Method for bending wave spring with concave hole

A wave spring and concave hole technology, applied in the field of stamping, can solve the problems of increased scrap rate and breakage, and achieve the effects of improving productivity, reducing scrap rate and good coincidence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0025] The invention is a bending method of a wave spring with a concave hole.

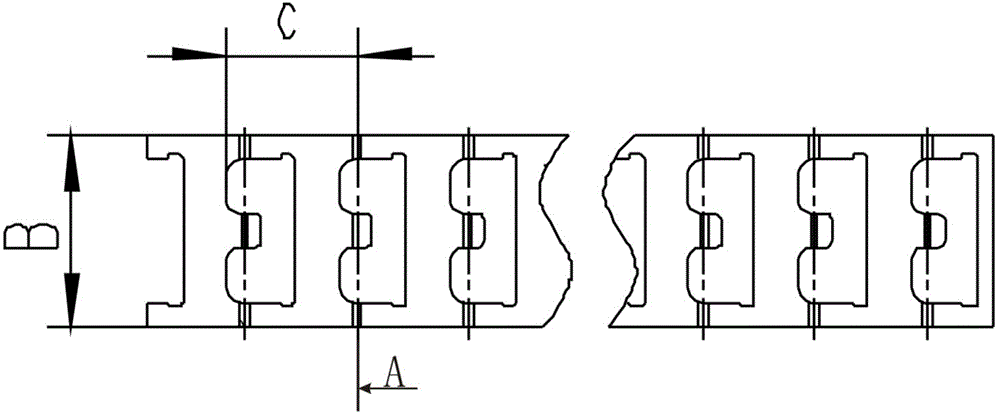

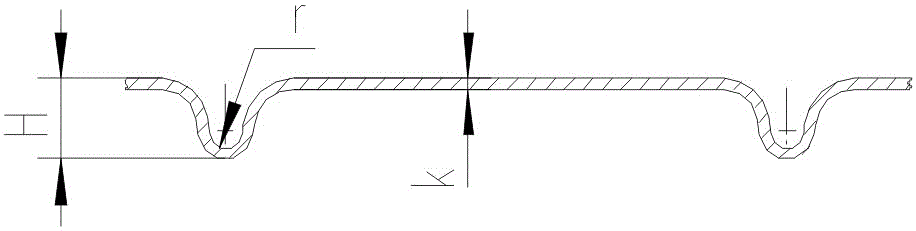

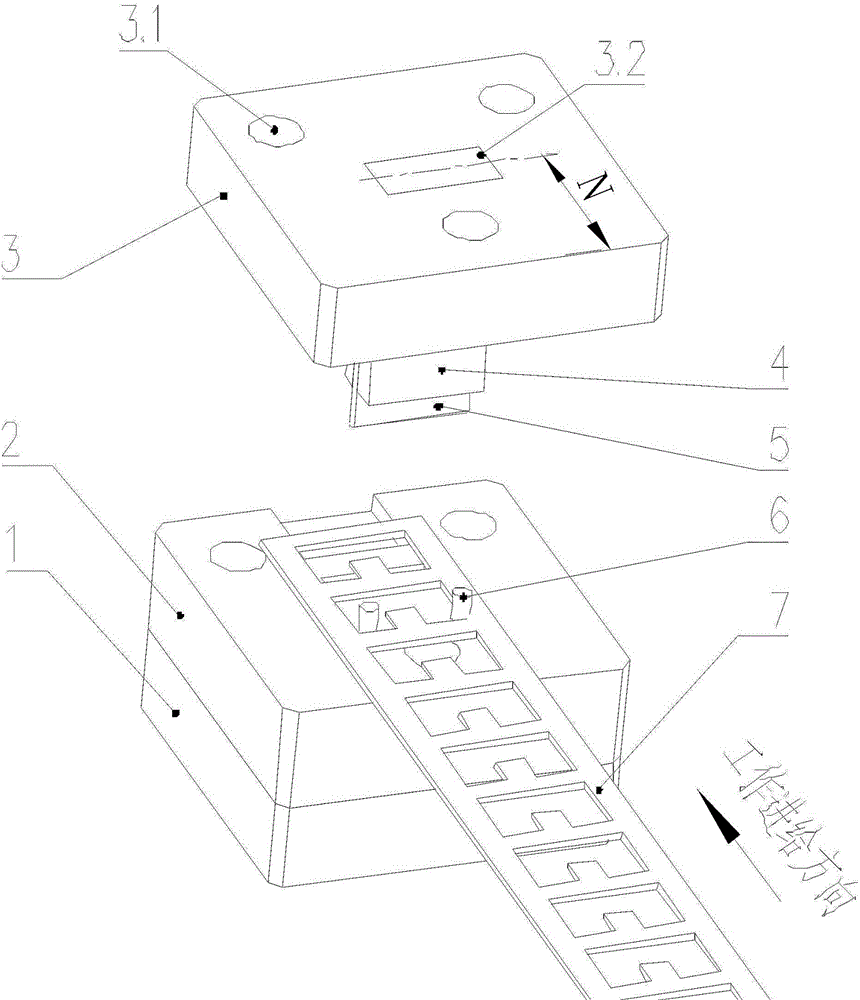

[0026] combine Figure 1-Figure 2 , on the wave spring 7 to be bent with a width of B and a thickness of K, several concave holes that have been stamped and approximately concave are arranged equidistantly in sequence, and a line connecting two convex parts of one concave hole to another adjacent concave hole The distance between the symmetrical centerlines of the two convex parts of the hole is set as C, and the symmetrical centerline of the two convex parts is referred to as line A for short, and each concave hole is bent from the line A, and each bending is required to be The inner radius of the bending po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com