Automotive urea tank metal tube bending mould

A metal pipe and urea tank technology, applied in the field of pipe bending, can solve the problems of metal pipe deformation, poor precision, affecting processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

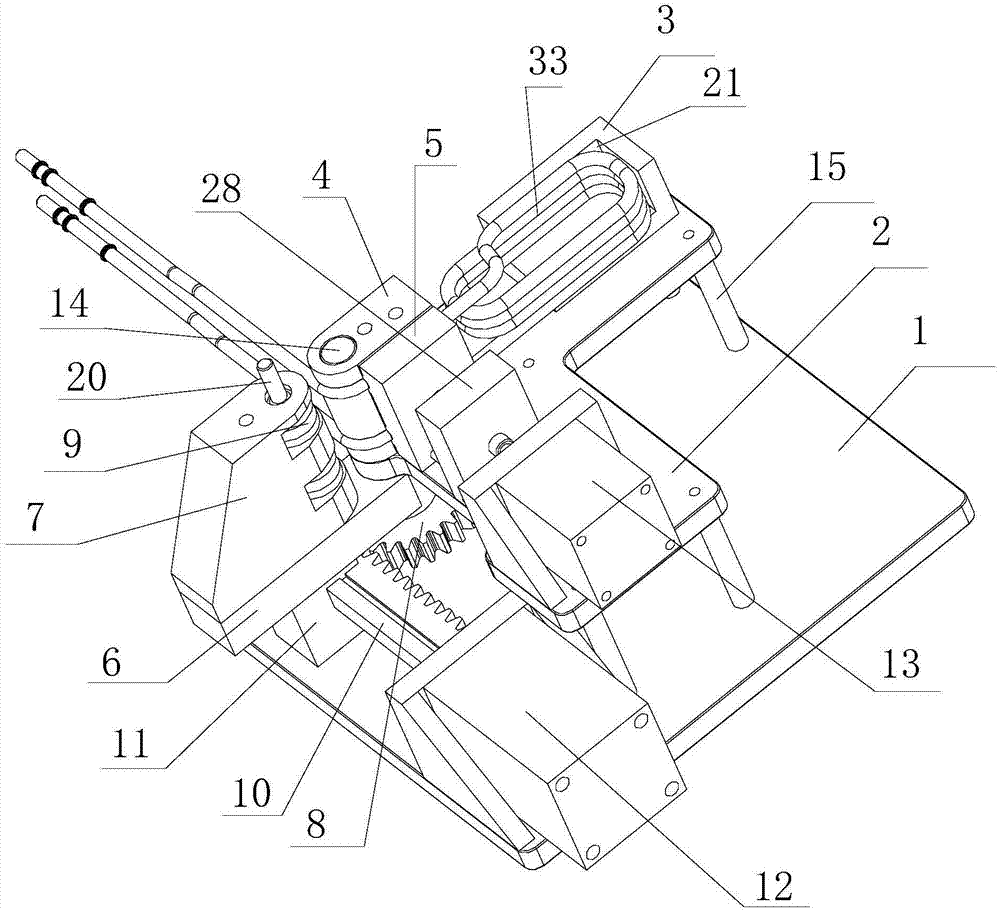

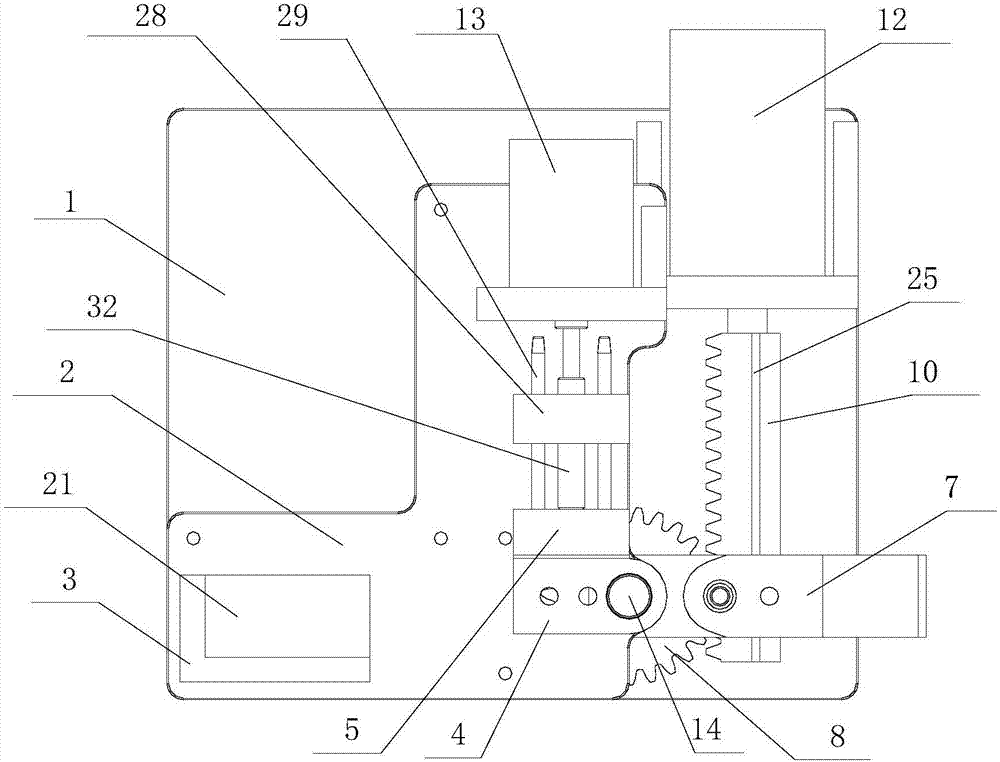

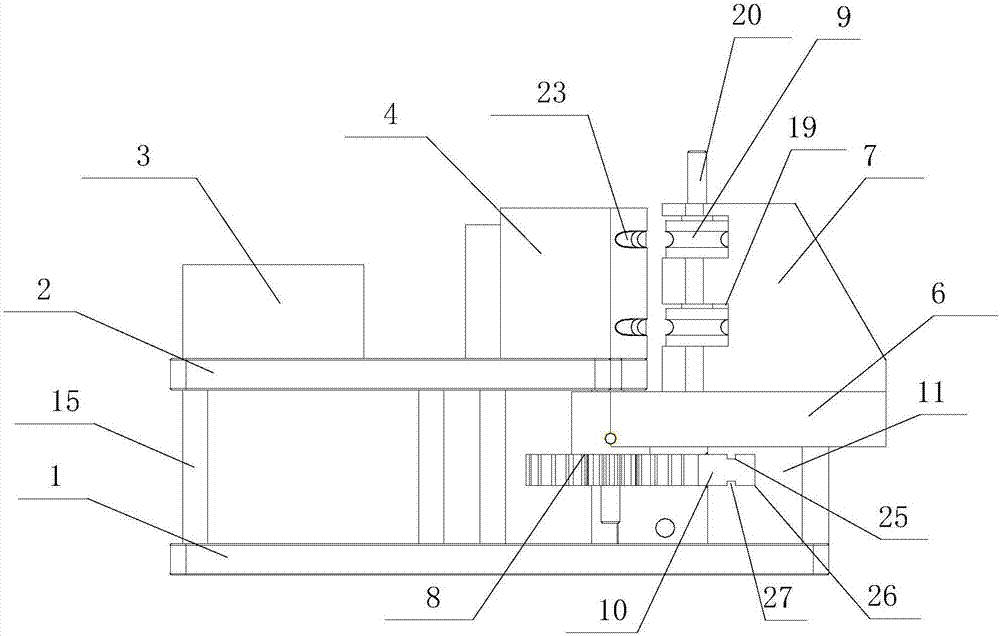

[0023] refer to Figure 1-Figure 11 , the present invention proposes a metal pipe bending mold for an automobile urea tank, including a base 1, a bottom plate 2, a first positioning block 3, a second positioning block 4, a pressing block 5, a first rocker arm 6, a second rocker arm 7, a gear 8. Two rollers 9, rack 10, rack positioning block 11, first drive mechanism 12, second drive mechanism 13, fixed rod 14, guide positioning plate 28 and guide post 29; wherein:

[0024] The base plate 2 is located above the base 1 and parallel to the base 1 , the bottom of the base plate 2 is connected to the base 1 through a plurality of support rods 15 , and the base plate 2 is provided with a second assembly hole 17 .

[0025] The first positioning block 3 and the second positioning block 4 are used for positioning and fixing the metal pipe, and the first positioning block 3 and the second positioning block 4 are all installed on the bottom plate 2, and the first positioning block 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com