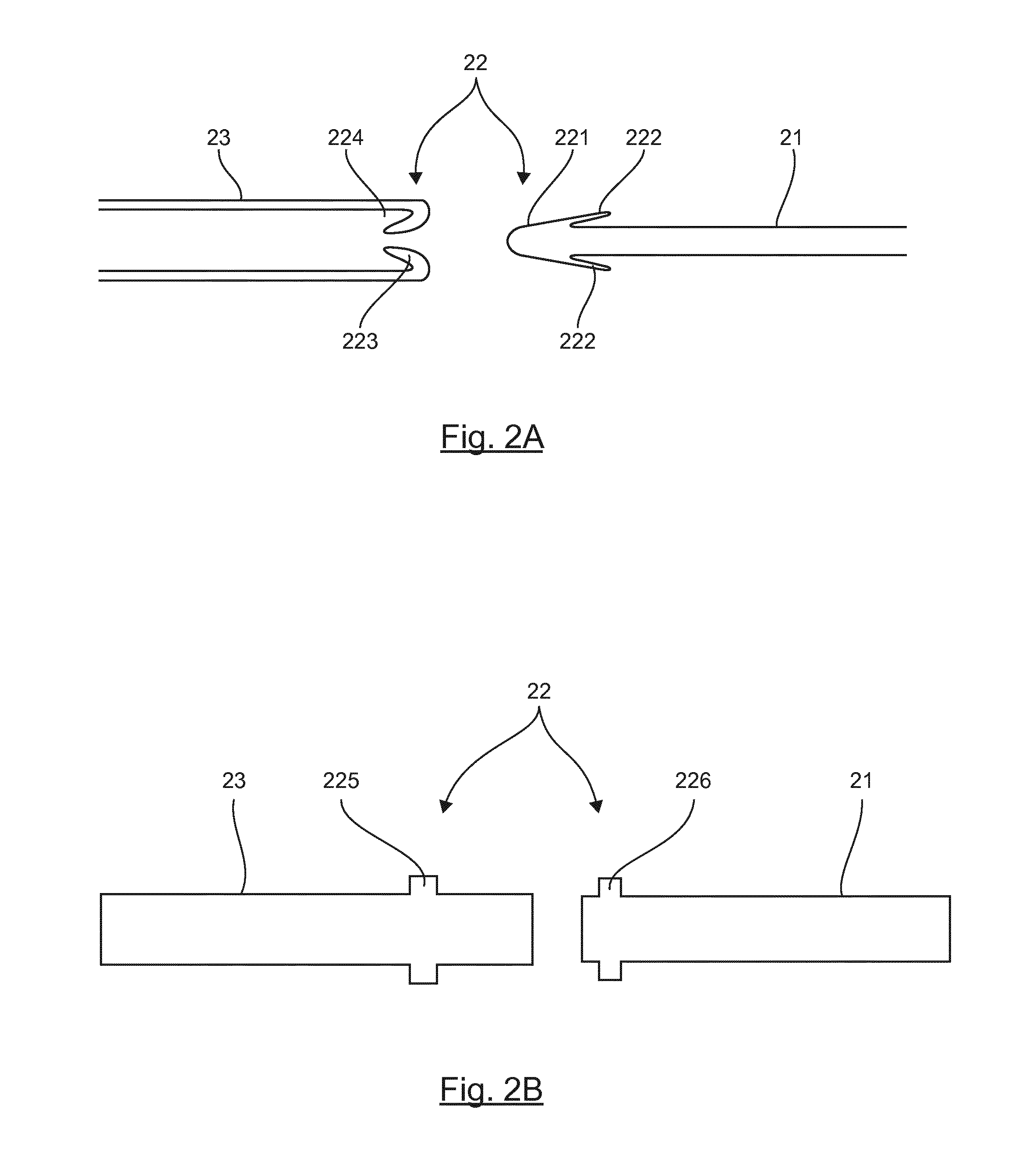

Implantable prosthetic device for weight loss in an obese or overweight patient comprising an inflatable gastric balloon and a duodenal prosthesis

InactiveUS20170000636A1CategoryFully bentNon-surgical orthopedic devicesObesity treatmentDuodenal prosthesisPyloric orifice

The invention relates to a prosthetic device intended for being implanted in a patient's gastrointestinal tract, said device comprising:an inflatable gastric balloon, the volume of which is modulatable;a duodenal prosthesis comprising a pre-pyloric flange and a flexible tubular body.According to the invention, such a device is characterized in that it comprises a system for coupling said balloon to said duodenal prosthesis; said duodenal prosthesis is compressible and expandable in a radial direction; said prosthesis has a wall that is fixedly attached, on at least one part of its length, to a helical frame and said helix has an irregular pitch.

Owner:ASSISTANCE PUBLIQUE HOPITAUX DE PARIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com