Patents

Literature

148results about How to "Quick bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

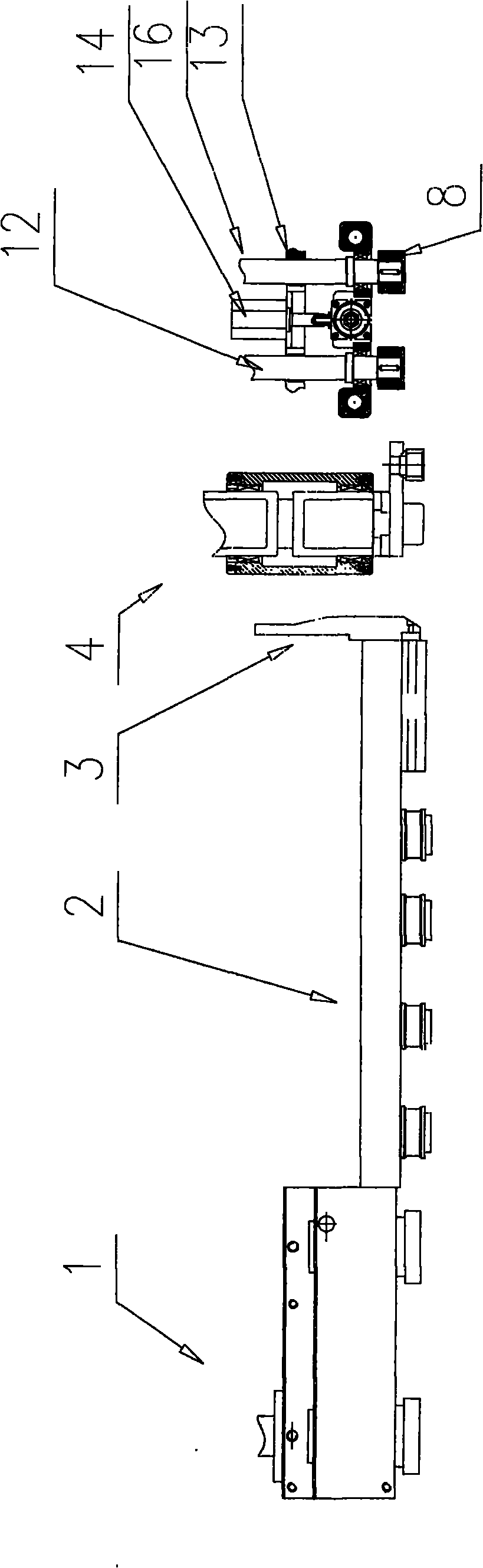

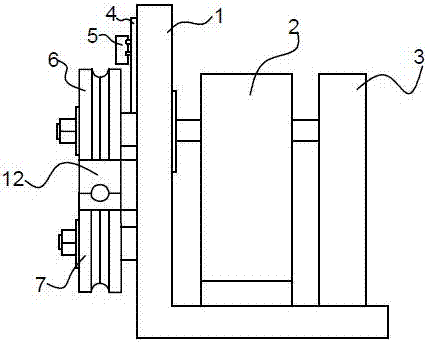

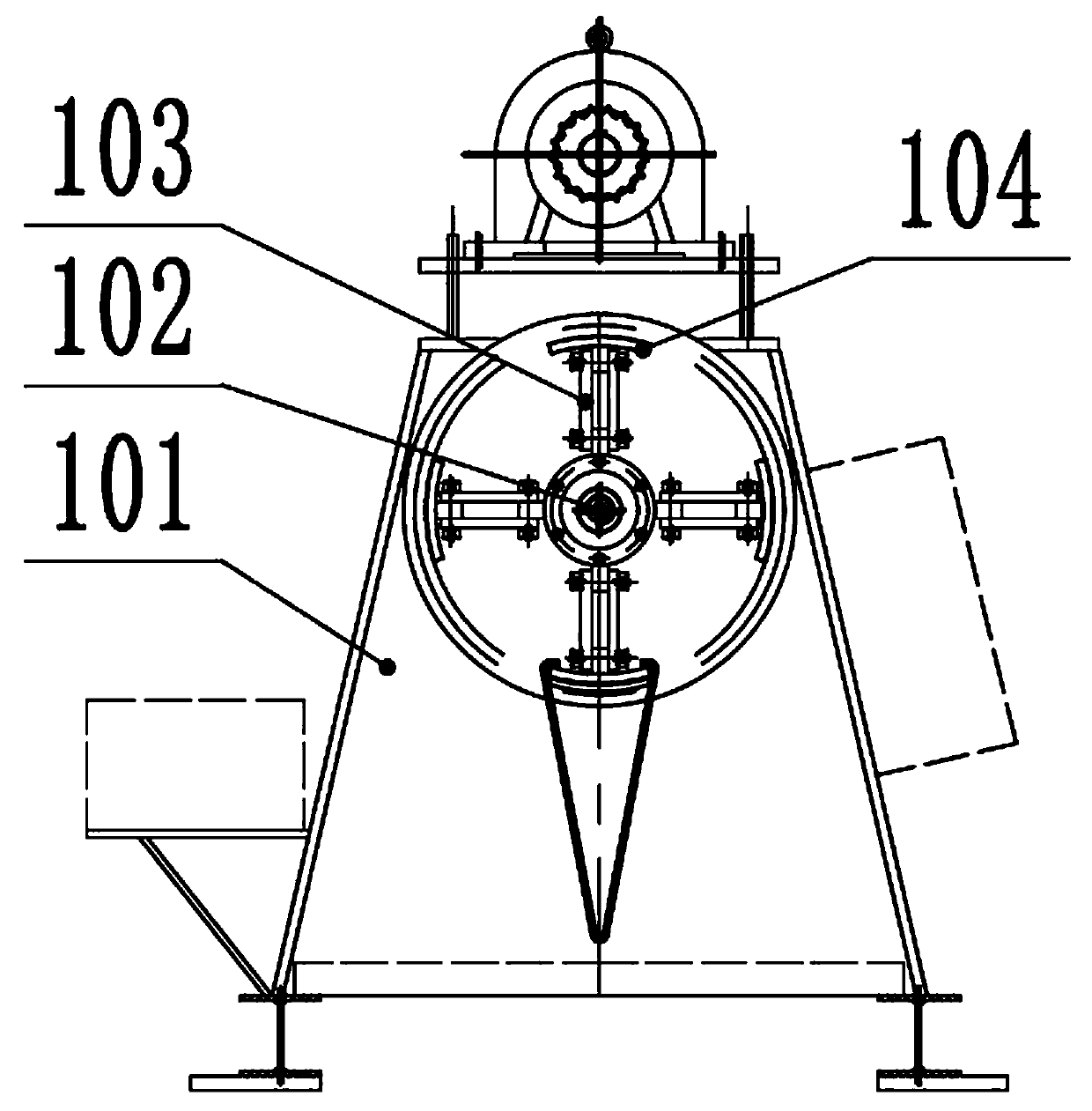

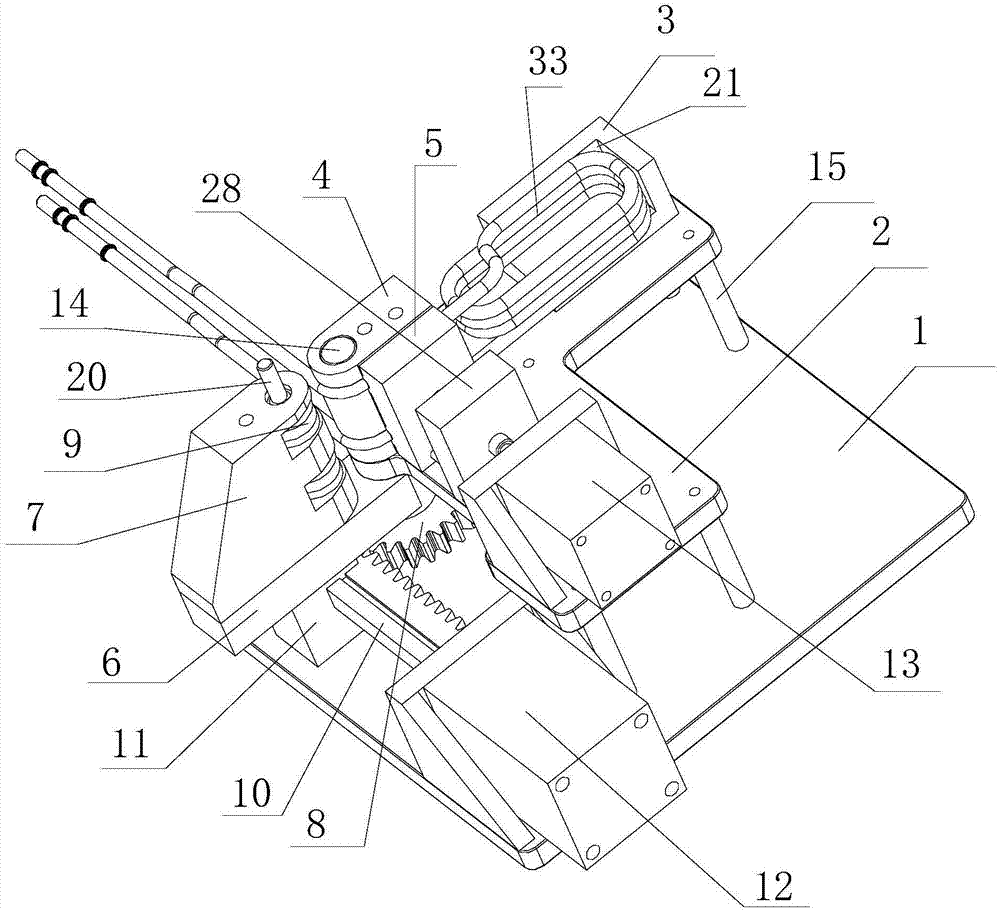

Inductance coil pin bending machine

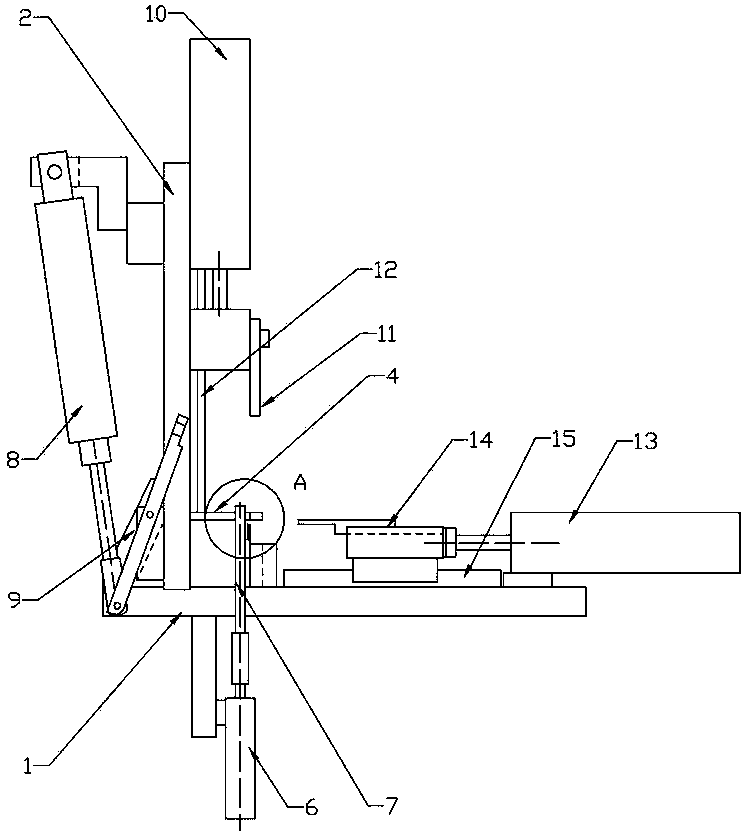

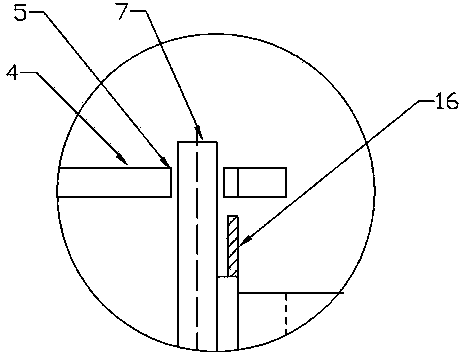

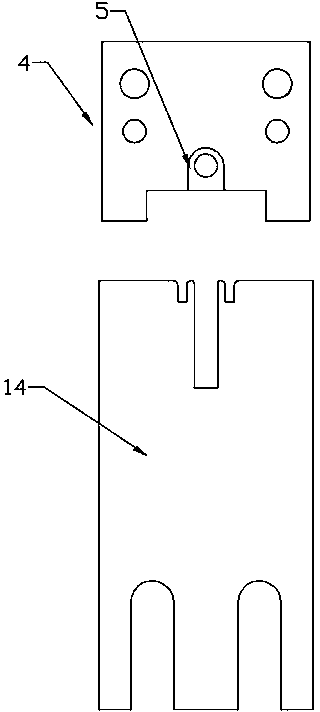

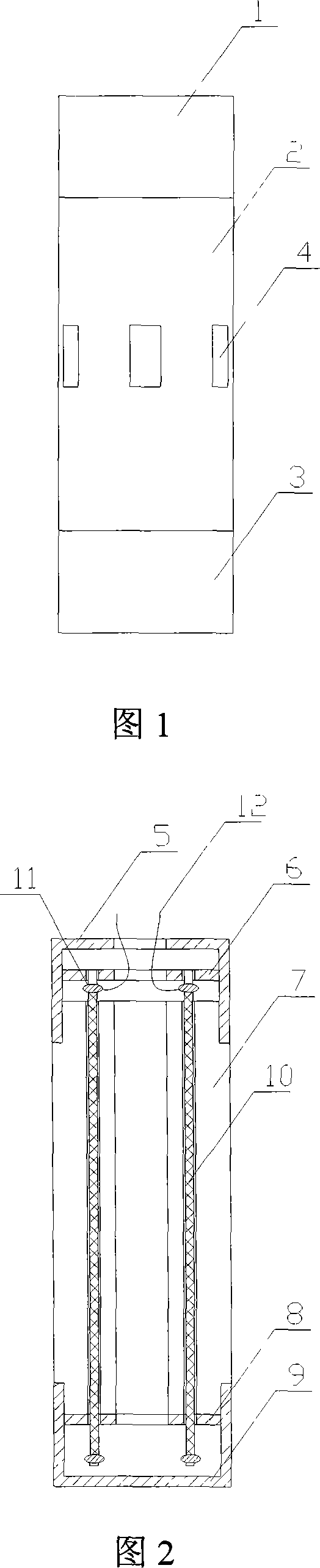

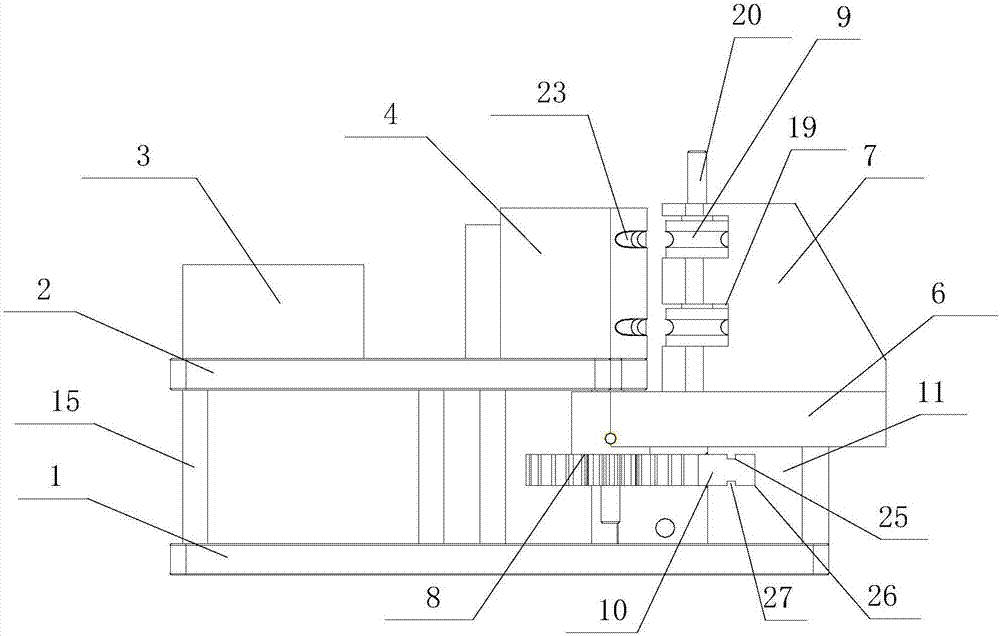

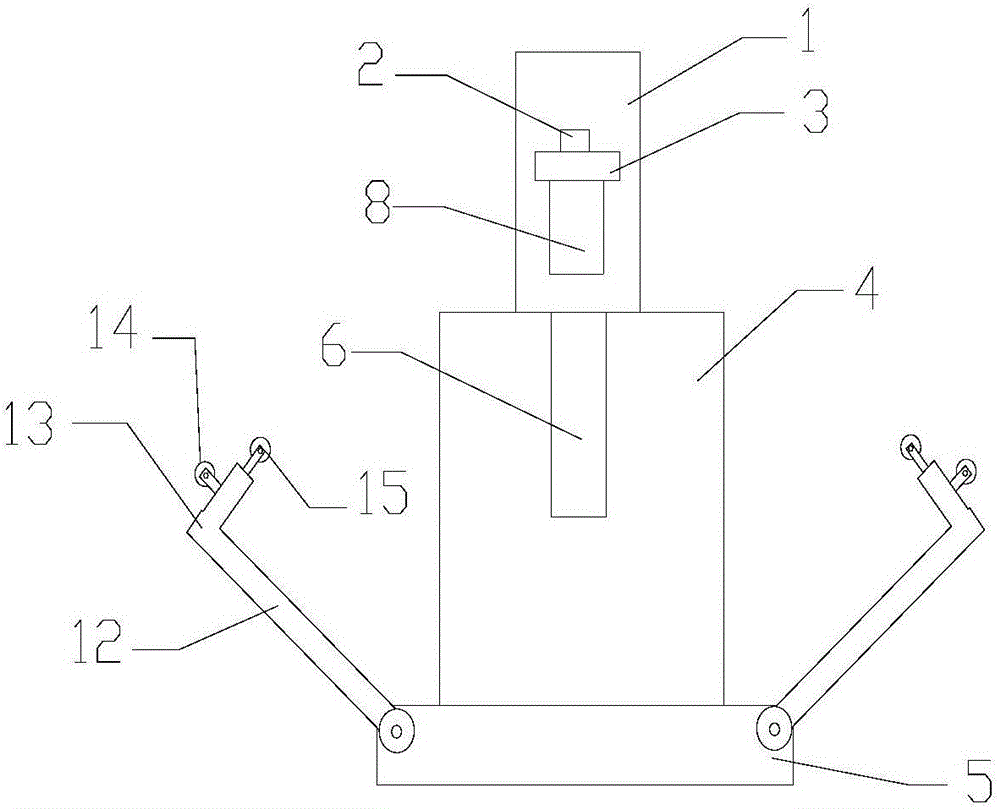

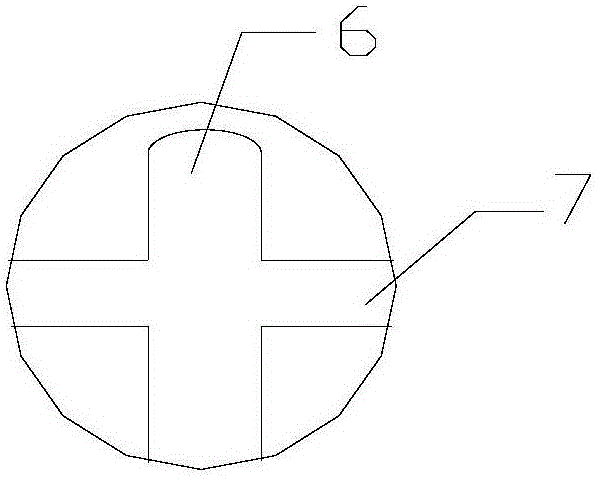

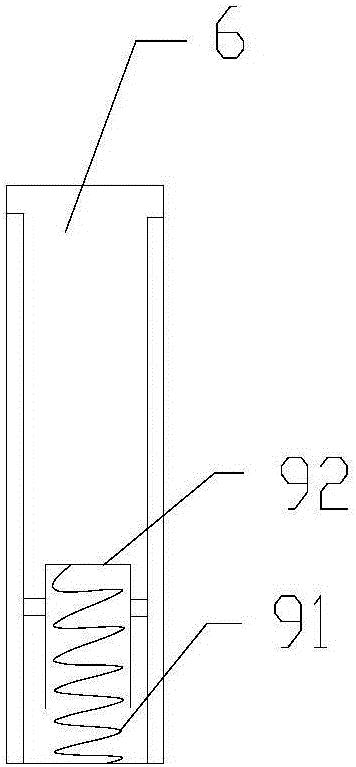

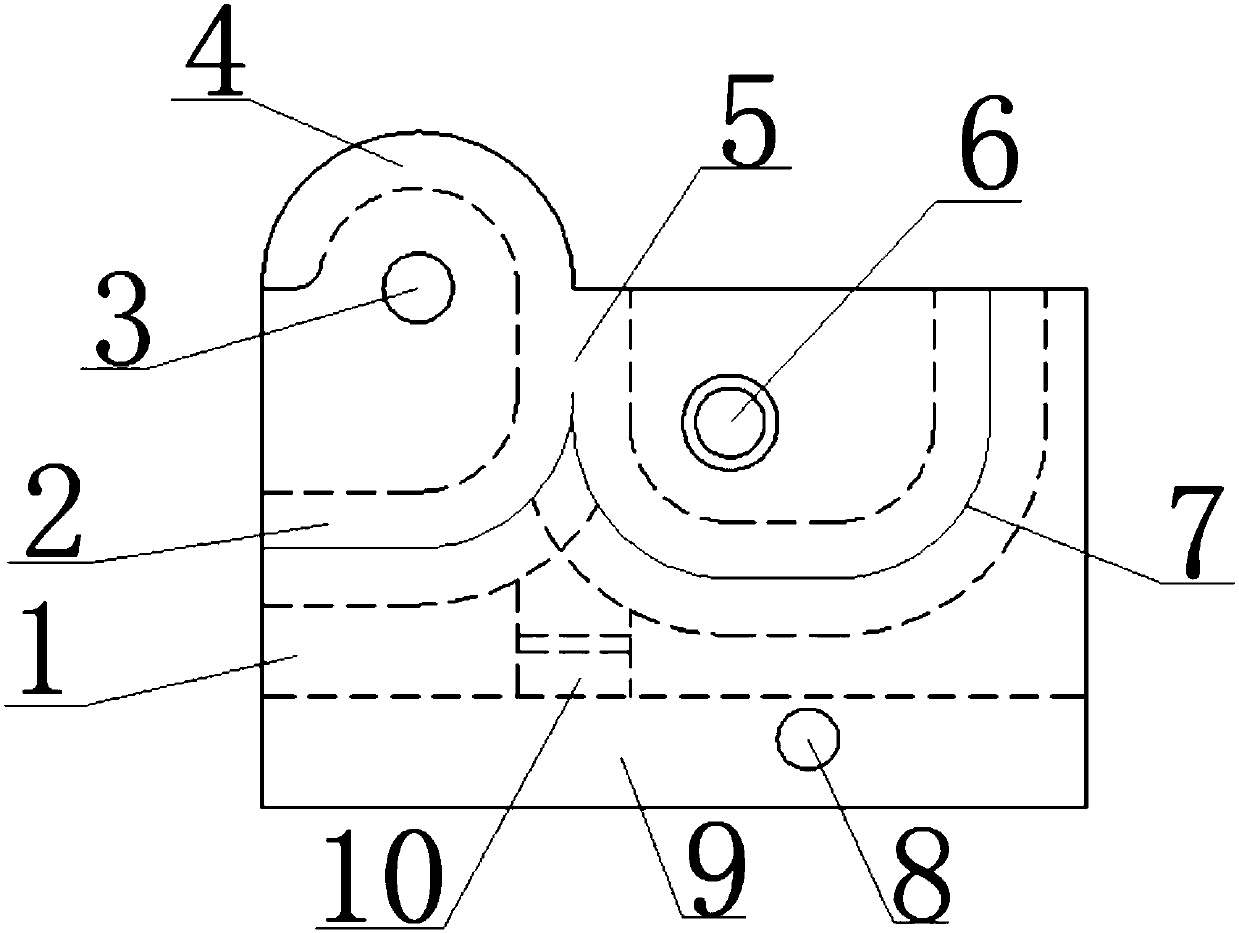

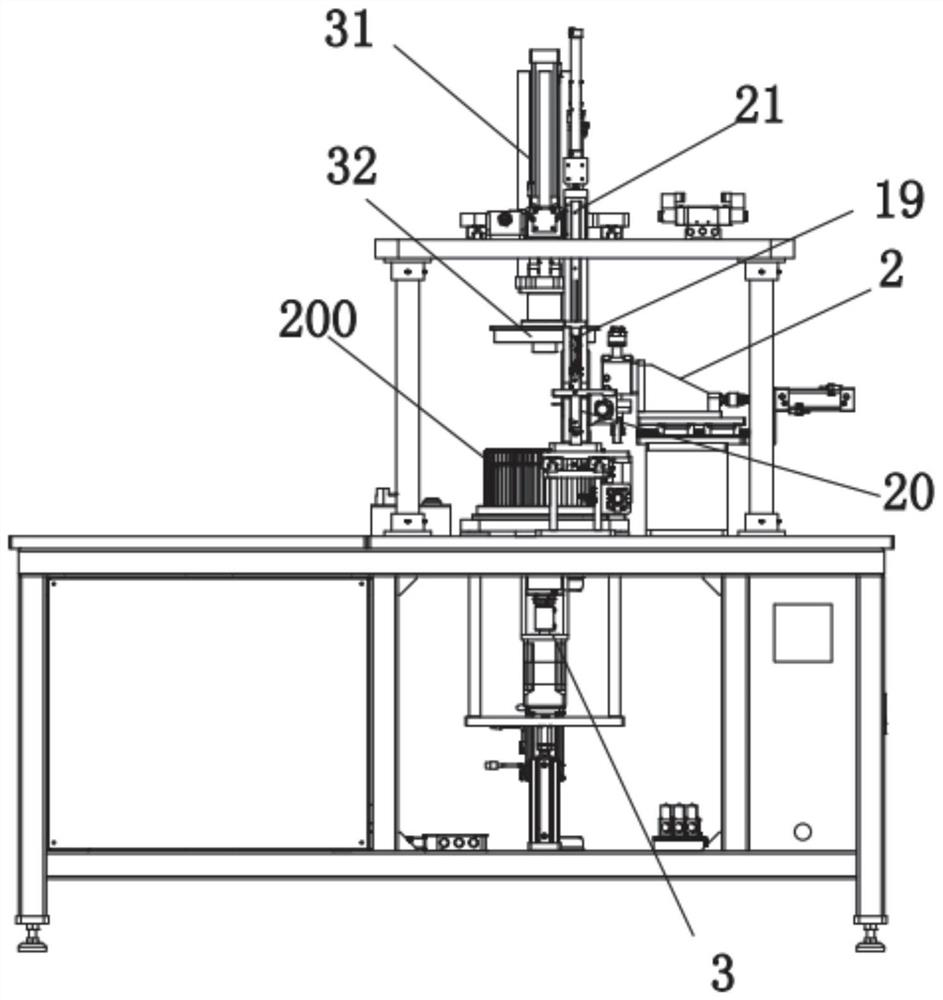

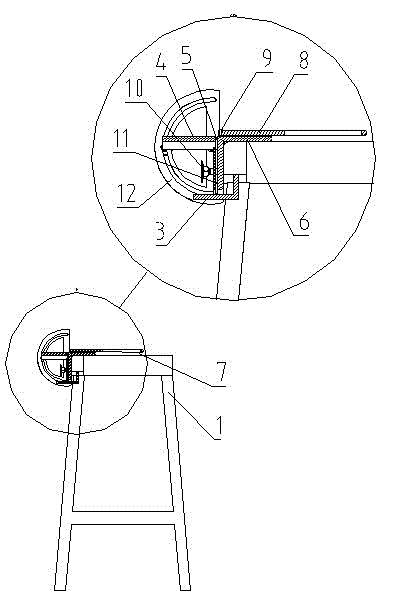

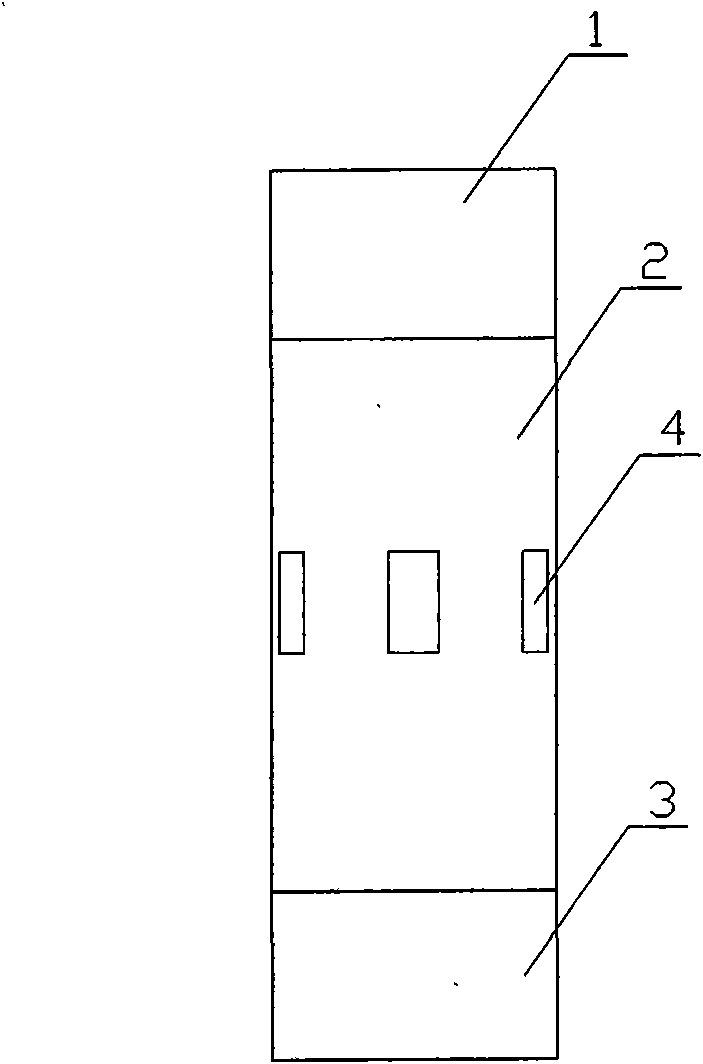

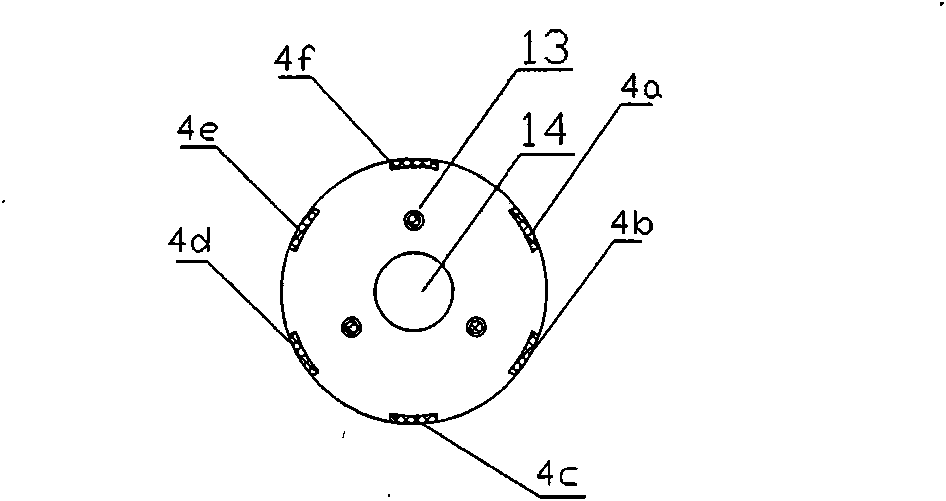

The invention relates to an inductance coil pin bending machine. The inductance coil pin bending machine comprises a machine base (1), a machine base stand column (2), an inductance coil fixing block (4), an upper pressing module, a lower bending module, a side bending module and a control system. The inductance coil fixing block (4) is arranged on a support in the middle of the machine base support column (2); the middle of the inductance coil fixing block (4) is provided with a through hole (5); a central positioning mandril (7) driven by a first air cylinder (6) is arranged right under the through hole (5). The inductance coil pin bending machine can rapidly bend the pins of an inductance coil, reduces the labor intensity of workers, improves the bending precision, reduces damage of the inductance coil, improves the utilization rate of the inductance coil and further improves the productivity.

Owner:资兴市弘电电子科技有限公司

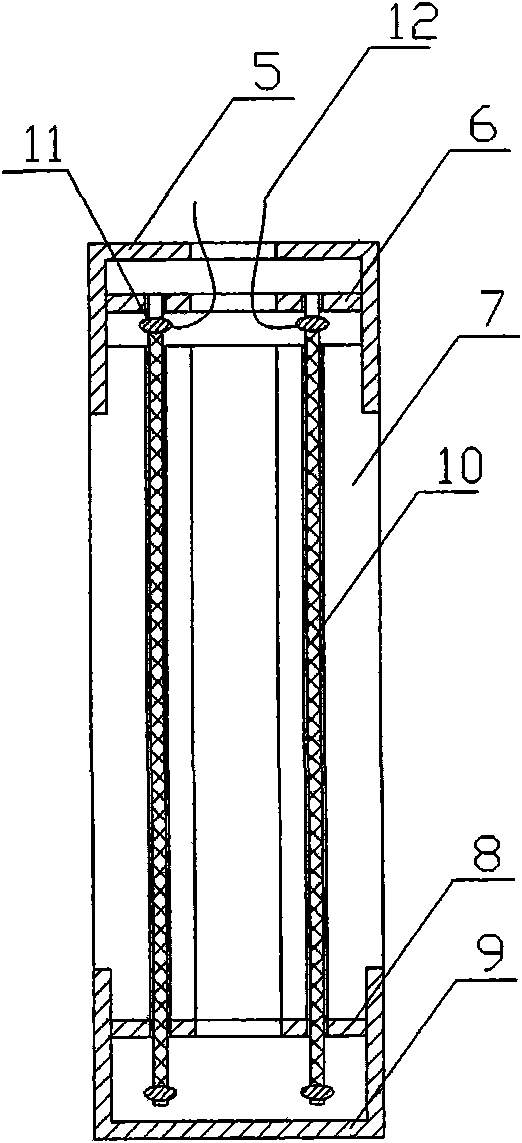

Mining constant-resistance yielding energy-absorbing impact-resisting supporting device

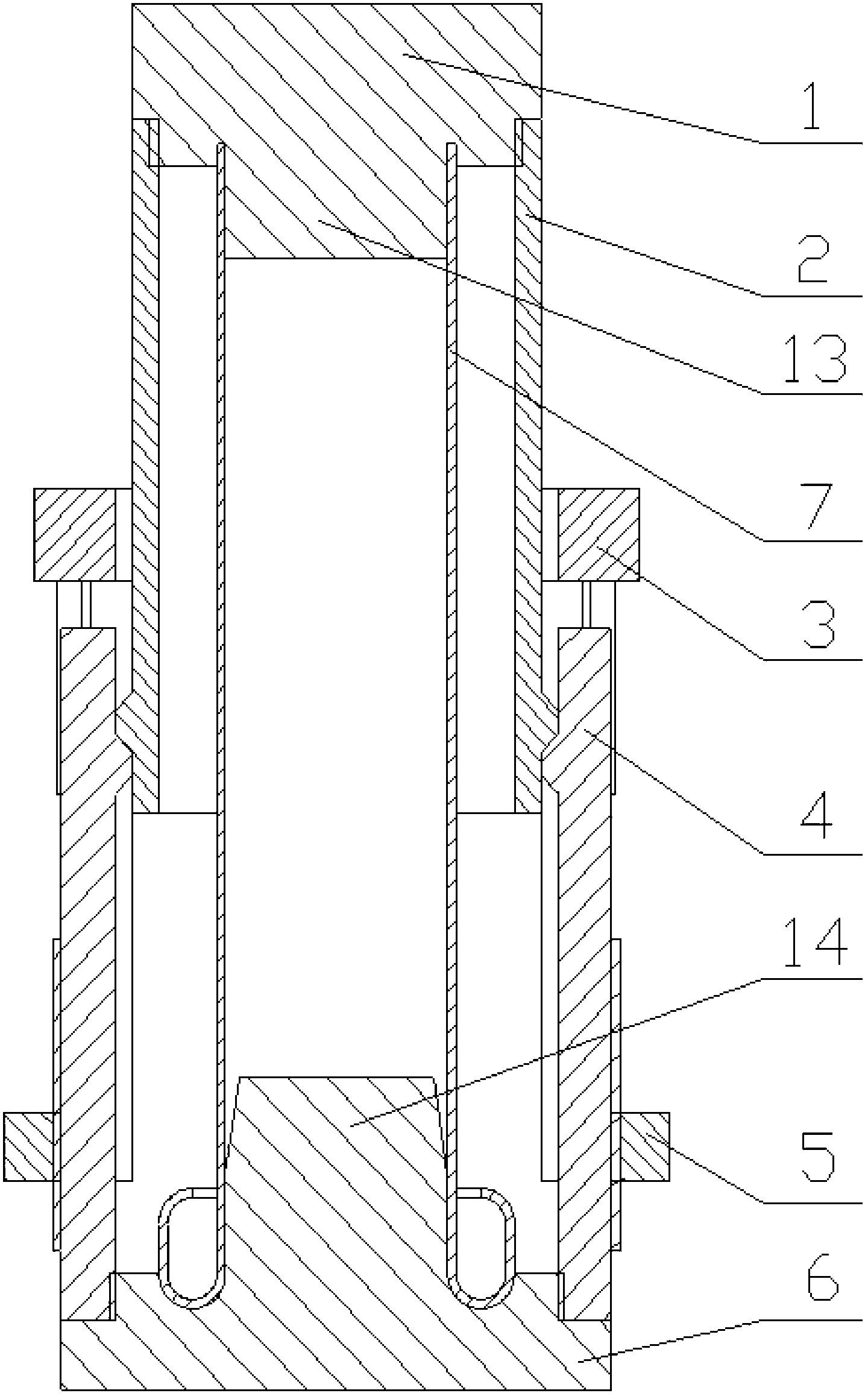

The invention discloses a mining constant-resistance yielding energy-absorbing impact-resisting supporting device and belongs to the technical field of coal mine safety supporting. The mining constant-resistance yielding energy-absorbing impact-resisting supporting device comprises a head cover, a first support barrel, a second support barrel, a base, a positioning ring and an anchoring force ring, the head cover is connected with the upper end of the first support barrel through a thread, the lower end of the first support barrel is in contact fit with the upper end of the second support barrel, the lower end of the second support barrel is connected with the base through the thread, an energy-absorbing core is mounted between the roof and the base, the positioning sleeve is sleeved outside the first support barrel and fixedly connected with the upper end of the outer wall of the second support barrel, and the anchoring force ring is fixedly sleeved on the middle-lower portion of the outer wall of the second support barrel. Yielding and energy absorption can be realized by the aid of outward turning of the barrel walls after the energy-absorbing core is under stress, and the mining constant-resistance yielding energy-absorbing impact-resisting supporting device is simple in structure, rapid in response, constant in resistance, large in deformation amplitude, high in energy-absorbing efficiency and capable of realizing quick yielding and pressure releasing under rock burst.

Owner:LIAONING TECHNICAL UNIVERSITY

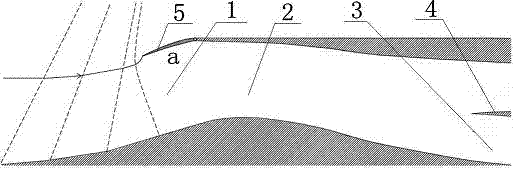

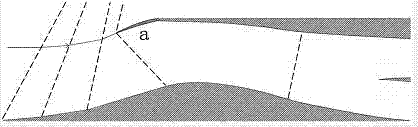

Supersonic aircraft air inlet channel with adjustable throat area and adjusting method

InactiveCN107023395AGuaranteed angle of attackIncrease the area ratioGas turbine plantsJet propulsion plantsInlet channelArea ratio

The invention relates to the field of supersonic propulsion and discloses a supersonic aircraft air inlet channel with an adjustable throat area and an adjusting method. The air inlet channel comprises a lip, a throat and an expansion section, a displacement mechanism is arranged in the air inlet channel, blades are arranged in the air inlet channel through the displacement mechanism, and the displacement mechanism can control the blades to move forwards and backwards and rotate in the air inlet channel. According to the supersonic aircraft air inlet channel and the adjusting method, large-scale and continuous adjustment of the throat area ratio can be realized, so that the air inlet channel always works in a low-loss state, and the adjusting process is simple and convenient.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

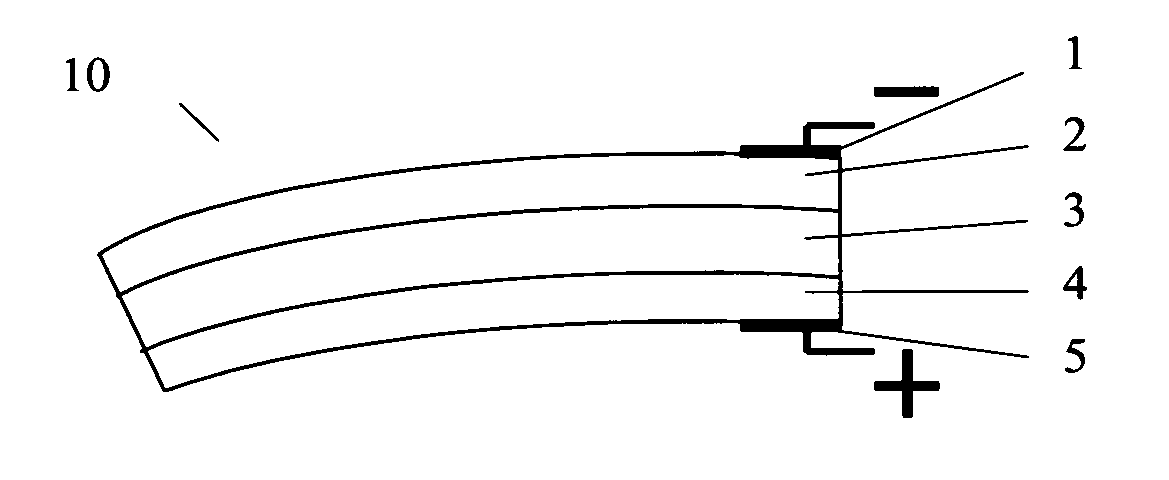

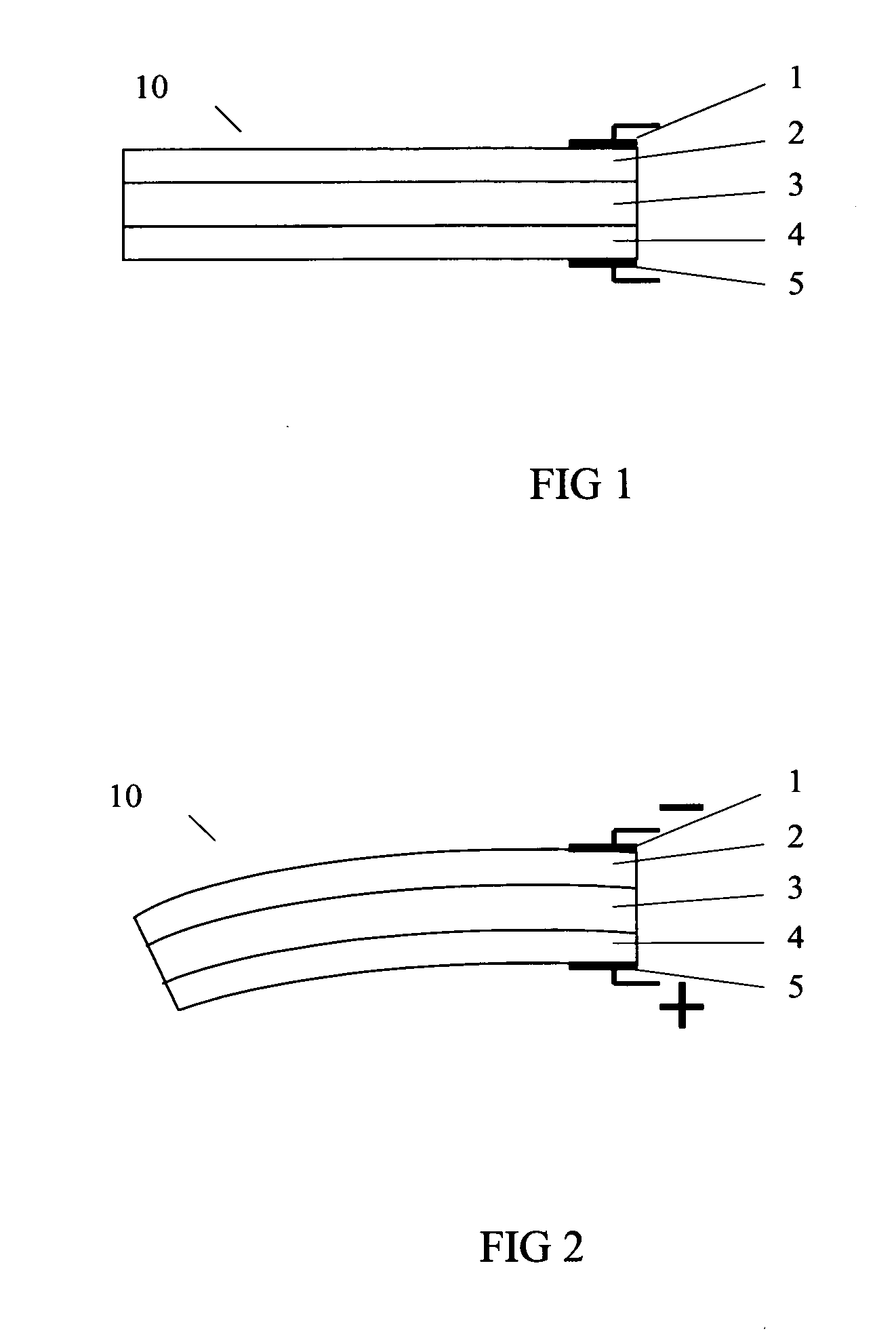

Layered actuator

InactiveUS20120211261A1Improve conductivityQuick bendingNon-insulated conductorsMachines/enginesCarbideEngineering

The layered actuator comprises at least two electrode layers and an electronically nonconductive membrane in between, where the electrode layer contains carbide-derived carbon, a polymer material and an ionic liquid. The layered actuator bends due to relocation of the membrane ions when direct current is applied to the electrodes.

Owner:UNIV OF TARTU

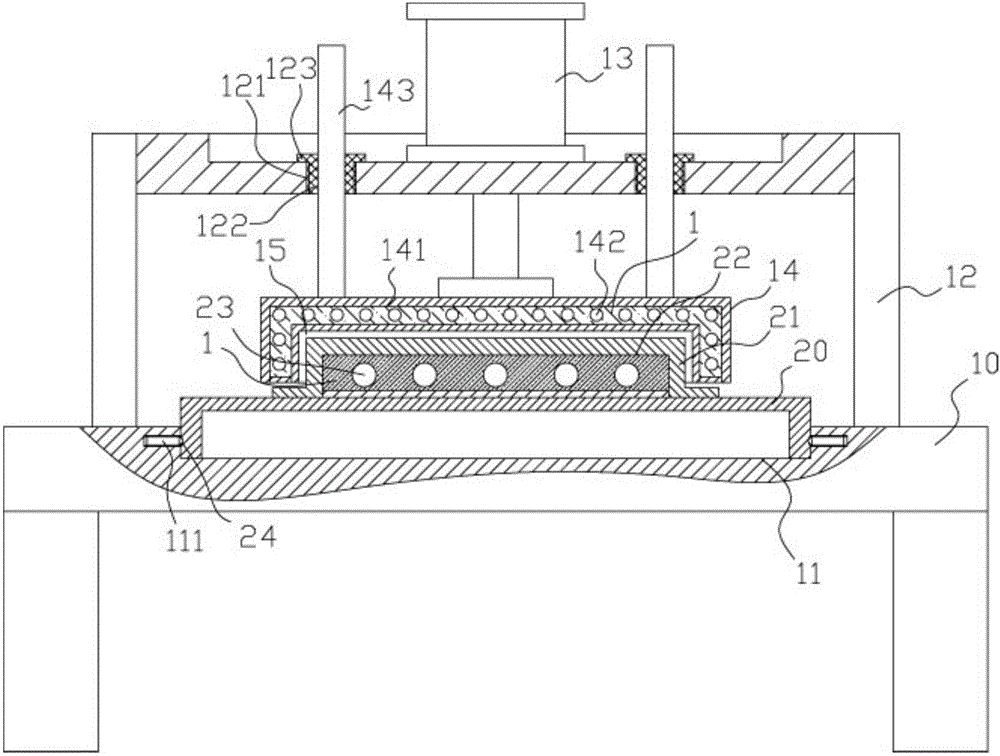

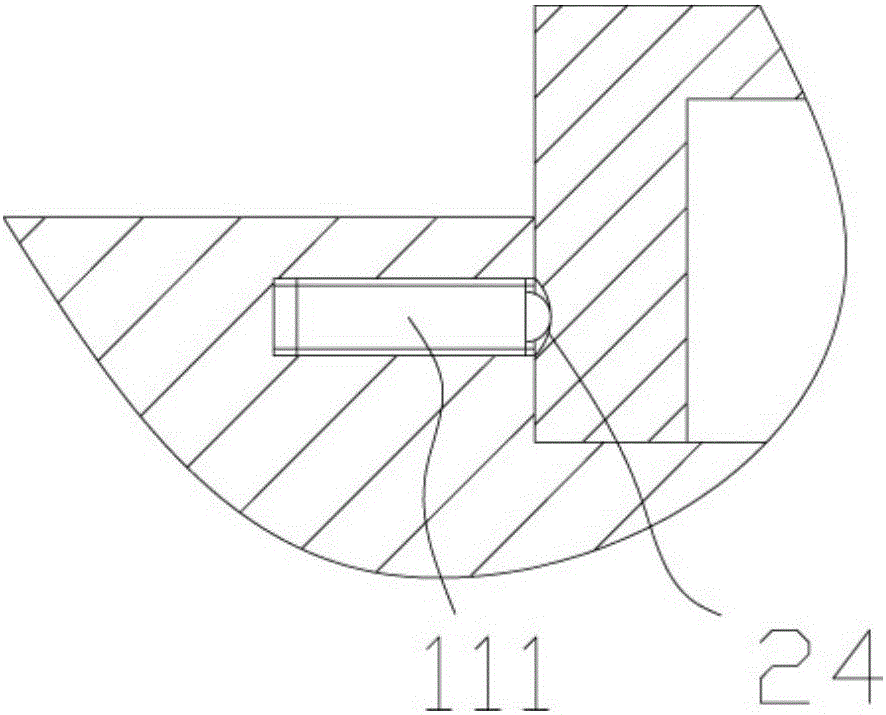

Plastic plate heating and bending mechanism

The invention discloses a plastic plate heating and bending mechanism. The plastic plate heating and bending mechanism comprises a machine frame, wherein a fixed groove is formed in the middle part of a top plate of the machine frame, a bottom heating seat is inserted in the fixed groove in a sleeving manner, a rectangular lower die block is fixed to the middle part of the top surface of the bottom heating seat, a cavity is formed in the middle part of the rectangular lower die block, a plurality of heating rods are fixed to the cavity, and magnesium oxide powder is stuffed between the heating rods and the inner side wall of the cavity; an upper connecting frame is fixed to the top plate of the machine frame, a pushing cylinder is fixed to the top surface of a middle connecting plate of the upper connecting frame, a push rod of the pushing cylinder penetrates through the middle connecting plate, an upper die block is fixed to the push rod, a compaction groove is formed in the middle part of the bottom surface of the upper die block, the upper part of the rectangular lower die block is inserted in the compaction groove in a sleeving manner, and the upper part of the rectangular lower die block is matched with the compaction groove; a heating cavity is formed in the upper die block, a plurality of upper heating rods are arranged in the heating cavity, and the magnesium oxide powder is stuffed between the upper heating rods and the heating cavity. Through the adoption of the plastic plate heating and bending mechanism, plastic plates can be quickly and automatically bent, the efficiency is high, and the effects are good.

Owner:浙江树源文具有限公司

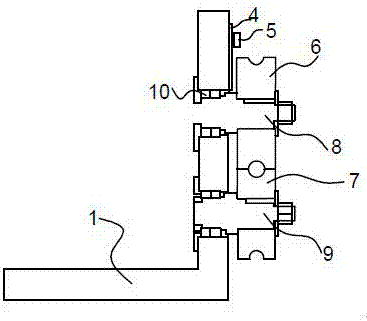

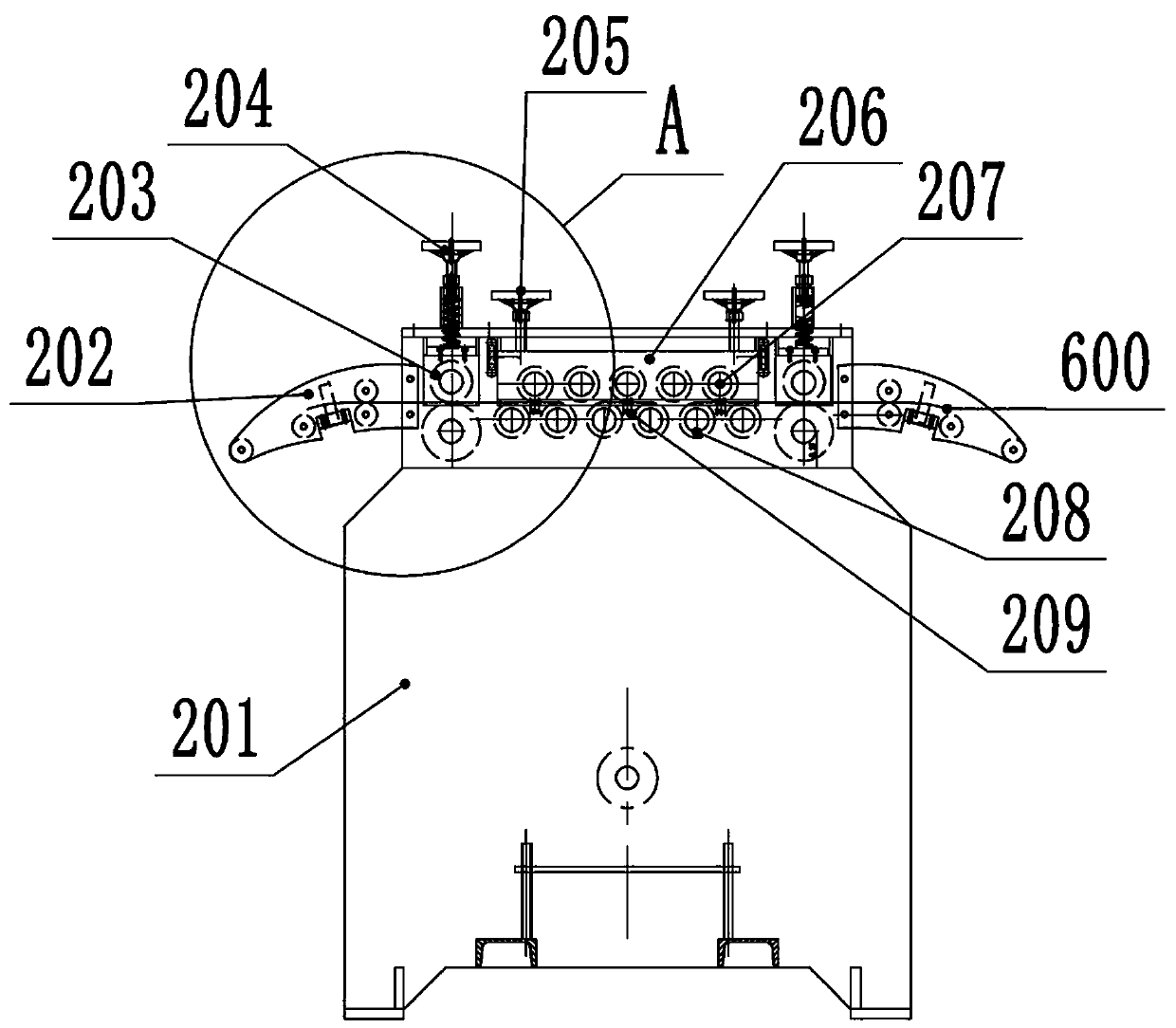

Back conveying and bending mechanism of reinforcing steel bar automatic bending machine

The invention relates to a back conveying and bending mechanism of a reinforcing steel bar automatic bending machine, which comprises a back conveying drive traction wheel, a back conveying driven traction wheel, a back conveying press wheel, a back conveying stand and a telescopic cylinder, wherein the back conveying stand is installed on a stand, and the upper part of the back conveying stand is provided with the back conveying press wheel which is connected with a back conveying press mechanism; the lower part of the back conveying stand is provided with a back conveying power shaft and a back conveying driven traction wheel shaft; the end parts of the back conveying power shaft and the back conveying driven traction wheel shaft are respectively provided with a back conveying traction wheel and the back conveying driven traction wheel which are positioned under the back conveying press wheel; the back conveying stand is connected to a telescopic unit; the back conveying power shaft is connected with a rotating drive unit; and a power transfer device is arranged between the back conveying power shaft and the back conveying driven traction wheel shaft. The invention expands the function of the bending machine and processes more stirrup products once; when the reinforcing steel bar rotates, the product does not rotate; and the bending machine not only bends a coil rod reinforcing steel bar, but also rapidly bends the stirrup product bent by a straight reinforcing steel bar commonly used by engineering.

Owner:TJK MACHINERY TIANJIN

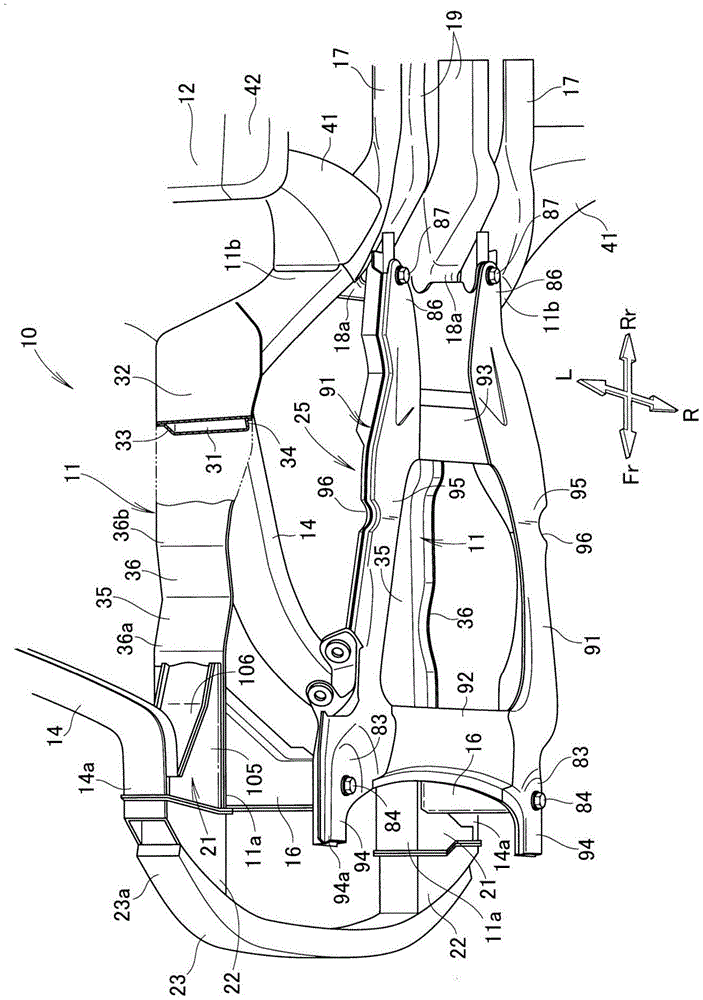

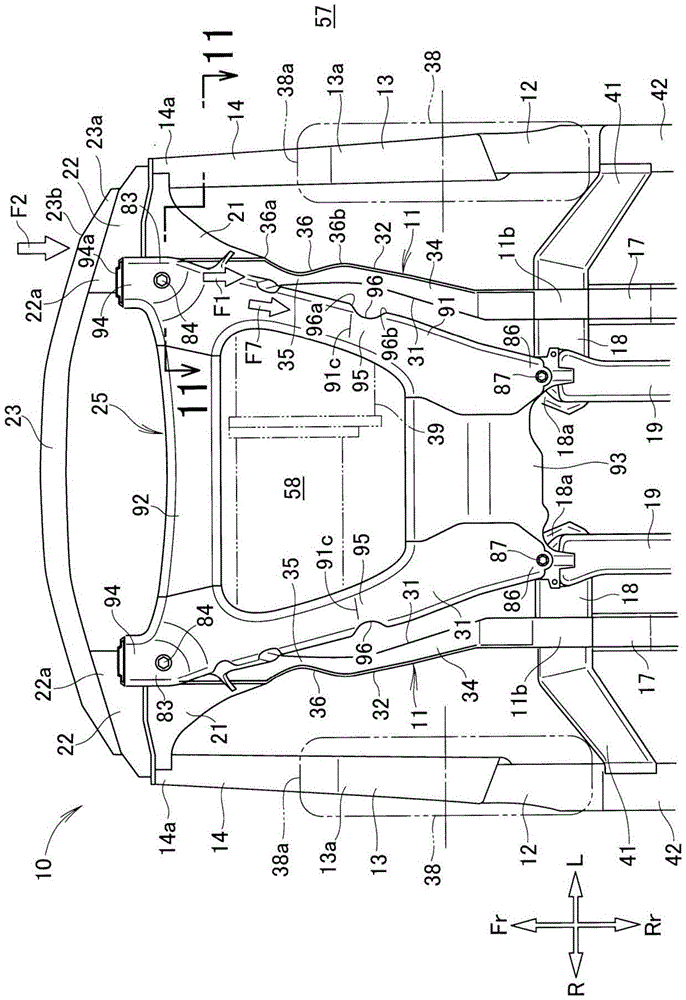

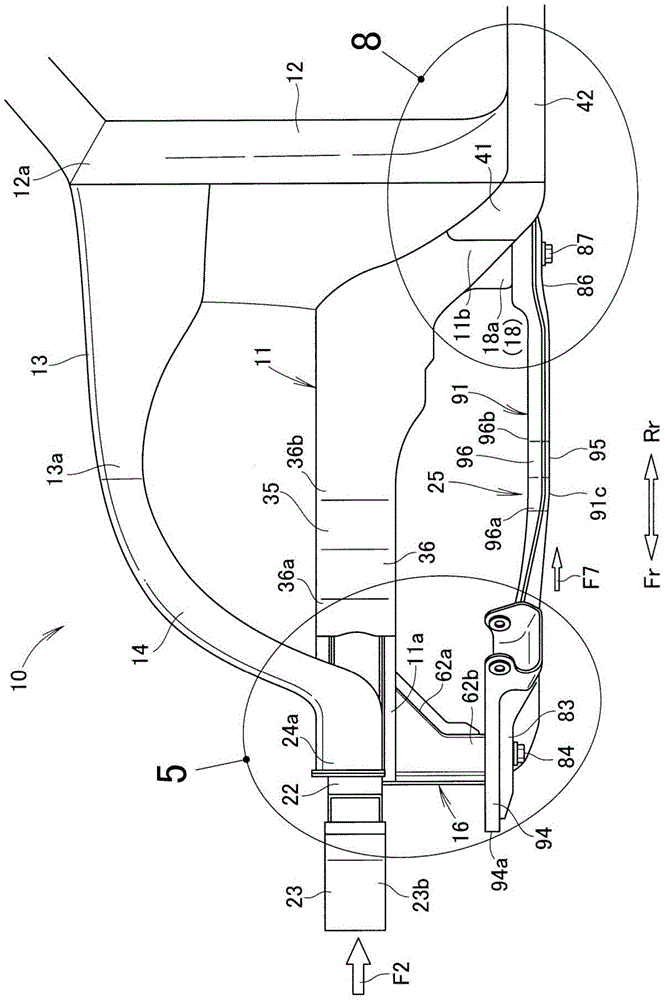

Vehicle front body structure

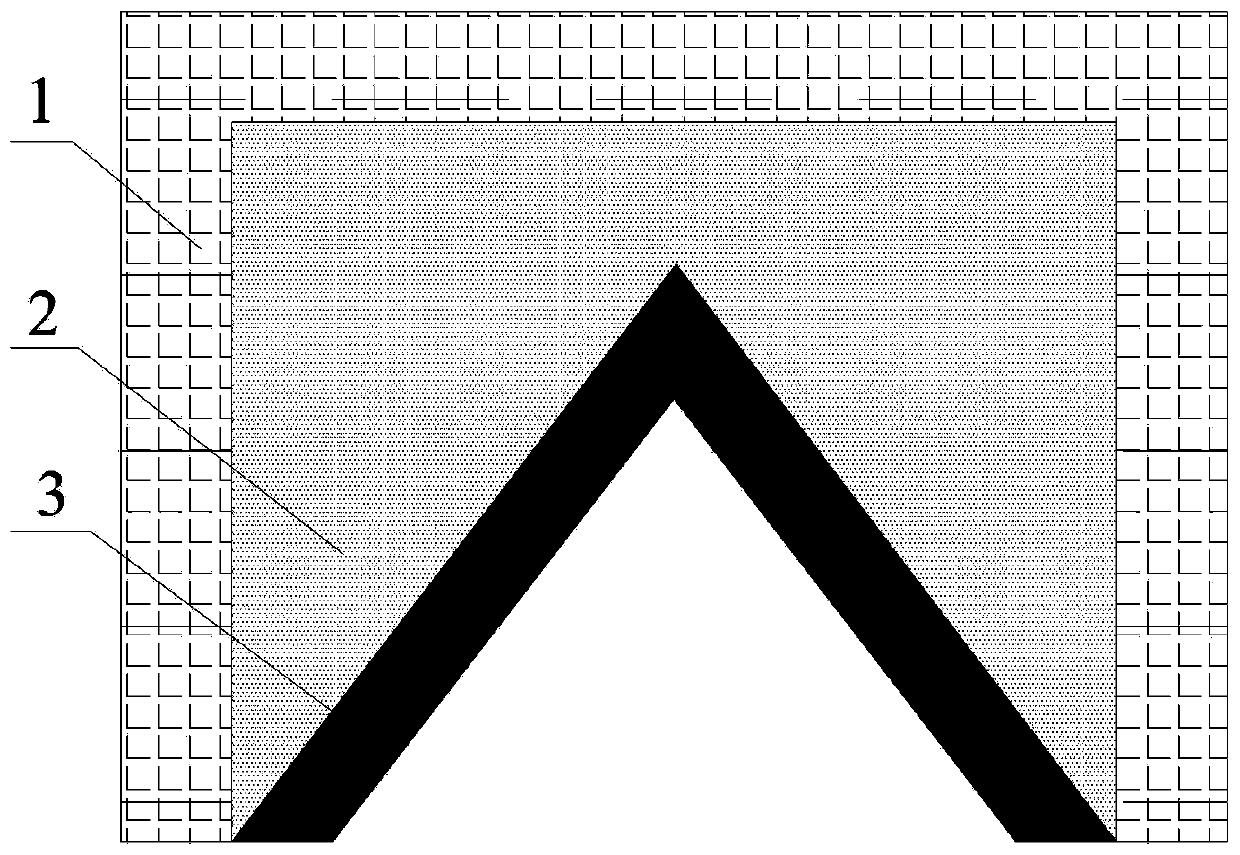

ActiveCN105882755ASmall sizeSuitable for absorptionUnderstructuresSuperstructure subunitsVehicle frameEngineering

In a vehicle front body structure (10), a subframe (25) is provided below a left front side frame (11) and a right front side frame (11). The left front side frame (11) has a first fragile portion (35). The subframe (25) has a second fragile portion (95) and an extension portion (94). When a bumper beam's left end portion (23a) and a left bumper beam extension (22) are crushed by an impact load, a front surface of the bumper beam's left end portion (23a) comes to substantially the same position as a front edge portion (23b) of the extension portion.

Owner:HONDA MOTOR CO LTD

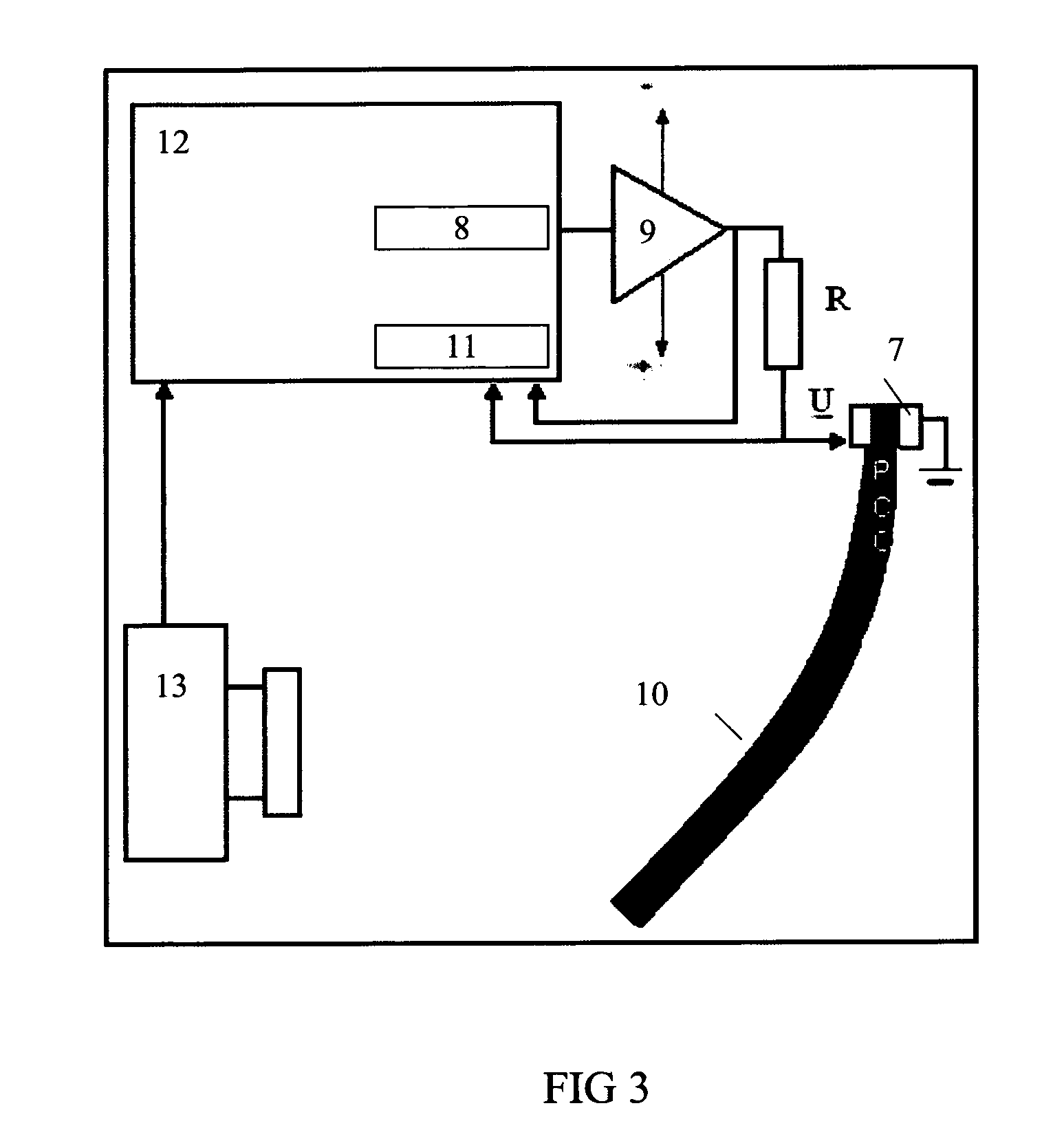

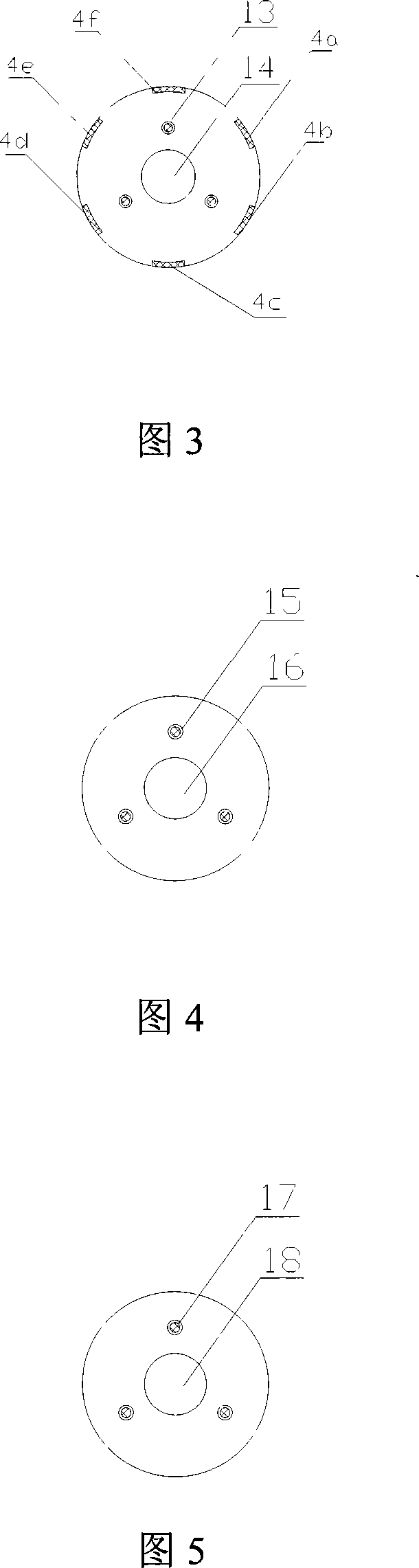

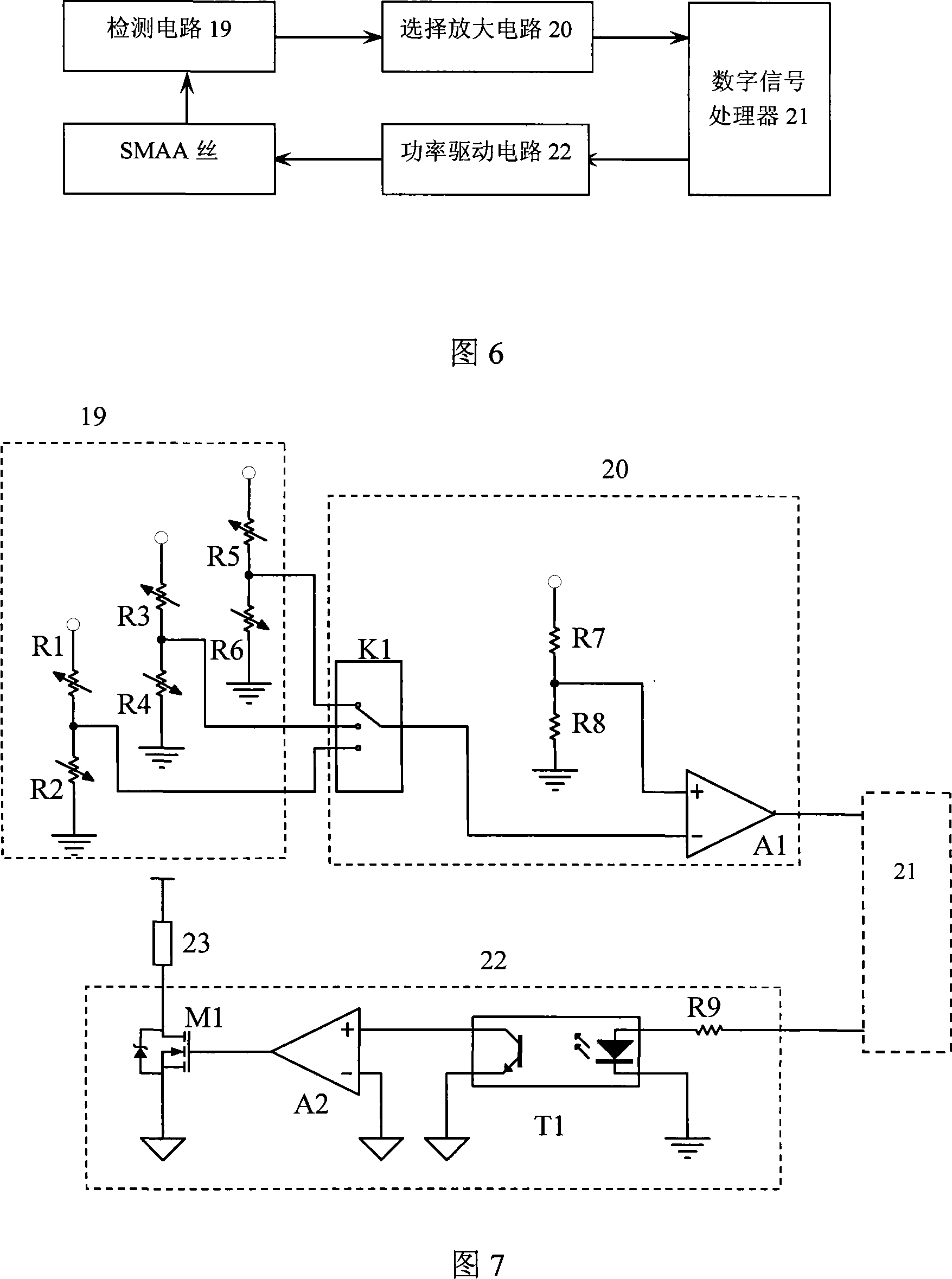

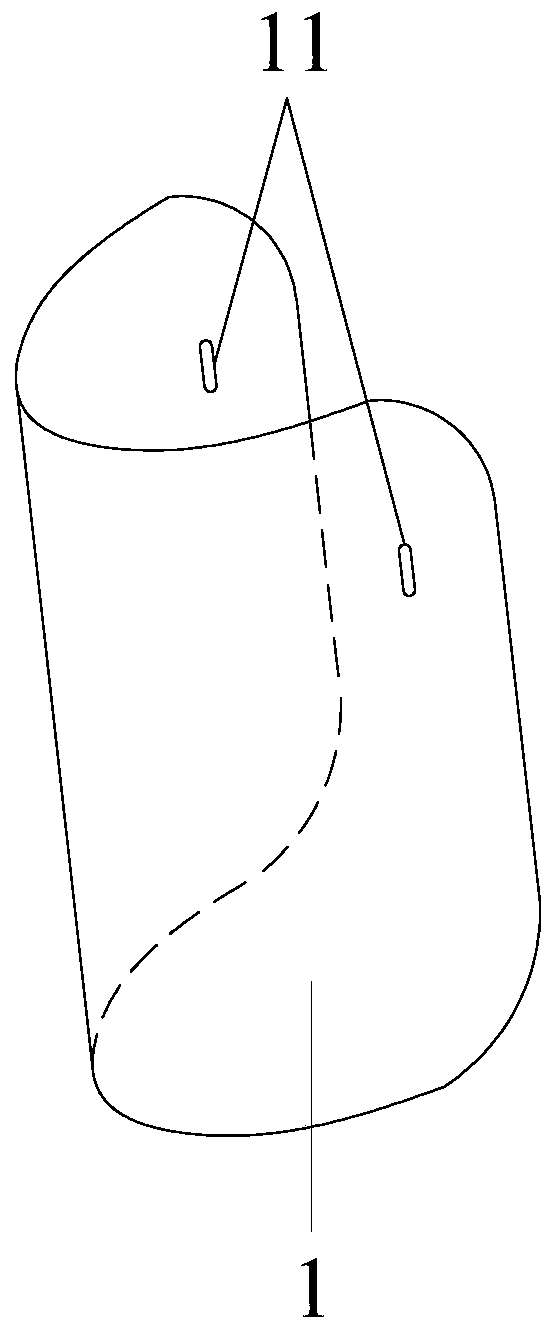

Space bending shape memory alloy driver and thereof drive control device thereof

InactiveCN101117952APrecise bendingCompactMachines/enginesMechanical power devicesSelf weightEngineering

The present invention discloses a space warp shape memory alloy driver and a driving control device. The driver comprises a U-shaped shape memory alloy wire, a plurality of curvature sensors, a molding rubber cylinder, a sleeve head, and shape memory alloy fixing sheets and positioning sheets. The driving controlling device comprises a detection circuit, a selective amplifying circuit, a digital signal processor and a power driving circuit. The present invention utilizes the characteristic that the shape memory alloy has the shape memory effect with the change of the temperature to realize the space free bending motion of the driver. The structure of the present invention is compact, the self weight is light, the output force-weight ratio is high, the motion is smooth, the control is flexible, the manufacture cost is low, the multi-direction bending can be realized, and the present invention has the space running capability. The present invention satisfies the comprehensive requirements of miniaturization, precise positioning and soft transmission, and has obvious technical superiority and potential and extensive application prospect in the fields of anthropomorphic mechanical arm, medical artificial limb and endoscope.

Owner:HUAZHONG UNIV OF SCI & TECH

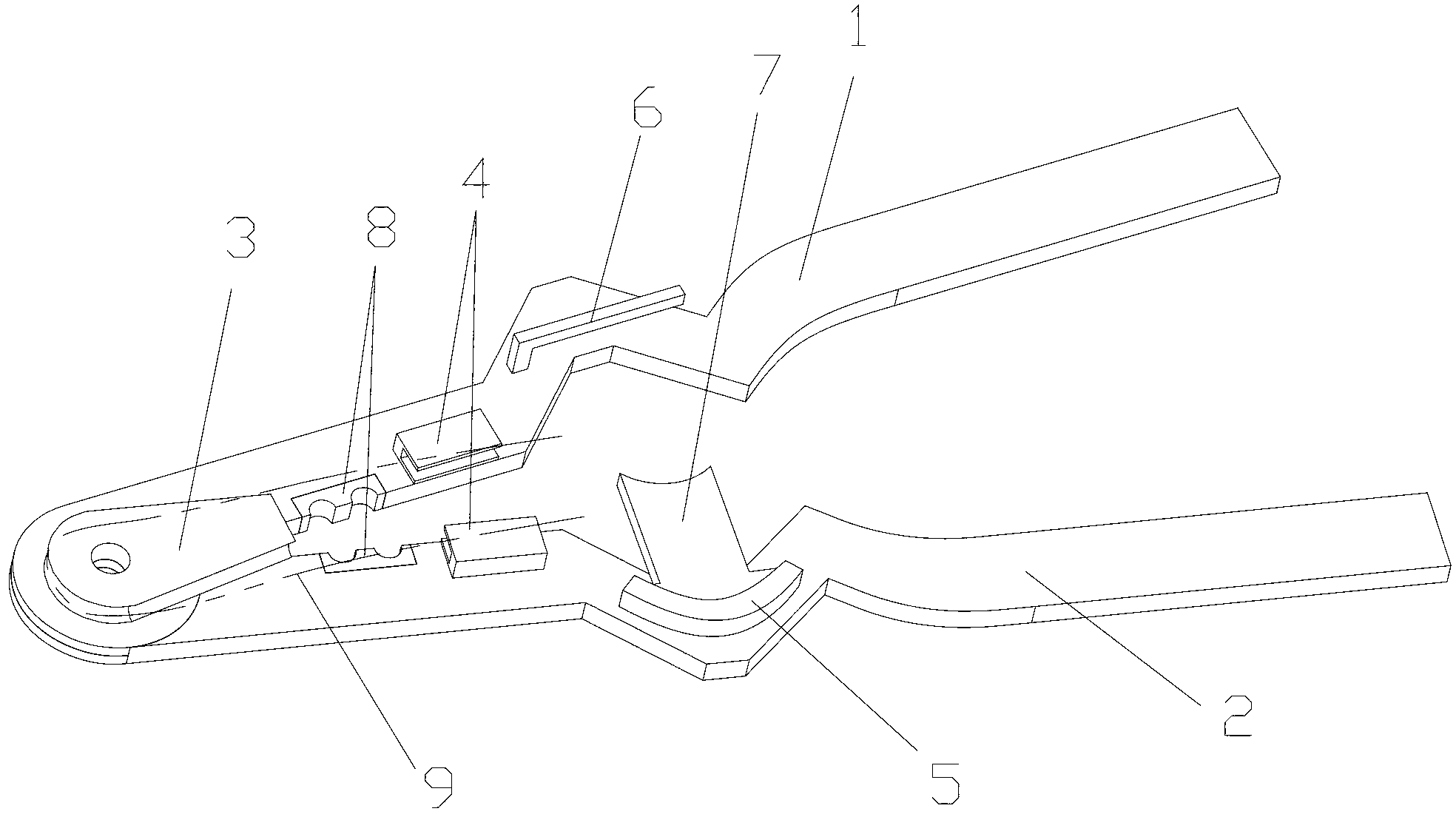

Multifunctional guy production clamp

InactiveCN103240687AThere will be no non-fit phenomenonGood cable bendingPliersApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention discloses a multifunctional guy production clamp which comprises an upper handle and a lower handle; one ends of the upper handle and the lower handle are connected together in a hinge mode; a connecting end of the upper handle and the lower handle is provided with a guy bending die which is provided with a circular arc end; the circular arc end of the guy bending die is provided with an annular guy limitation groove along the circular arc face; the upper handle and the lower handle are provided with wire pressing blocks which are used for fixing a guy position; and the upper handle and the lower handle are also provided with installation fixtures of UT cable clamps. According to the multifunctional guy production clamp, the wire pressuring blocks are utilized to fix the guy position, the guy bending die is utilized to bend the guy, and accordingly the guy is good in bending and rapid to be bent; a finished steel strand is pushed into a wedge-shaped wire clamp through the installation fixtures of the UT cable clamps; and a whole process is finished through the operation of the upper handle and the lower handle, strong brawn and arm force and abundant production experience are not needed of a worker, no strike is needed to be performed on an external case of the UT cable clamp, and non-adherence of the guy and a tongue is avoided.

Owner:STATE GRID CORP OF CHINA +1

Simple bending device

InactiveCN107159757ASimple structureEasy to operateEpoxy resin coatingsReduction driveWear resistant

The invention provides a simple bending device. The simple bending device comprises a frame, a combination wheel placed on the frame, and a speed reducer connected with the frame; the frame is L-shaped; the speed reducer is placed on a step surface of the frame; the combination wheel is placed on the side surface of the frame, and is connected through a shaft during placing; the shaft penetrates through the frame to communicate with the speed reducer; and a motor is arranged at one end of the speed reducer. The simple bending device is simple in structure and convenient in operation, can perform positioned bending within 180 degrees according to angles, and quickly bends pipe-shaped parts to improve the production efficiency; bent pipe fittings are high in precision, not easy to drape and high in generality; and the simple bending device can bend workpieces with different sizes and different specifications, is low in cost, is additionally provided with a wear resistant coating layer for improving the durability, and prolongs the service life.

Owner:宁波奇尘电子科技有限公司

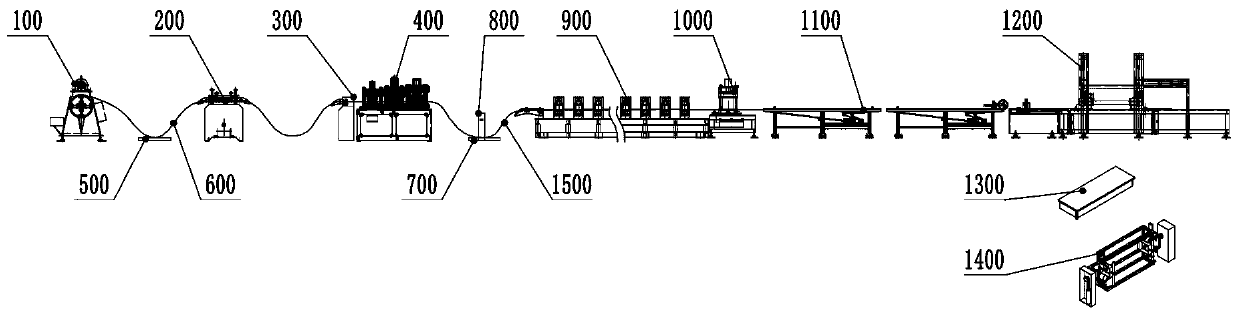

Box body welding production line and production method

The invention discloses a box body welding production line and a production method. The production line comprises a plate discharge hole forming equipment line, a rolling forming line, a punching device, a bending device and a welding device; the plate discharge hole forming equipment line is used for leveling steel and punching the surface of the steel, and a material plate is manufactured; the rolling forming line is used for rolling a bending edge on the material plate; the punching device is used for cutting off the material plate into a plurality of groups, each group of material plates comprises four continuous sections, and the four sections are corresponding to four side wall plates of the box body; the bending device is used for bending the cut material plate into a side wall frame of the box body; and the welding device is used for welding the frame into a whole box body. The full-automatic production line and process of punching, rolling, cutting, bending and welding are adopted, so that full-automatic forming from the steel plate to the box body is realized, the processing of hole forming and three-dimensional features on the side wall of the box body is completed once,the production efficiency is high, the labor cost is low, and the processing quality is high.

Owner:LAIZHOU KASIKAITE IND & TRADE CO LTD

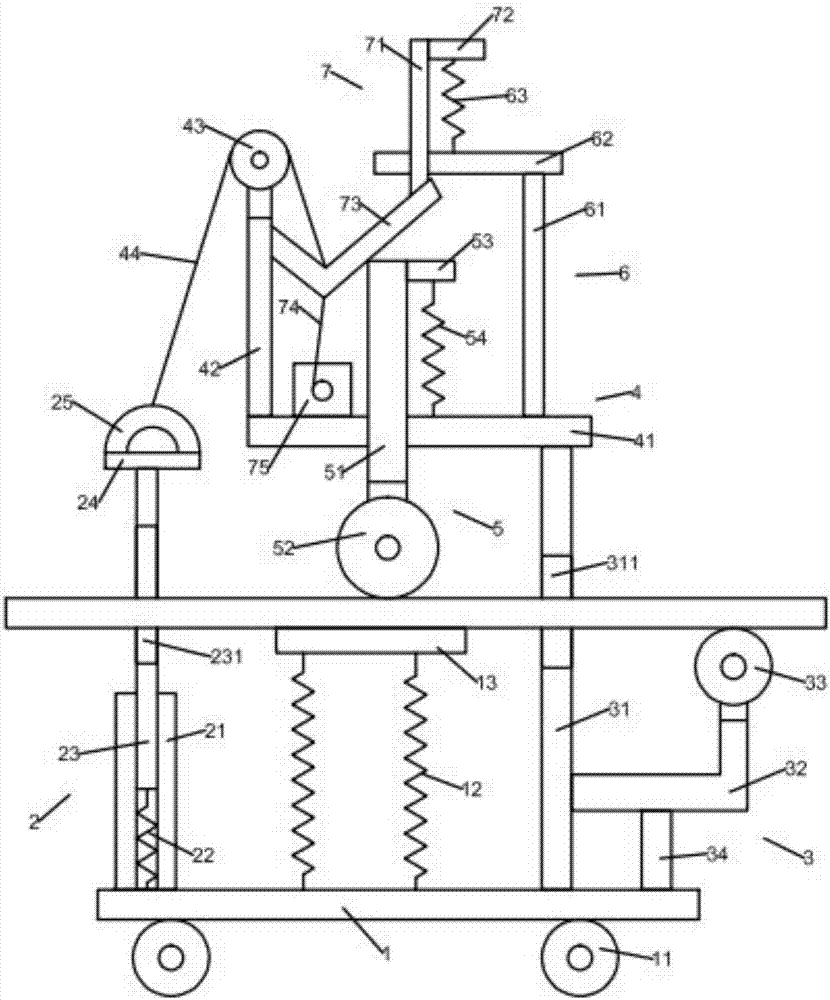

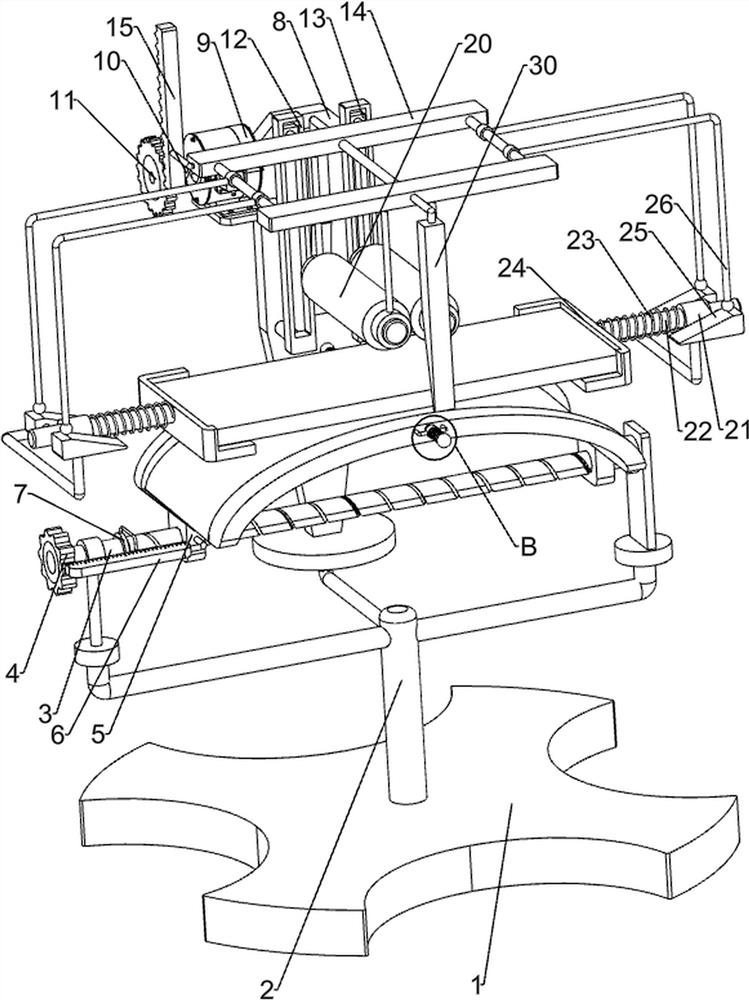

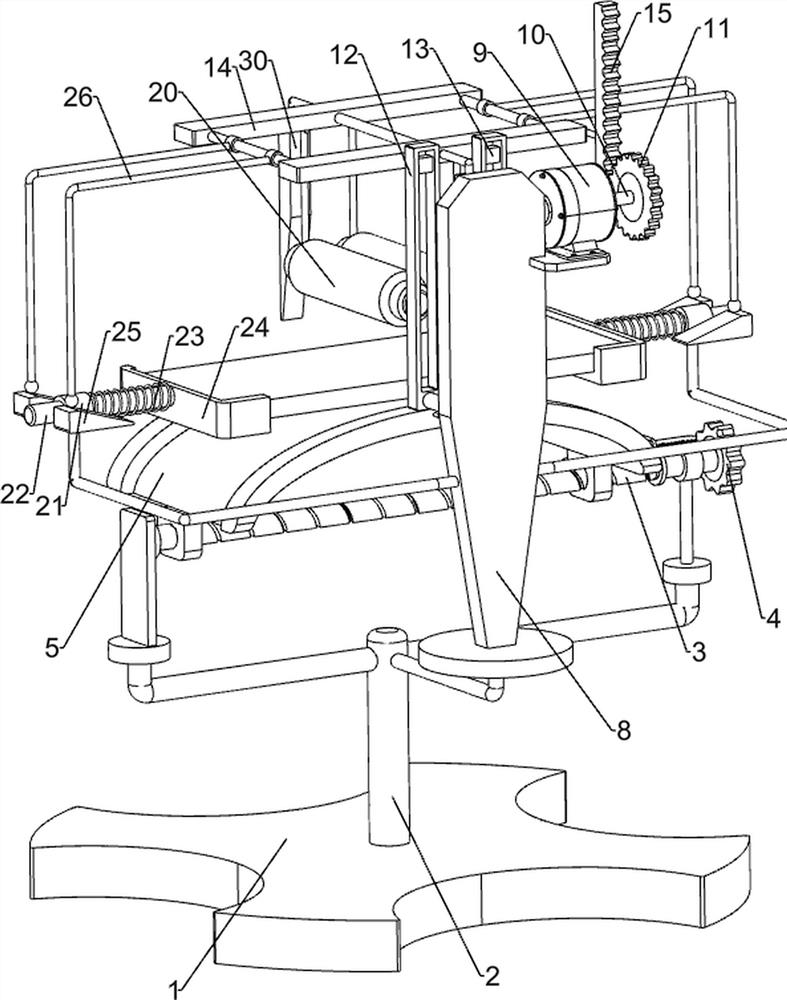

Efficient steel bar bending equipment in field of construction engineering

An efficient steel bar bending device in the field of construction engineering, the high-efficiency steel bar bending device in the field of construction engineering includes a base plate, a pulling device located above the base plate, a bracket device, a support plate device arranged on the bracket device, The abutting device arranged on the support plate device, the positioning device located above the support plate device, and the motor device arranged on the support plate device. The high-efficiency steel bar bending equipment in the construction engineering field of the present invention can quickly bend steel bars, has high bending efficiency, is simple to operate, is convenient to use, has low manual labor intensity, and is high in safety, and is suitable for popularization and application.

Owner:广州百士臣科技有限公司

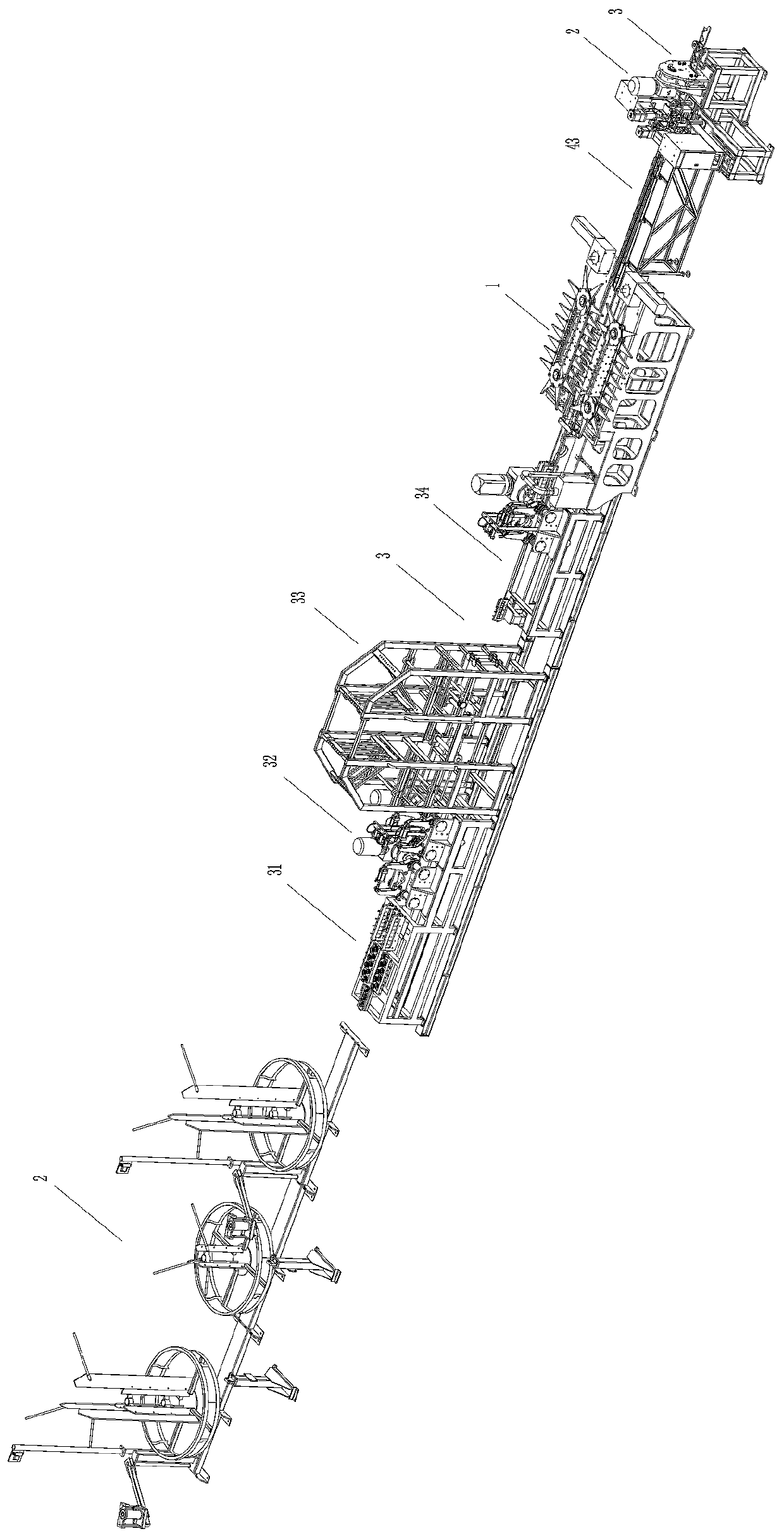

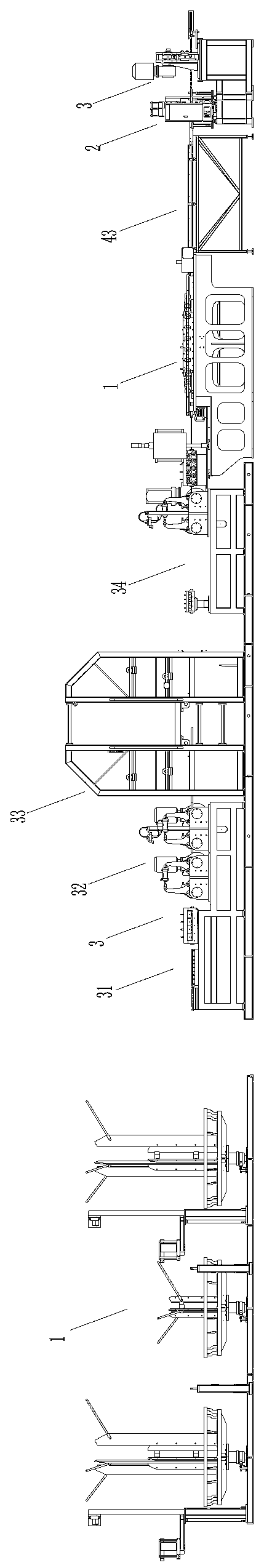

Plane truss production line

PendingCN109648007AQuick bendingThe style is fixed and beautifulMetal working apparatusProduction lineRebar

The invention belongs to the field of plane truss production, and particularly relates to a plane truss production line. The plane truss production line comprises a placing device, a straightening roller pressing device, a waving device, a welding device and a shearing device, wherein the waving device comprises a waving base, a waving drive, a side steel bar guide pipe, a fixed waving device anda movable waving device, and the fixed waving device comprises a first rotating shaft and a first crawler belt, triangular plates are fixed on the outer side of the first crawler belt, and the movablewaving device comprises a sliding guide rail, a sliding base, a second rotary shaft and a second crawler belt, triangular plates are fixed on the outer side of the second crawler belt, and the wavingdrive is connected with the first rotary shaft and the second rotary shaft; the welding device comprises a welding frame and welding heads; the shearing device comprises a shearing base and a cutterframe, and a cutter rotating shaft is arranged on the cutter frame, a cutter connecting part sleeves the cutter rotating shaft, and a shearing cutter is hinged to the lower part of the cutter connecting part. According to the plane truss production line, the steel bar can be processed into the plane truss, the processing process is automatic, the efficiency is high, and the method is suitable forlarge-scale plane truss processing.

Owner:浙江亿洲机械科技有限公司

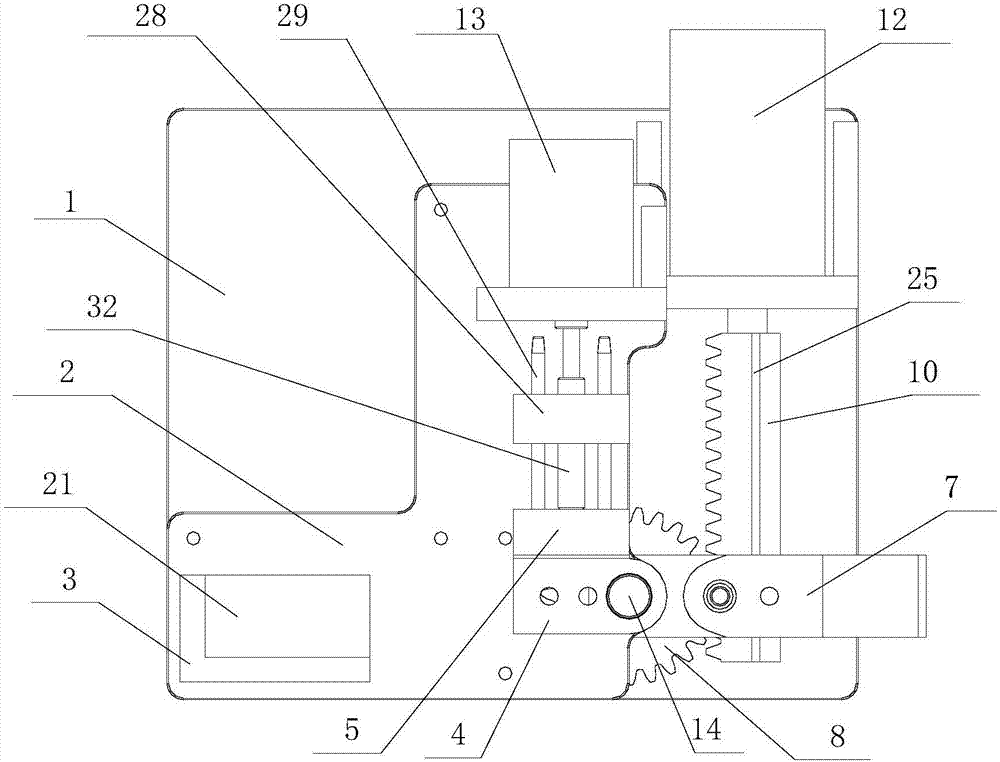

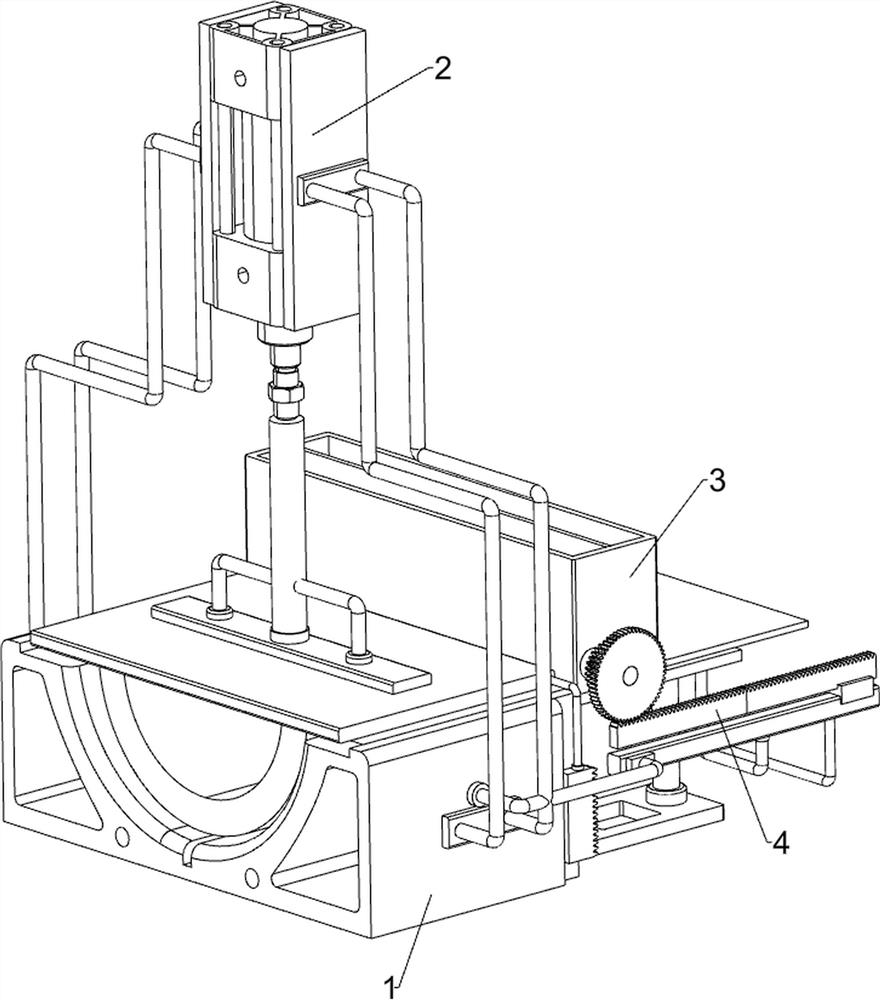

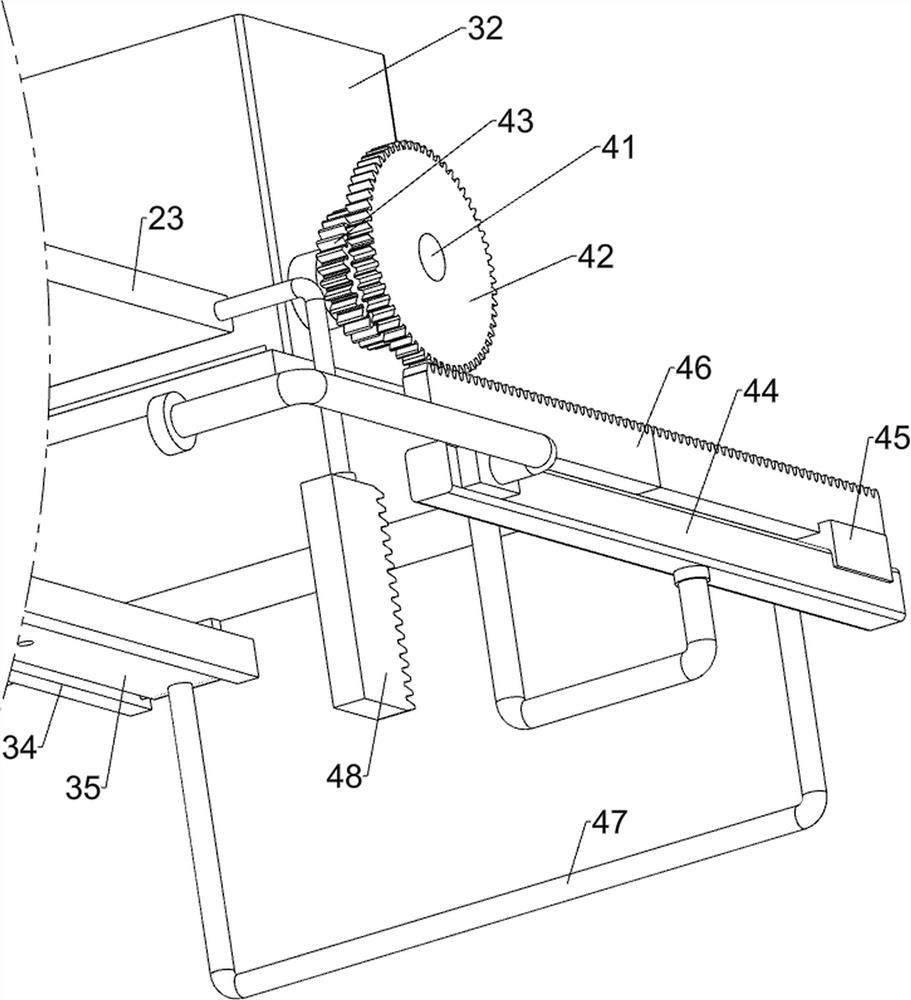

Automotive urea tank metal tube bending mould

ActiveCN107052111AAchieve bendingAvoid wrinklesShaping toolsMetal-working feeding devicesEngineeringTube bending

The invention provides an automotive urea tank metal tube bending mould. The automotive urea tank metal tube bending mould comprises a base, a base plate, a first locating block, a second locating block, a press block, a first rocker arm, a second rocker arm, a gear, two rolling wheels, a rack, a rack locating block, a first driving mechanism, a second driving mechanism and a fixing rod. The first locating block and the second locating block are used for locating and fixing a metal tube. The press block and the second locating block are arranged in a face-to-face mode, and the press block is driven by the second driving mechanism to get close to or keep away from the second locating block. The fixing rod sequentially penetrates through a first assembling hole, a second assembling hole and a third assembling hole to be fixedly connected with the gear, and is connected with the second locating block in a rotating mode and fixedly connected with the first rocker arm. The rack is meshed with the gear and connected with the first driving mechanism. The first driving mechanism drives the rack to move. According to the automotive urea tank metal tube bending mould, the rolling wheels and third locating grooves can conduct guided bending on the metal tube, and therefore the inner side of the metal tube is prevented from obvious corrugation, deformation of the metal tube is avoided, and the flatness ratio formed after bending is accomplished can be improved.

Owner:ANHUI ZHONGDING KEUMAH AUTO HOSE & PIPE ASSEMBLY

Clamping bending fixture for automobile wire harness

The invention discloses a clamping bending fixture for an automobile wire harness. The spring-back bending fixture for the wire harness is sequentially provided with a base and a bending main body from bottom to top, wherein the top of the bending main body is sunken downwards to form a bending groove and a wire holding groove which are mutually staggered, the depth of the bending groove is greater than the depth of the wire holding groove, and a spring-back mechanism is arranged at the bottom of the bending groove. The spring-back bending fixture for the wire harness further comprises a stamping head, wherein the stamping head is capable of carrying out reciprocating motion in the bending groove along a vertical direction to extrude or keep away from the wire harness located in the wire holding groove; the base is provided with clamping mechanisms along the two sides of the wire holding groove, and each clamping mechanism comprises a main rod, a branch rod, a first rolling wheel and a second rolling wheel; one end of the main rod is hinged on the base, and the other end of the main rod is connected with the branch rod to form an L-shaped structure; and the first rolling wheel is arranged on the top of the branch rod, the second rolling wheel is arranged on the head of the branch rod, and the automobile wire harness is capable of sequentially penetrating through the first rolling wheel and the second rolling wheel. The bending fixture is capable of rapidly bending the automobile wire harness.

Owner:WUHU EXCELLENCE WIRE HARNESS SYST

Method for preparing flexible linear cutting cable

ActiveCN110790622AGood flexibilityStrong cutting abilityNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusMechanical engineeringExplosive Agents

The invention discloses a method for preparing a flexible linear cutting cable. The method comprises the following steps: vulcanizing and curing double-component room-temperature vulcanized silicone rubber by using a vulcanizing agent so as to prepare a cutting cable sheath; filling the sheath with an explosive and the double-component room-temperature vulcanized silicone rubber, and pressing an energy gathering groove; performing vulcanizing and curing by using the vulcanizing agent so as to prepare a cutting cable chemical bar with the energy gathering groove; and further mixing and fillingmetal powder and the double-component room-temperature vulcanized silicone rubber into the energy gathering groove of the cutting cable chemical bar, and performing pressing under the action of vulcanizing and curing of the vulcanizing agent, so as to form an energy gathering cover. The energy gathering cover of the flexible linear cutting cable prepared by using the method not only has very goodflexibility, but also is tightly combined with the cutting cable chemical bar, so that the cutting cable has very good flexibility and bending performance, and the explosion cutting capability can beimproved.

Owner:ZHONGBEI UNIV +1

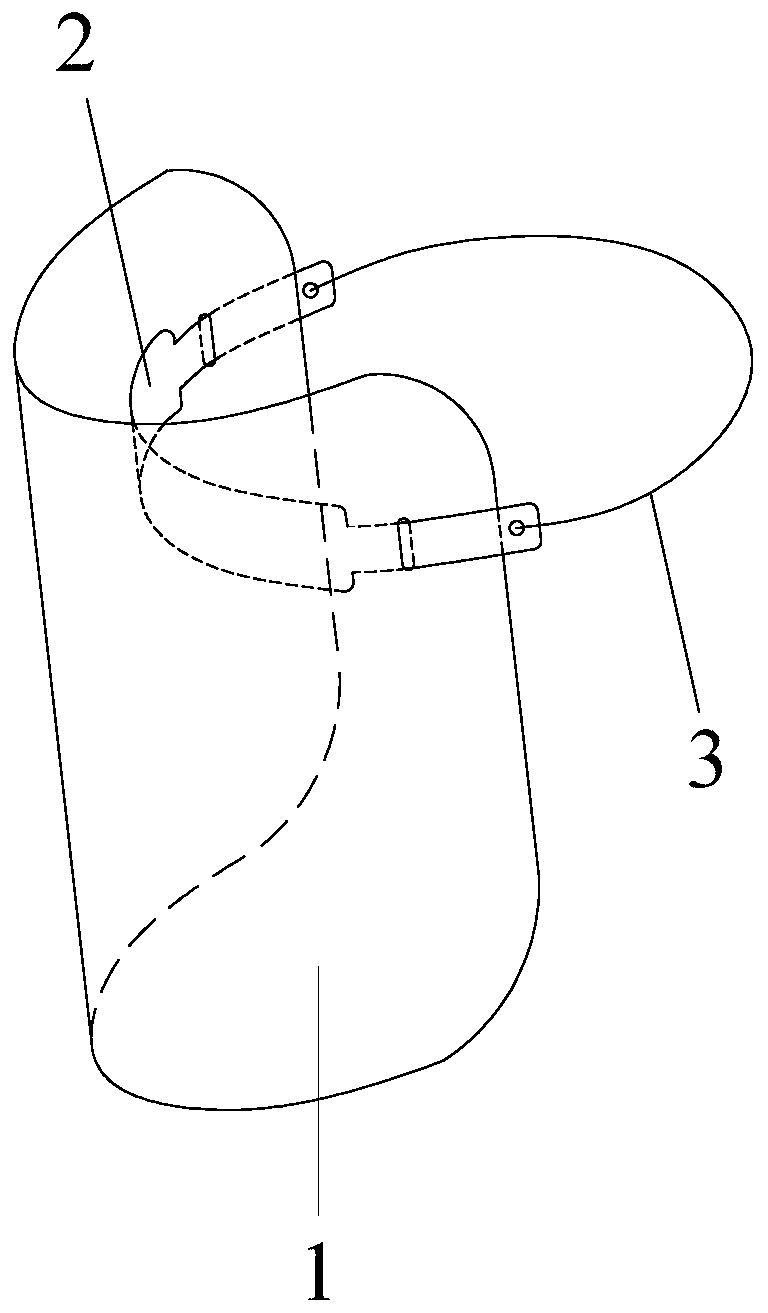

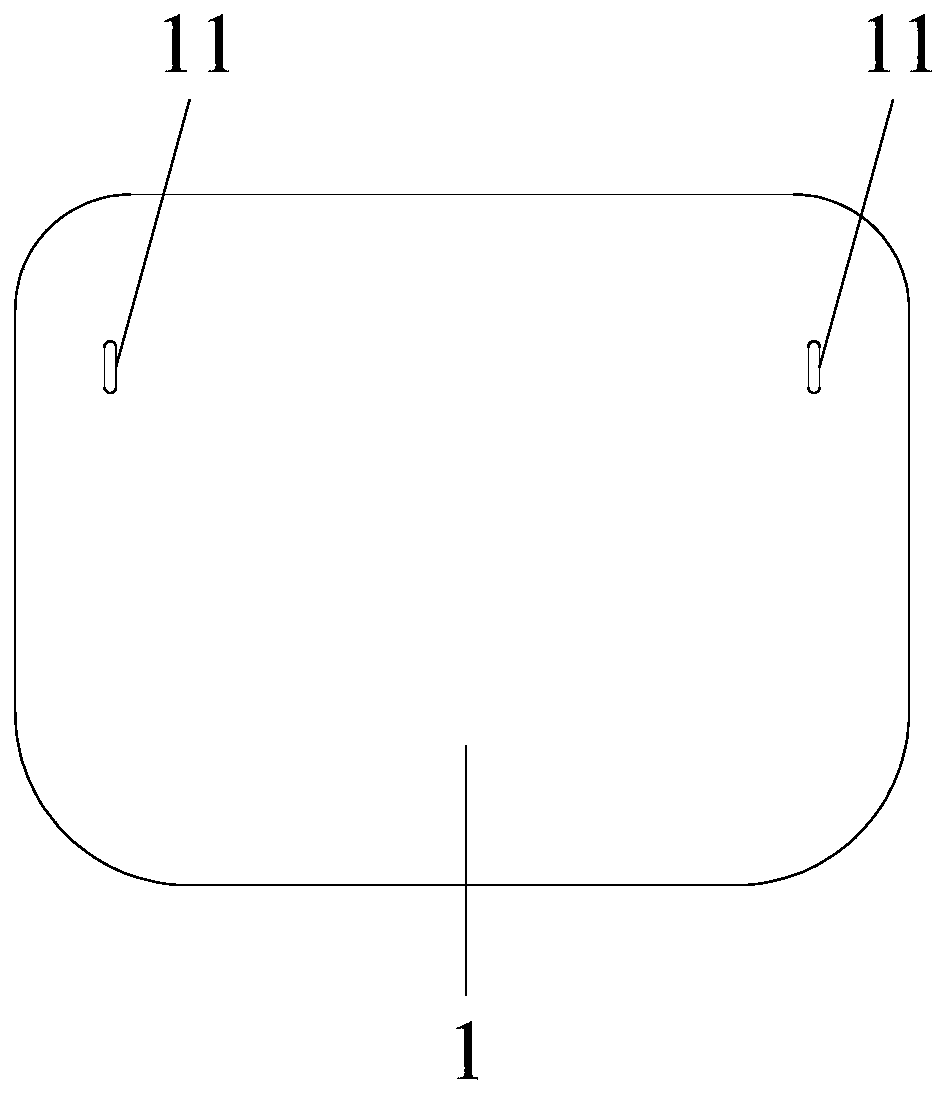

Protective mask

The invention discloses a protective mask comprising a panel, a fixing strip and a hanging rope, the panel is a transparent thermoplastic material plate; the fixing strip is a thermoplastic plate; thesize of the panel is matched with that of the face of a person; and adjusting areas are arranged on the two sides of the panel respectively. Each adjusting area is provided with at least one strip-shaped hole; all the strip-shaped holes are vertically formed, the width of the fixing strip is matched with the length of the strip-shaped holes, the two ends of the fixing strip penetrate through onestrip-shaped hole in the adjusting areas on the two sides respectively, the two ends of the fixing strip are detachably connected with the two ends of the hanging rope, the fixing strip is used for being worn on the forehead of a human body, and the hanging rope is used for fixing the fixing strip. The fixing strip is worn on the forehead, the hanging rope is hung on the afterbrain, the panel is bent due to bending of the fixing strip, the bent panel can shield the eyes, the nose and the mouth of a person, prevent aerosol, droplets, body fluid and blood from splashing or splashing and preventthe aerosol, the droplets, the body fluid and the blood from invading the human body, and the protective mask is simple in structure, convenient to use, rapid to produce, low in cost and convenient topopularize.

Owner:山西康宁医药科技有限公司

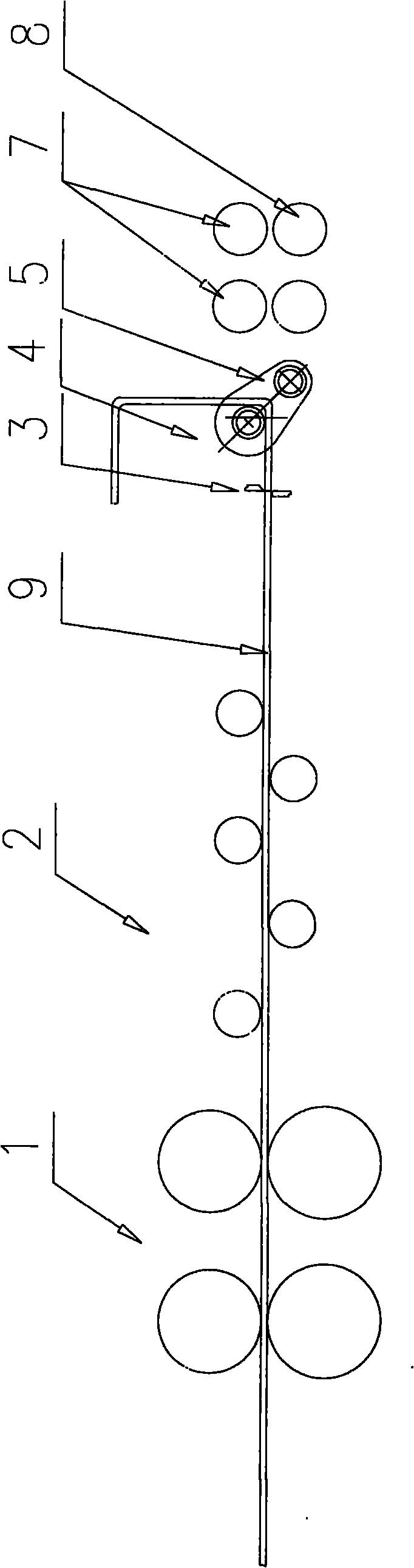

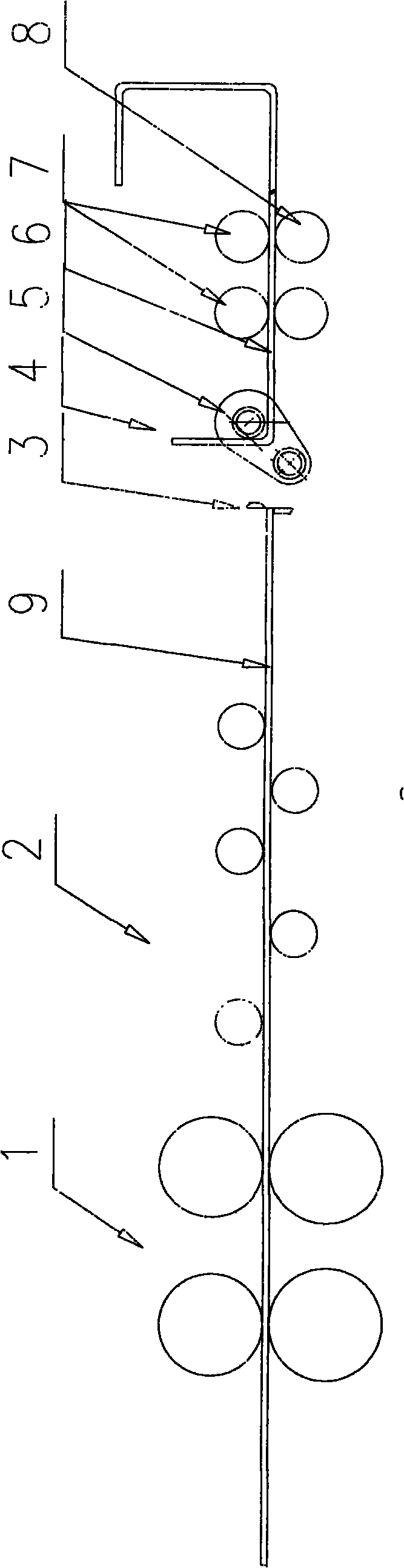

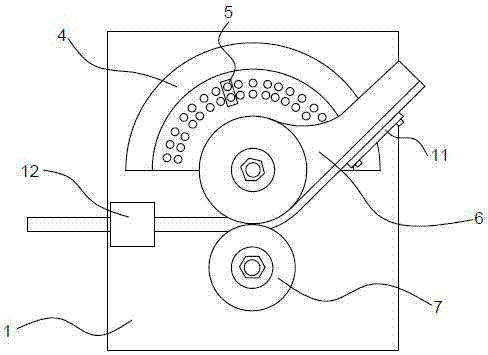

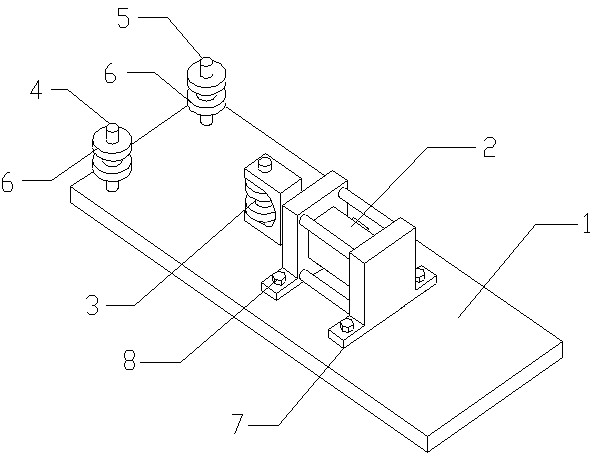

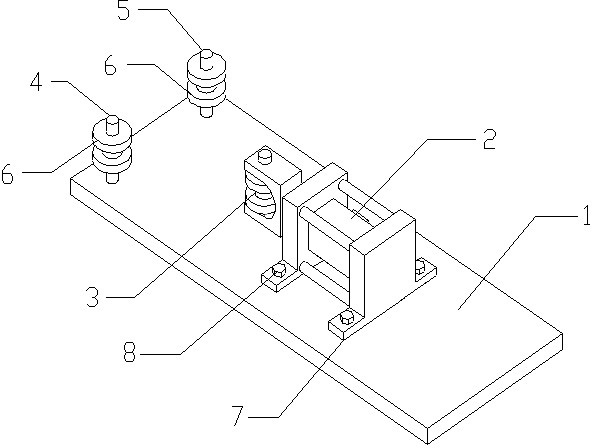

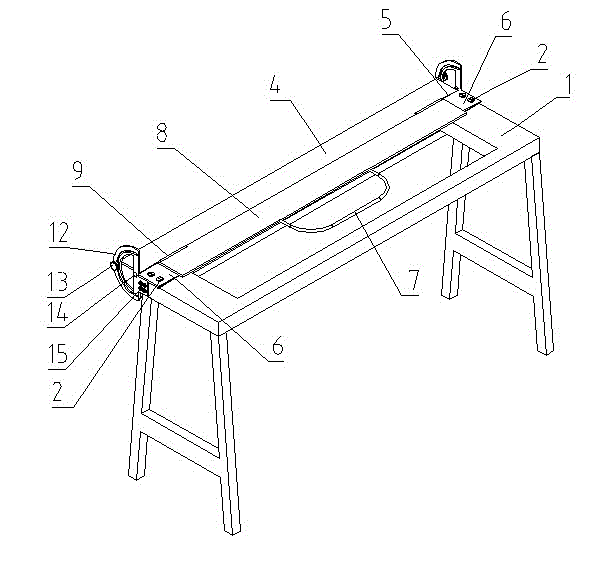

Bending machine

The invention discloses a bending machine which comprises a base (1), wherein a hydraulic cylinder (2) is arranged on the base (1); a jacking wheel (3) is arranged on the end part of a stretchable end of the hydraulic cylinder (2); a first shaft (4) and a second shaft (5) are correspondingly arranged on two sides in front of the jacking wheel (3); and rolling wheels (6) are symmetrically arranged on the first shaft (4) and the second shaft (5). The bending machine provided by the invention can reduce manpower, quickly bend and increase efficiency.

Owner:JIANGYIN DADI EQUIP

Pipe bending mold, pipe bending machine and pipe bending method

ActiveCN107649585ASame basic sizeSimple structureShaping toolsHeat exchange apparatusCivil engineering

The invention relates to a pipe bending mold. The pipe bending mold comprises an upper mold and a lower mold which have the same structure and are matched up and down; the upper mold or the lower moldcomprises a main body, an L-shaped pipe bending cavity and a U-shaped pipe bending cavity are formed in the upper end face of the main body in an inward sinking mode, and the L-shaped pipe bending cavity and the U-shaped pipe bending cavity are partially overlapped to form a shared pipe bending cavity; one of the opening ends of the L-shaped pipe bending cavity is the shared pipe bending cavity,a semicircular protruding plate is formed in the front end face of the main body in an outward protruding mode, and a shared pipe bending cavity extending cavity is formed in the side face of the protruding plate along circular arc of the protruding plate from the opening end of the shared pipe bending cavity in an inward sinking mode; a positioning cavity communicating with the shared pipe bending cavity is further formed in the rear end face of the main body in an inward sinking mode, and the central axis of the positioning cavity is coincident with the central axis of the shared pipe bending pipe cavity; and the upper mold and the lower mold are matched up and down. The invention further discloses a pipe bending machine and a pipe bending method. A straight pipe can be bent at one timethrough the pipe bending mold, the pipe bending machine and the pipe bending method, manufacturing time is shortened, and the heat exchanging cost is reduced.

Owner:成都实好电器有限公司

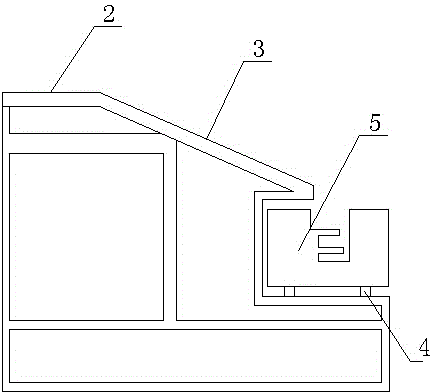

Comprehensive steel bar straightening, cutting and bending machine

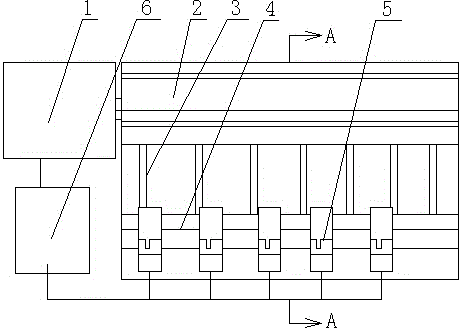

The invention relates to the technical field of building machines, in particular to a comprehensive steel bar straightening, cutting and bending machine. The comprehensive steel bar straightening, cutting and bending machine is characterized by comprising a machine frame, the upper face of the left end of the machine frame is provided with a steel bar straightening and cutting machine provided with a first power device, the upper face of the right side of the machine frame is provided with a longitudinal conveying and storing platform, the middle of the right side of the machine frame is provided with a transverse conveying device which is of a downward-inclining structure, the lower face of the right side of the machine frame is provided with a sliding rail provided with a bending device, the bending device is provided with a machining inlet, the output part of the transverse conveying device is arranged in the machining inlet, the bending device comprises a plurality of bending machine single bodies arranged on the sliding rail, the machining inlet serves as the inlet of the bending machine single bodies, the bending machine single bodies are provided with racks, center shafts and bending arms, and the center shafts and the bending arms are installed on the racks and connected with a second power device. The comprehensive steel bar straightening, cutting and bending machine has the advantages of being low in labor intensity and high in production efficiency.

Owner:CHANGGE JUBA MACHINERY

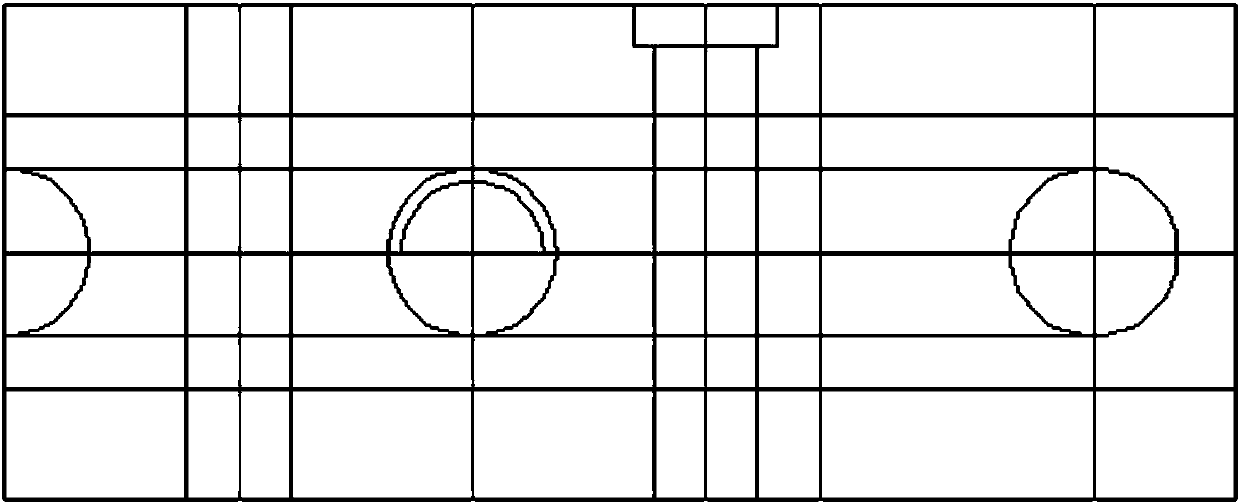

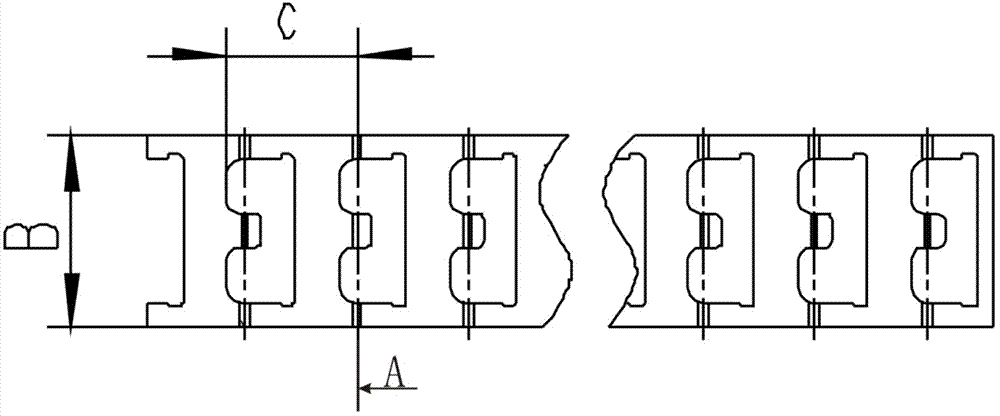

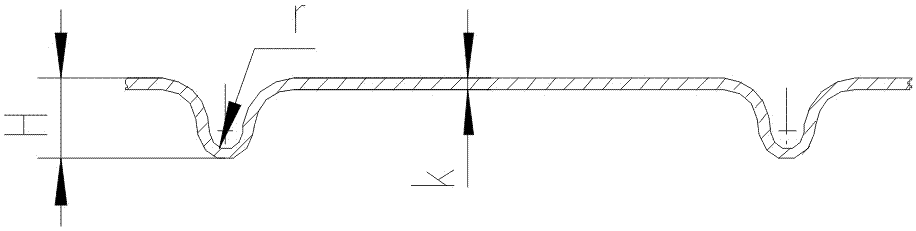

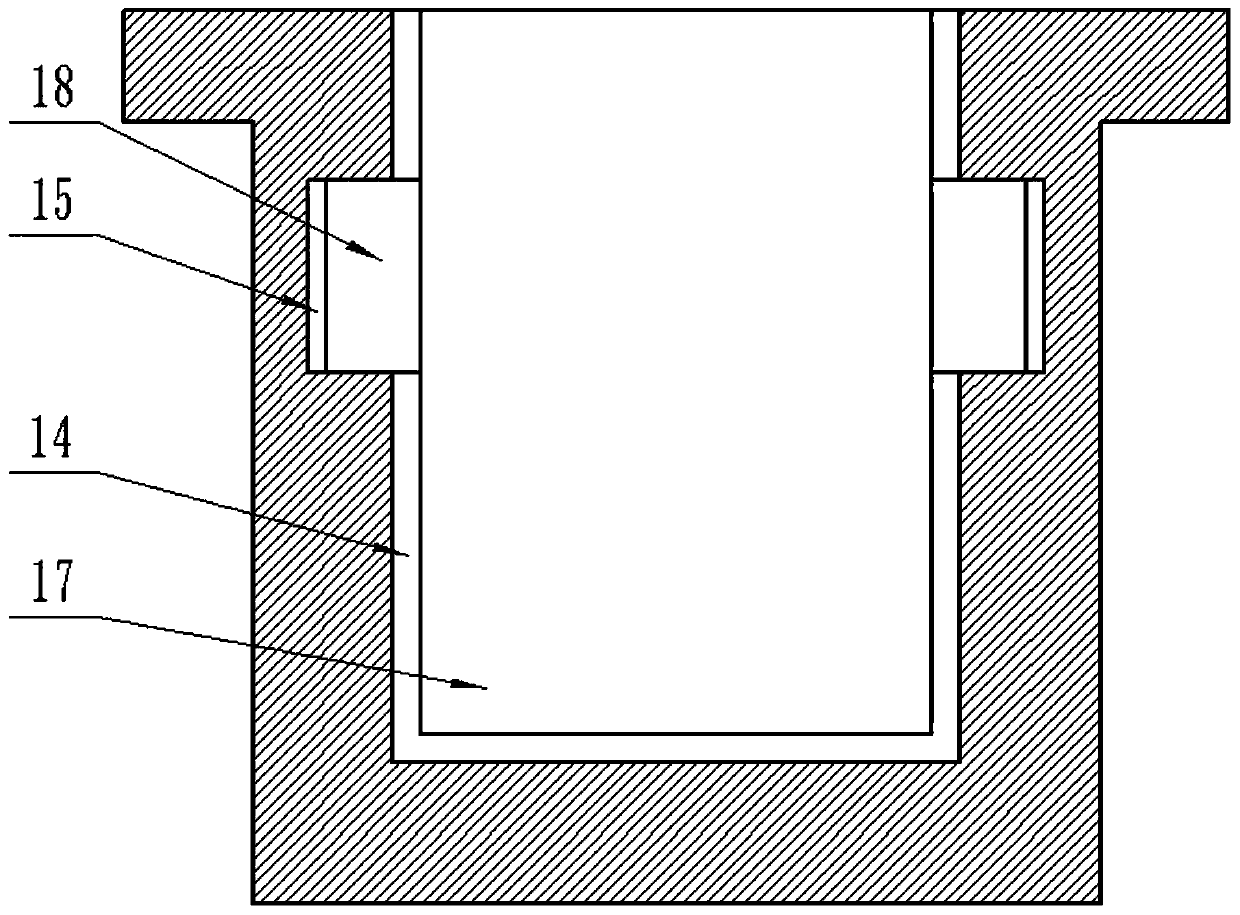

Method for bending wave spring with concave hole

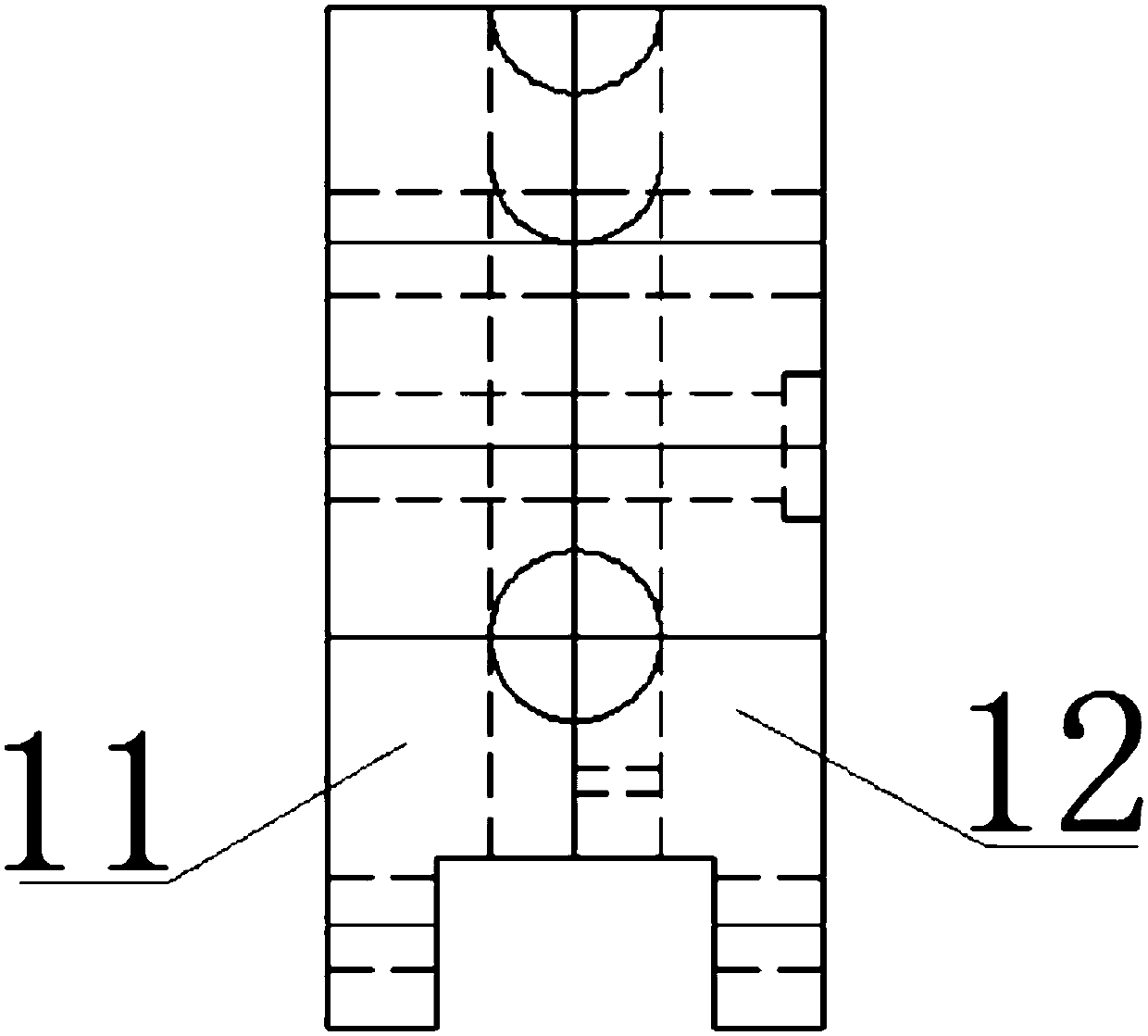

The invention discloses a method for bending a wave spring with concave holes. The wave spring (7) to be bent has a width B and a thickness K and is provided with a plurality of concave holes; a pad plate (1) and a concave die (2) are fixed on a working table of a press machine through threaded through holes (8) of the concave die; a positioning pin (6) is installed inside a positioning pin hole (9); a convex die (3) is linked with a punching platform of the press machine through a threaded through holes (3.1) of the convex die; as N equals to M, a bending pressure head (5) can enter a bending groove (10); when the wave spring to be bent is positioned through the positioning pin, the punching platform moves downwards to bend the wave spring to be bent from the concave holes, and the bent parts of the wave spring meet the requirements of H and r; and the bent wave spring to be bent is taken out from the bending groove and moved to a discharge groove (11) so as to accomplish the bending process of the wave spring to be bent at one of the concave holes. The wave spring can be formed by repeating the bending process, the productivity is improved, and the rejection rate is reduced.

Owner:LUOYANG BEARING RES INST CO LTD

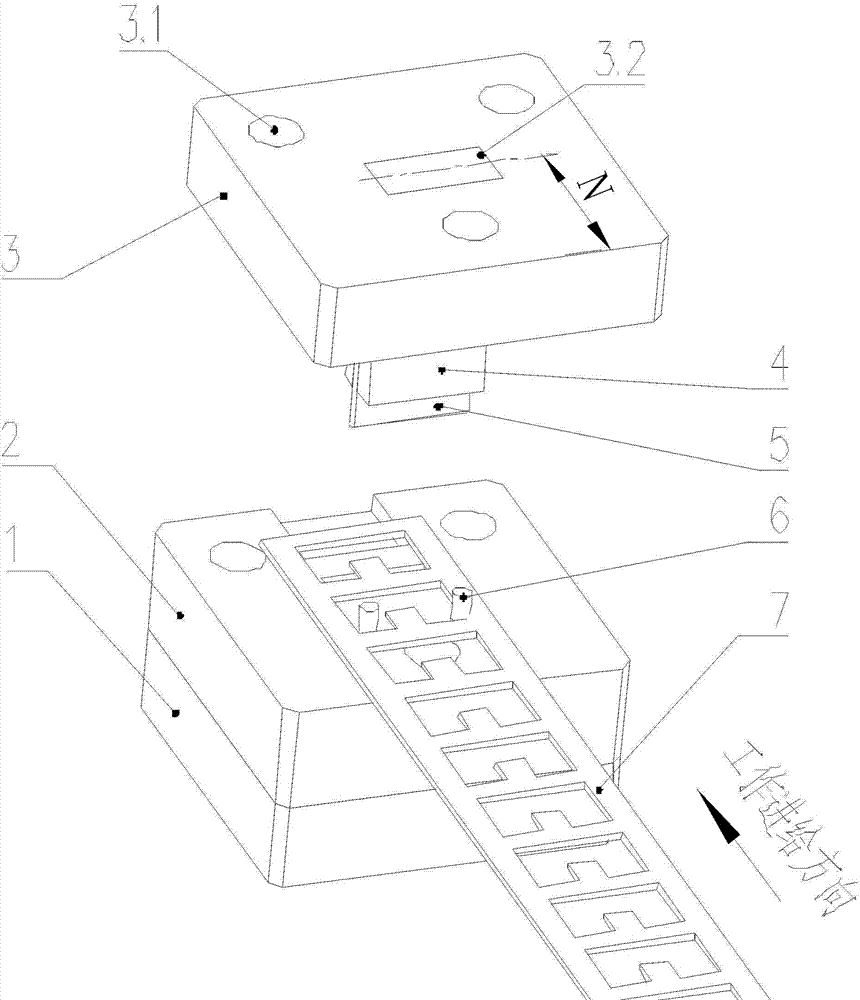

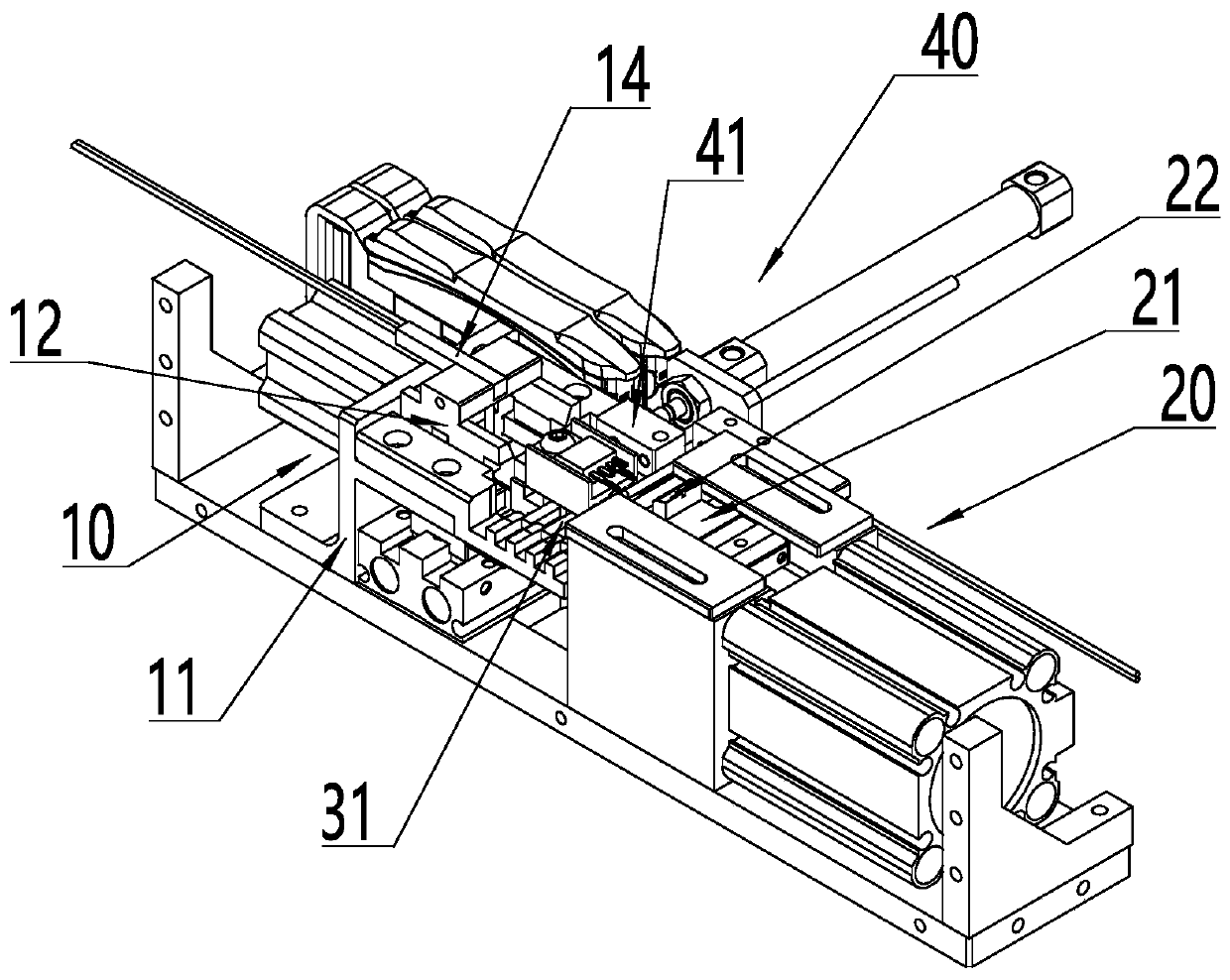

Automatic pin bending mechanism of electronic element

The invention discloses an automatic pin bending mechanism of an electronic element. The automatic pin bending mechanism comprises the following components of a holding device, a bending device, a discharging device, a pushing device, wherein the holding device comprises a fixing frame and a U-shaped retainer which is arranged on the fixing frame, and the retainer is arranged on the fixing frame through a first driving cylinder; the bending device comprises a pushing block, the pushing block is arranged on the side part of the fixing frame, and a bending head is arranged at one end, close to the holding frame, of the pushing block; the discharging device comprises an opening and closing block, and the movable opening and closing block is arranged below the fixing frame; the pushing devicecomprises a pushing block, and the pushing block is arranged at the side part of the fixing frame. Through the matching action of the retaining device, the bending device, the discharging device and the pushing device, the functions of workpiece positioning, pin bending, waste parts discharging and good parts blanking are realized, the device mechanism is compact, the installation space is saved,the pins can be quickly positioned and accurately bent, and the production efficiency and quality are improved.

Owner:ZHUHAI ZHIXIN AUTOMATIC TECH CO LTD

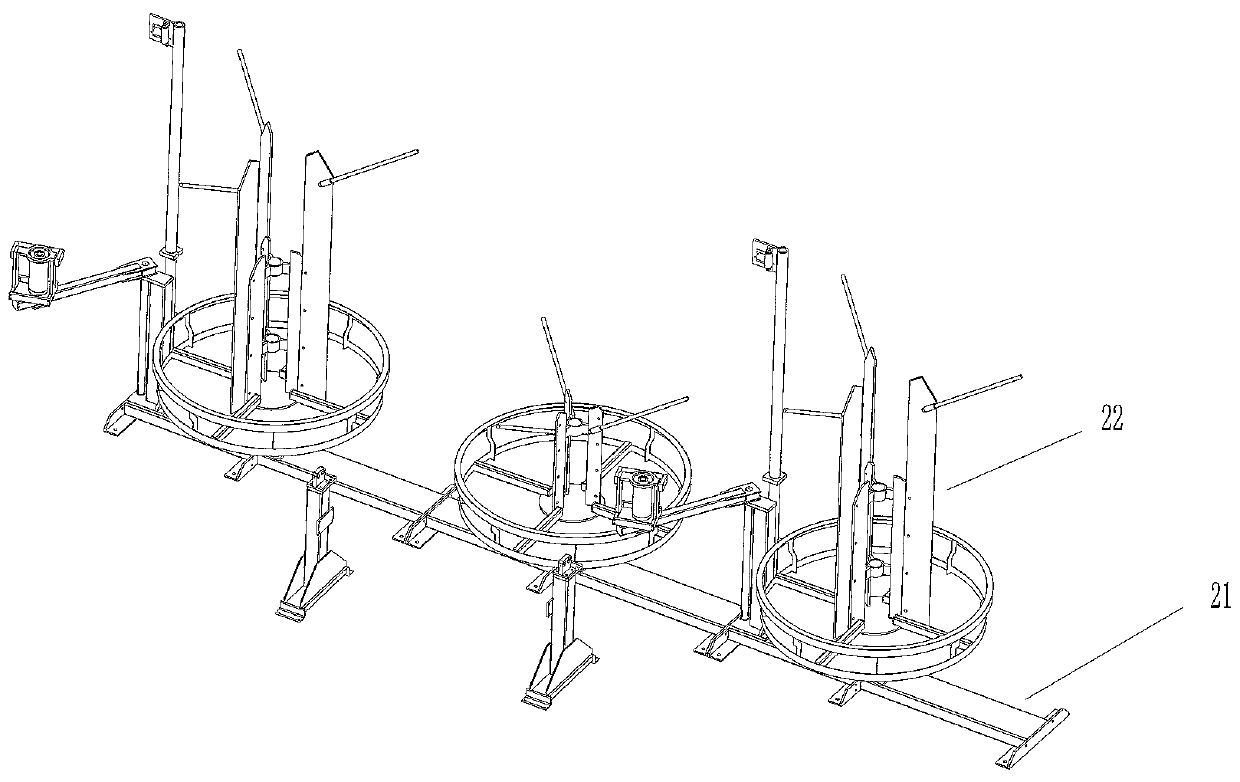

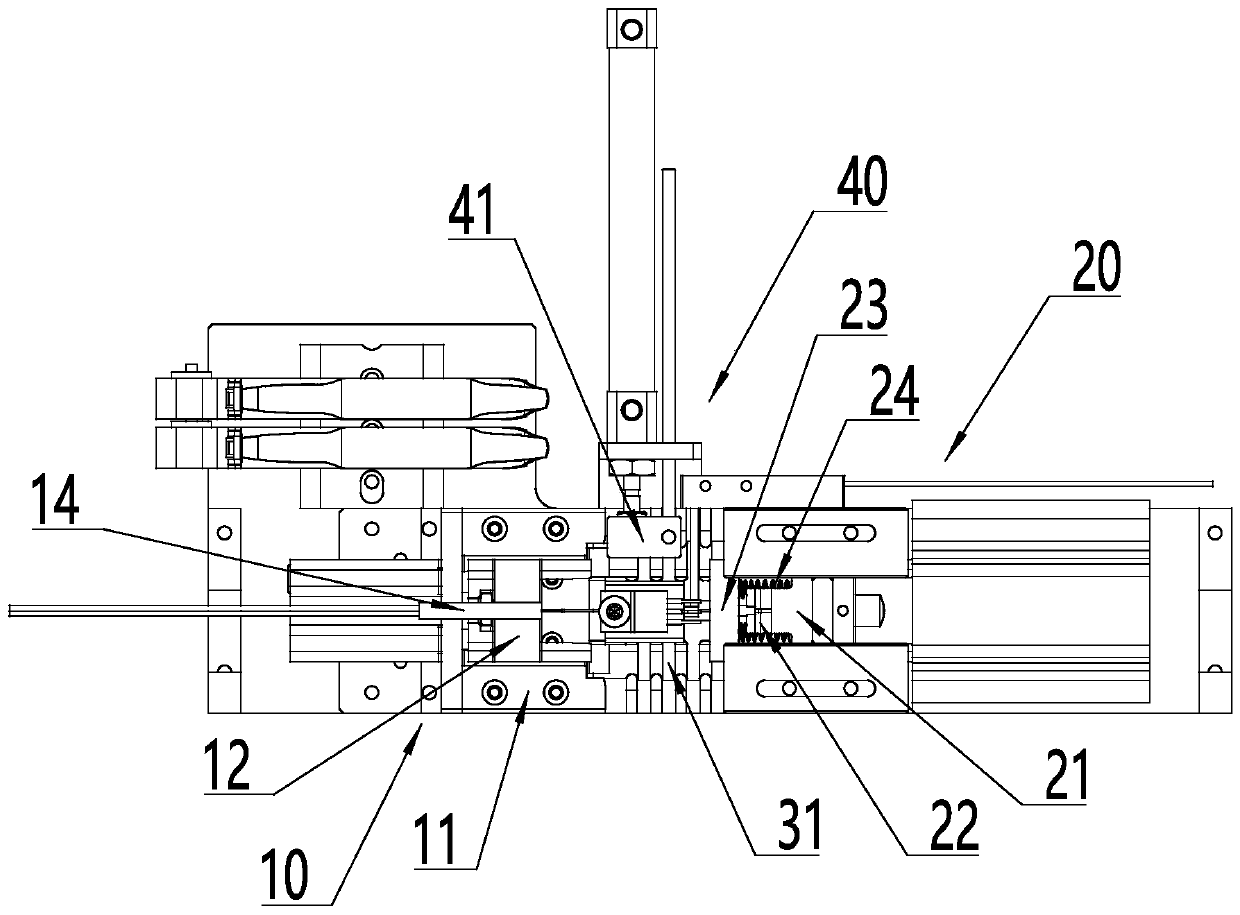

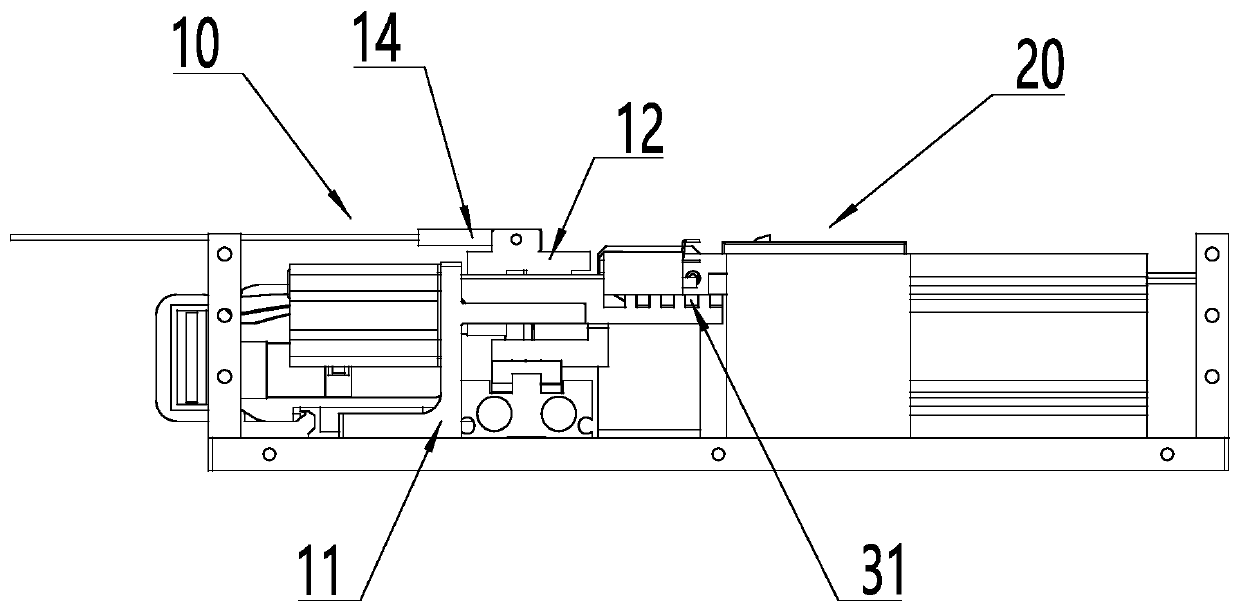

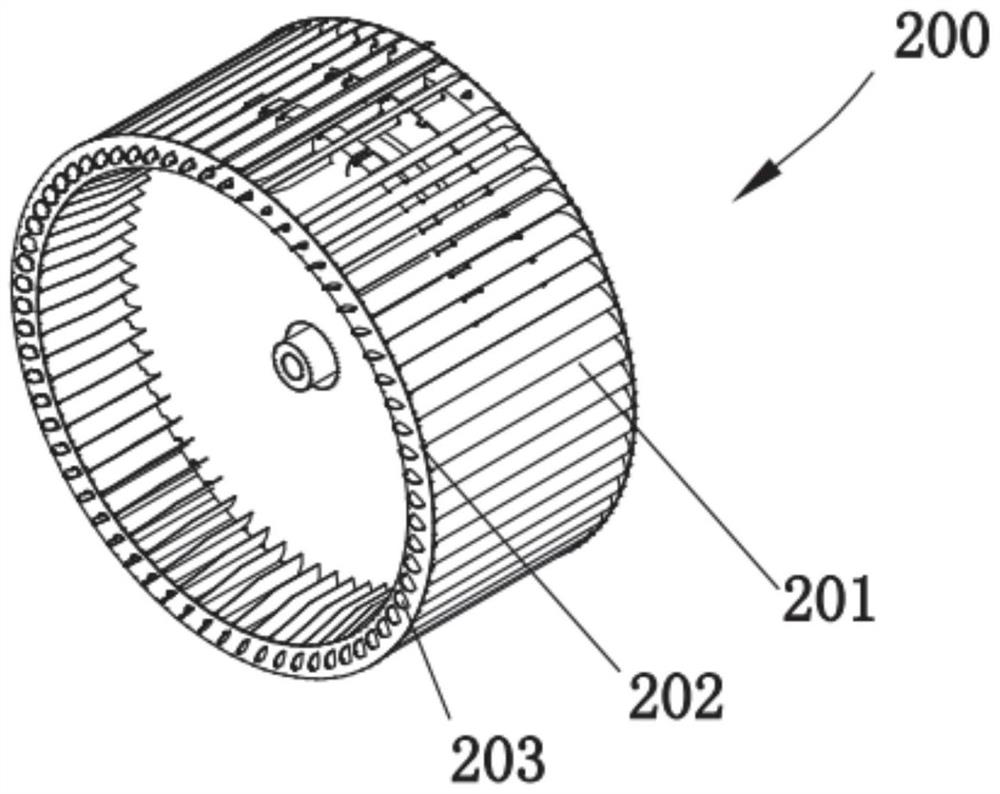

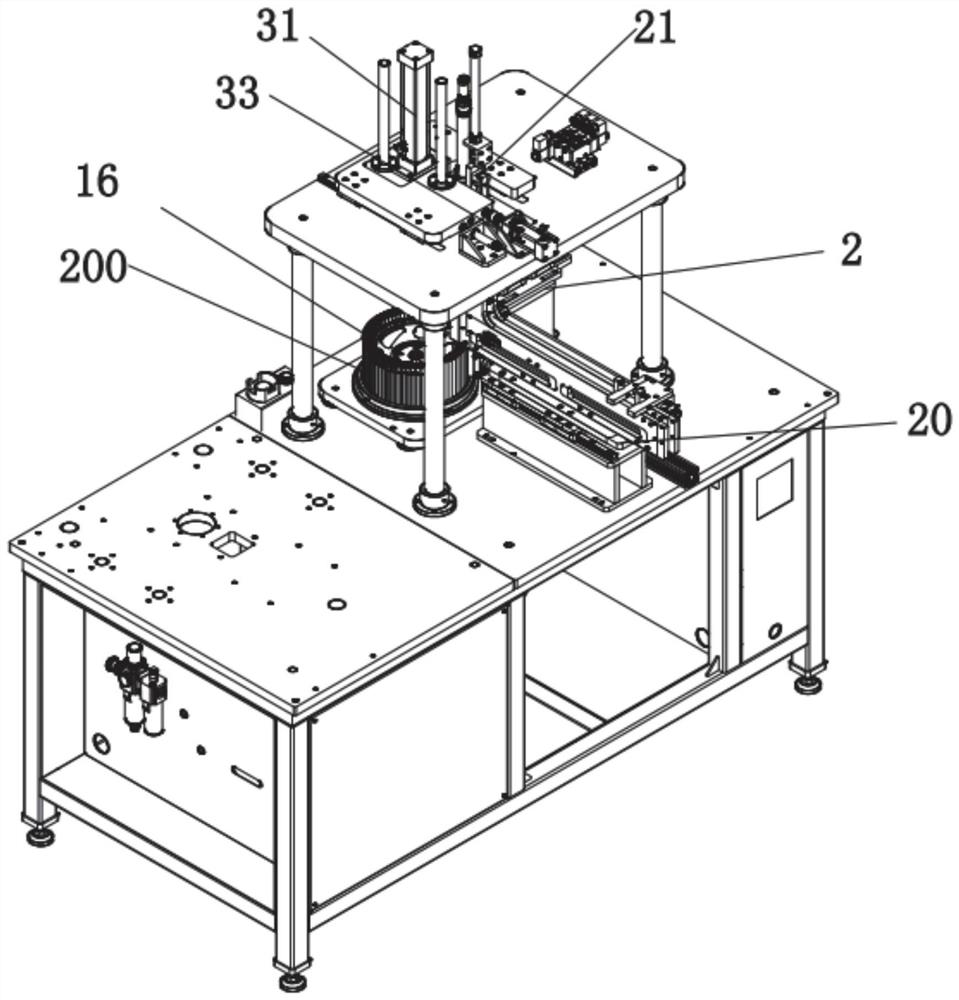

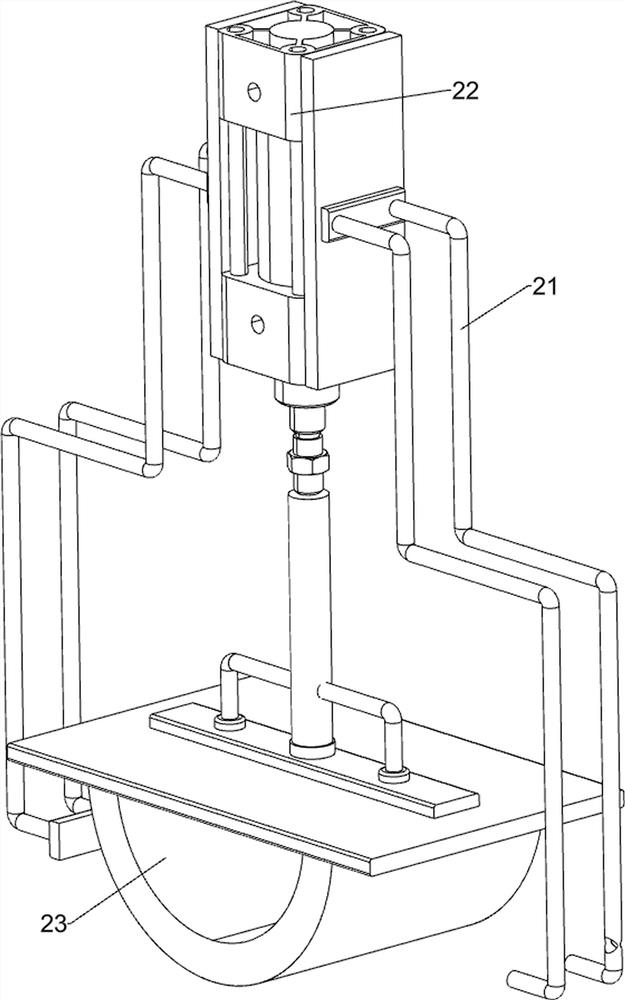

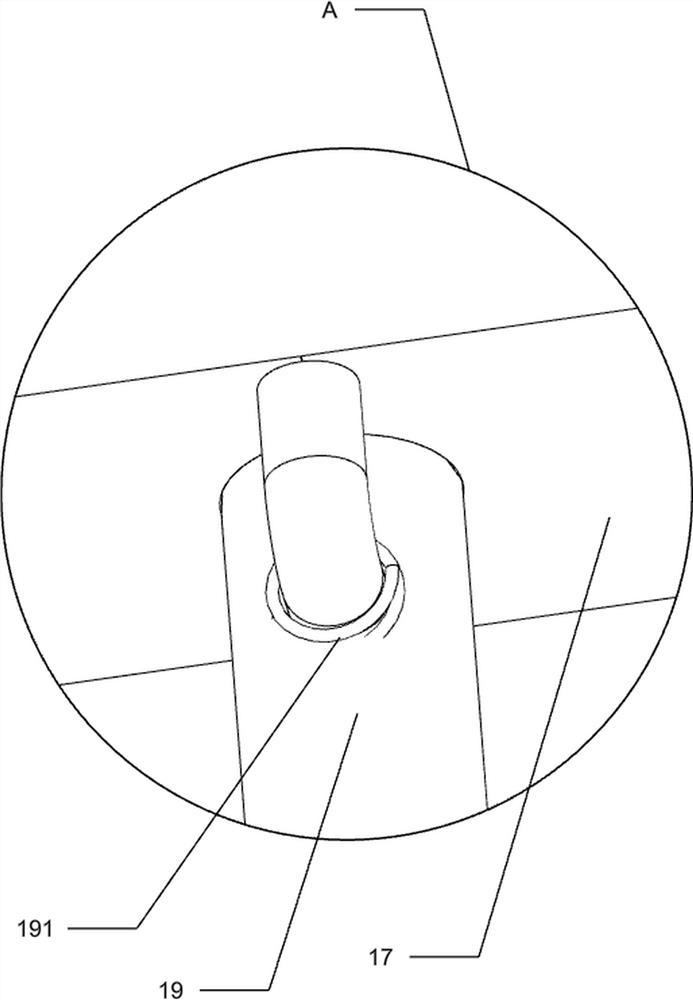

Blade assembling equipment

PendingCN114393408ARealize automatic feeding processQuick bendingOther manufacturing equipments/toolsMetal working apparatusImpellerClassical mechanics

The invention discloses blade assembling equipment which comprises a rack, a bending mechanism, a rotating mechanism, an impeller positioning mechanism and an assembling mechanism, the bending mechanism, the rotating mechanism and the impeller positioning mechanism are mounted on the rack, the assembling mechanism is used for assembling a blade into the impeller positioning mechanism, the impeller positioning mechanism is rotatably mounted on the rotating mechanism, and the bending mechanism comprises an up-down telescopic driving part and a bending roller. The bending roller is installed at the telescopic end of the up-down telescopic driving piece so as to roll and bend the tip end of the blade. Automatic feeding and assembling of the blades and rapid bending of the tip ends of the assembled blades can be achieved, after an impeller is installed on the impeller positioning mechanism, the lower telescopic driving piece enables the bending roller to abut against an end plate of the impeller, the impeller positioning mechanism is driven by the rotating mechanism to drive the blade to be bent, and the blade tip ends can be bent rapidly. Furthermore, the bending roller rolls while bending the tip of the blade and flattening the tip on the end plate, so that the tip of the blade can be quickly bent, and the bending quality is stable.

Owner:湖南创研智能装备有限公司

Portable simple metal sheet bending device

The invention provides a portable simple metal sheet bending device. The portable simple metal sheet bending device is provided with a rack, a front grooved plate, a rear grooved plate, a limiting block, a bending plate, an adjustable threaded rod, a plate groove adjusting block and angle adjusting blocks, wherein the front grooved plate, the rear grooved plate, the limiting block, the plate groove adjusting block and the angle adjusting blocks are mounted on the rack; the front grooved plate, the plate groove adjusting block and the rear grooved plate form a long sheet metal bar insertion groove (plate groove), and the width of the plate groove is adjusted through the adjustable threaded rod and a fixed threaded rod; the angle adjusting blocks are provided with bevel protractors; the bent angle is adjusted through the angle adjusting blocks, and adjusting, positioning and bending at any angle can be conducted within 180 degrees according to the required bending angle; after the angle is adjusted and fixed, sheet metal is inserted into the plate groove to the limiting block at the required appropriate position, a handgrip is pulled up to drive the bending plate to bent the sheet metal, and then quick bending of the sheet metal is completed; the purposes of easy operation and quick bending are achieved.

Owner:FUJIAN LONGYAN ERBIN AGRI DEV

Bending method for producing metal bent pipe

The invention discloses a bending method for producing a metal bent pipe. The bending method is characterized by comprising the following processing steps: (1) a drawing of the qualified metal bent pipe is tailored at the ratio of 1: 1; (2) the tailored drawing is bonded on a working platform; (3) one end of a metal straight pipe blank is fixed on the working platform, and the fixed end of the metal straight pipe blank is overlapped with one end of the metal bent pipe drawing on the working platform; (4) external force is applied to a free end of the metal straight pipe blank, meanwhile, the bent part of the metal straight pipe blank is acidized through use of concentrated acid, and the acidizing direction is accordant with the bending direction of the metal straight pipe blank until the bending shape of the metal straight pipe blank is overlapped with the bending shape of the drawing on the working platform, so that the metal bent pipe is obtained; and (5) the residual concentrated acid on the bent pipe is cleaned by alkali solution. The bending method needs no pipe bending machine, only adopts manual operation to finish the pipe bending process, and can conveniently and quickly bend a small amount of metal pipes.

Owner:NINGGUO DAQUAN MACHINERY

Hoop bending device

PendingCN112122420AQuick bendingQuick placementMetal-working feeding devicesPositioning devicesStructural engineeringWorkbench

The invention relates to a bending device, in particular to a hoop bending device. The hoop bending device can automatically conduct feeding and discharging. The hoop bending device comprises a workbench, a bending assembly and a feeding assembly, wherein the bending assembly is installed on the workbench and conducts bending in a lifting mode, and the feeding assembly is installed on the workbench and conducts feeding in a sliding mode. According to the hoop bending device, materials can be rapidly bent through the bending assembly, the materials can be rapidly placed through the feeding assembly, the materials can be automatically put down through a moving assembly, and equipment is safer to use; and the bent materials can be automatically pushed out through a second connecting rod and apush block, and the safety of the equipment is further improved.

Owner:欧行

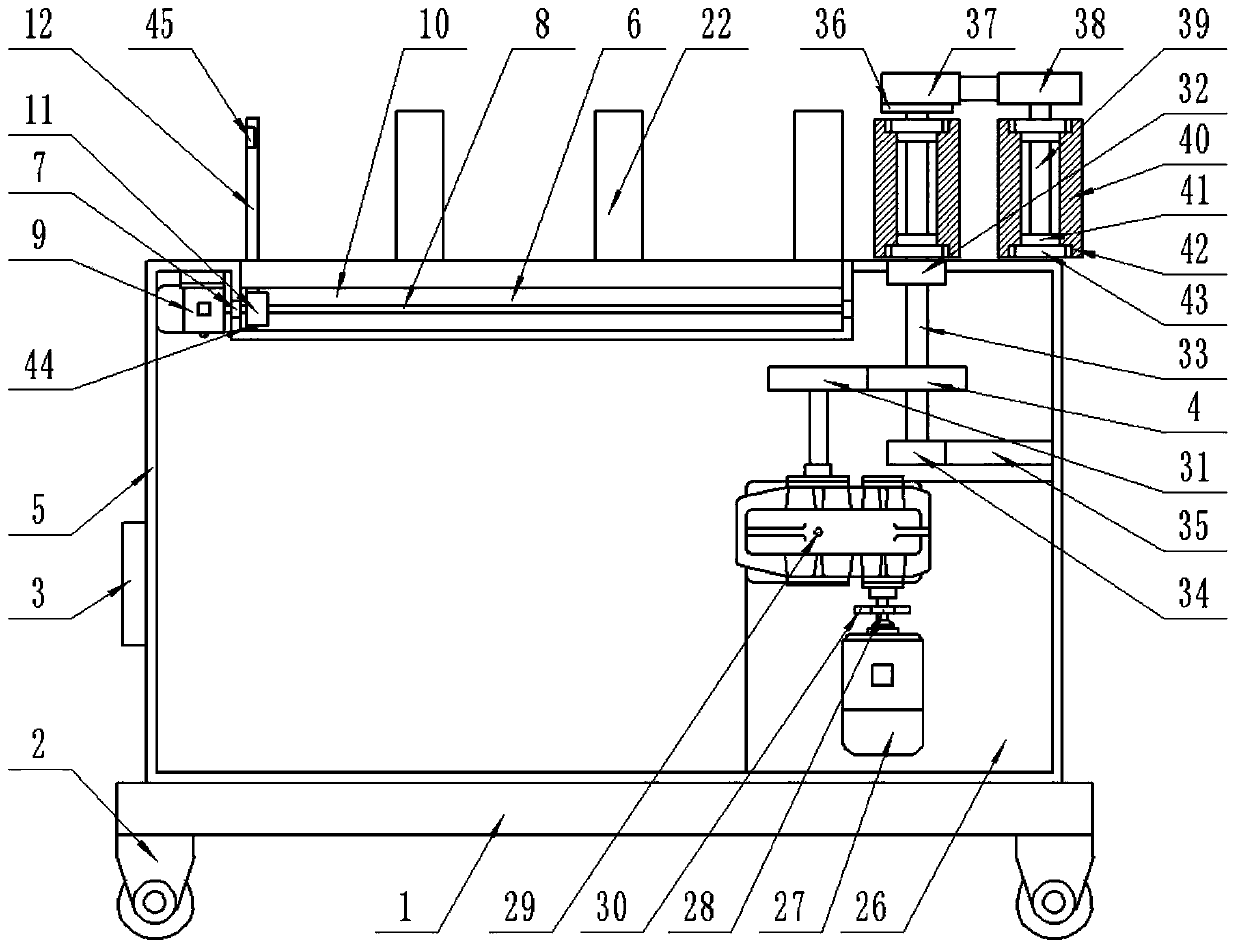

Efficient steel bar bending equipment

The invention discloses efficient steel bar bending equipment. The efficient steel bar bending equipment comprises a base, wherein universal wheels are arranged at four corners below the base, a bending driving box device is arranged above the base, a controller is arranged on the outer side surface of the bending driving box device, an automatic adjusting type steel bar conveying device is arranged on one side above the bending driving box device, and the other side of the bending driving box device is provided with an automatic steel bar bending device; and the automatic adjusting type steelbar conveying device is used for gathering and sorting steel bars through the cooperation of two reinforcing steel bar gathering blocks and telescopic rods, and then a screw rod is used for driving asteel bar movable baffle plate to move, so that the steel bars can move quickly; and the steel bar automatic bending device adjusts the distance between the two bent rotating cylinders through the hydraulic oil cylinder, and the two bent rotating cylinders rotate to bend the steel bars so as to complete the bending of the steel bars. The efficient steel bar bending equipment has the beneficial effects of being convenient to operate and high in practicability.

Owner:张庆琳

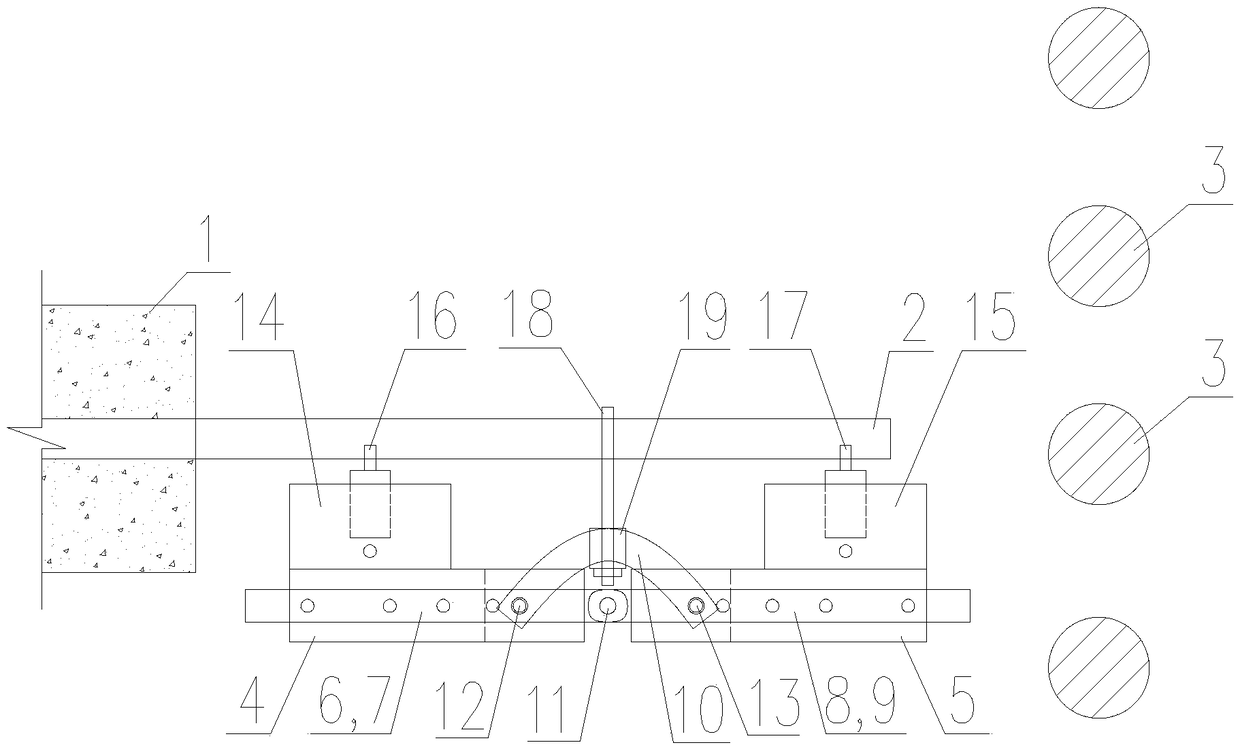

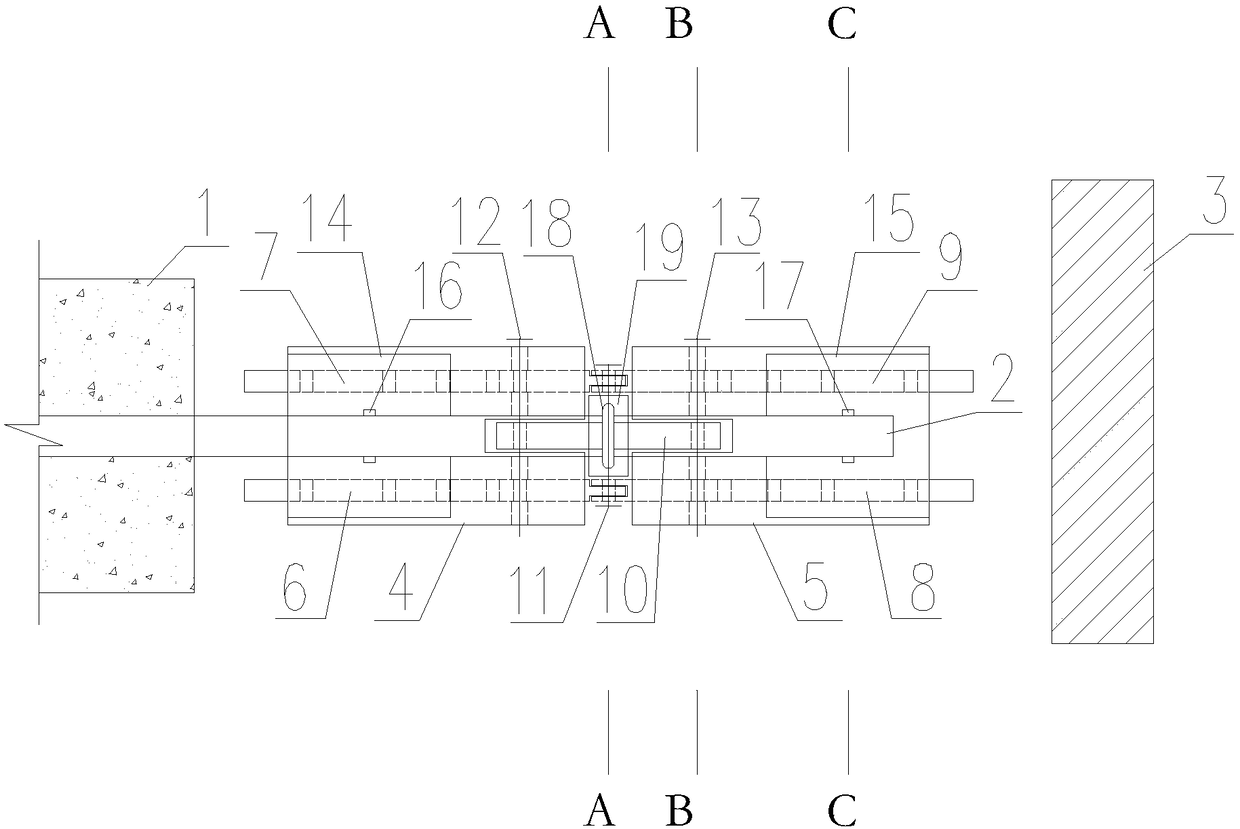

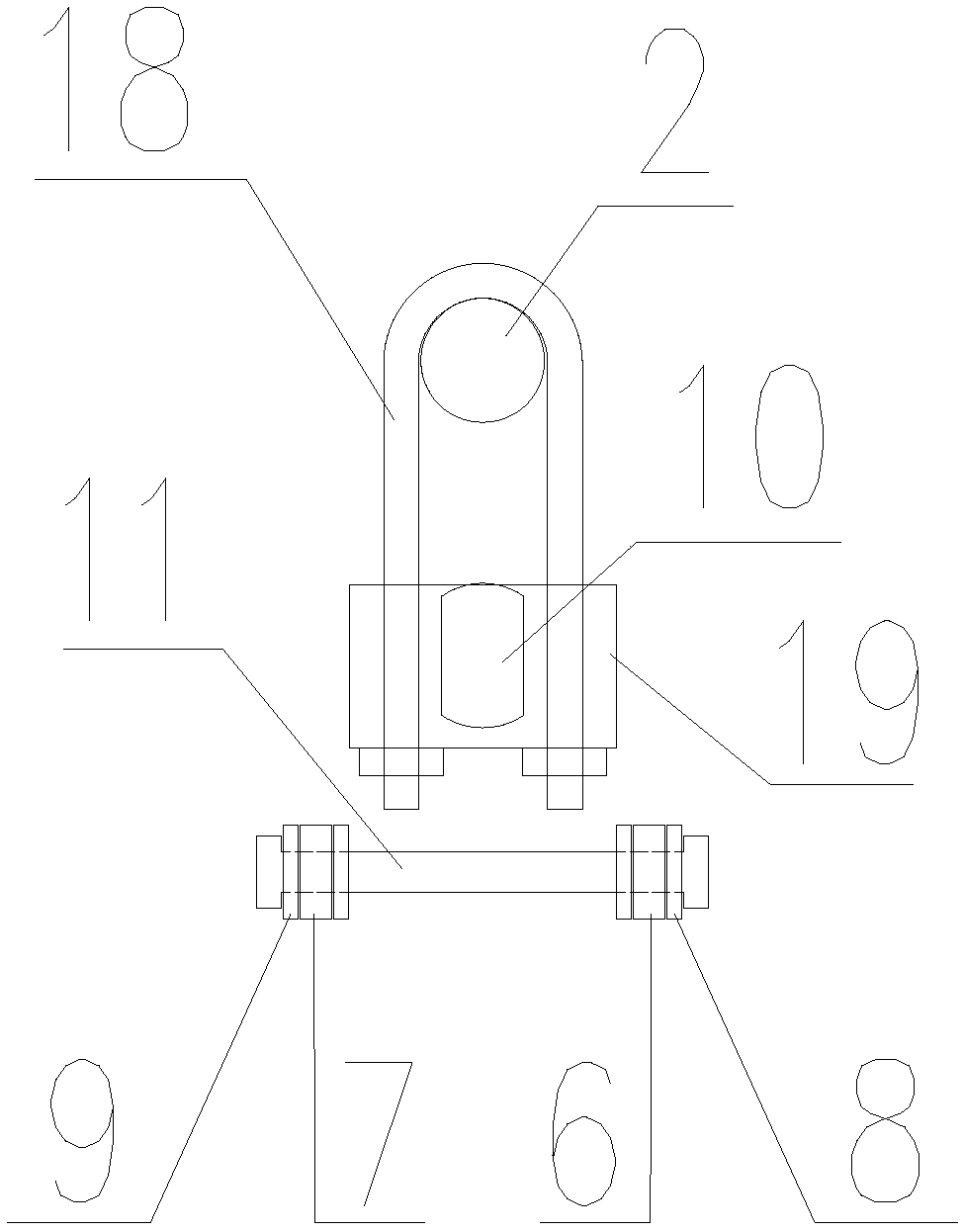

Steel bar bending device and method and application of steel bar bending device

The invention discloses a steel bar bending device and method and application of the steel bar bending device. By usage of the device and the method, in the narrow space, air pressure can be utilizedas power, and a steel bar is simply and rapidly bent by any angle. The device is mainly composed of two punching supports, four sliding chain rods, an anti-tension curved bar, two air cylinders and aU-shaped pull rod. The bending method comprises the steps that firstly, the steel bar bending device is arranged, the air cylinders work, air cylinder push rods apply thrust to the two sides of the steel bar through arc push heads, the U-shaped pull rod pulls the middle of the steel bar, and the steel bar is stressed and bent; secondly, work inserting holes of the sliding chain rods and the anti-tension curved bar are replaced, the air cylinders work again, and the steel bar is stressed and further bent; and thirdly, the second step is repeatedly conducted till the steel bar is bent in place.According to the application, the steel bar bending device is applied to beam-beam and beam column component lap joint in assembled reinforced concrete building construction.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Actuating control device for spatial-bending shape memory alloy actuator

InactiveCN101598118APrecise bendingQuick bendingMachines/enginesMechanical power devicesDigital signal processingControl manner

The invention discloses an actuating control device for a spatial-bending shape memory alloy actuator. The device comprises a detecting circuit, a selection and amplification circuit, a digital signal processor and a power actuation circuit, wherein the detecting circuit is used for detecting bending signals of the shape memory alloy actuator and transmitting the bending signals acquired in all directions to the selection and amplification circuit; the bending signals are transmitted to the digital signal processor after being selected and amplified; the digital signal processor calculates and determines the heating pulse time of shape memory alloy wires according to the difference between desired signals and actual signals and outputs control electric signals to the power actuation circuit; and the power actuation circuit controls the operation status of the shape memory alloy actuator by communicating and stopping the heating of the shape memory alloy wires. The actuating control device for the spatial-bending shape memory alloy actuator adopts current actuation control, has simple control mode, and is convenient for integration and miniaturization. The actuation control device for the spatial-bending shape memory alloy actuator meets the comprehensive requirement of miniaturization, precision positioning and flexible transmission and has outstanding technical advantage and potential and broad application prospects in the fields of humanoid robots, medical artificial limbs, endoscopes and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Electronic product production material bending device

The invention relates to a bending device, in particular to an electronic product production material bending device. According to the electronic product production material bending device provided bythe invention, an electronic product can be fixed, and the bending radian of the electronic product can be adjusted according to needs. The electronic product production material bending device comprises a mounting base used for mounting the whole device; an adjusting assembly mounted on the mounting base and adjusted in a rotating manner; a moving assembly mounted on the adjusting assembly and used for providing power to move; a bending assembly mounted on the moving assembly and bent in a sliding manner; a placing assembly mounted on the moving assembly and used for placing the electronic product. Through cooperation of a threaded rod and an arc-shaped template, different bending angles can be adjusted according to the requirements of production materials, and through cooperation of a gear and a rack, enough power can be provided for bending of the production materials.

Owner:JIANGSU DINGGE ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com