Back conveying and bending mechanism of reinforcing steel bar automatic bending machine

A technology of bending mechanism and hoop bending machine, applied in the field of return bending mechanism, which can solve the problems of limited size of hoops, inability to quickly bend long hoops, and inability to fully meet the needs of production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

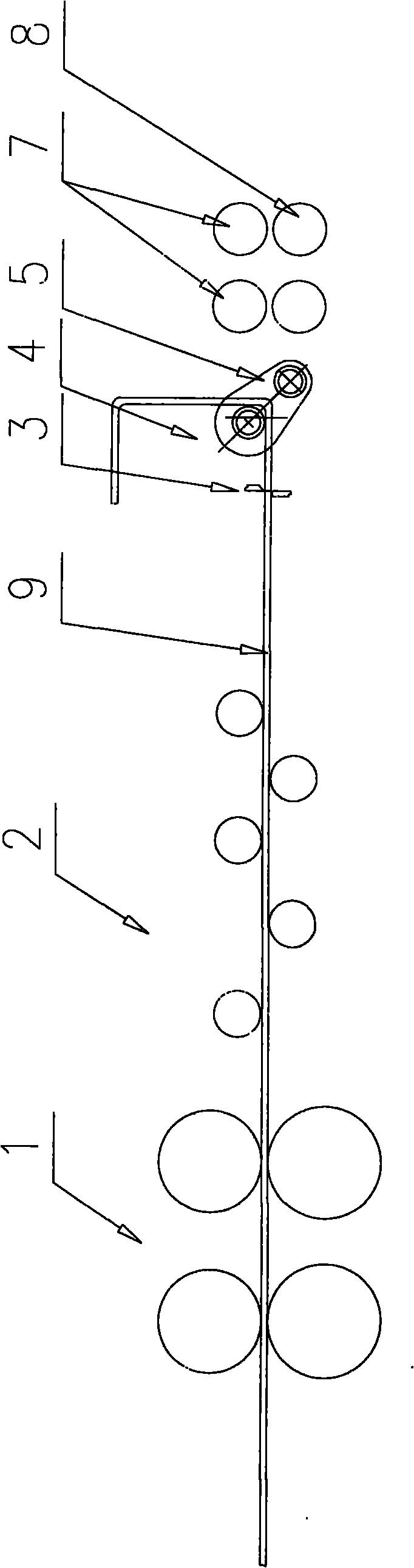

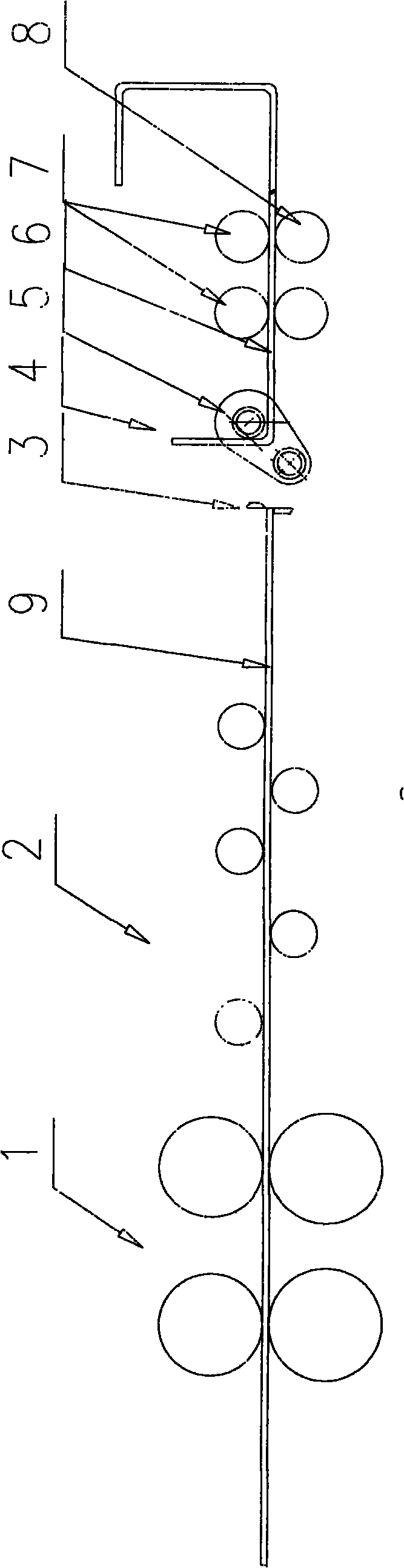

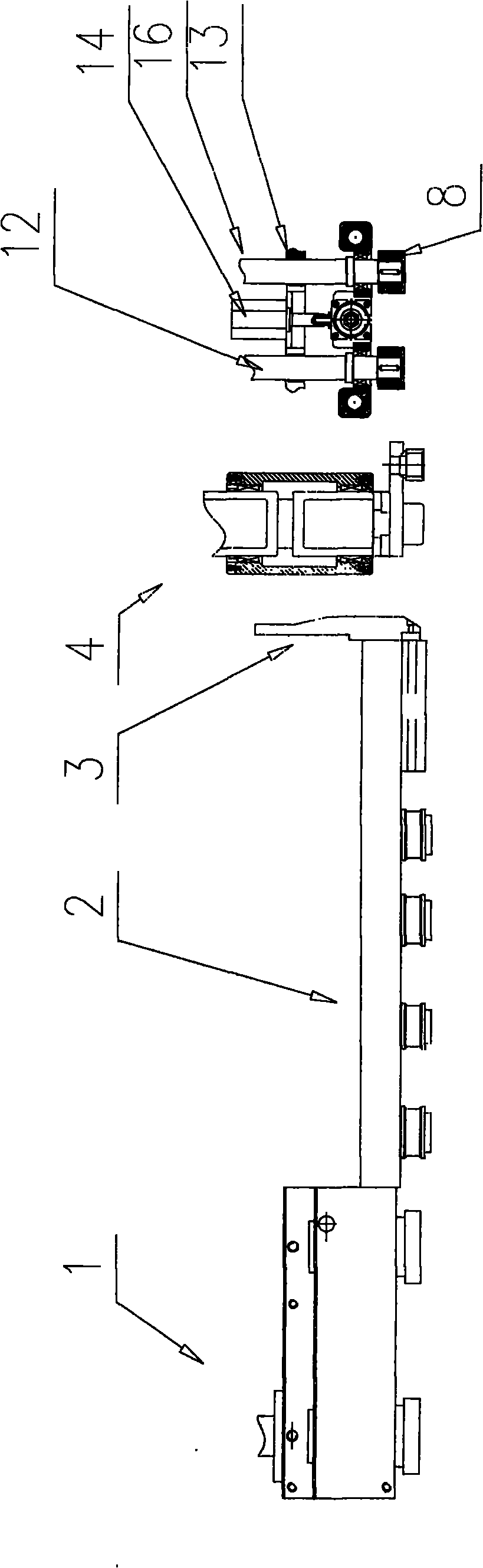

[0016] figure 1 It is a schematic front view of the structure of the present invention: figure 2 yes figure 1 After the steel bar is cut in the middle, the schematic diagram of the other end of the steel bar is bent after being sent back: image 3 yes figure 1 Schematic top view of the structure; Figure 4 yes figure 1 Schematic front view of the return mechanism; Figure 5 yes Figure 4 Sectional view of part 8 of middle return traction pulley; Figure 6 yes Figure 4 The top view of the 8 parts of the middle return traction wheel.

[0017] The invention provides a loopback bending mechanism of an automatic hoop bending machine for steel bars. The loopback bending mechanism is located behind the bending mechanism and the shearing mechanism, and its structure includes: loopback active pulley 8, loopback driven pulley 11, loopback pressure wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com