Plane truss production line

A flat truss, production line technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of easily broken steel bars, difficult to grasp the angle, time-consuming and labor-intensive, etc., to achieve automatic processing, beautiful fixation, overall strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] Example.

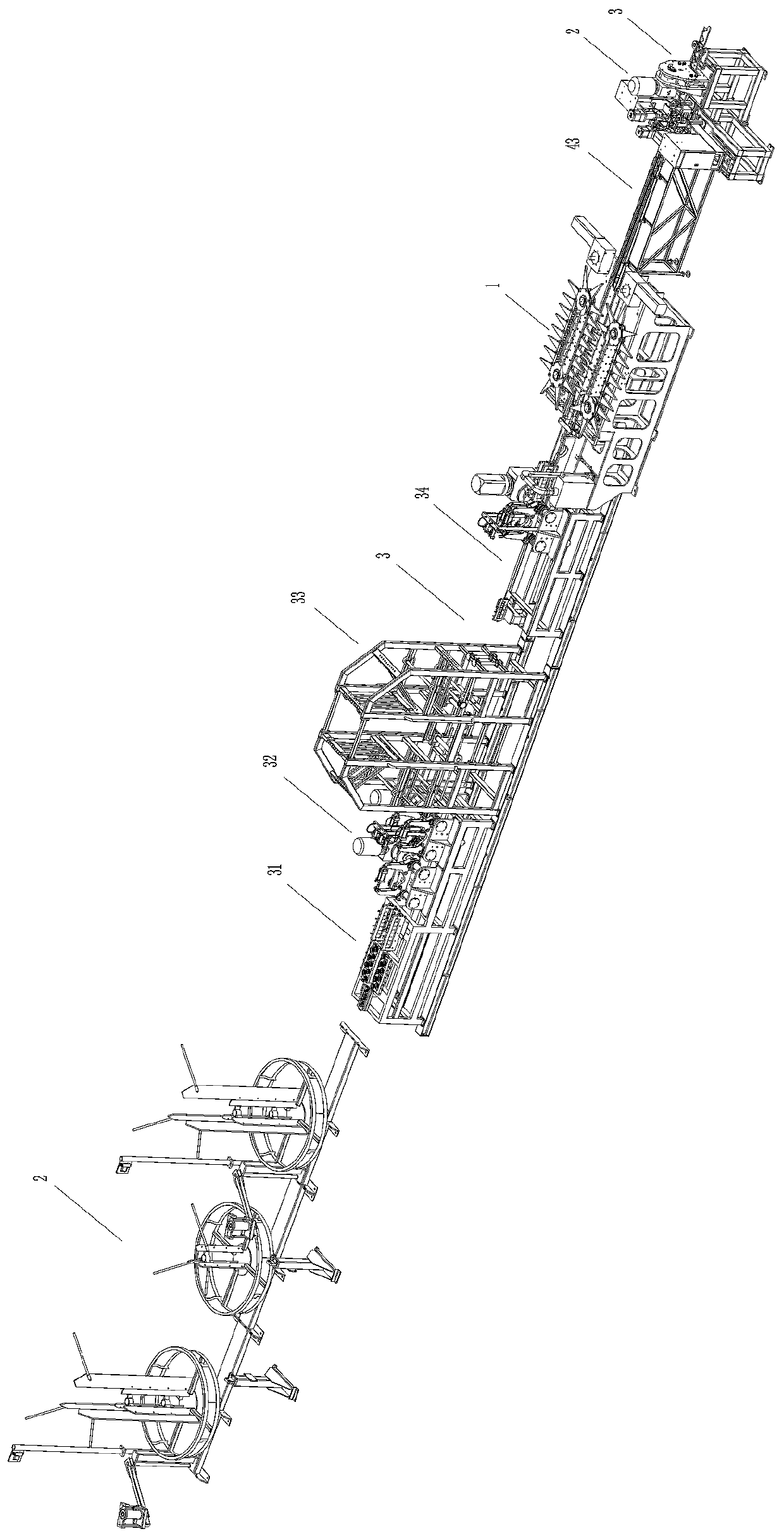

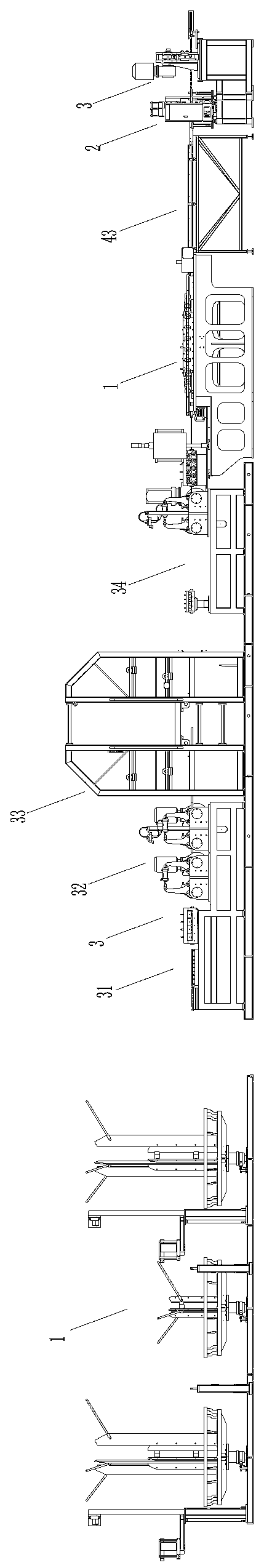

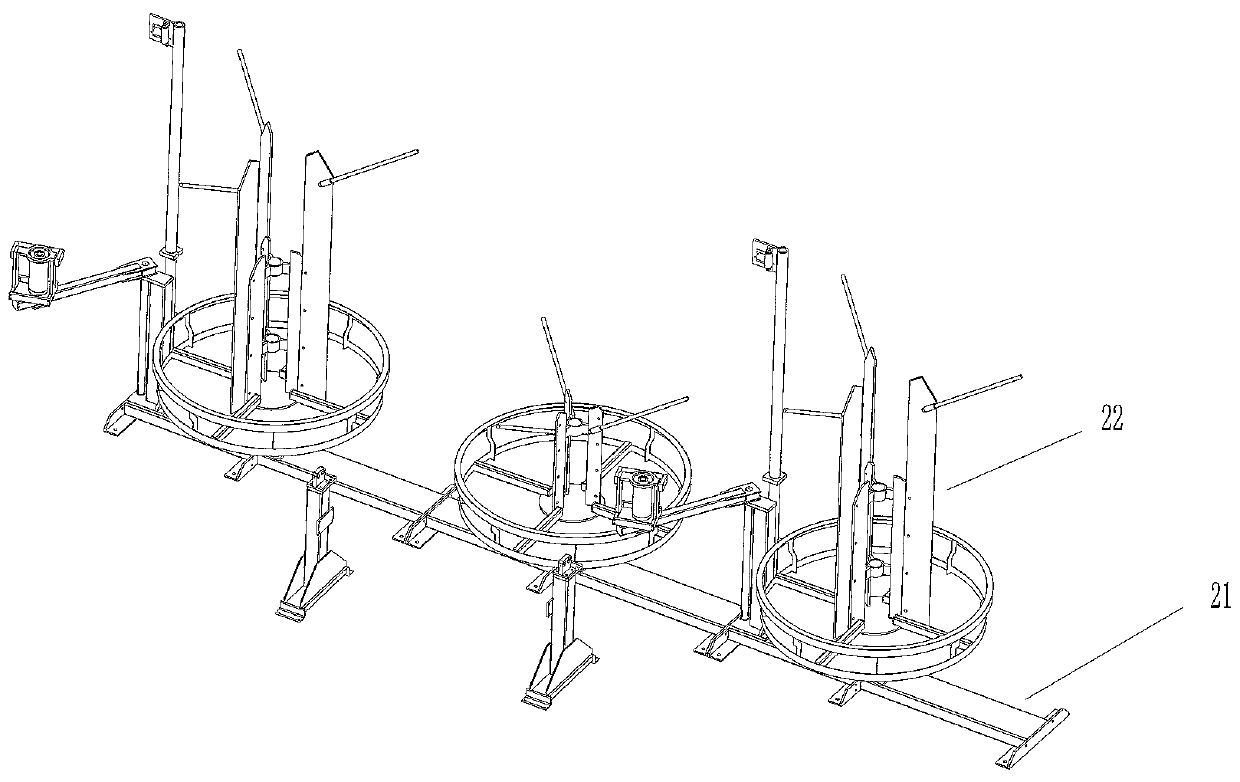

[0042] Such as Figure 1-4 As shown, this embodiment includes a pay-off device 2 and a straightening and rolling device 3 , a folding device 1 , a welding device 4 and a shearing device 5 connected in sequence. The pay-off device 2 is used to place the steel bar roll and derive three steel bars used as a welded plane truss from the steel wire roll. The pay-off device 2 includes a pay-off base 21, three placement racks 22 installed on the pay-out base 21, and the placement rack 22 is rotatably connected with the pay-off base 21, and the placement frame 22 is used for winding the reinforcing bar that has not been processed through straightening. Wherein, because the required diameter of the reinforcing bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com