Actuating control device for spatial-bending shape memory alloy actuator

A memory alloy and memory alloy wire technology, which is applied in the direction of mechanisms, machines/engines, and mechanical equipment that generate mechanical power, can solve problems such as use restrictions, and achieve the effects of good adaptability, wide application prospects, and compact mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

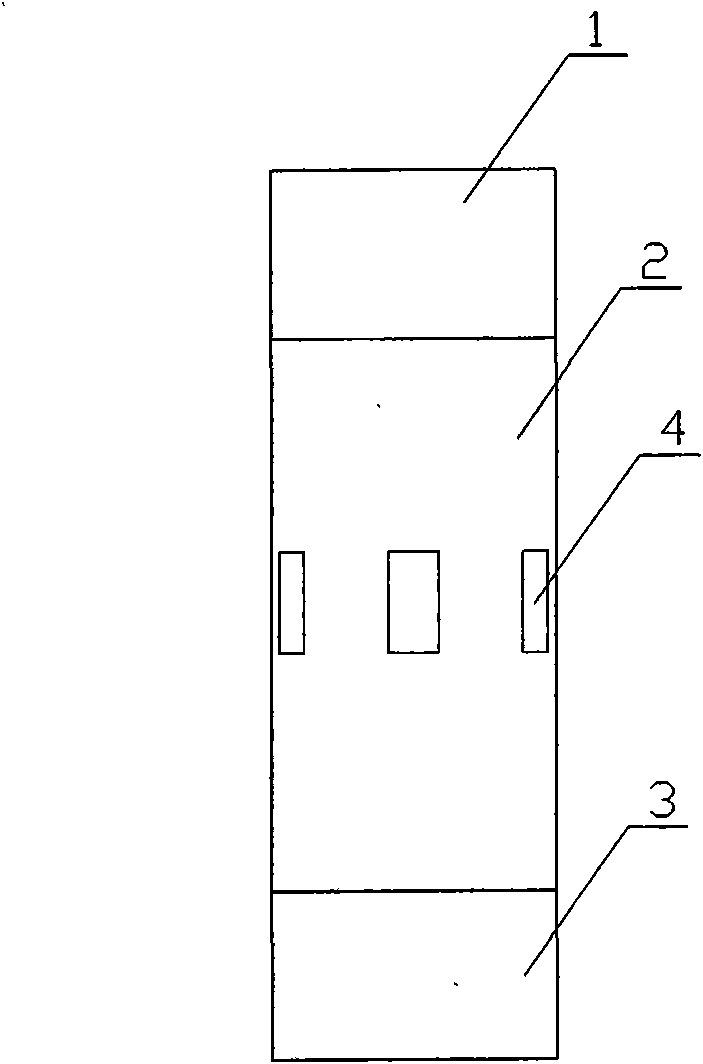

[0015] Such as figure 1 and figure 2 As shown, the space bending SMAA includes an end fixing part 1 , a motion executing part 2 and a front connecting part 3 .

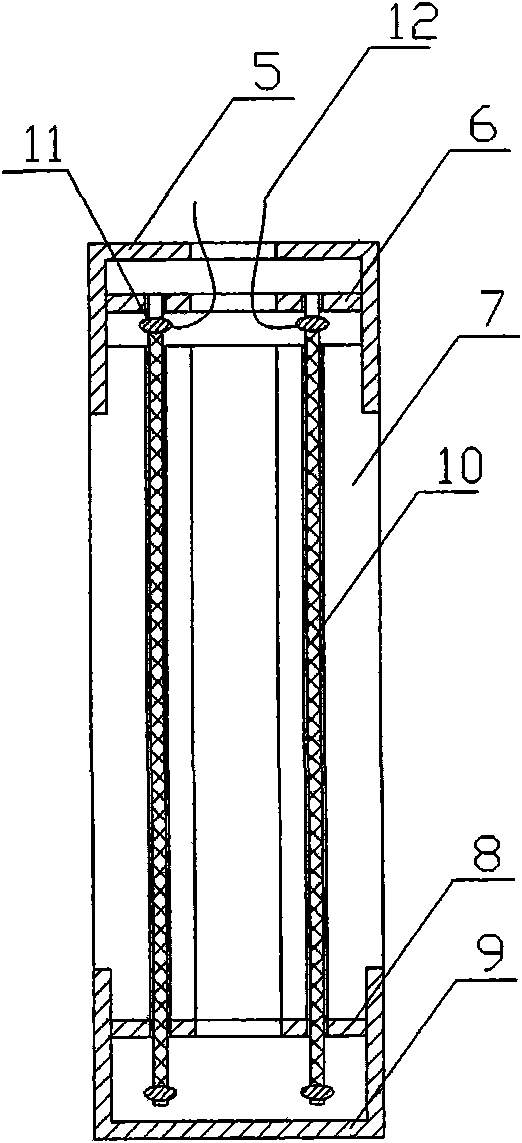

[0016] The end fixing part 1 includes an end sleeve 5 and an SMA wire fixing piece 6 , and the SMA wire fixing piece 6 is fixed in the end sleeve 5 . Such as Figure 4 As shown, the SMA wire fixing piece 6 is provided with a first central through hole 16 and n positioning holes 15, wherein, 3≤n≤6, and the n positioning holes 15 are centered on the first central through hole 16 in the SMA wire Symmetrical distribution on the fixed piece 6.

[0017] The motion executing part 2 is composed of a mold glue cylinder 7 , a "U" shape memory SMA wire 10 and a curvature sensor 4 .

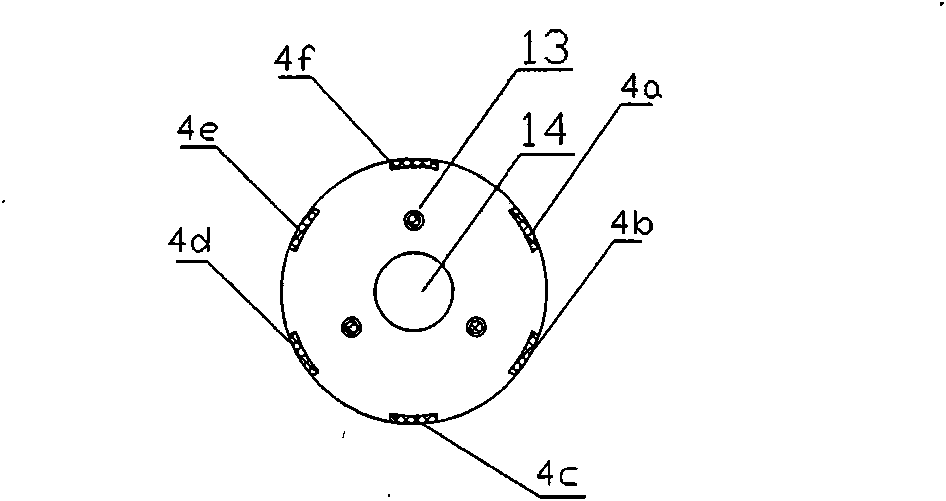

[0018] Such as image 3 As shown, the second central through hole 14 and n embedded wire through holes 13 are provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com