Patents

Literature

64results about How to "Processing automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

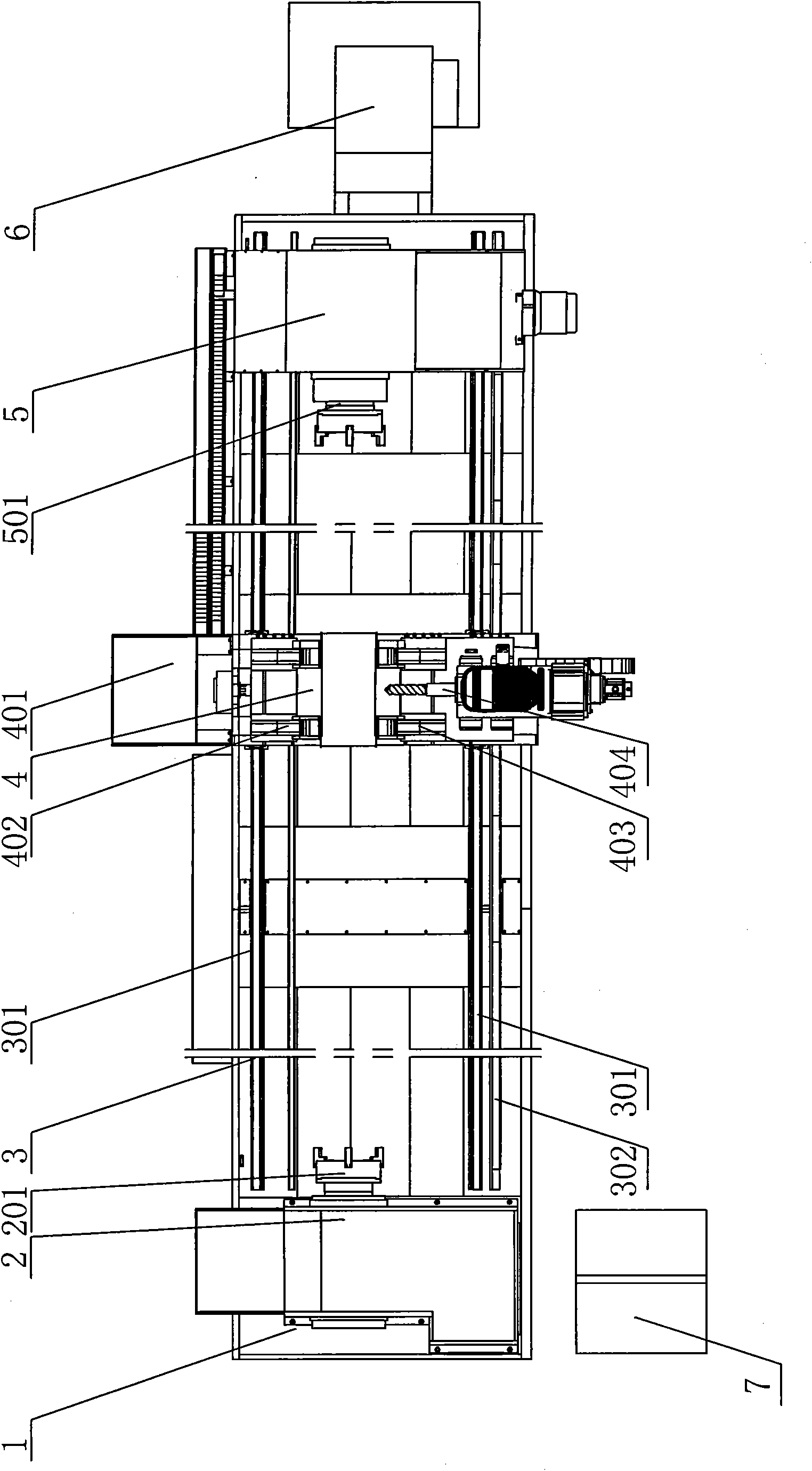

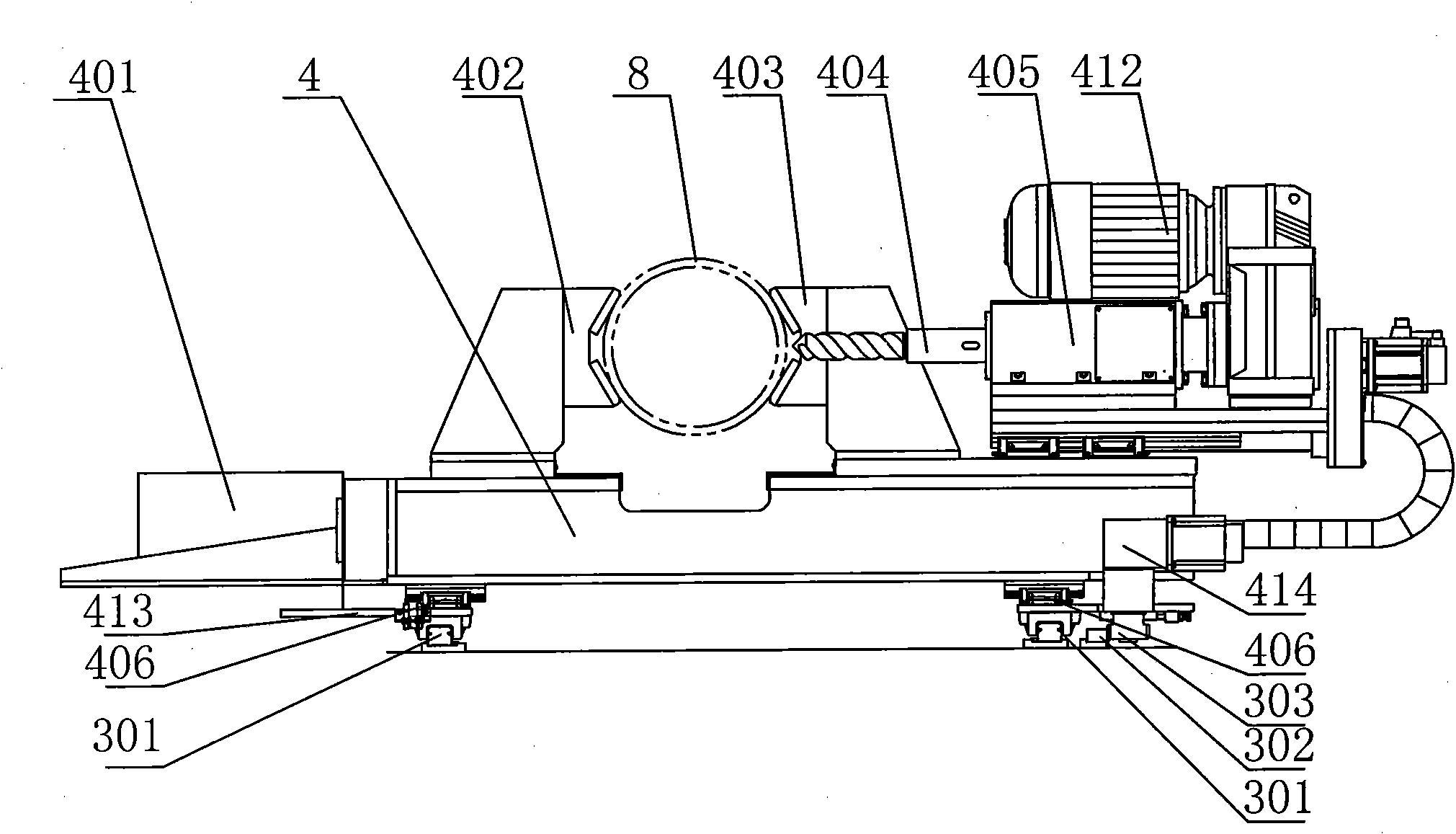

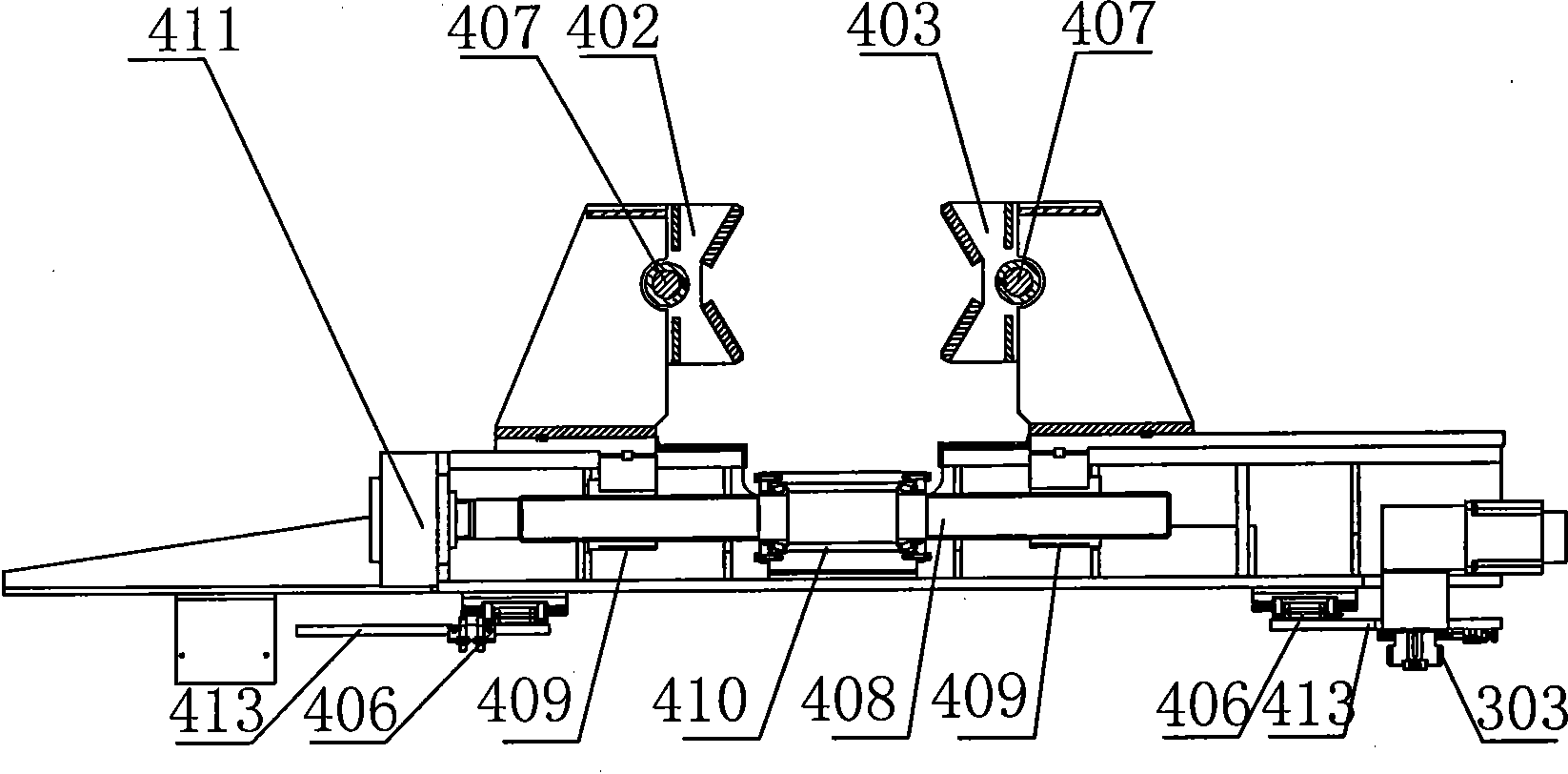

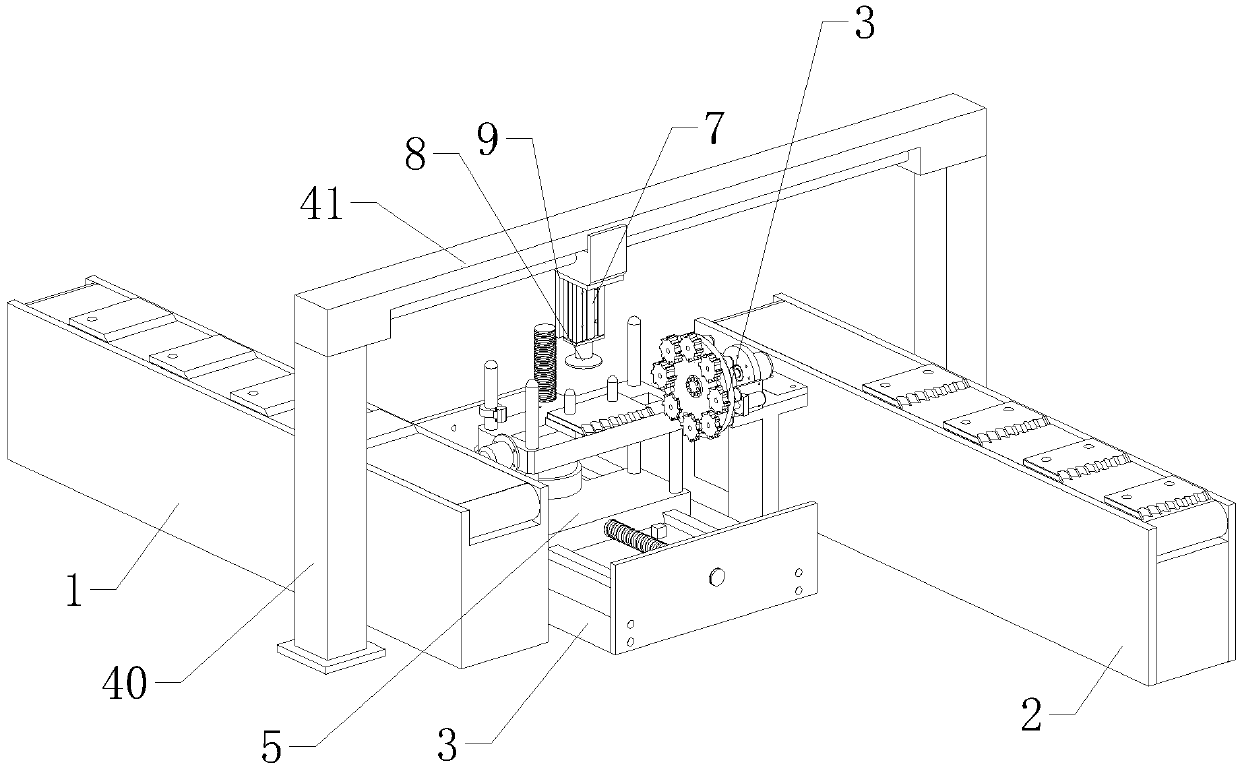

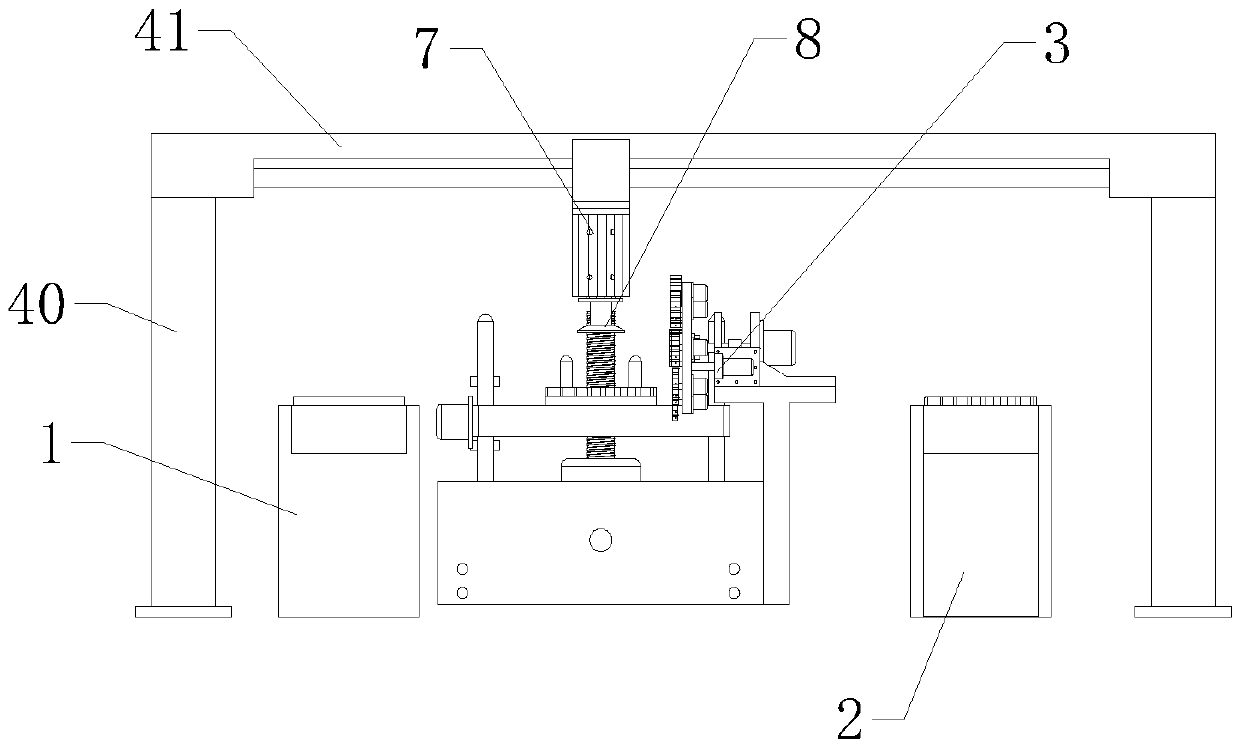

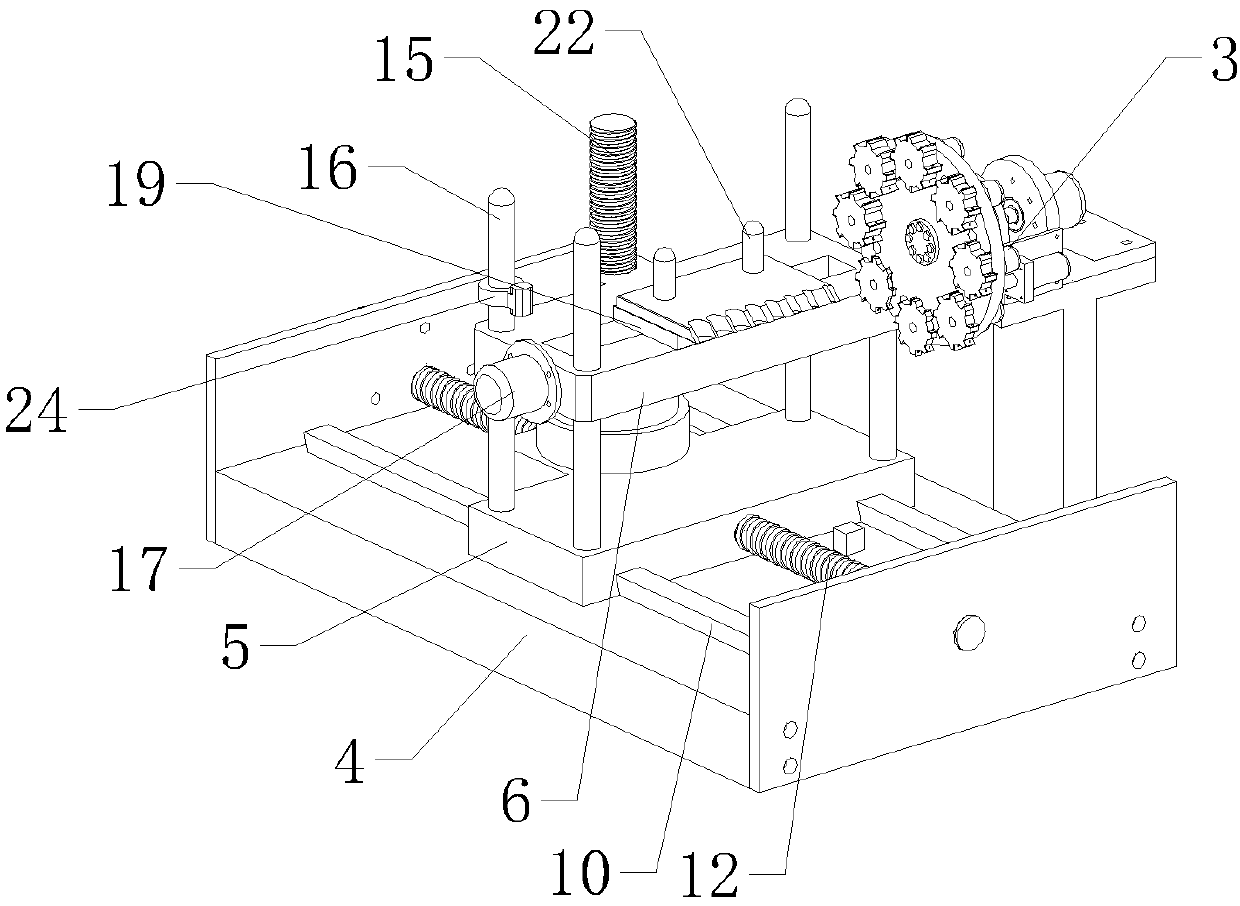

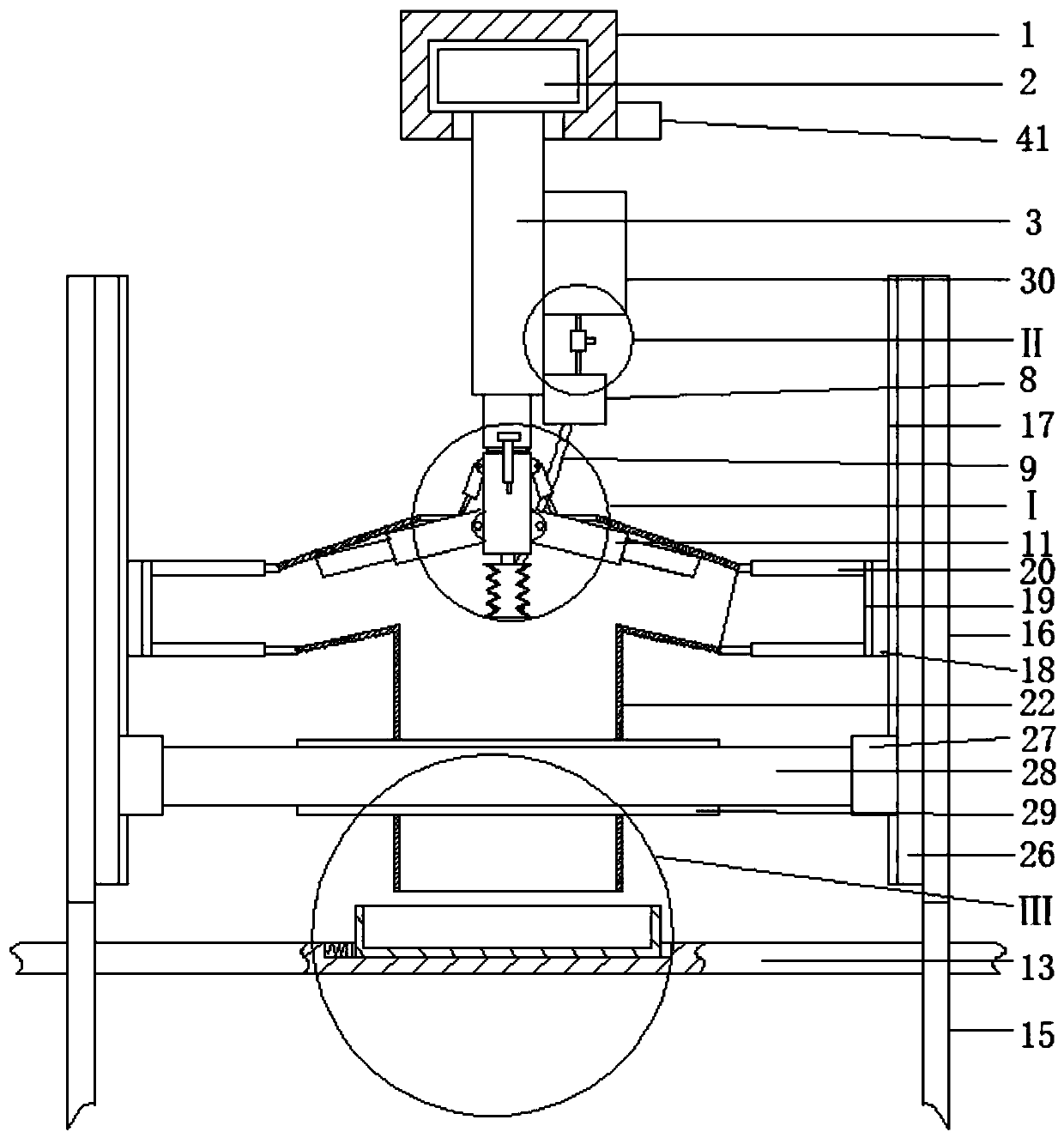

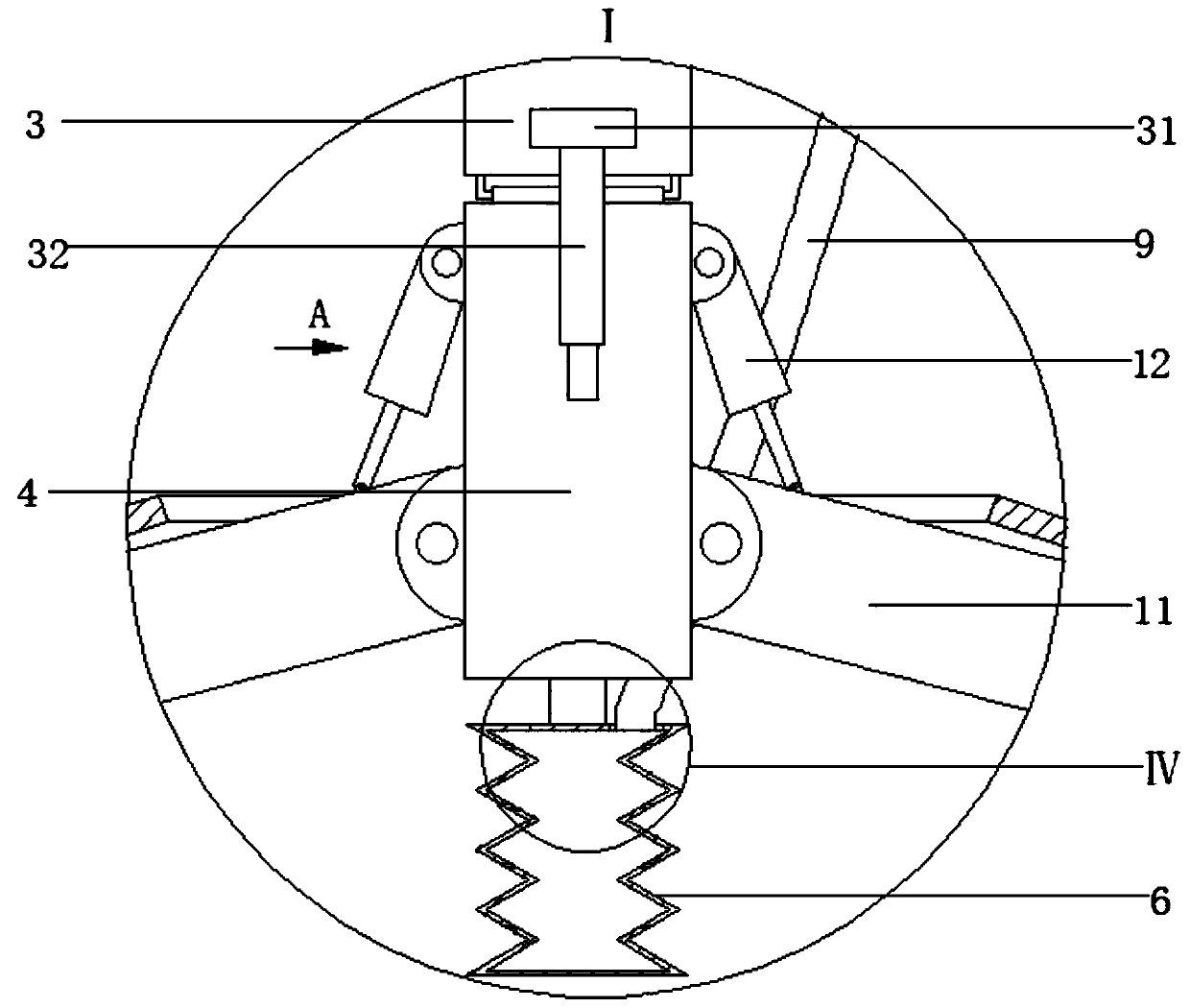

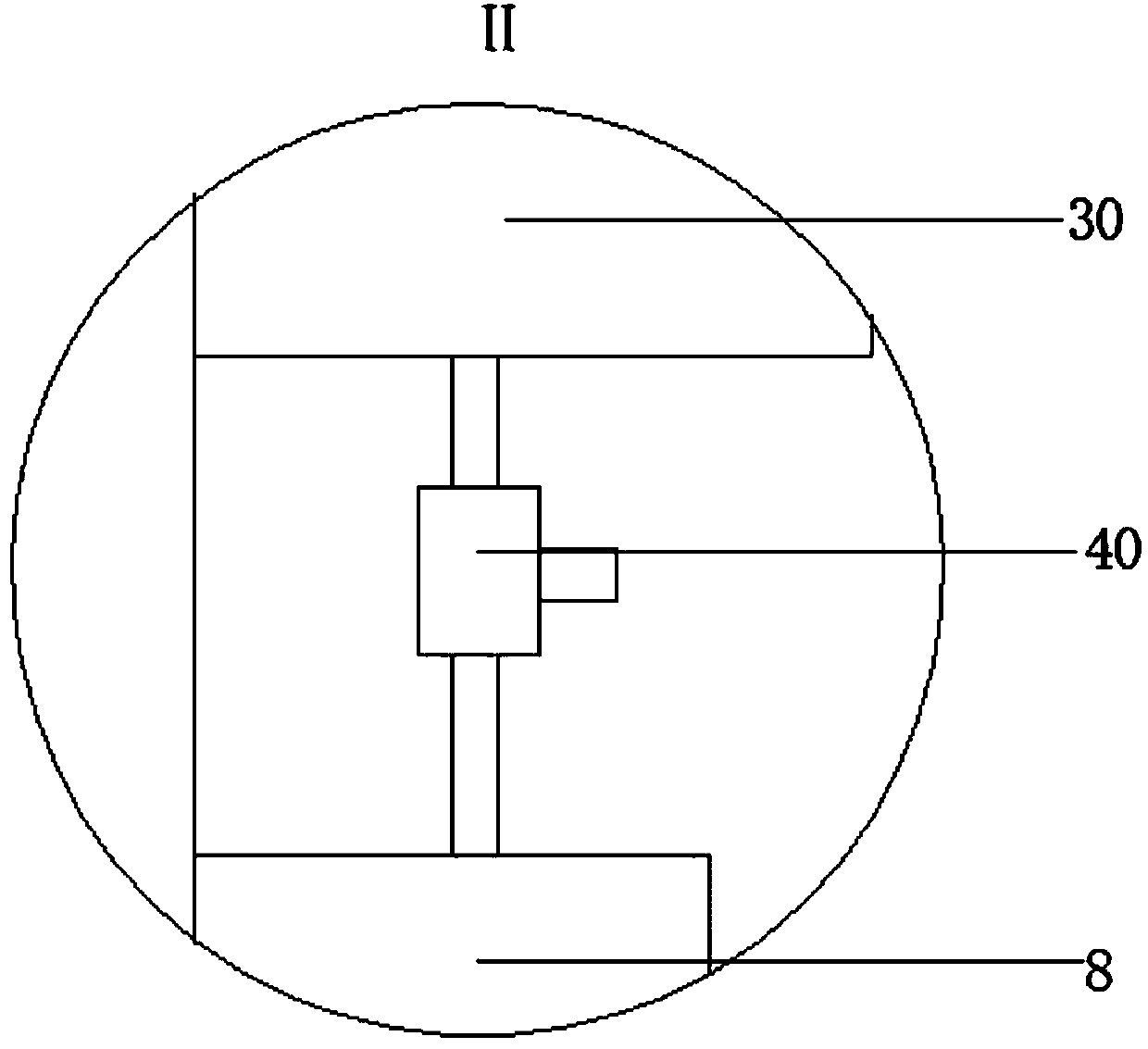

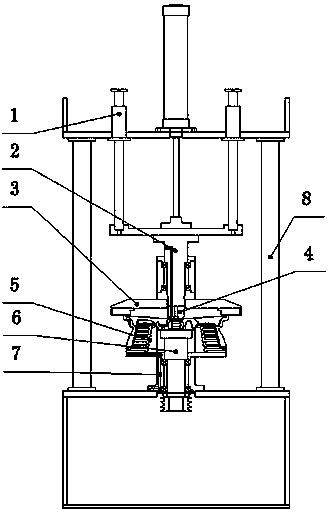

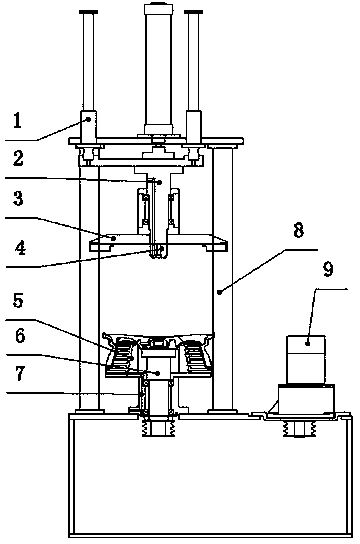

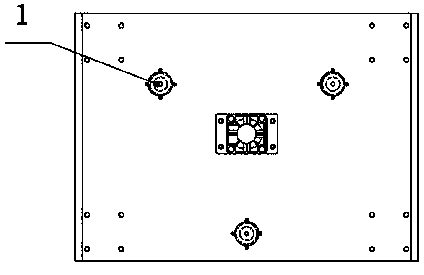

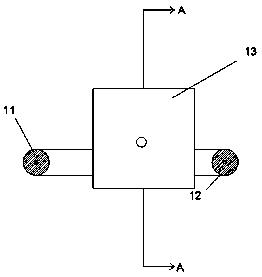

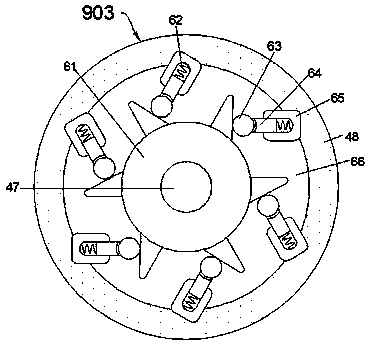

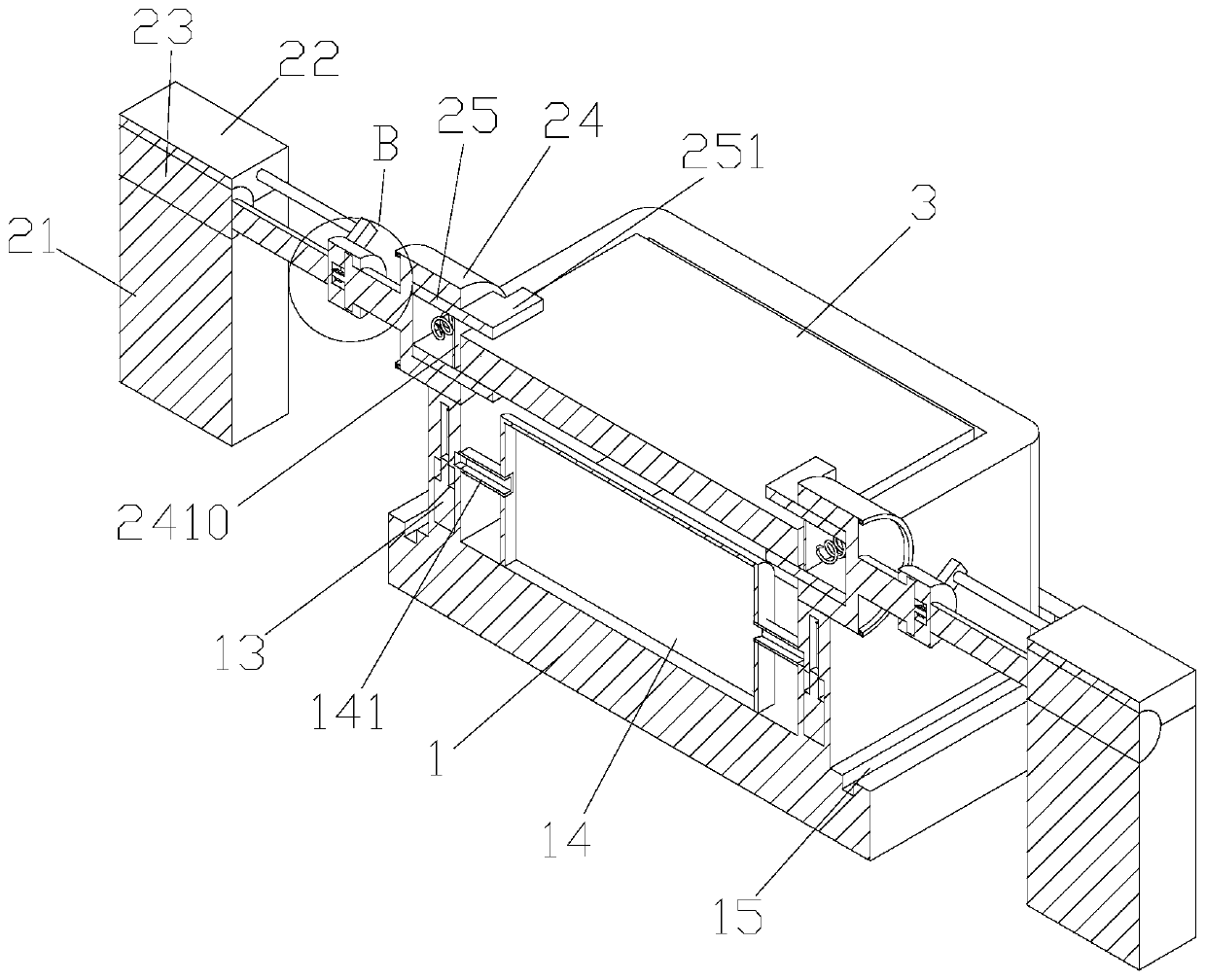

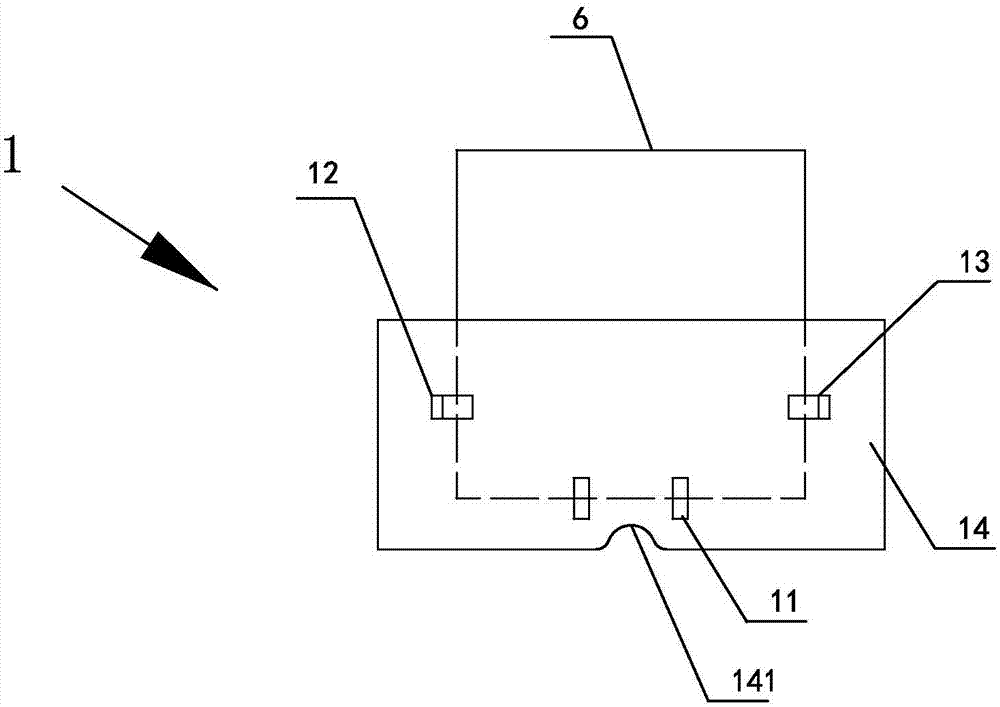

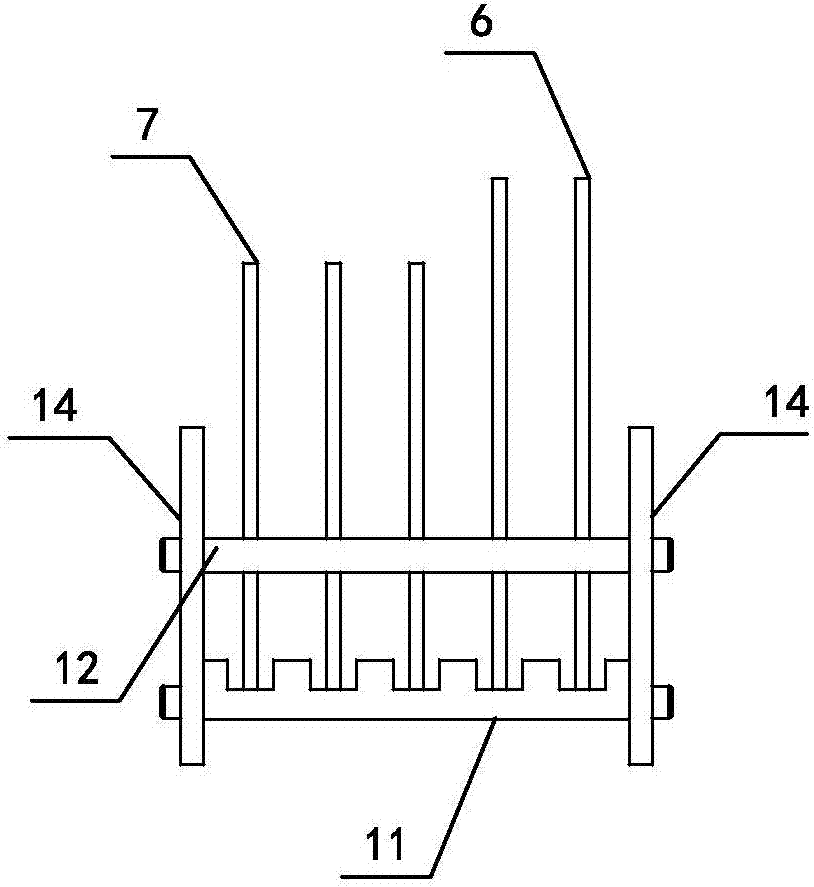

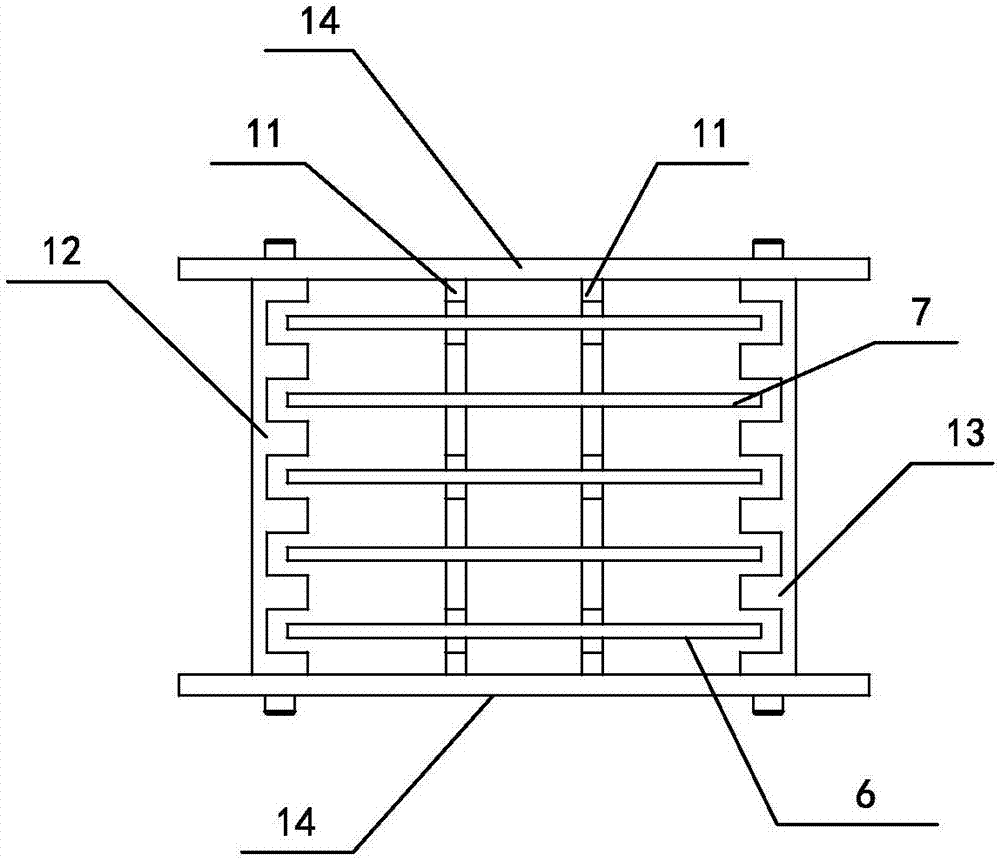

Drilling platform of pipe numerical control drilling machine

InactiveCN101954501AMove preciselyProcessing automationAutomatic control devicesFeeding apparatusNumerical controlGear drive

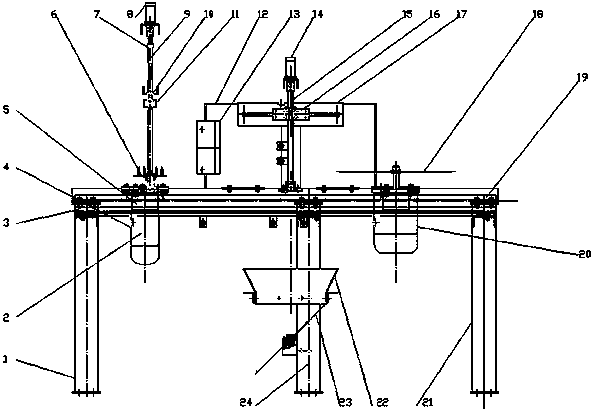

The invention relates to a drilling platform of a pipe numerical control drilling machine. The drilling platform is arranged between a main shaft rotating device and a tailstock; the electrical and hydraulic control can be realized by a numerical control platform; a pipe wall clamping assembly and a drilling power head assembly are arranged on the drilling platform; a guide rail sliding block arranged at the bottom of the drilling platform is matched with a linear guide rail at the upper part of a machine body; and a gear driven by a motor, which is arranged on the drilling platform, is meshed with a rack at the upper part of the machine body. The drilling platform can be conveniently, quickly and accurately moved to the required position by numerical control programming so as to be used for firmly clamping the machined pipe, safely and stably drilling and machining a through hole on the outer wall of the pipe automatically, efficiently, conveniently and safely.

Owner:WUXI HUALIAN PRECISION MACHINERY

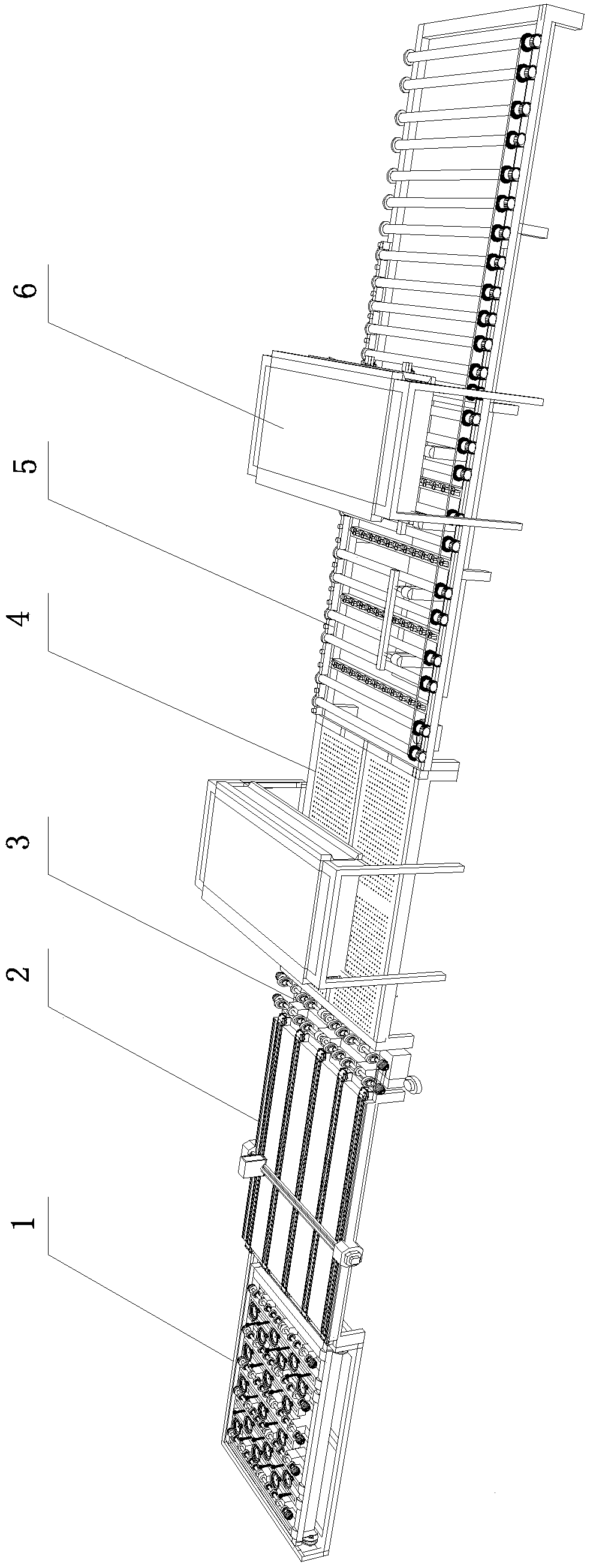

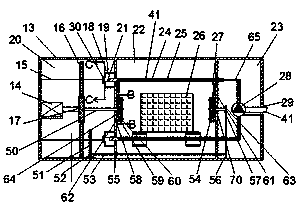

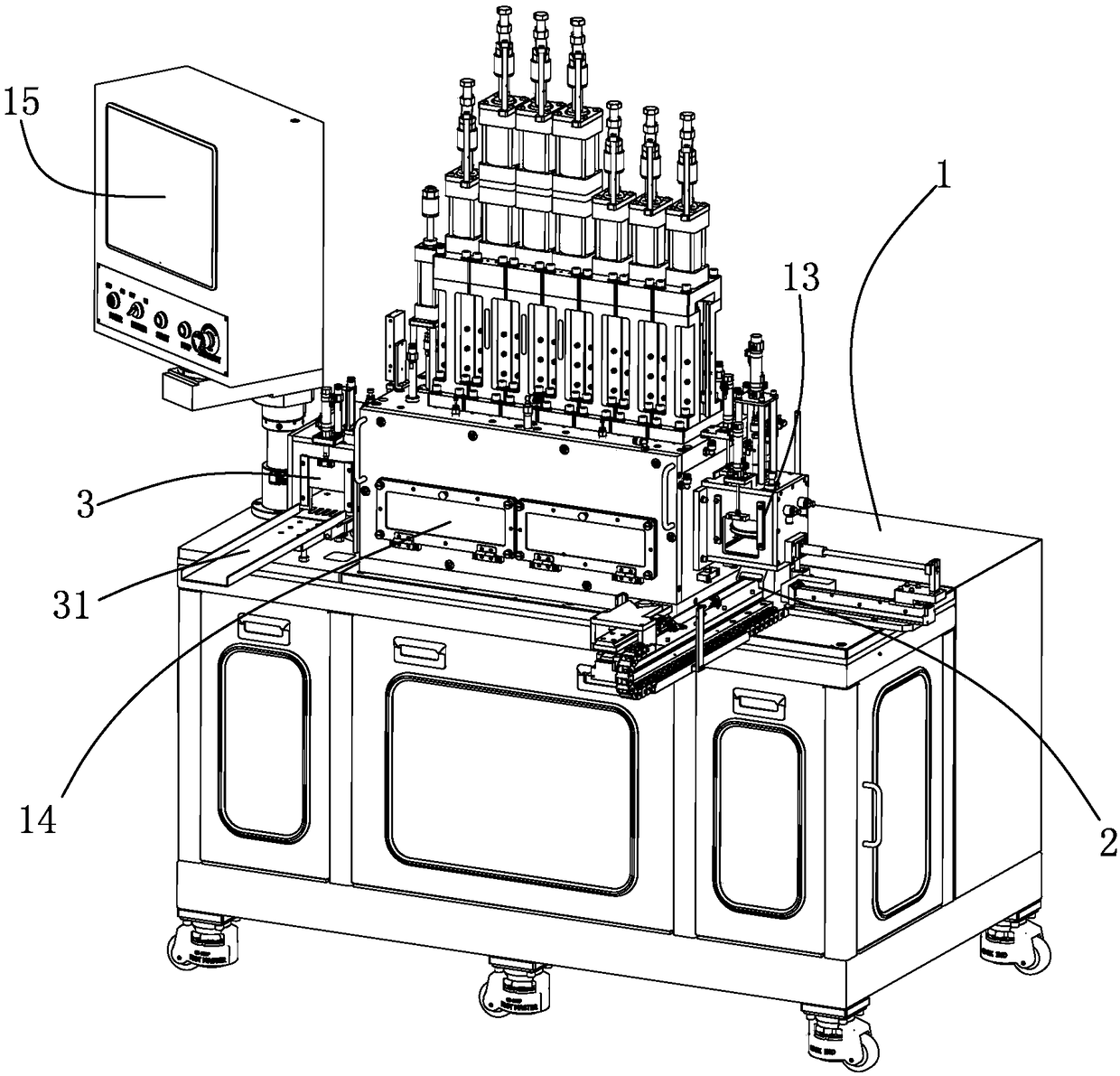

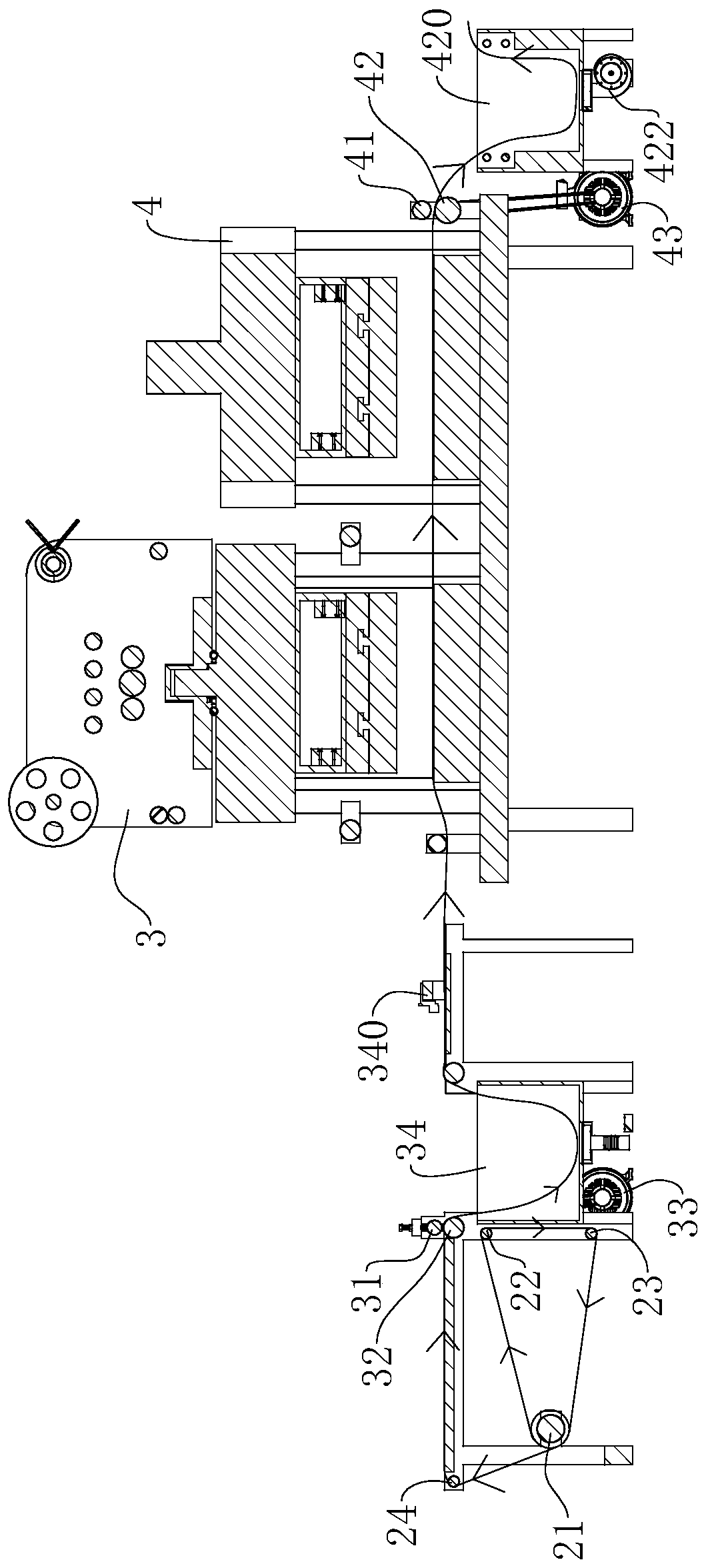

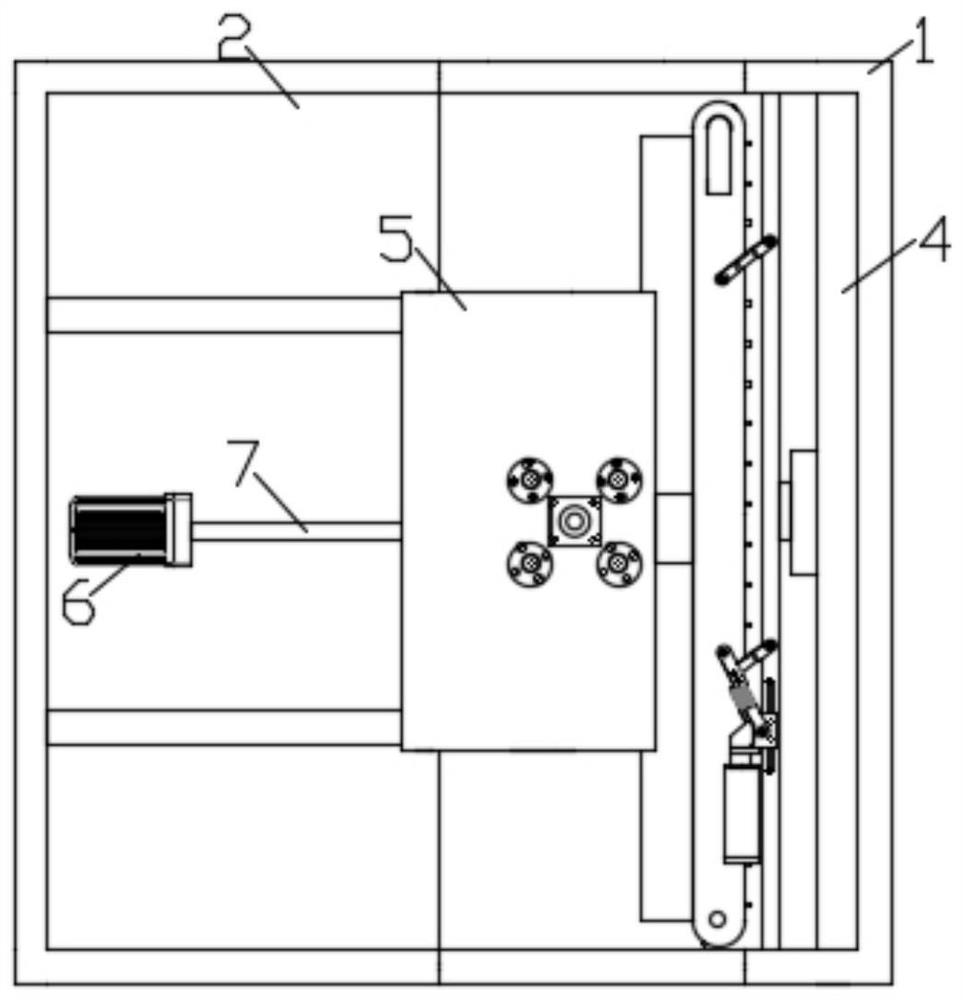

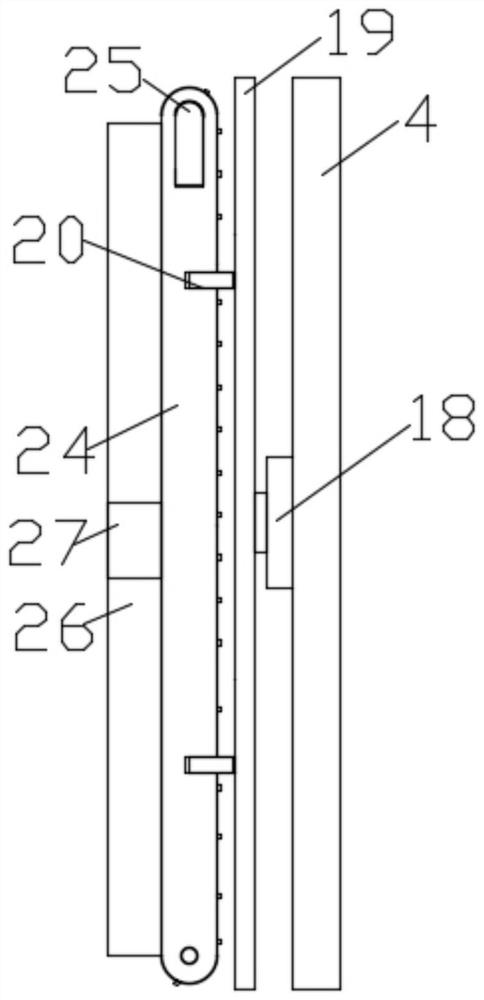

Full-automatic glass slitting and edge-grinding assembly line

PendingCN108943422ALow processing and production costsHigh degree of automationWorking accessoriesStone-like material working toolsTime efficientWater resources

The invention relates to a full-automatic glass slitting and edge-grinding assembly line. The assembly line is sequentially provided with a full-automatic glass loading machine, a full-automatic glasscutting machine, an automatic glass breaking table and a full-automatic glass edge grinding machine in the moving direction of glass. The assembly line can achieve the effects of full-automatic glassloading, feeding, cutting, breaking and edge grinding, the trouble of manual glass loading, manual cutting, manual breaking and manual edge grinding is avoided, moreover, the production environment protection efficiency of workers in each link is improved, machining of the glass is finer, the resource waste is reduced by utilizing recycling of the water resources, meanwhile, the equipment is protected, the automation degree is high, the production efficiency is high, the product percent of pass is high, the labor is saved, the time is saved, the glass slitting cost is reduced, and the safetyis high.

Owner:鹏凯(天津)玻璃有限公司

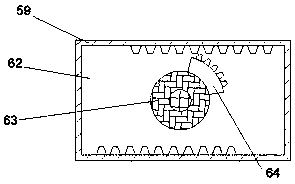

Wood cutting machine capable of recycling chippings

InactiveCN107718198AIncrease profitChanging the situation where debris cannot be recycledGripping devicesClamping devicesWood machiningEngineering

A wood cutting machine with recyclable debris mainly includes a bottom plate, and support plates are fixedly connected to both sides of the top of the bottom plate, and fixed plates are fixedly connected to the opposite sides of the support plates through support columns, and fixed A screen is arranged on the board, and the two sides of the top of the fixed board are fixedly connected with sliding rods through connecting columns, and one side of the supporting board is fixedly connected with the first motor through the base, which solves the problem that the existing wood cannot be cut. Recycling debris requires manual processing, which improves the utilization rate of wood, reduces people's work burden, improves people's work efficiency, and changes the situation that wood cutting equipment on the market cannot recycle debris. , to ensure that wood processing is more environmentally friendly and more automatic. The device has a simple structure and is easy to operate.

Owner:刘毓玉

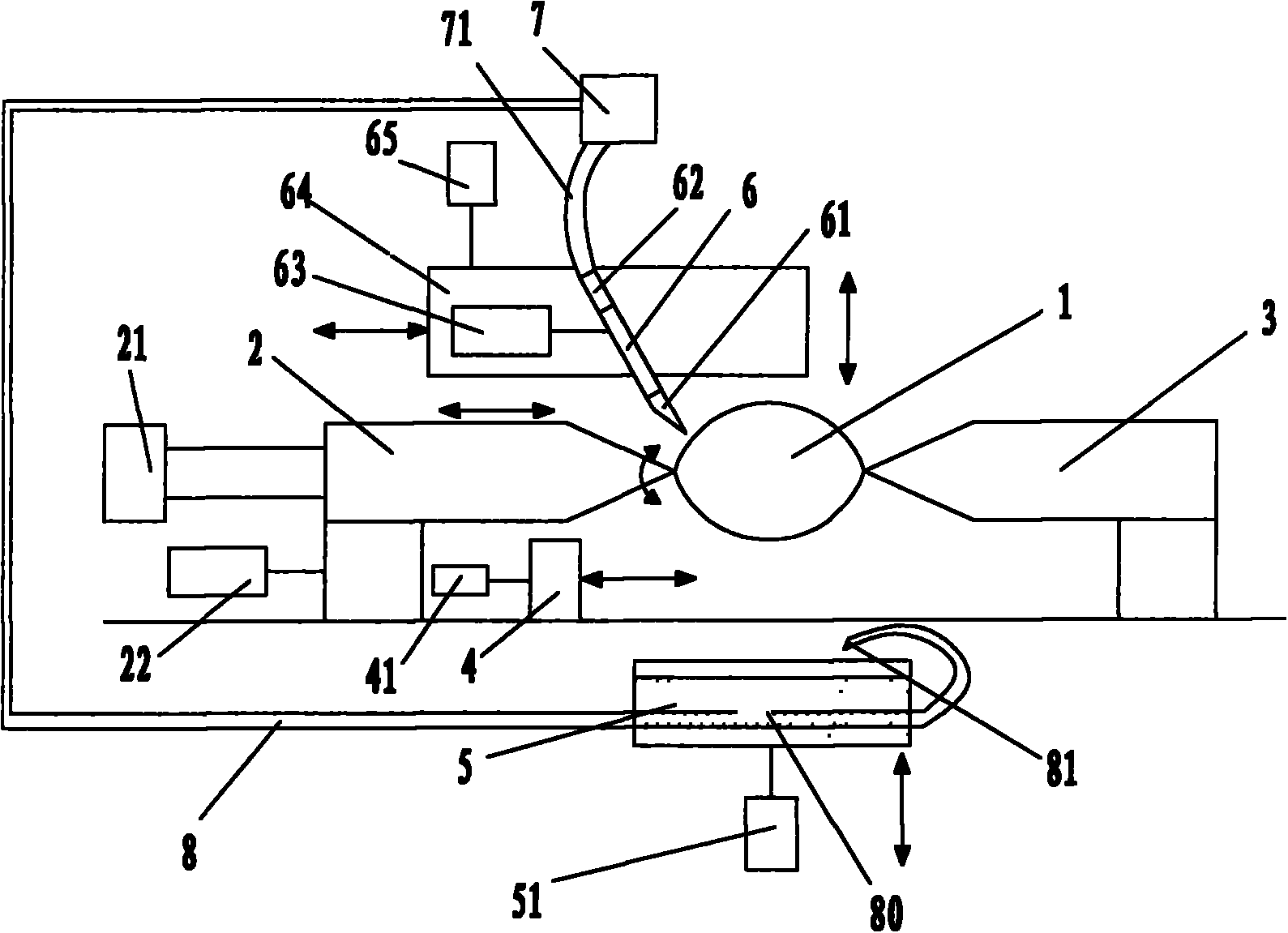

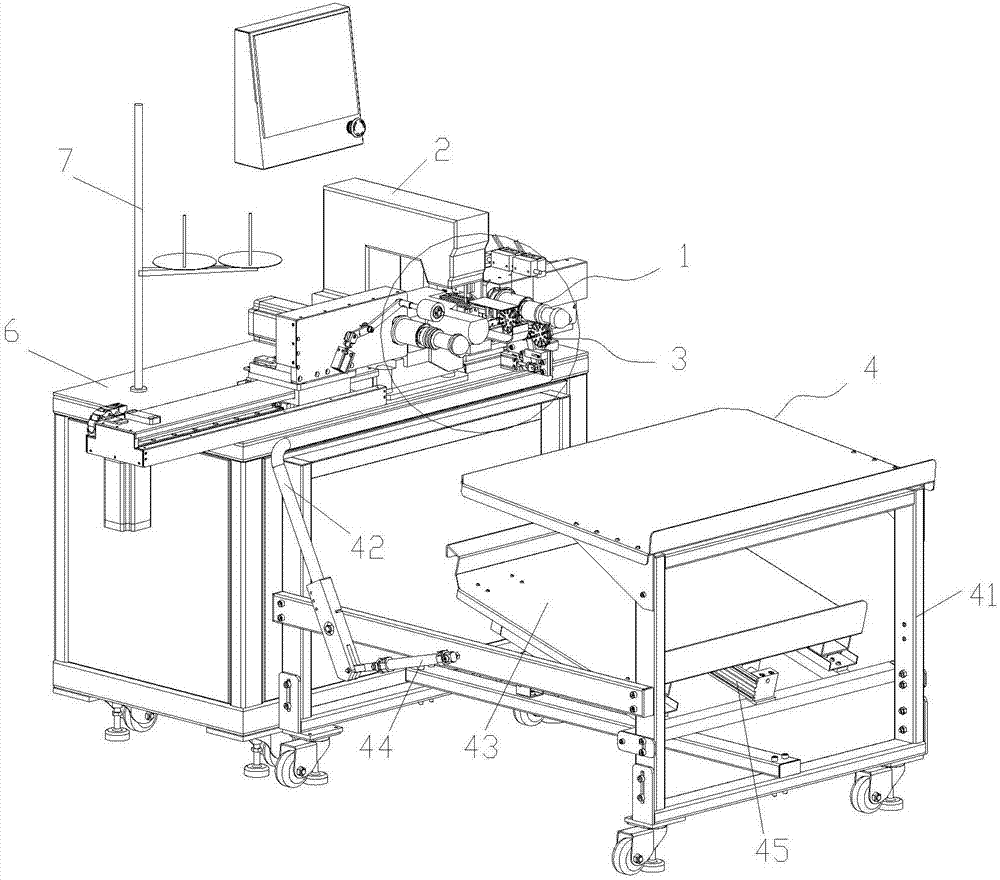

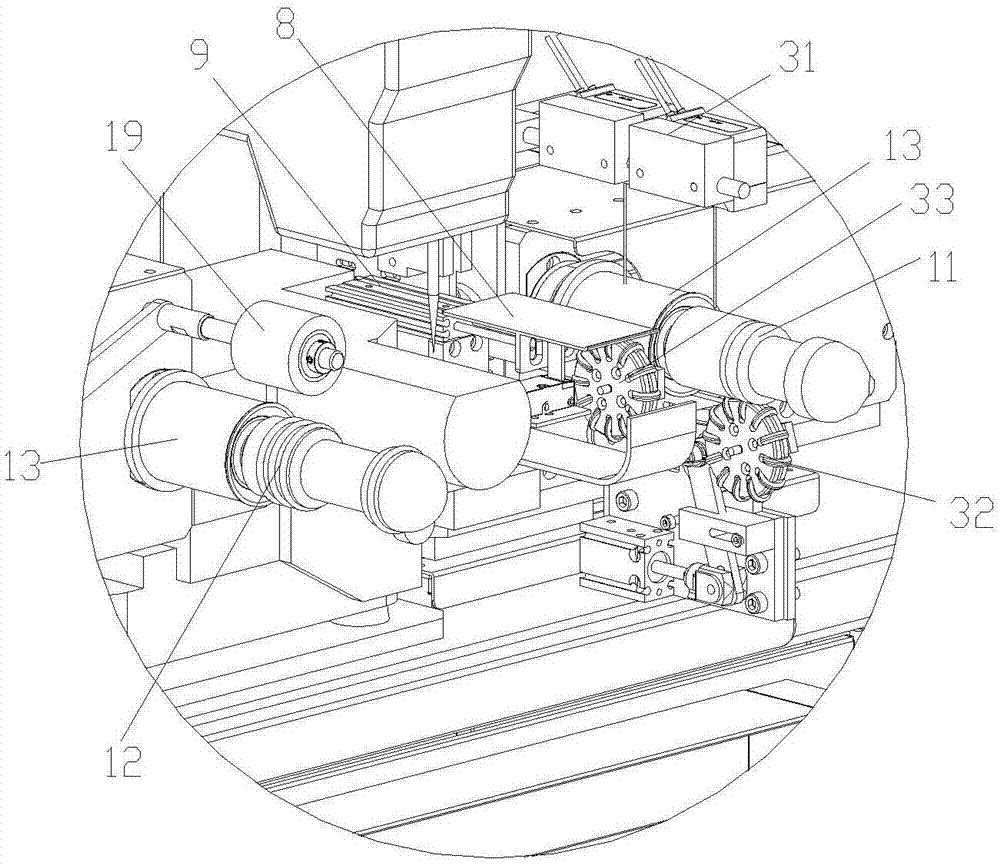

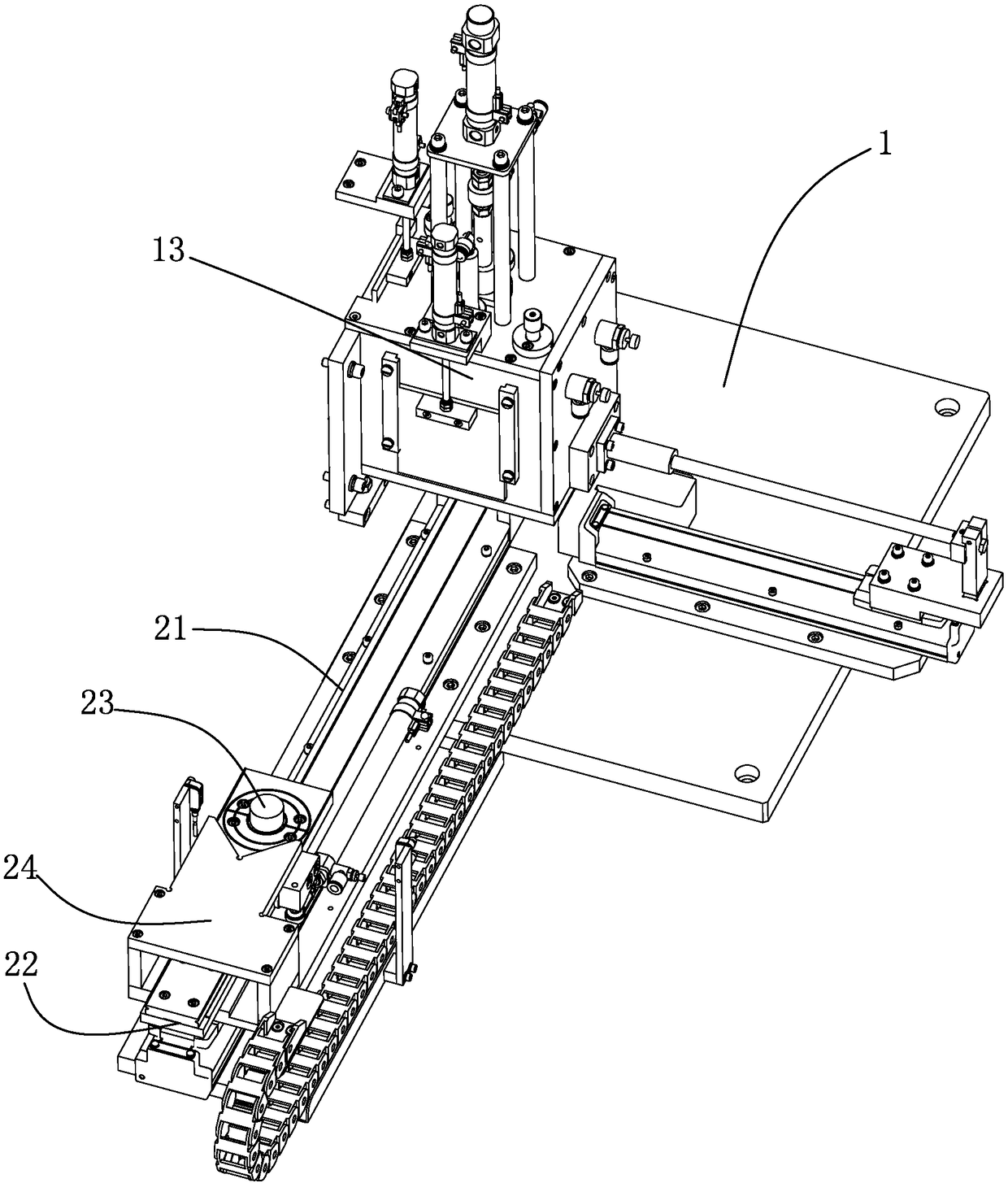

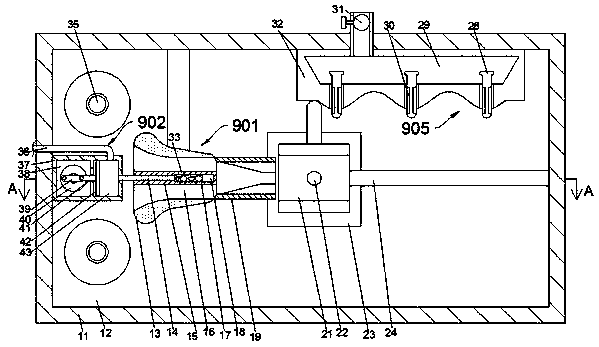

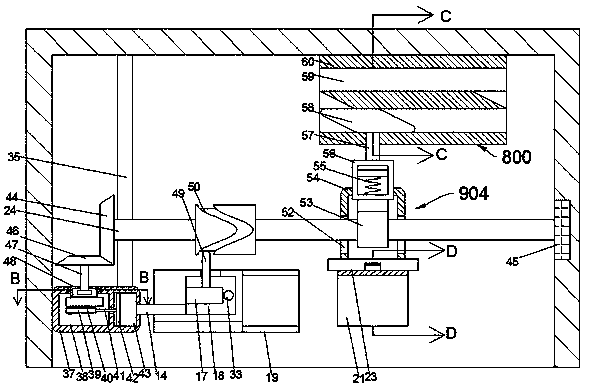

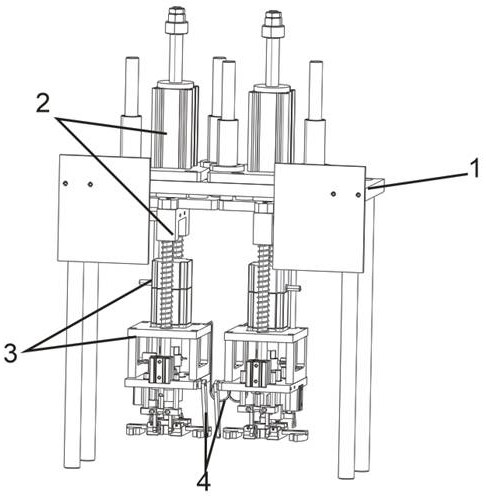

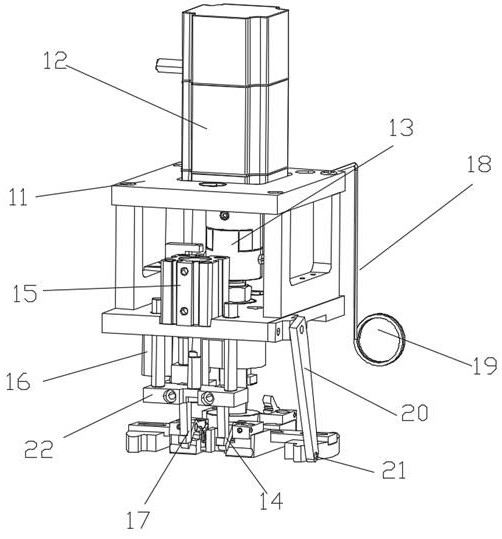

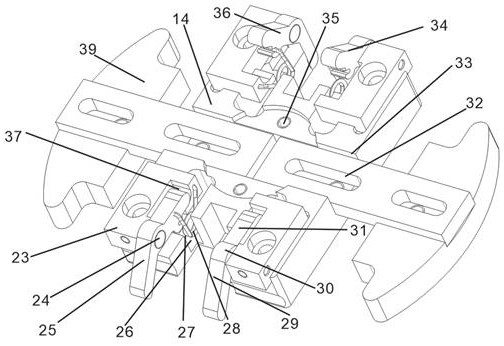

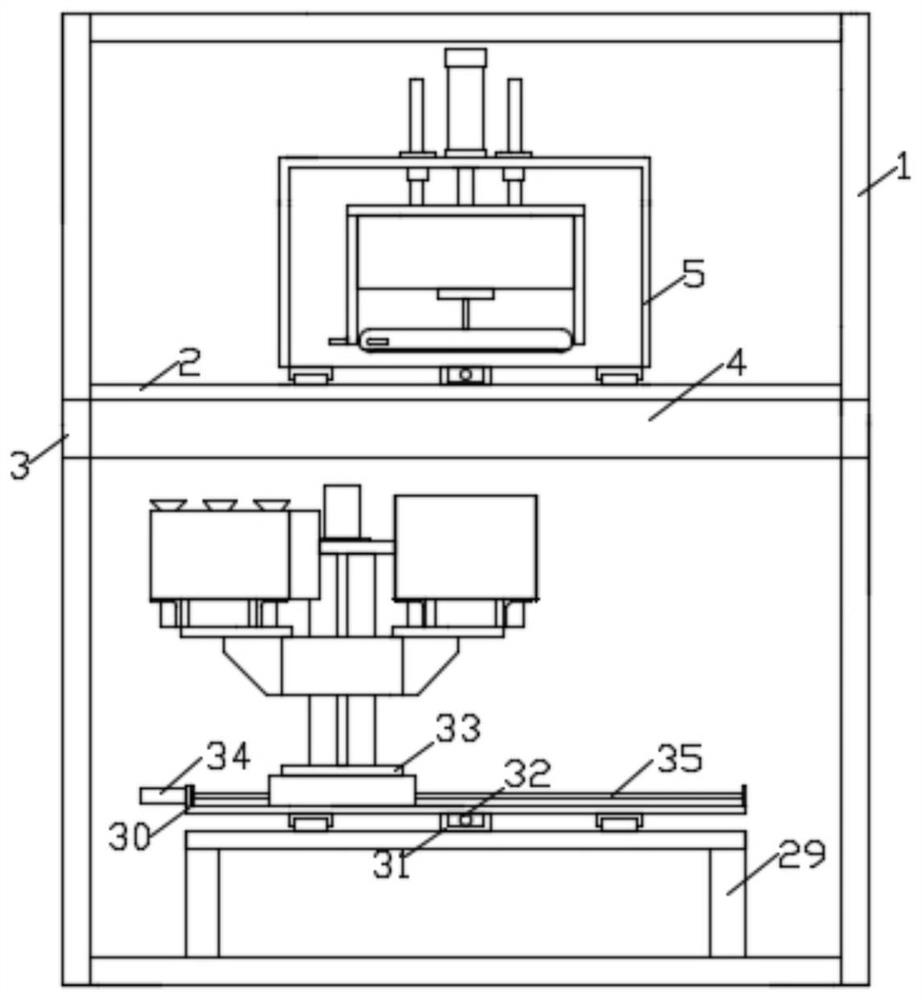

Automatic processing equipment of wire stripping blade and cutting and milling angle control method thereof

ActiveCN108672777AProcessing automationAutomatic control devicesFeeding apparatusMilling cutterSlide plate

The invention relates to the field of automatic processing, and particularly relates to automatic processing equipment of a wire stripping blade and a cutting and milling angle control method thereof.The automatic processing equipment comprises an original product conveying belt, a finished product conveying belt, a material moving mechanism, a positioning mechanism, a three-axis speed regulatingmechanism and a cutting and milling mechanism, wherein the three-axis speed regulating mechanism comprises a bottom plate, an X-axis displacement mechanism, a Y-axis displacement mechanism and a Z-axis displacement mechanism, the X-axis displacement mechanism is horizontally arranged on the top of the bottom plate, a sliding plate which can horizontally move is arranged on the X-axis displacementmechanism, the Z-axis displacement mechanism is arranged on the top of the sliding plate, a lifting platform which can vertically move is arranged on the Z-axis displacement mechanism, the Y-axis displacement mechanism is arranged on the top of the lifting platform, and the positioning mechanism can be connected with the Y-axis displacement mechanism in a horizontal moving mode. According to theautomatic processing equipment of the wire stripping blade, wire stripping grooves with different inclinations can be cut and milled without adjustment of the posture and angle of a milling cutter, sothat the wire stripping blade is automatically, flexibly and conveniently processed.

Owner:沈燕春

Novel conveying equipment for garment production

ActiveCN111115141ANot easy to slipWill not be damagedMechanical cleaningPressure cleaningManufacturing lineSizing

Novel conveying equipment for garment production comprises an electric sliding rail of a hanging type conveyer. A plurality of first sliders are installed in the electric sliding rail in a matched mode. First electric telescopic rods with downward movable rods are fixedly installed at the bottoms of the first sliders correspondingly. Vertical plates are hinged to the lower ends of the movable rodsof the first electric telescopic rods. Rectangular blocks are fixedly installed on the front side walls of the movable rods of the first electric telescopic rods. Fifth electric telescopic rods are arranged on the lower sides of the rectangular blocks. Elastic telescopic pipes with closed upper and lower end openings are fixedly installed at the bottoms of the vertical plates through connection rods. Through a reasonable structure, garment sizing, garment dedusting, garment ironing, garment folding, packaging and other series of automatic processing procedures are achieved, a garment production line is shortened, thus the needed plant area and garment production time are reduced, the garment processing process is more automatic, the phenomenon of too many unqualified garment products caused by errors of manual garment treatment is avoided, and garment production quality is improved.

Owner:潜江东颢制衣有限公司

Coating brushing machine for aluminum alloy rim

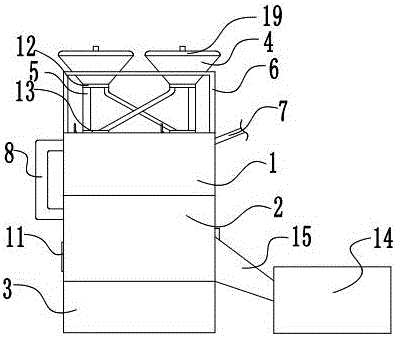

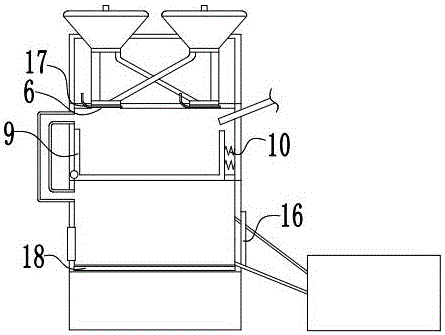

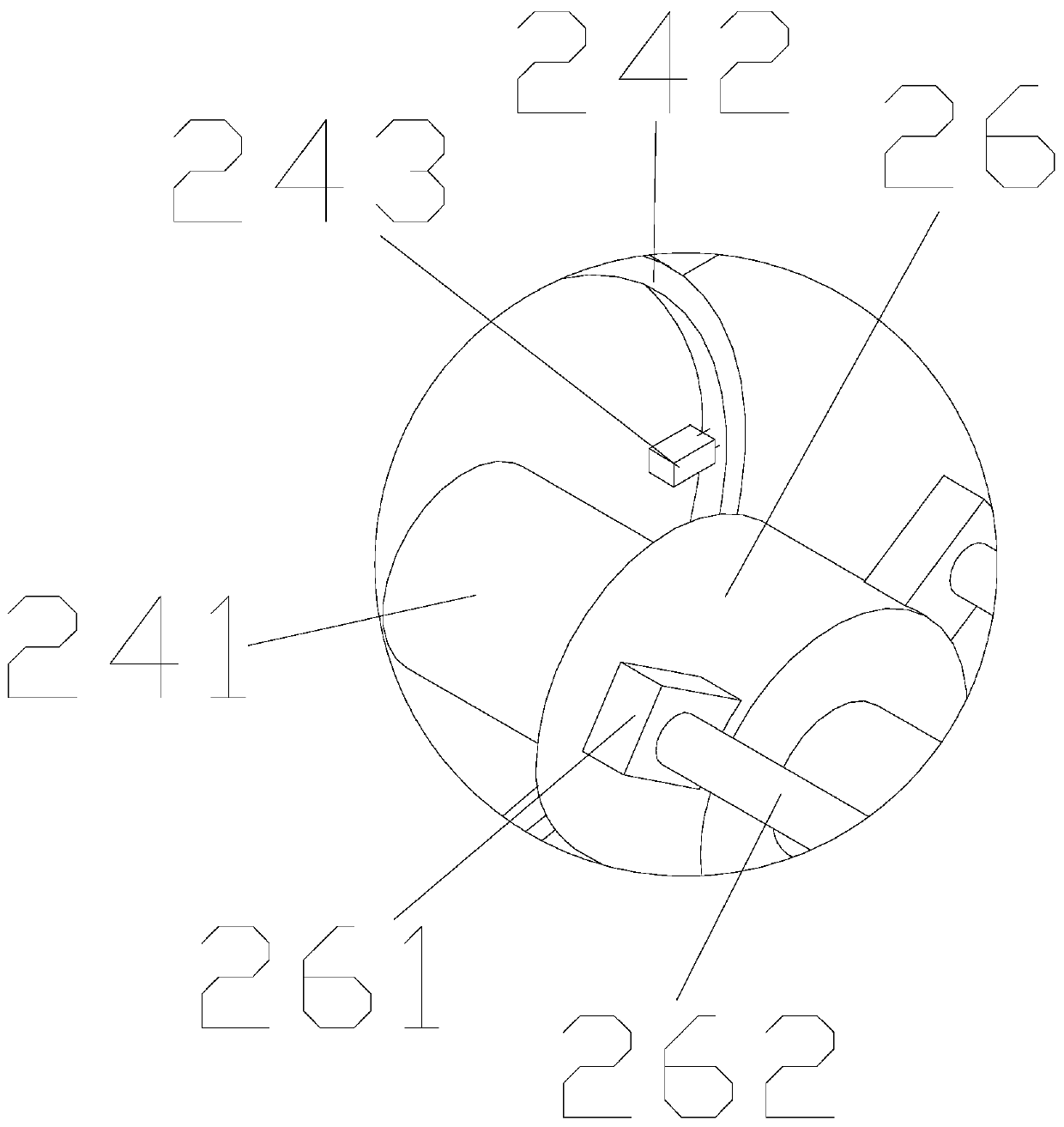

InactiveCN103721887ANo wasteProcessing automationLiquid surface applicatorsCoatingsElectric machineryBrush

A coating brushing machine for an aluminum alloy rim comprises a guide mechanism (1), an upper main shaft (2), a pressing mechanism (3), an upper fur brush (4), lower fur brushes (5), a lower main shat (6), a support seat (7), a base (8) and a motor (9), and is characterized in that the lower main shaft (6) is provided with a workblank, and the lower main shaft and the workblank can rotate; the pressing mechanism (3) is pressed downwards, so that painting flows to the upper fur brush and the lower fur brushes respectively from the support seat (7) and the upper main shaft (2) through a guide groove, and the inner lower chamber and the surface of the workblank are coated with the coating. The coating brushing machine has the benefits that the coating is pressed on the surfaces of the fur brushes through the guide groove with fixed time and fixed quantity; the coating is uniform; the coating quantity can be adjusted according to actual machining situation, so that waste is avoided. The machining process is automatic, the time consumption is short, and the production efficiency is high.

Owner:JIANGSU TIANHONG MACHINERY IND

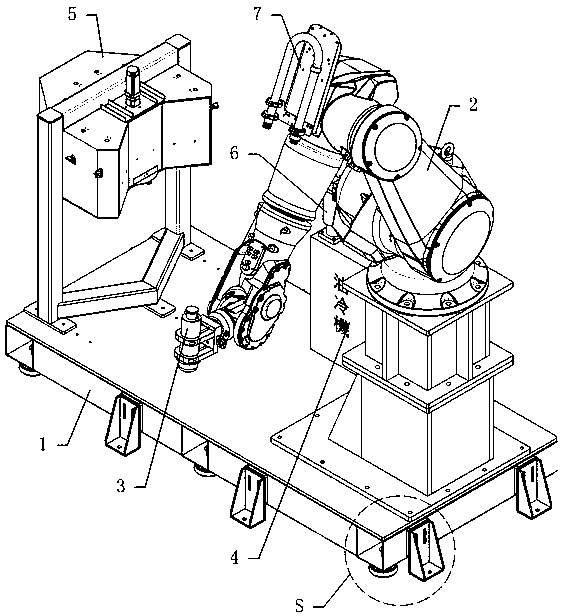

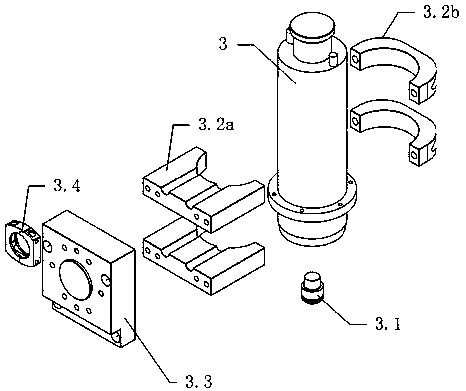

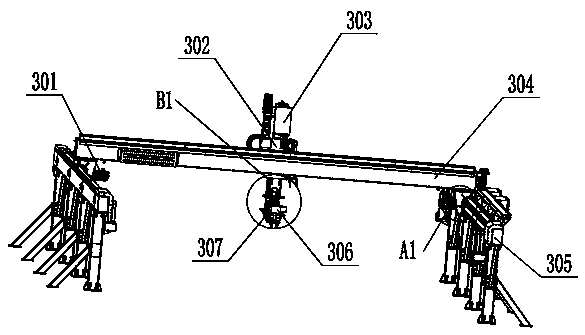

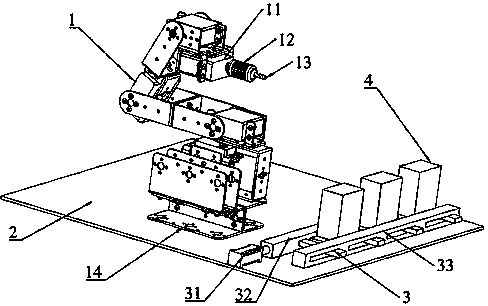

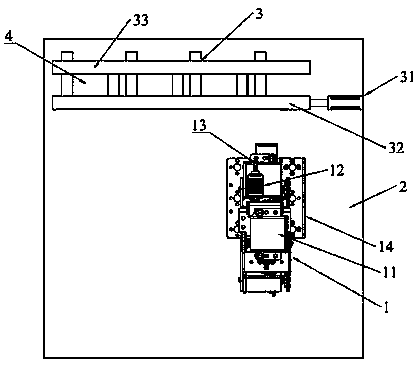

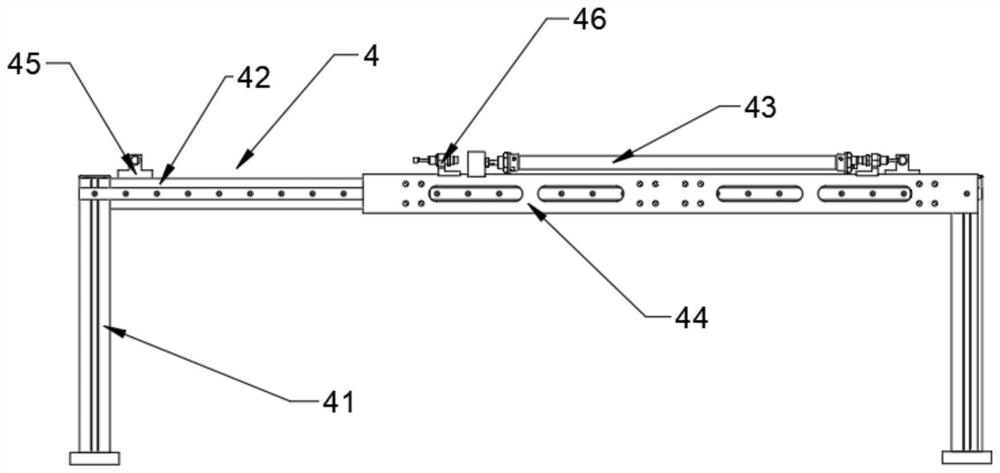

Mechanical arm device of bathtub machining system

PendingCN108381300ASmall footprintProcessing automationProgramme-controlled manipulatorLarge fixed membersElectricityEngineering

Owner:佛山市高明亚太建材有限公司

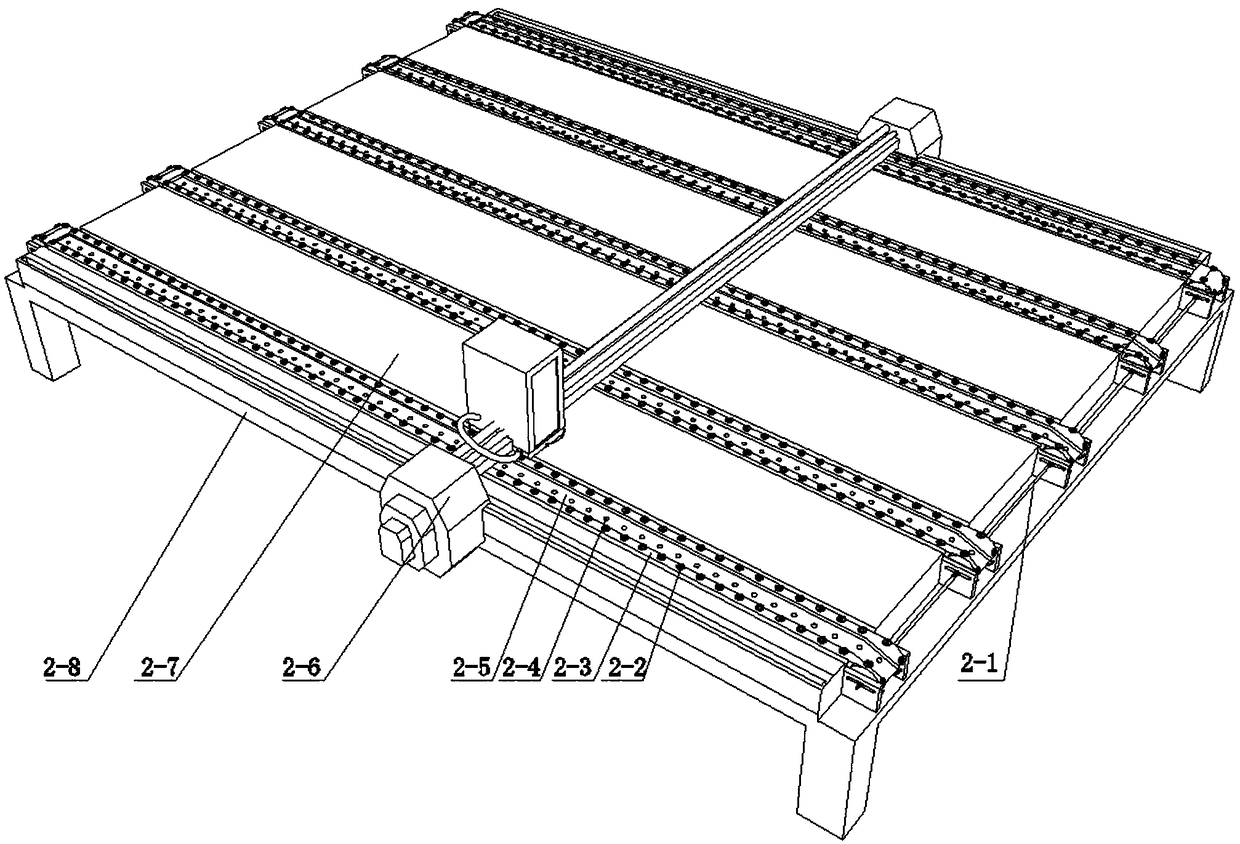

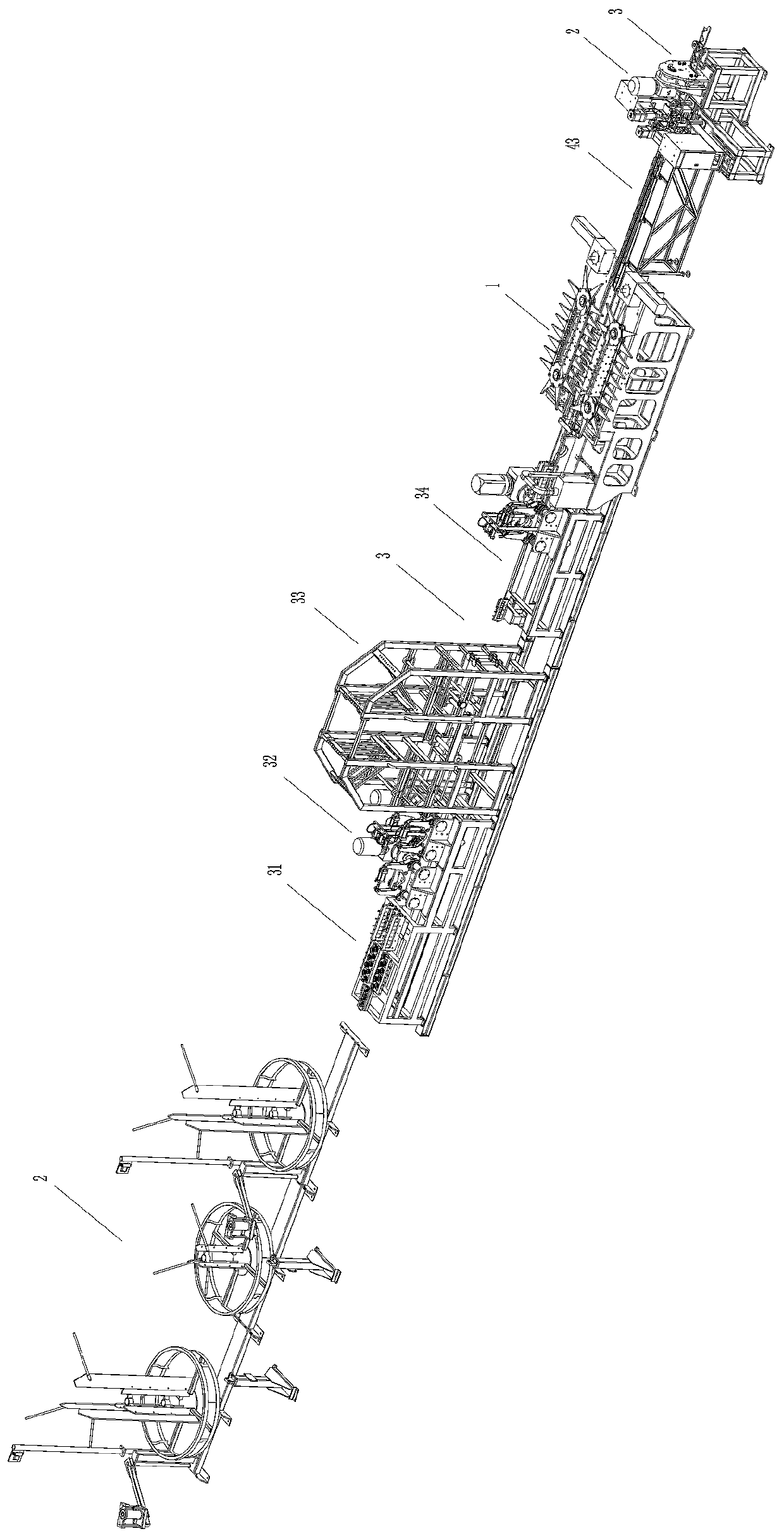

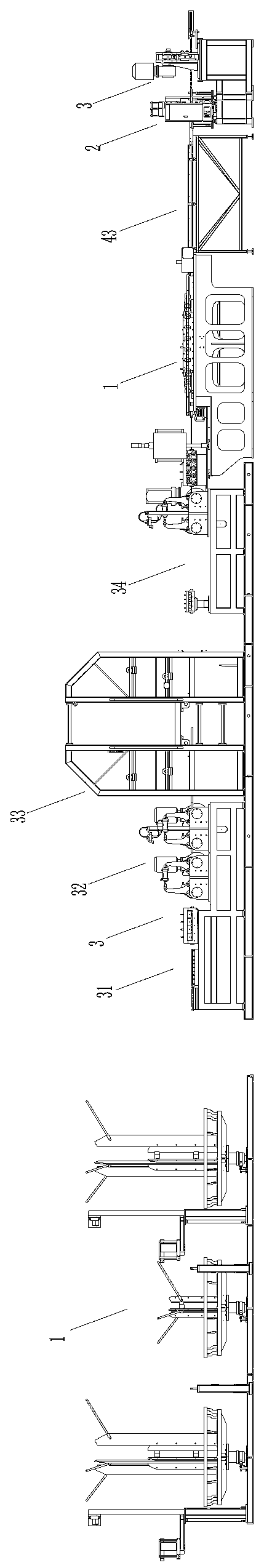

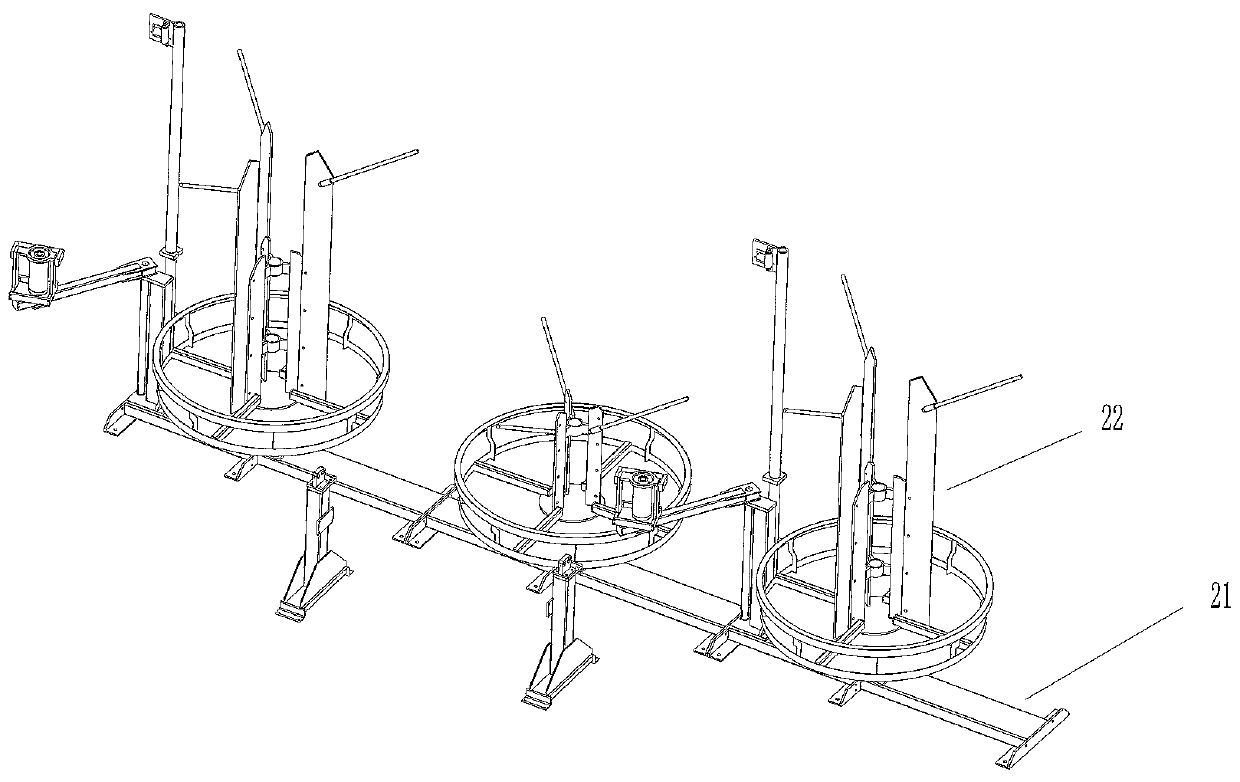

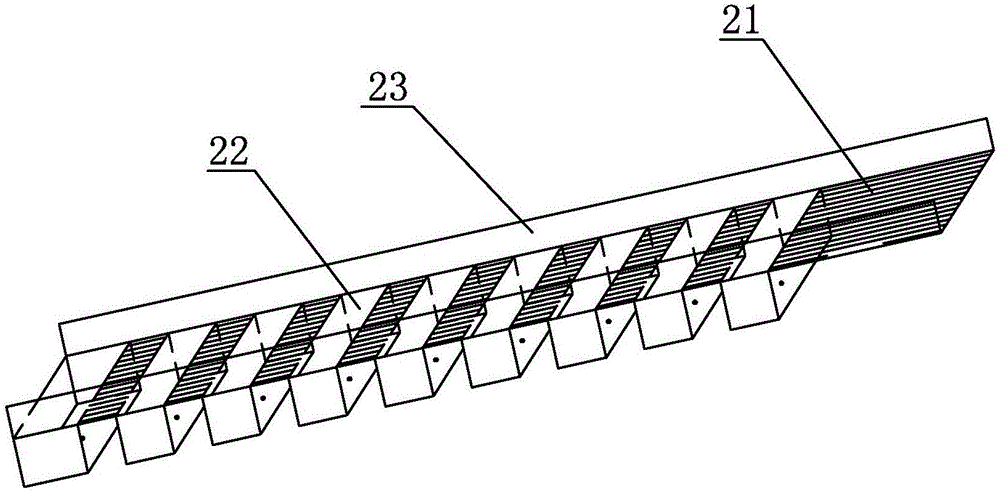

Plane truss production line

PendingCN109648007AQuick bendingThe style is fixed and beautifulMetal working apparatusProduction lineRebar

The invention belongs to the field of plane truss production, and particularly relates to a plane truss production line. The plane truss production line comprises a placing device, a straightening roller pressing device, a waving device, a welding device and a shearing device, wherein the waving device comprises a waving base, a waving drive, a side steel bar guide pipe, a fixed waving device anda movable waving device, and the fixed waving device comprises a first rotating shaft and a first crawler belt, triangular plates are fixed on the outer side of the first crawler belt, and the movablewaving device comprises a sliding guide rail, a sliding base, a second rotary shaft and a second crawler belt, triangular plates are fixed on the outer side of the second crawler belt, and the wavingdrive is connected with the first rotary shaft and the second rotary shaft; the welding device comprises a welding frame and welding heads; the shearing device comprises a shearing base and a cutterframe, and a cutter rotating shaft is arranged on the cutter frame, a cutter connecting part sleeves the cutter rotating shaft, and a shearing cutter is hinged to the lower part of the cutter connecting part. According to the plane truss production line, the steel bar can be processed into the plane truss, the processing process is automatic, the efficiency is high, and the method is suitable forlarge-scale plane truss processing.

Owner:浙江亿洲机械科技有限公司

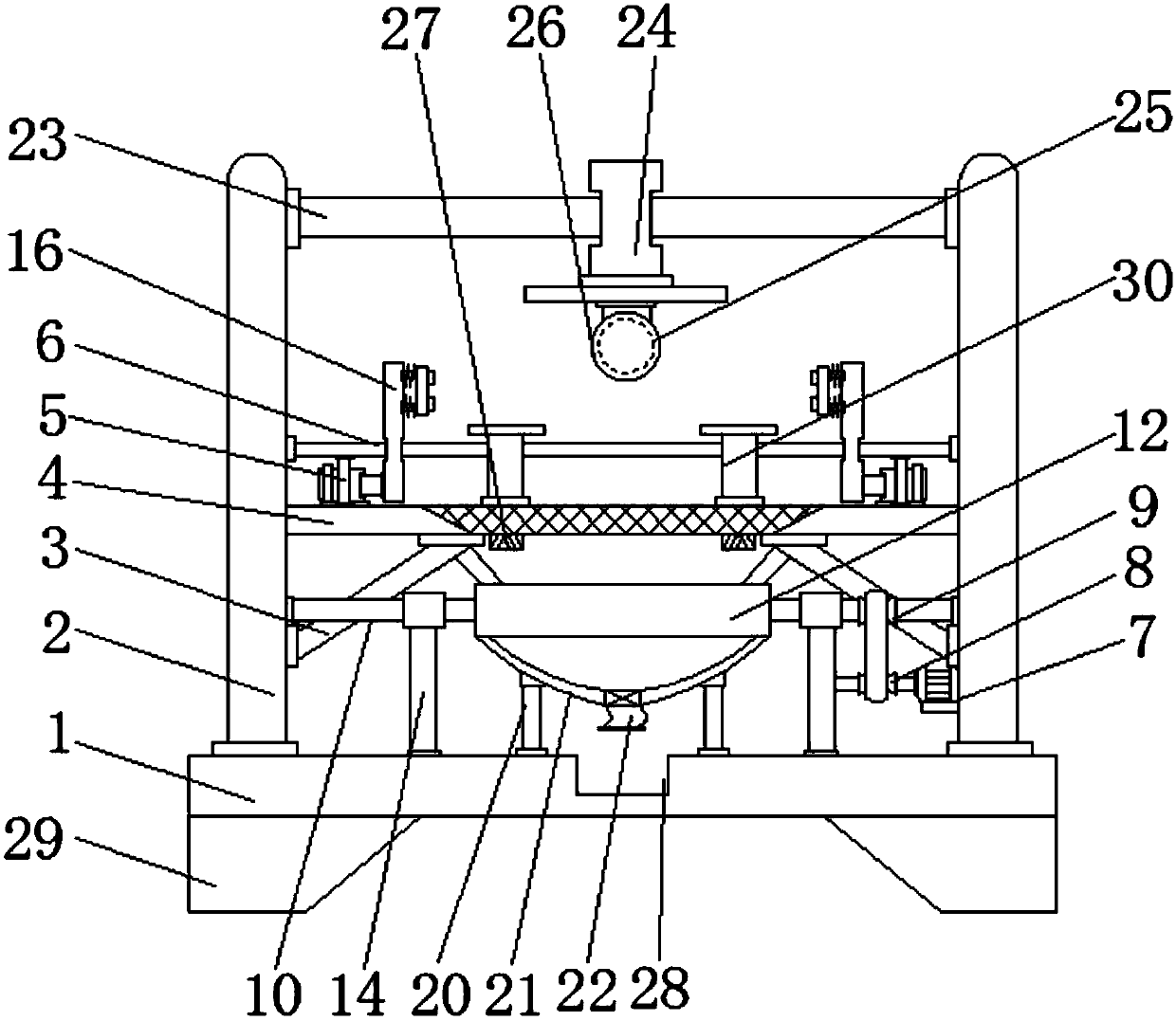

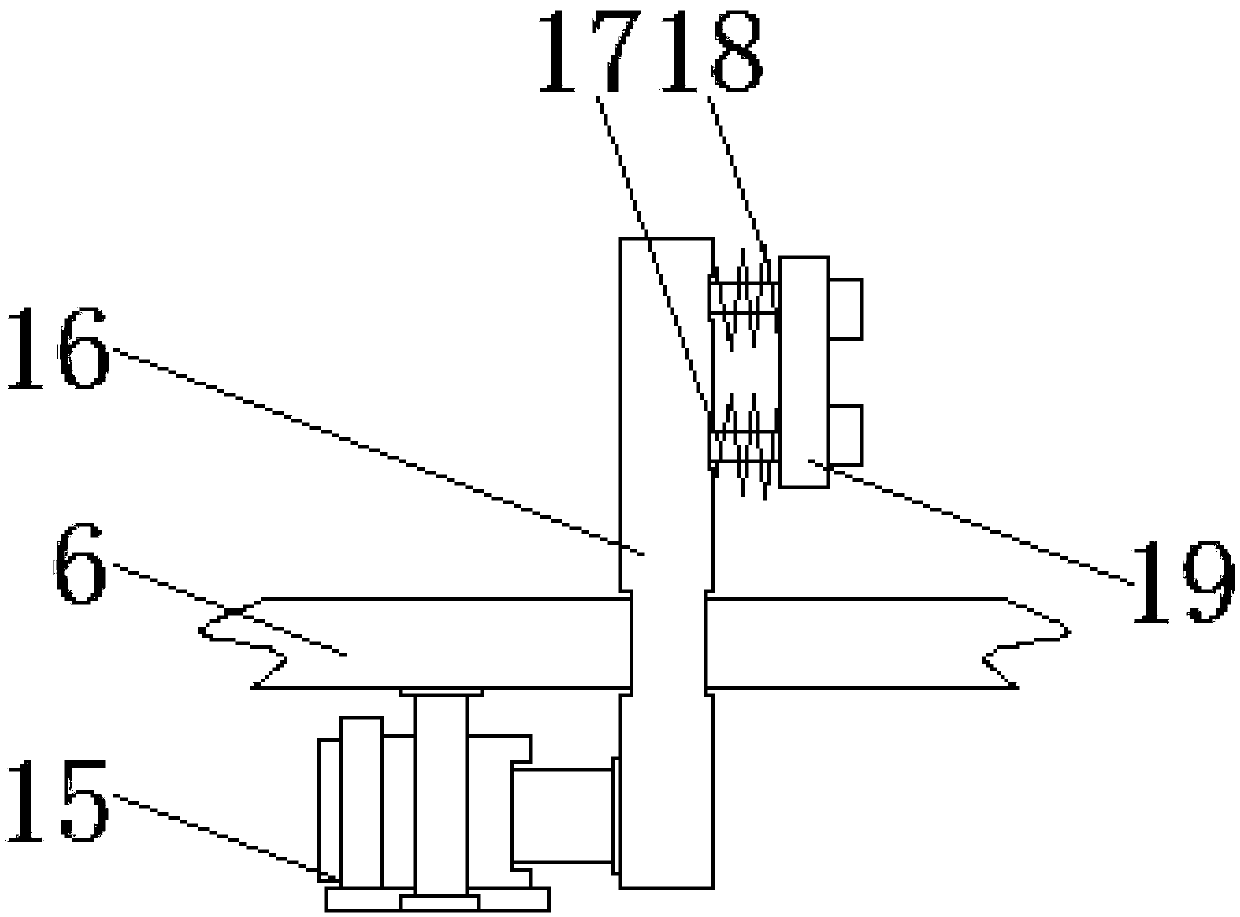

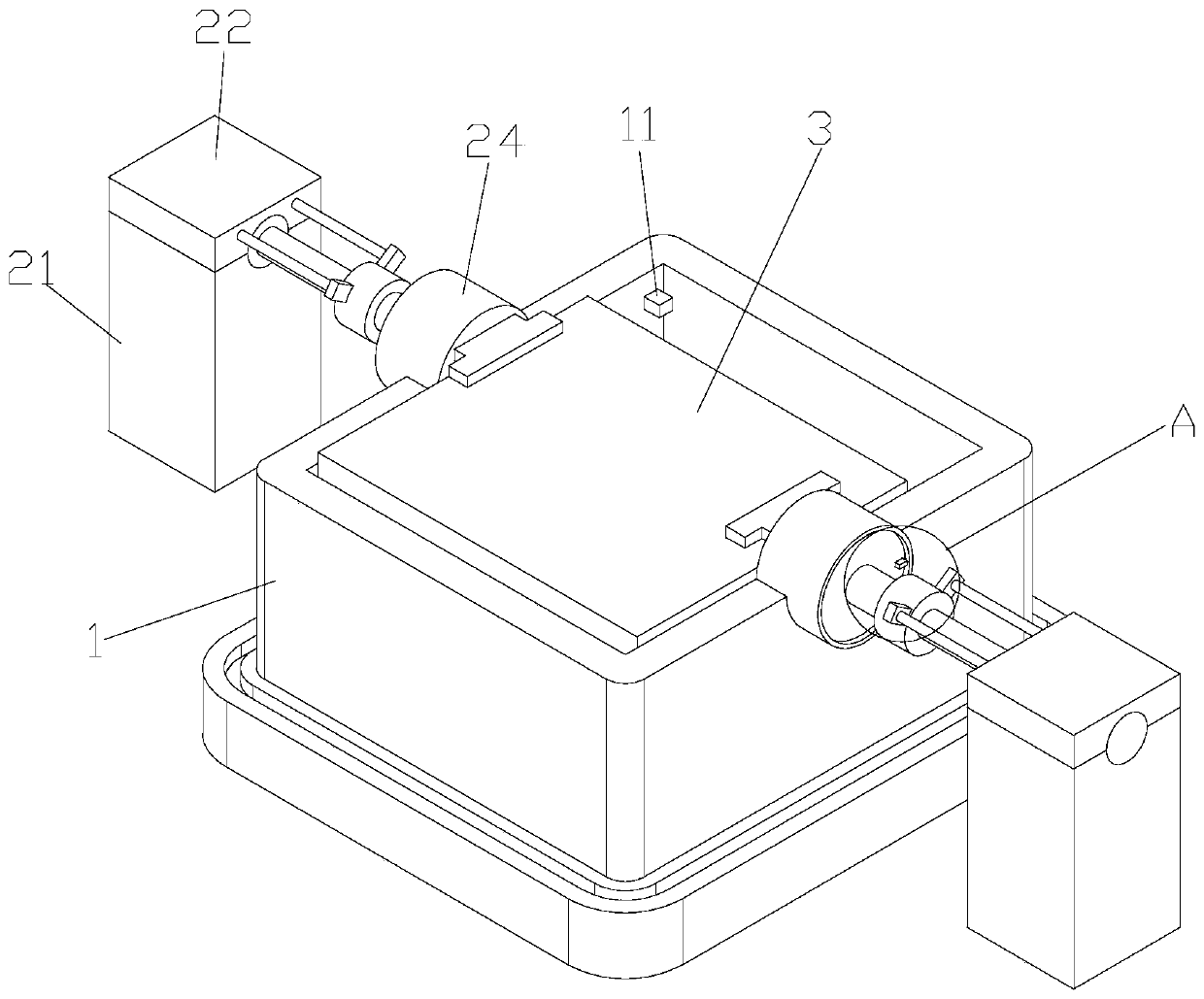

Automatic tender coconut processing machine

ActiveCN108618167AEfficient processingEfficient processing and productionClimate change adaptationHuskingDrive motorEngineering

The invention discloses an automatic tender coconut processing machine which is provided with a rack. A front linear guide rail (3) is arranged on the rack, a rotary nail disc device is arranged on the front linear guide rail (3), and a coconut compressing device is arranged above the rotary nail disc device. A coconut shell cutting device is arranged behind the coconut compressing device, a coconut bottom cutting device is arranged behind the coconut shell cutting device, and a recycling device is below the coconut bottom cutting device. The rotary nail disc device is composed of a nail disc(6) and a driving motor (2). The coconut compressing device is composed of a servo motor (8), a lead screw (9), a pressing-down frame (7) and a pressing block (11). The coconut bottom cutting device is composed of a servo motor (14), a lead screw (15), a gripper (16), a saw blade (18) and a motor (20). The recycling device is composed of a hopper (22) and a turnover plate (23). The automatic tender coconut processing machine has the advantages that automation of tender coconut processing and producing is achieved, the labor cost is reduced, and the production efficiency is improved.

Owner:HAINAN UNIVERSITY

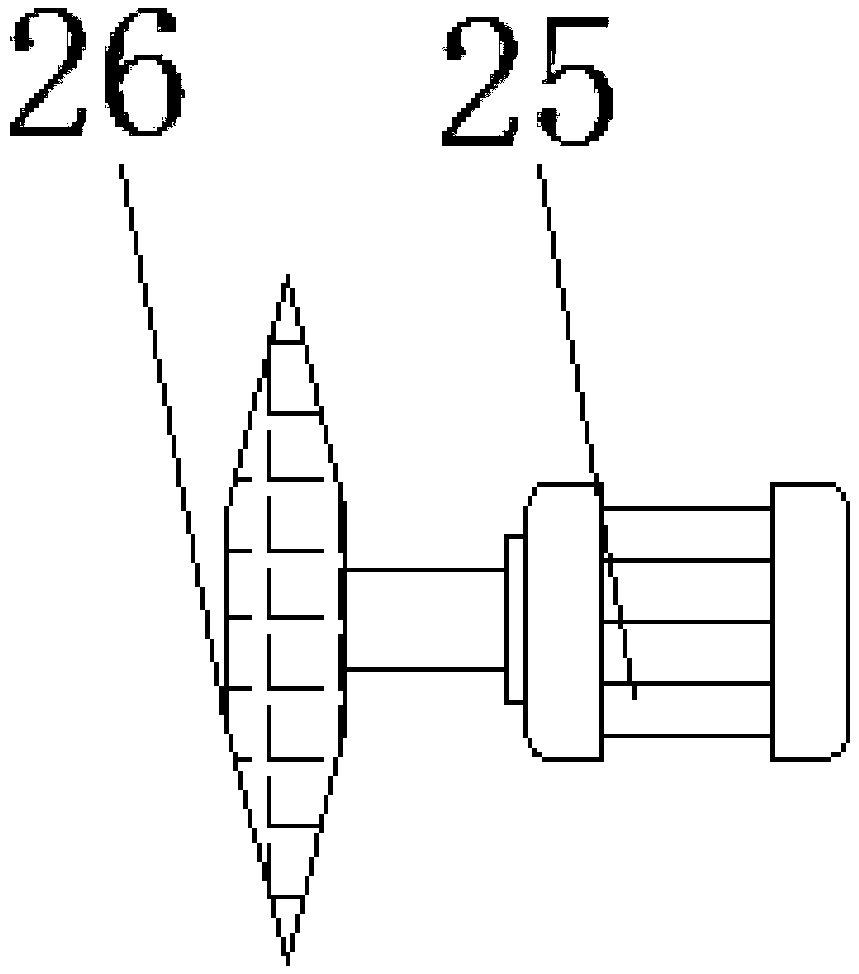

Blade head

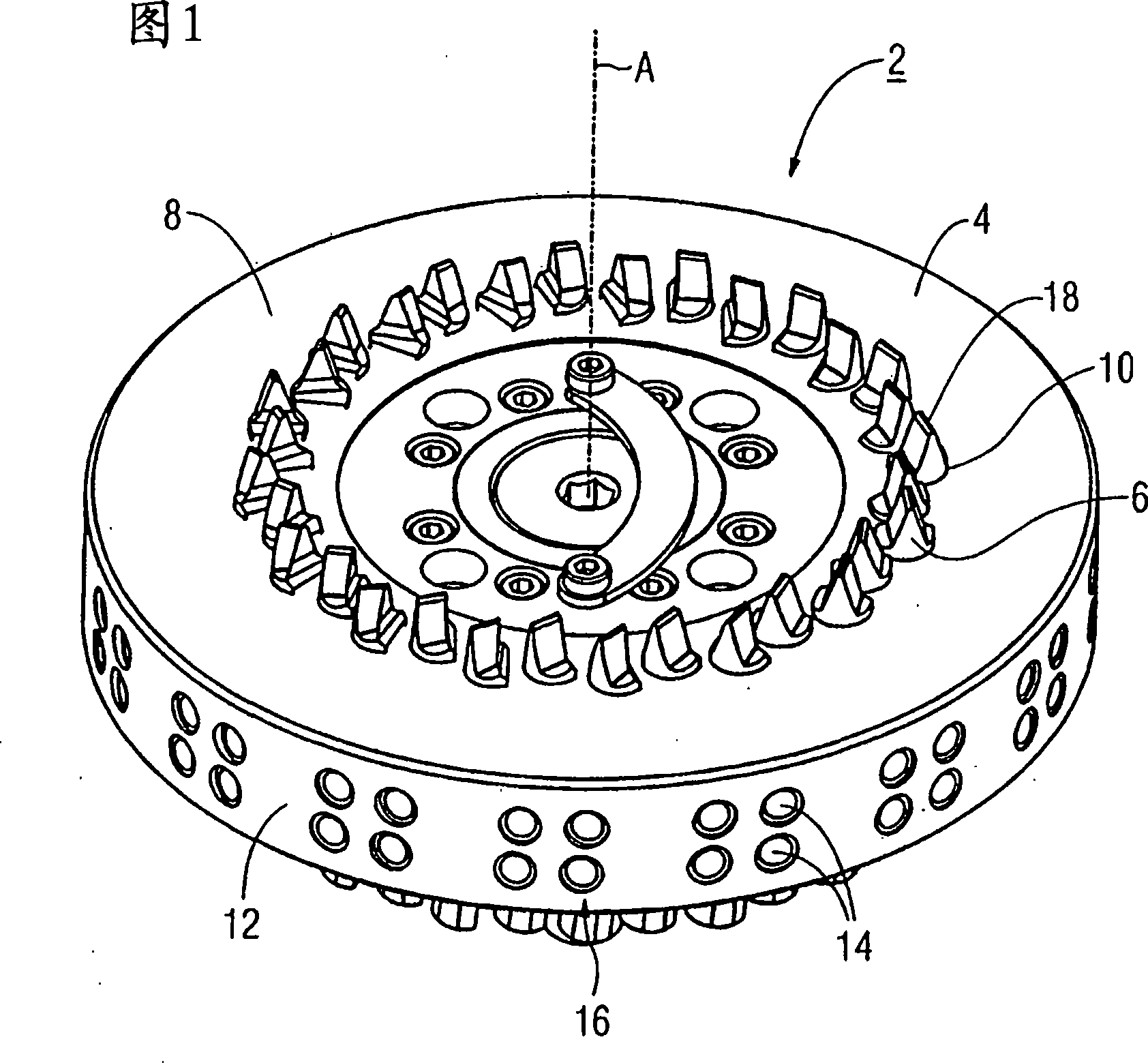

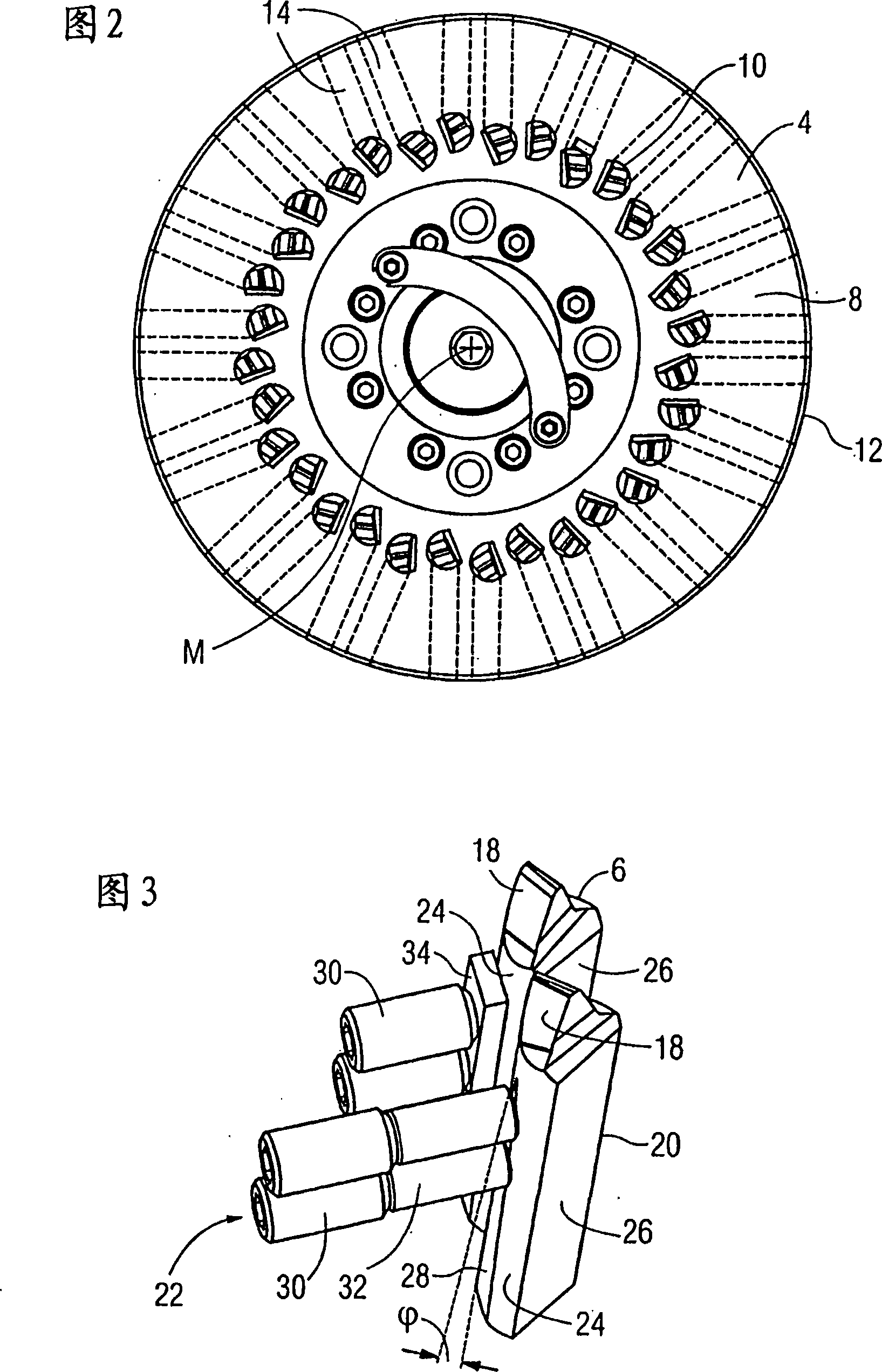

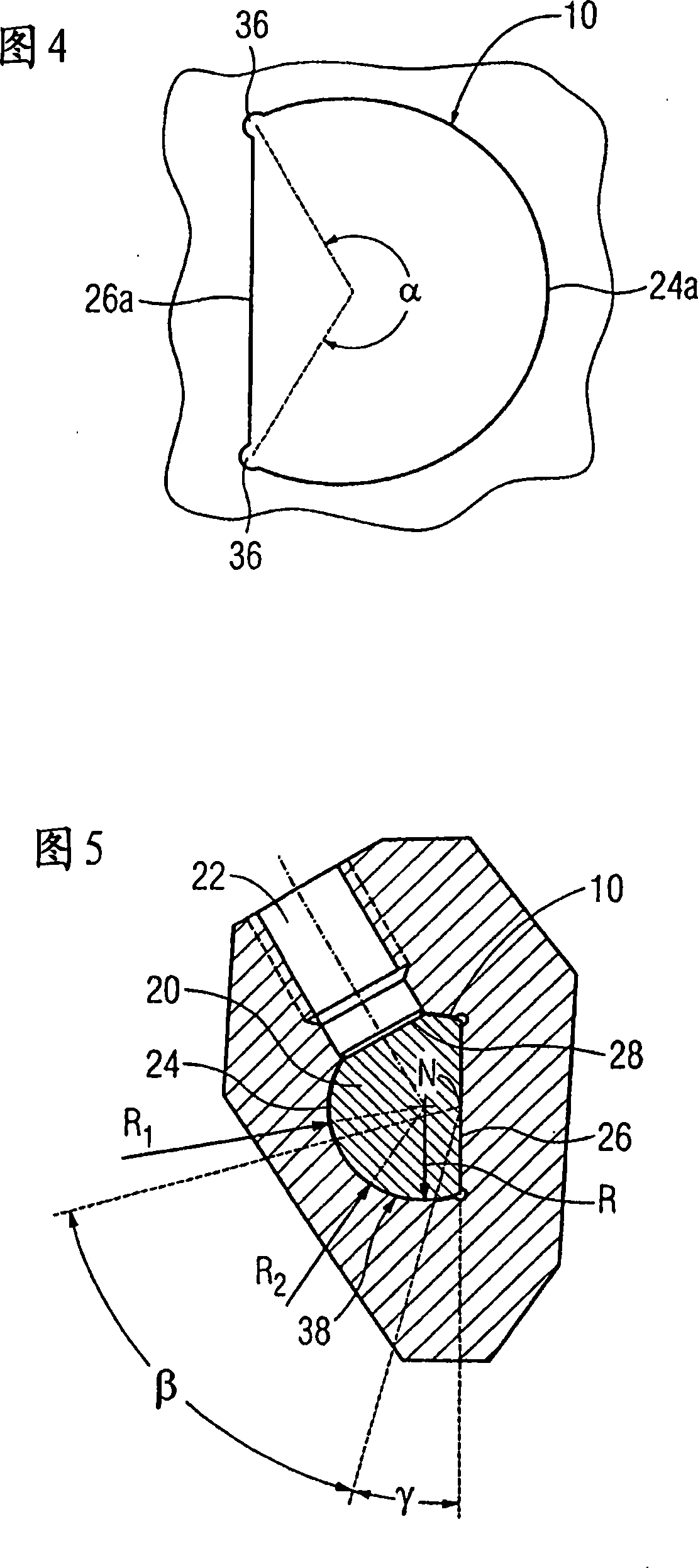

InactiveCN101218059AAchieving Complementary StructuresEasy to replaceMilling cuttersGear teeth manufacturing toolsEngineeringCircular segment

The cutter head (2) includes a disc-shaped cutter holder (4) and a plurality of rod-shaped cutters (6) with handles (20). The disk-shaped tool holder (4) has a plurality of tool seats (10), into which tool holders (20) of rod-shaped tools (6) are inserted. The handle (20) has an arcuate cross-section. In order to achieve a simple and reliable fixing of the rod-shaped tool (6) in the tool seat (10), the tool seat (10) complementary to the rod-shaped tool (6) has an arcuate cross-section, so that the rod-shaped tool (6) Insert into the knife seat (10) with its knife handle (20) respectively precisely. The non-positive fastening is only achieved by pressing the clamping screw (22) of the rod-shaped tool (6).

Owner:KENNAMETAL INC

Workpiece cleaning device

ActiveCN108580401AQuick washReduce processing timeToothed gearingsCleaning using liquidsEngineeringMechanical engineering

Owner:XIAMEN LANZHIBO ENVIRONMENTAL PROTECTION TECH

Automatic drawing, gluing and glitter scattering machine for artware

InactiveCN103770550AAvoid instabilityHigh scrap rateDecorative surface effectsSpecial ornamental structuresMechanical engineeringGlitter

The invention provides an automatic drawing, gluing and glitter scattering machine for artware. The automatic drawing, gluing and glitter scattering machine is characterized by comprising a stander, wherein two opposite fixed arms are arranged on the stander; a horizontal driving device is connected with a rotary driving device to drive the fixed arms; a hollow drawing and gluing arm is arranged on the stander; a drawing pen is arranged at the lower end of the drawing and gluing arm; the upper end of the drawing and gluing arm is connected with the front end of a glue pipe containing glue; the rear end of the glue pipe is connected with a gas source through a gas pipe; the horizontal driving device is connected with a vertical driving device to drive the drawing and gluing arm; a glitter box containing glitters is arranged at a lower position between the two fixed arms of the stander; the vertical driving device is connected with and drives the glitter box; the horizontal driving device, the vertical driving device, the rotary driving device and the gas source are connected with a programmable controller and are controlled by the programmable controller. The automatic drawing, gluing and glitter scattering machine is high in drawing, gluing and glitter scattering efficiency for the artware and stable in quality.

Owner:林跃进

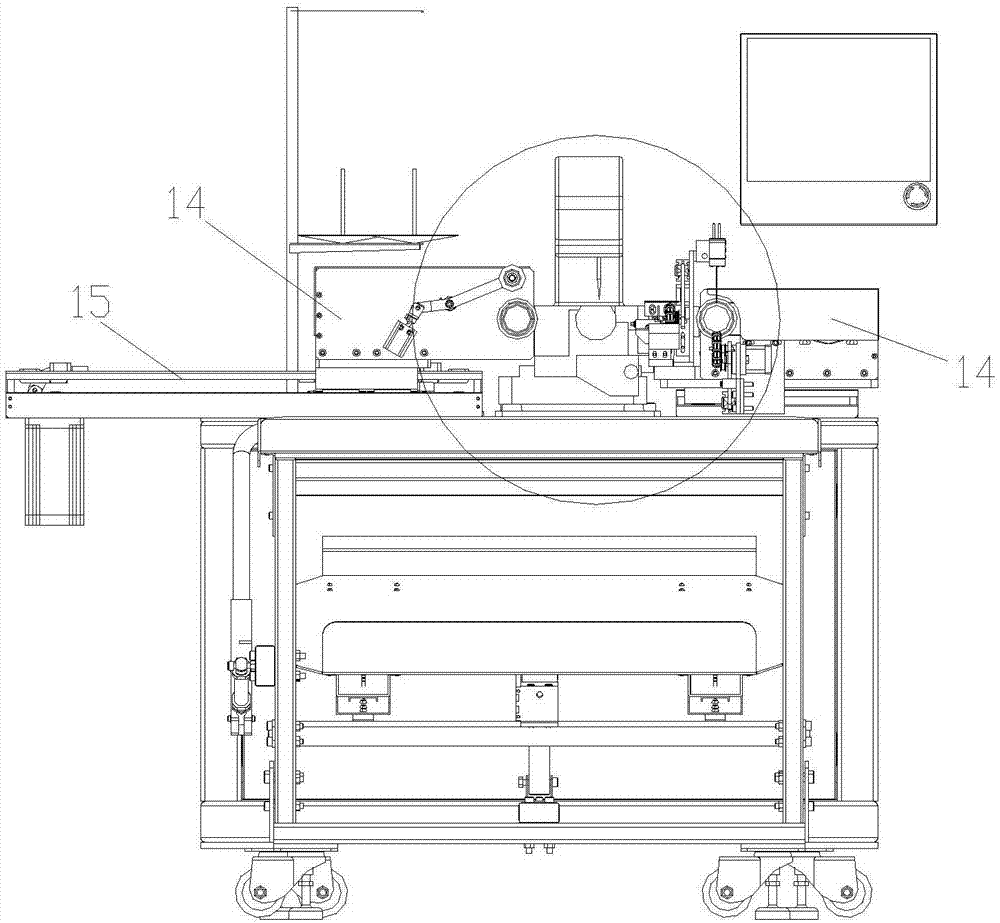

Automatic waistband elastic ribbon feeding machine

InactiveCN107237049AAchieving preliminary positioning suturesSmall sizeWork-feeding meansEngineeringLaser sensor

The invention discloses an automatic waistband elastic ribbon feeding machine and relates to the field of garment processing devices. The automatic waistband elastic ribbon feeding machine comprises a trousering holding mechanism for expanding and stretching a trouser fabric, an elastic ribbon roller synchronously moving with the trousering holding mechanism, a stitching machine for sewing an elastic ribbon on a trousering, a deviation rectifying mechanism for adjusting the movement trajectories of the trousering and the elastic ribbon, a sensor and a material receiving mechanism. The trousering holding mechanism comprises two fabric rollers arranged oppositely. Elastic ribbon rollers coaxial with the fabric rollers are arranged on the fabric rollers. A trousering and elastic ribbon align-sewing position is obtained through the sensor, and the elastic ribbon rollers and the fabric rollers can rotate with respect to each other. The stitching machine is arranged between the two fabric rollers. A partition plate for separating the trousering and the elastic ribbon is also arranged on the feeding path from the fabric rollers to the stitching machine. The deviation rectifying mechanism comprises a laser sensor and a deviation adjusting wheel. The laser sensor detects the overlapping size of the trousering and the elastic ribbon on the fabric rollers. The deviation adjusting wheel is used for adjusting the holding depth of the trousering on the fabric rollers. The material receiving mechanism is located below the fabric rollers.

Owner:FAR EAST CLOTHES SUZHOU CO LTD

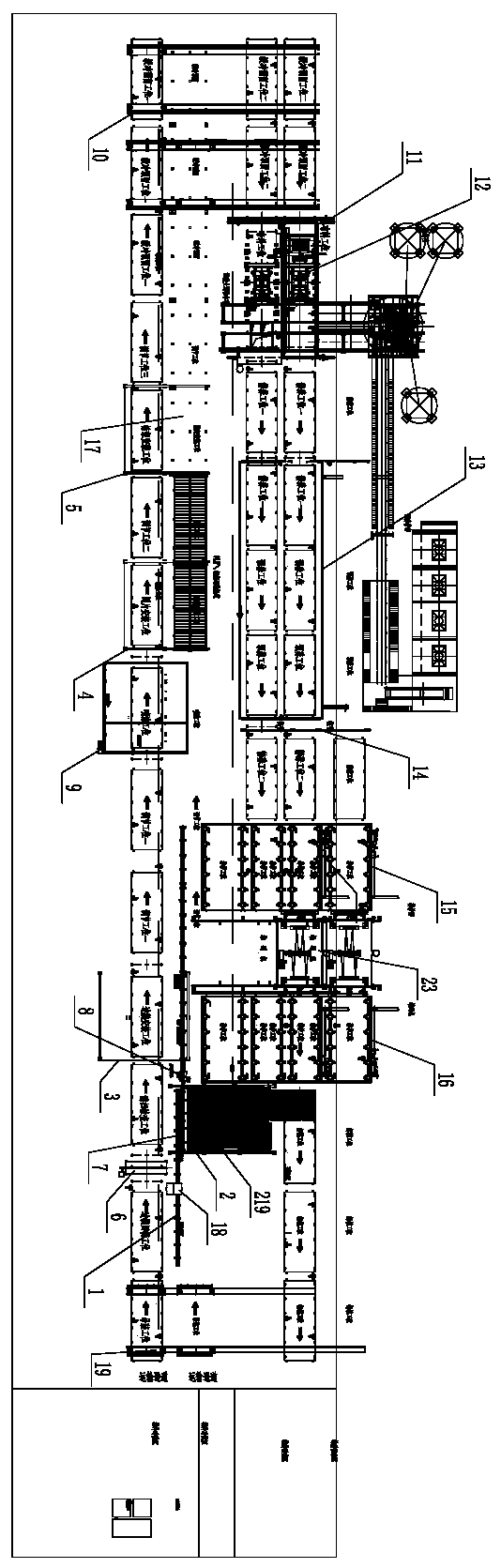

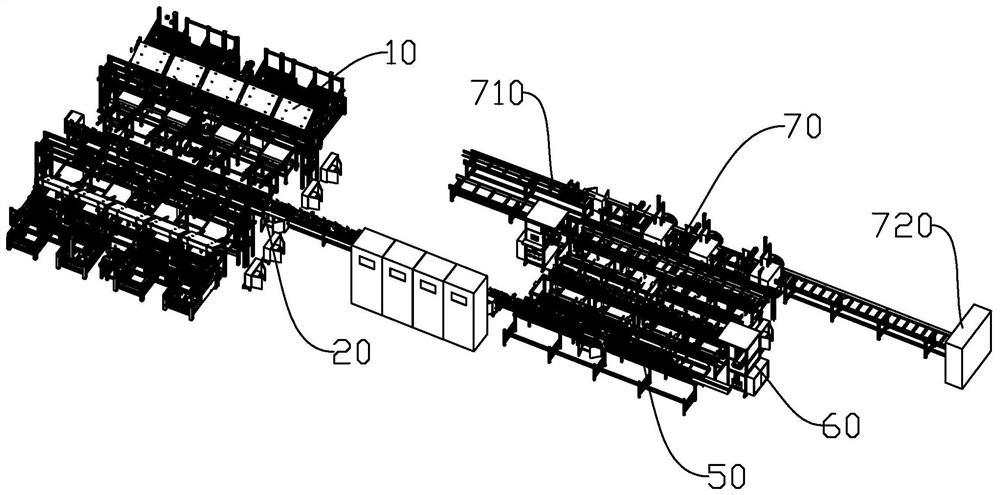

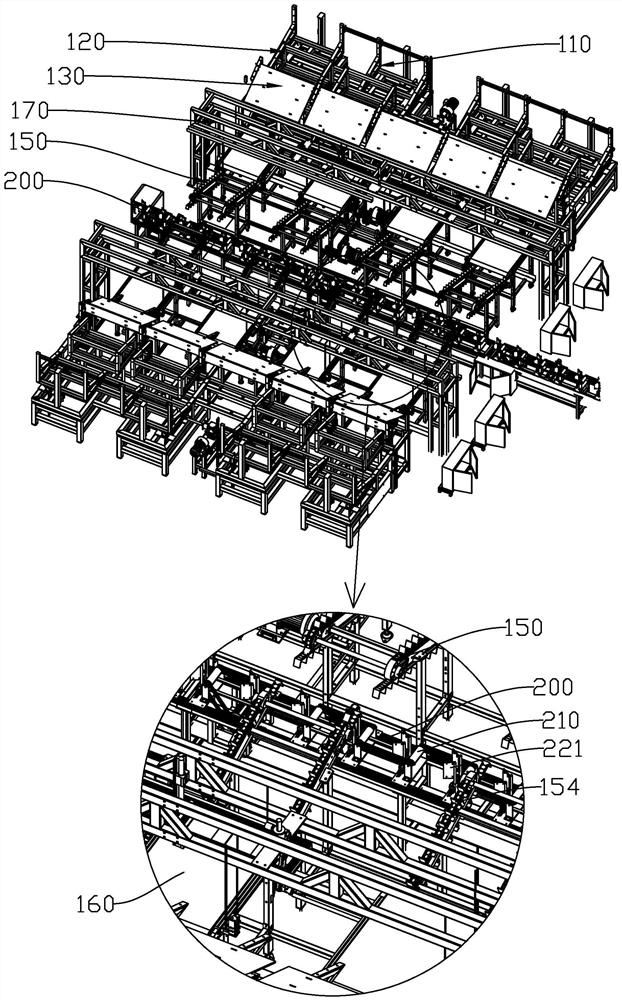

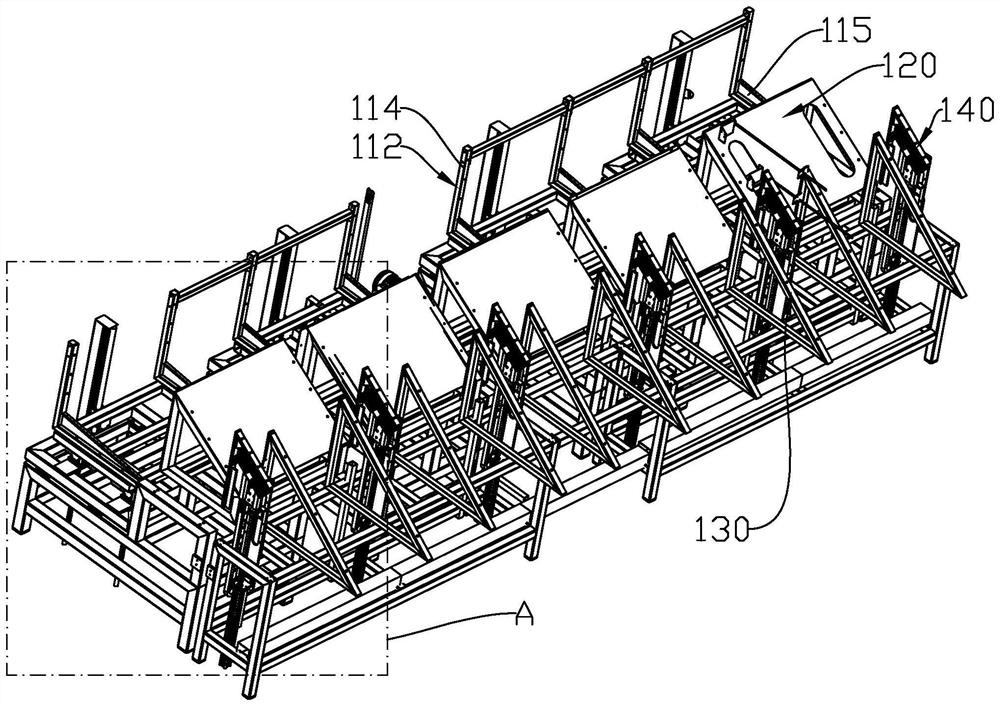

Processing line of concrete laminated plate and processing method thereof

PendingCN111015924ARealize automatic processingProcessing automationCeramic shaping plantsAuxillary shaping apparatusEngineeringStructural engineering

The invention discloses a processing line of a concrete laminated plate and a processing method of the processing line and belongs to the technical field of preparation of concrete prefabricated components. The processing line comprises a side framework warehousing roller way and a hoisting station. An side framework warehouse used for storing a side framework is arranged in front of the tail endof the side framework warehousing roller way. A cleaning inspection station, a side framework mounting station, at least one first adjusting station, a spraying station, a mesh mounting station, a second adjusting station, a truss mounting station, an adjusting station and at least one first buffer reserving station are sequentially arranged in the outward direction of the left end of the hoistingstation. At least one second buffer reserving station is arranged in front of the first buffer reserving station at the tail end, and a material distribution station, a static curing station, a pre-curing kiln, a napping machine, a first curing kiln, a stacking machine, a second curing kiln and at least one die disassembling station are sequentially arranged in the outward direction of the rightend of the second buffering reserving station at the tail end. The processing line has the beneficial effects of high efficiency and low labor intensity.

Owner:江苏众为智能科技有限公司 +1

Non-spherical glass lens moulding press

PendingCN108516667AProcessing automationLabor savingGlass reforming apparatusEngineeringMachining process

The invention belongs to the technical field of glass lens processing, and relates to a non-aspheric glass lens moulding press. The moulding press comprises a rack and a working chamber, a displacement mechanism and an export mechanism which are arrange on the rack. Under the action of the displacement mechanism, a work piece passes heating station, a pressing station for pressing formation and acooling station for cooling, and then is pushed out to the export mechanism and is exported, namely, the forming and processing of the work piece is finished, the whole processing process is automatic, the labor force is saved, and the processing efficiency is high.

Owner:GUANGDONG KINGDING OPTICAL TECH CO LTD

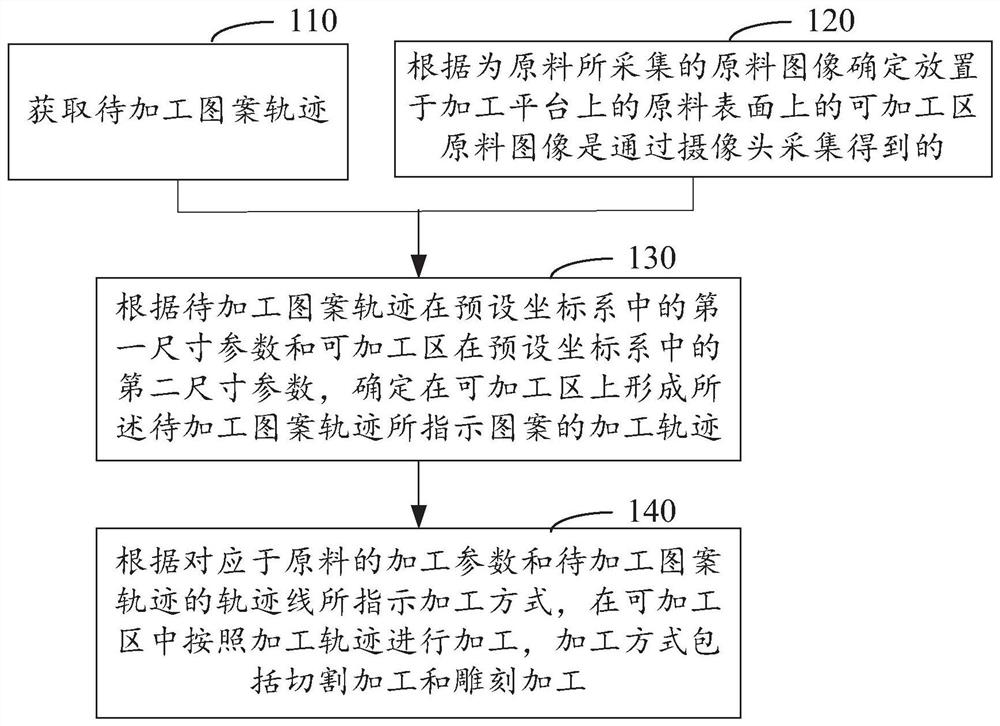

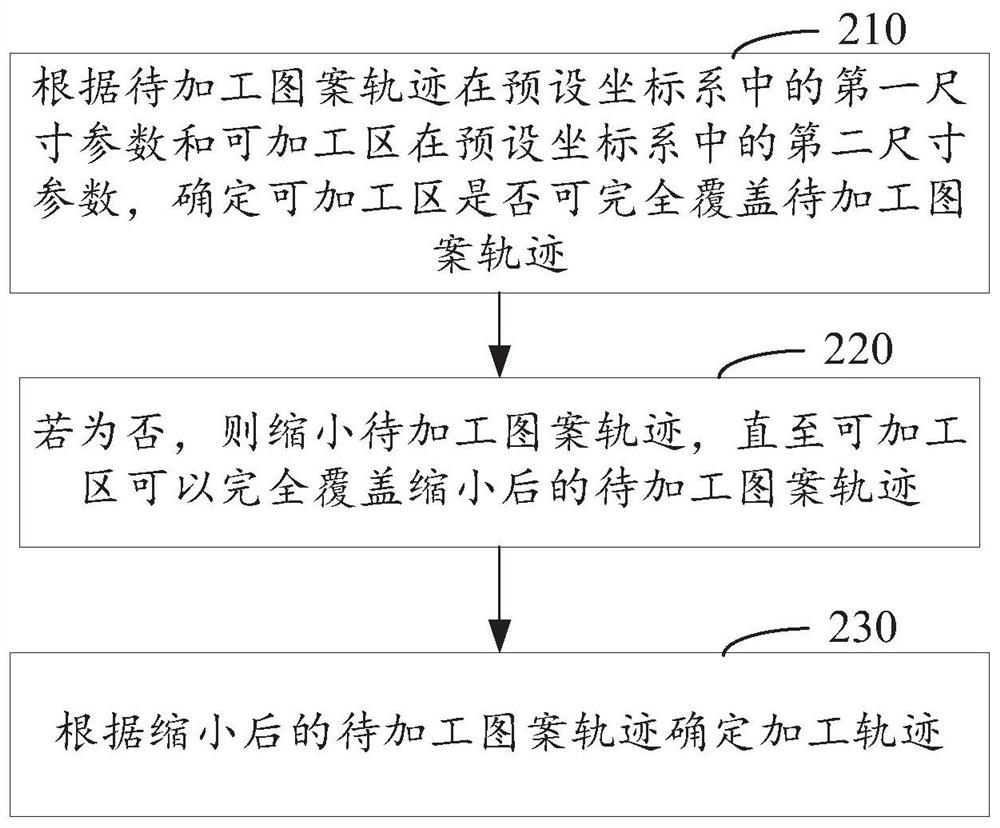

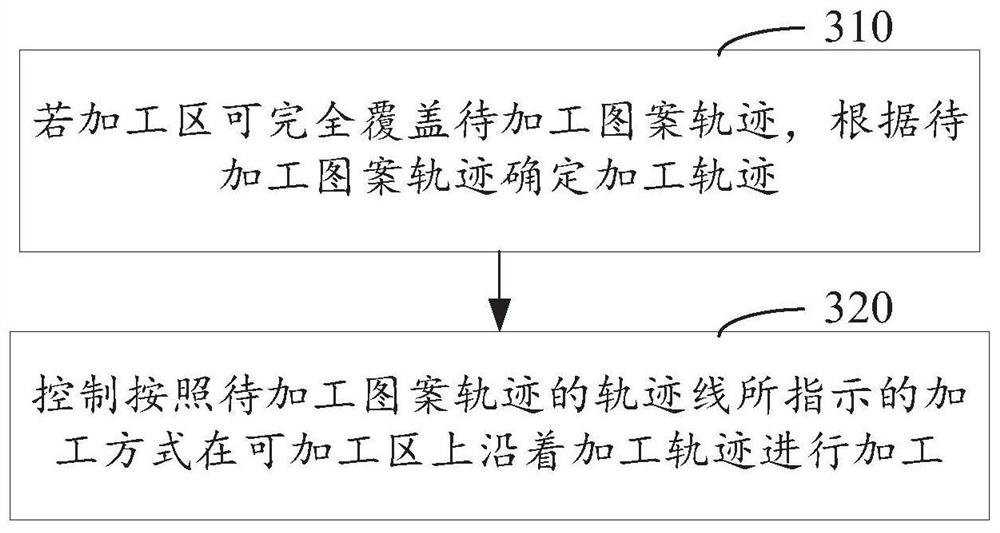

Laser processing control method and device and laser processing equipment

ActiveCN113290313AAvoid situations that are not fully formed on the feedstockProcessing automationLaser beam welding apparatusLaser processingMachining

The embodiment of the invention provides a laser processing control method. The method comprises the steps that a to-be-processed pattern track is obtained; a machinable area on the surface of a raw material placed on a processing platform is determined according to a raw material image acquired for the raw material, wherein the raw material image is acquired by a camera; according to a first size parameter of the to-be-processed pattern track in a preset coordinate system and a second size parameter of the machinable area in the preset coordinate system, a processing track of a pattern indicated by the to-be-processed pattern track on the machinable area is determined; and according to machining modes indicated by the machining parameters corresponding to the raw material and a track line of the to-be-machined pattern track, machining is conducted in the machinable area according to the machining track, wherein the machining modes comprise cutting machining and carving machining. Automatic laser processing is realized, and the processing efficiency is improved.

Owner:SHENZHEN MAKER WORKS TECH CO LTD

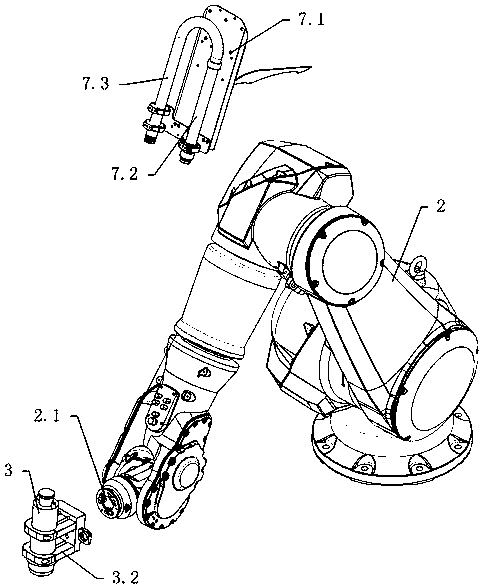

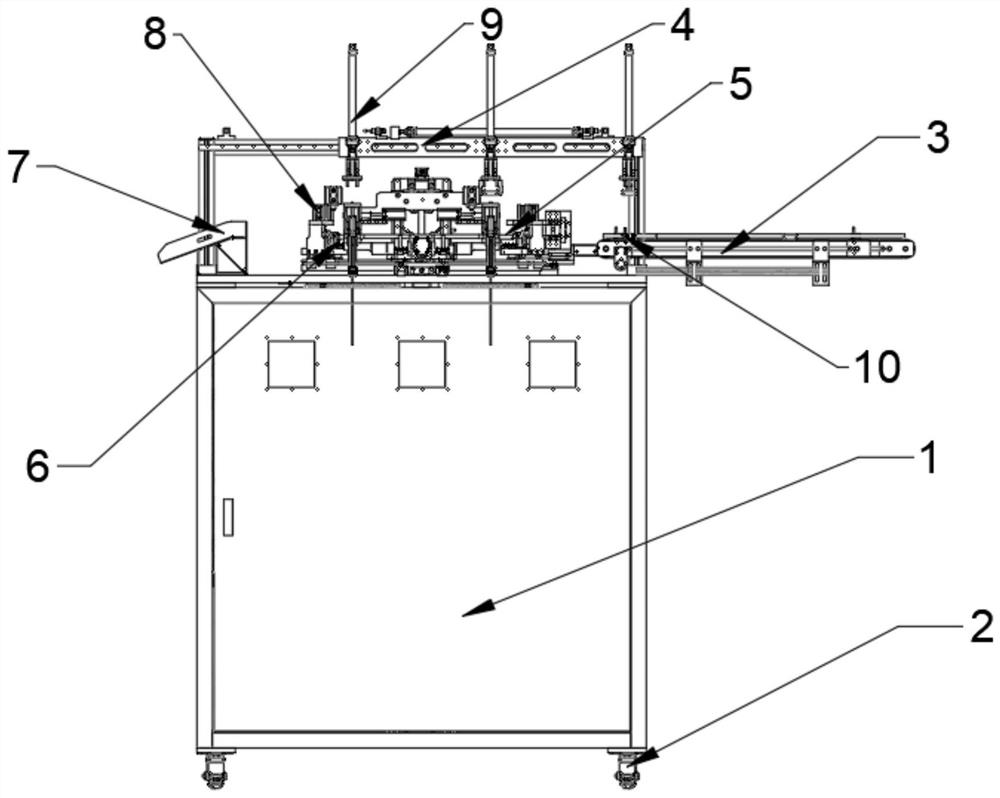

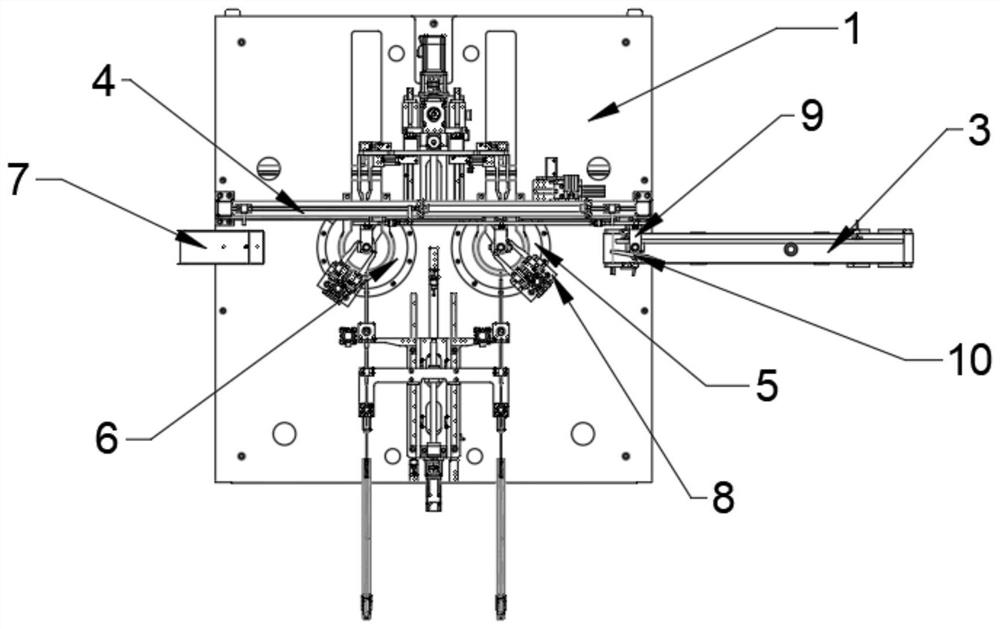

A plastic window hole milling process based on a hole milling manipulator, and equipment

ActiveCN104162703AProcessing automationReduce human involvementMilling equipment detailsManipulatorMachining process

A plastic window hole milling process based on a hole milling manipulator and equipment are disclosed. The equipment comprises the manipulator, a servo motor, an electric spindle, a milling cutter, a support, a pedestal, section bar clamps, an air cylinder, a sliding clamping plate and a fixed clamping plate. The manipulator is driven by the servo motor. The tail end of the manipulator is provided with the electric spindle. The electric spindle drives the milling cutter to rotate. The sliding clamping plate and the fixed clamping plate are installed on the pedestal. Sides of the sliding clamping plate and the fixed sliding plate are provided with transversal bar mechanisms. The fixed clamping plate is provided with a square groove along the length direction. The transversal bar mechanisms at a side of the sliding clamping plate pass through the square groove of the fixed clamping plate. The air cylinder is disposed at the top of the sliding clamping plate. A piston rod of the air cylinder is connected to the top end of the sliding clamping plate by welding. Section bars are disposed among the transversal bar mechanisms of the sliding clamping plate and the fixed sliding plate. According to the process and the equipment, the automatic manipulator is utilized to drive the milling cutter to achieve the hole machining step of the section bars, thus achieving automatic machining, reducing the degree of participation of manual work, and improving the machining precision and machining consistency.

Owner:UNIV OF JINAN

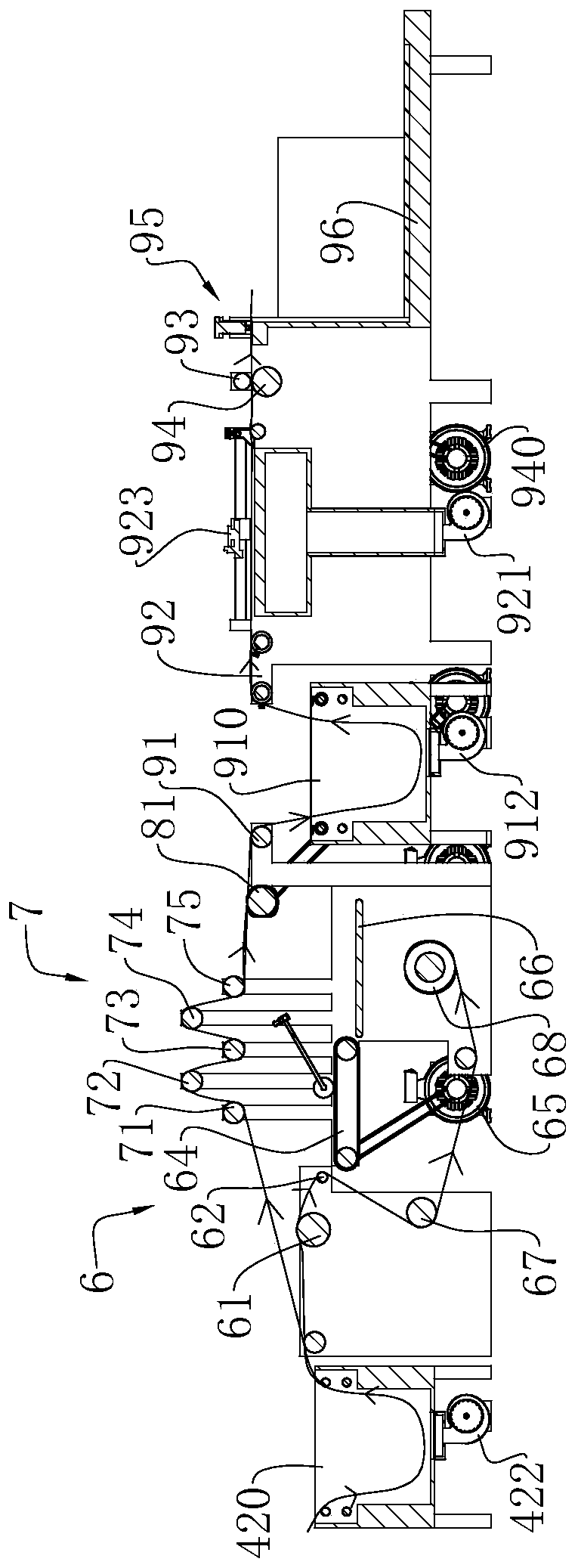

Full-automatic inductance crochet needle machine

The invention belongs to the technical field of crochet needle machines, and particularly relates to a full-automatic inductance crochet needle machine. The machine comprises an electrical cabinet and a synchronous belt line, an equidistant carrying device is installed above the electrical cabinet, carrying clamps are installed on the front side of the equidistant carrying device, the number of the carrying clamps is three, and the three carrying clamps are arranged at equal intervals; a first winding device is installed on the right side of the upper portion of the electrical cabinet, a second winding device is installed on the left side of the upper portion of the electrical cabinet, pressing devices are arranged on the upper portions of the outer sides of the first winding device and the second winding device correspondingly, and a discharging device is installed on the left side of the upper portion of the electrical cabinet; and the discharging device is located on the left side of the second winding device, and the synchronous belt line is located on the right side of the first winding device. When the machine is used for machining, the first winding device and the second winding device can be used for winding magnetic rings at the same time, and the production efficiency can be improved through simultaneous machining.

Owner:苏州德固机械有限公司

Pipe material packaging device

PendingCN114261596APackaging AutomationProcessing automationWrappingPackaging automatic controlEngineeringMaterials processing

The invention discloses a pipe material packaging device and belongs to the field of pipe material processing equipment, automatic pipe material processing and packaging are carried out, manpower input is reduced, and the pipe material packaging device comprises a grading feeding device, a laser marking machine, a laser marking auxiliary device, a radial pipe material transferring device, a pipe material cap plugging device, an automatic packaging mechanism and a pipe material conveying device. The grading feeding device comprises a base, a storage frame, a first distributing rack and a second distributing rack, the laser marking auxiliary device comprises a clamping base and a clamping roller set, the radial pipe transferring device comprises a transverse conveying rack and a shifting rod piece, a power device is arranged on the transverse conveying rack, and the pipe cap plugging device comprises a device body. A four-axis robot and a cap pushing arm are arranged on the device body, the automatic packaging mechanism is used for packaging the processed pipe materials and comprises a strapping machine, a material pushing machine and a film laminating machine, and a radial pipe material transferring device is arranged on the side portion of the strapping machine.

Owner:ZHEJIANG HAILIANG

Chicken foot mixing device

The invention discloses a chicken foot mixing device. The chicken foot mixing device comprises a mixing box, a heating box and a vibration motor, which are connected in sequence from top to bottom, wherein the mixing box is connected with a plurality of hoppers for loading seasonings; the hoppers are connected with a plurality of feeding pipes with different pipe diameters; one feeding pipe corresponding to each hopper is communicated to a feeding hole formed in the mixing box; each feeding hole is connected with a first separation blade for blocking the feeding hole in a clamping manner; the mixing box is communicated with a water pipe through which water enters; the mixing box is communicated with the heating box; a seasoning box, which is capable of overturning when the load is over-weighted, is hinged between the mixing box and the heating box; the seasoning box is located below the feeding hole and the water pipe; a tension spring is connected between the seasoning box and the mixing box; an inlet through which chicken feet enter is formed in a side wall of the heating box. The chicken foot mixing device is simple to operate and the consistency of produced products is high.

Owner:CHONGQING SHUNTAI FOOD

Fabric compounding apparatus with deodorizing and refreshing function

InactiveCN110239199AGuaranteed firmnessProcessing automationLamination ancillary operationsLaminationInjection portShake up

The invention discloses a fabric compounding apparatus with deodorizing and refreshing function. The fabric compounding apparatus comprises a hot-melting box, wherein a compounding chamber provided with a forward opening is arranged in the hot-melting box, the inner wall of the top end of the compounding chamber is fixedly provided with a gathering device, and the gathering device can pass through the track block arranged on the inner wall of the top end of the compounding chamber. According to the present invention, the glue in the pipeline is saturated, the same sample injection amount is controlled based on the same pushing distance, the position of the injection port is changed, and the staggered opening of the upper injection port and the lower injection port is achieved by using the repeated structure, such that the firmness of the composite fabric is ensured while the impact of the glue overflow on the beautify is avoided; the mechanism for moving the fabric left and right can slide up and down, and contacts the wave surface to shake up and down, such that the volatilizing of the irritating odor on the fabric can be accelerated; and the mechanism moves to push the perfume pouring structure to slide up and down so as to automatically process the deodorized and refreshed fabric.

Owner:佛山市智布互联纺织有限公司

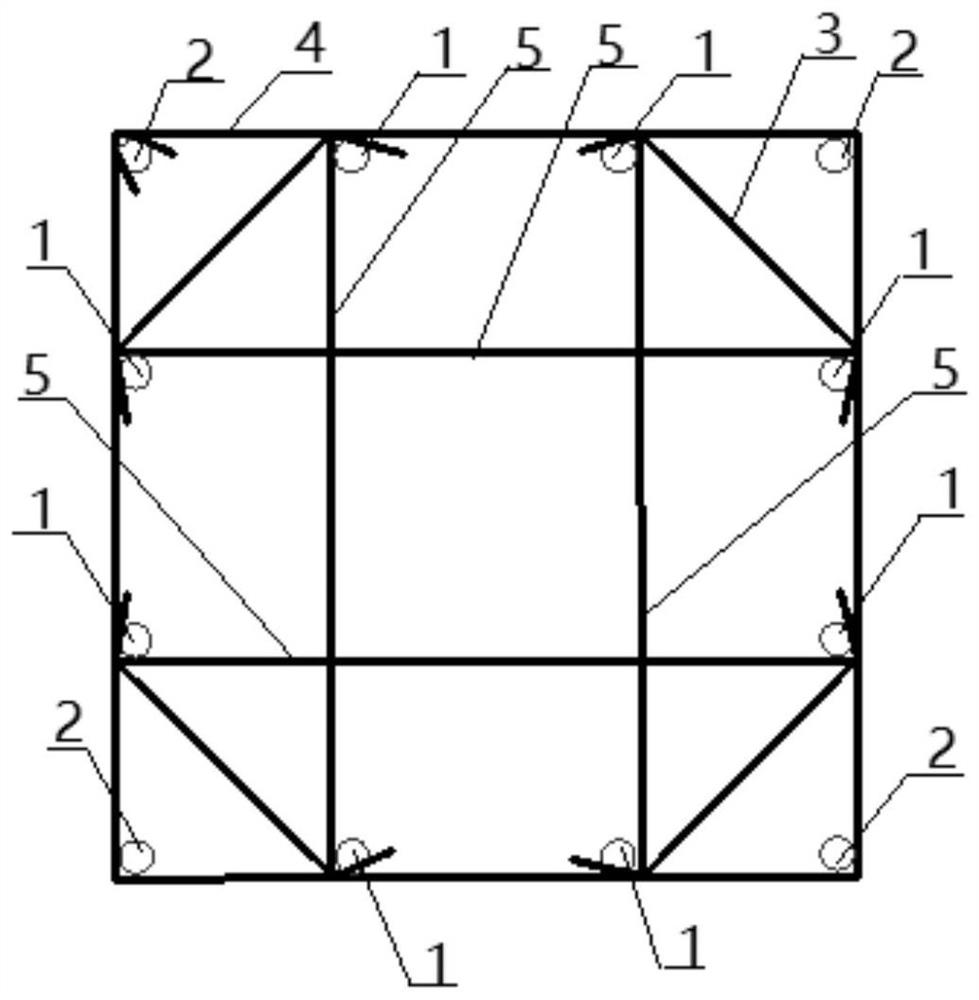

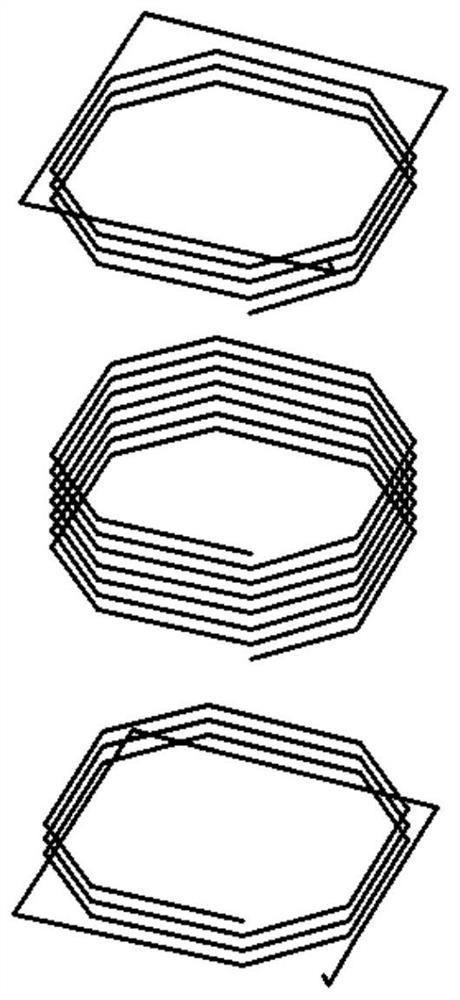

Reinforced concrete frame column steel reinforcement cage and manufacturing method thereof

InactiveCN112538933AProtection from deformation and aliasingLose weightStrutsBuilding reinforcementsRc framesEngineering

The invention discloses a reinforced concrete frame column steel reinforcement cage and a manufacturing method thereof. The reinforced concrete frame column steel reinforcement cage comprises a lowergrouting sleeve steel reinforcement cage body and an upper stand column steel reinforcement cage body, the inner layer of the upper stand column steel reinforcement cage body is formed by arranging longitudinal main reinforcements into an octagon shape, octagonal spiral stirrups are bound outside the main reinforcements, the outer layers of the octagonal spiral stirrups are formed by arranging longitudinal main reinforcements into a rectangle, and rectangular stirrups are fixed outside the main reinforcements. According to the steel reinforcement cage and the manufacturing method of the steelreinforcement cage, the octagonal stirrup form is adopted, automatic, efficient and high-quality machining of the formed reinforcement framework can be achieved, the section is restrained more effectively through the continuous spiral stirrups, the section bearing capacity is improved, and the overall frame rigidity is improved; and meanwhile, dead weight of the steel reinforcement cage is reduced, the consumption of reinforcing steel bars is saved, the working efficiency is improved, and the engineering quality is guaranteed.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Mattress production process

ActiveCN110182747APrevent disengagementIncrease gravitational potential energyUpholstery manufactureProduct inspectionCoil spring

The invention discloses a mattress production process. The mattress production process comprises the following steps that a, feeding and feeding detection are carried out, specifically, whether raw materials are suitable and qualified or not is directly related to the production and quality of mattress finished products; b, cotton pleating and spring connecting are carried out, specifically, cotton pleating is to turn cotton used in mattress fabrics onto a cloth material, a final expression form is the bottom fabric on the topside of a mattress, and spring connecting is to connect coil springsinto a whole; c, bed cutting and bed net manufacturing are carried out, specifically, the bed cutting is to cut the cloth material which is subjected to cotton pleating to the size of a mattress, anda bed net is formed by fixing a spring net formed by spring connecting, an interlocking spring net or an independent bag spring net with frame iron according to the bed net manufacturing; d, bottoming is carried out, specifically, cotton felt or other cushion layers are spread on the bed net, and then fabrics which are subjected to cotton pleating is placed; e, edge surrounding is carried out, specifically, the finished mattress is placed on a machining table, and the upper fabric and the lower fabric are sewed together through a edge surrounding machine; and f, finished product inspection iscarried out, specifically, all indexes of the manufactured mattress products are inspected, and the manufactured mattress products are packaged before leaving the factory.

Owner:佛山市顺德区库斯家具实业有限公司

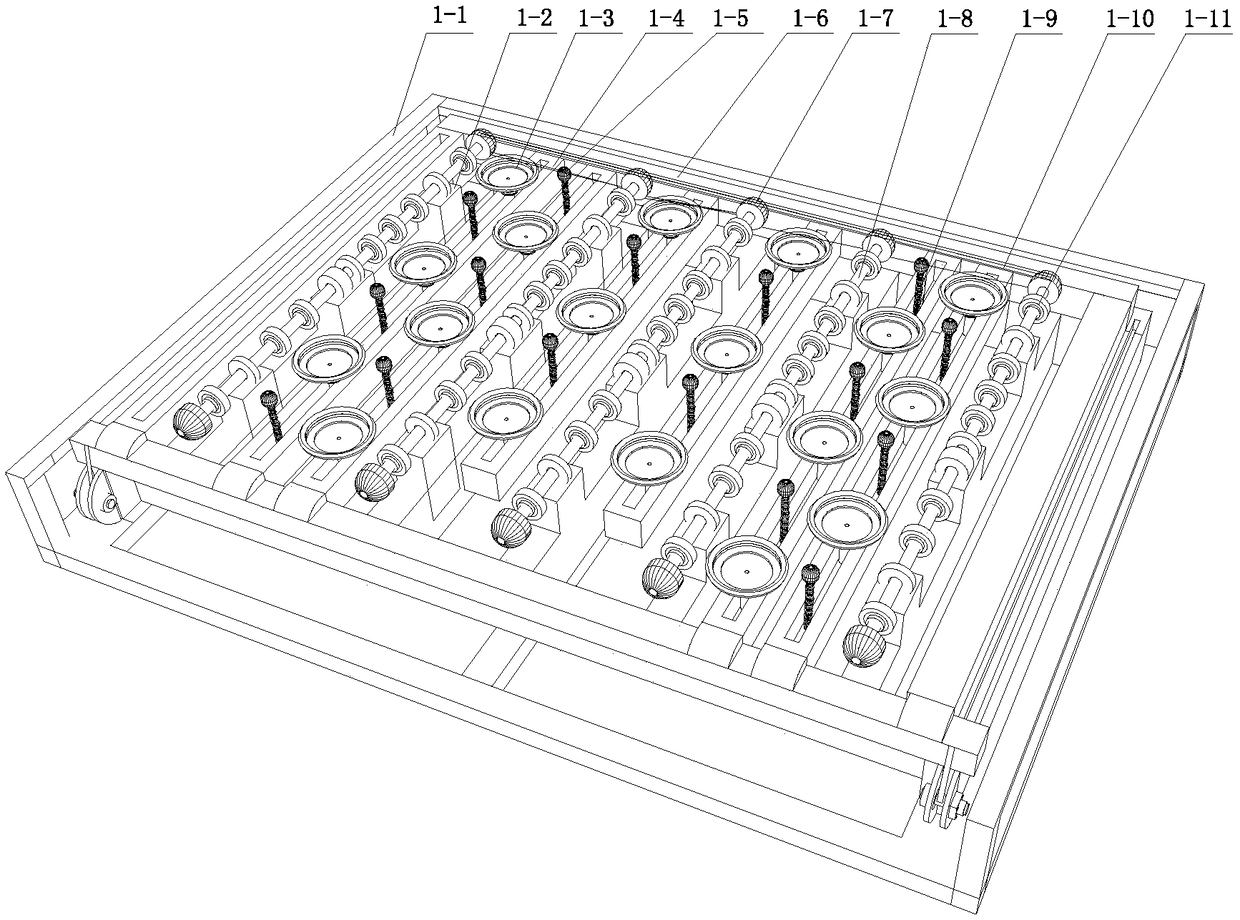

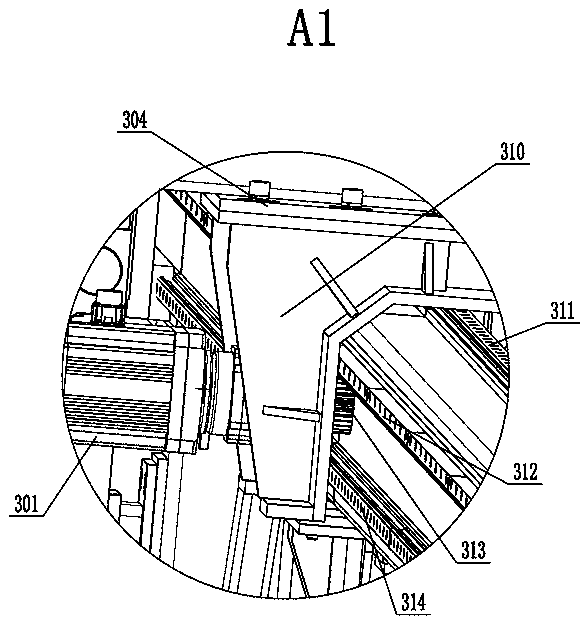

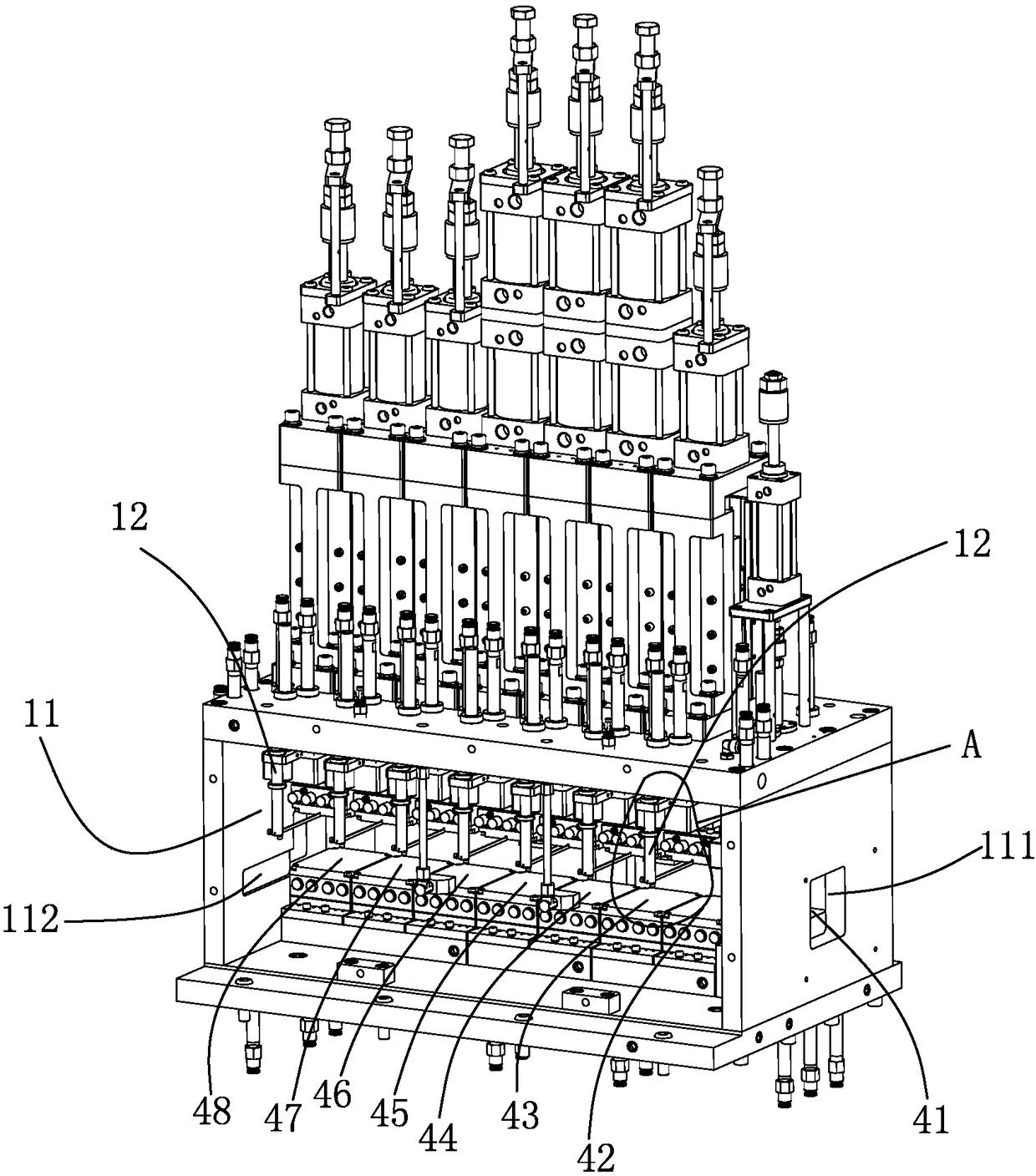

Machining and locating device, machining machine tool and machining method

The invention discloses a machining and locating device, a machining machine tool and a machining method. The machining and locating device comprises collecting boxes used for loading to-be-machined pieces and a locating platform which is used for bearing the collecting boxes and locating the to-be-machined pieces loaded in the collecting boxes, wherein at least one locating mechanism is arranged on the locating platform; each locating mechanism corresponds to one collecting box and comprises a right locating rod and a floating location mechanism which are used for locating the to-be-machined pieces in the left-right direction as well as a lower locating rod used for locating the to-be-machined pieces in the vertical direction. The machining and locating functions and the clamping function of the machining platform are separated regionally, locating of multiple to-be-machined pieces can be finished once, independent locating for each to-be-machined piece before machining is not needed, so that time occupied by shutdown of a machine tool machining head waiting for locating of the to-be-machined pieces is reduced, overall machining efficiency of the machine tool is effectively improved, besides, the structure is simplified, stability and reliability of machining are improved, and yield is increased finally.

Owner:SUZHOU GFD AUTOMATION TECH

Mask ear belt mounting mechanism

The invention provides a mask ear belt mounting mechanism. The mask ear belt mounting mechanism comprises a fixing frame, two identical ear belt mounting devices are arranged on the fixing frame, and each ear belt mounting device is composed of a pushing device, a rotary length control device and a wire passing device; each pushing device comprises a pushing air cylinder, a pushing seat is fixed to each air cylinder shaft, two opposite pushing shafts are fixed to each pushing seat, and ultrasonic welding heads are fixed to the bottoms of the pushing shafts; each rotary length control device comprises an air cylinder fixing seat, and the pushing shafts penetrate through the air cylinder fixing seats and are in clearance fit with the air cylinder fixing seats; meanwhile, the ultrasonic welding heads are located on the bottom faces of the air cylinder fixing seats, rotary air cylinders are fixed to the air cylinder fixing seats, and rotary shafts penetrate through the air cylinder fixing seats to be fixed to rotary seats; four clamps are correspondingly distributed on the rotary seats, two T-shaped length control seats are further fixed to the rotary seats, and clamp closing air cylinders and clamp opening air cylinders for controlling the clamps to be loosened or clamped are further arranged on the air cylinder fixing seats; and each wire passing device comprises a wire rod I and a wire rod II which are provided with wire holes, and the two wire rods are both fixed to the air cylinder fixing seats.

Owner:JINHUA SHENGCHANG MACHINERY

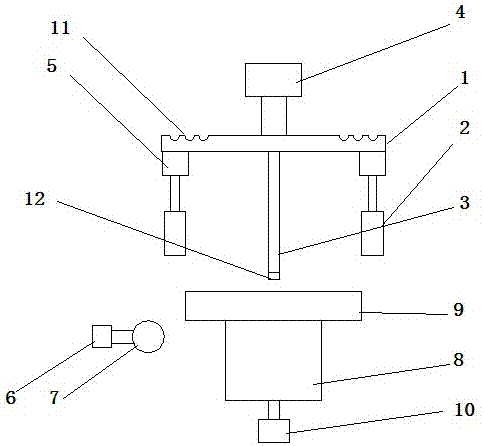

Die for crimping

The invention discloses a mold for crimping, which comprises an upper mold and a lower mold; the upper mold includes a horizontally arranged cantilever, a first pressing block, and a column, and a first driving mechanism is arranged above the cantilever, and the first pressing block Driven by the second driving mechanism; the first driving mechanism drives the cantilever and the column to move down the mold; the lower mold includes a base and a second pressing block driven by the third driving mechanism, and the moving direction of the second pressing block is perpendicular to the moving direction of the cantilever , the base includes a support rod and a model plate arranged on the top of the support rod, the model plate is arranged parallel to the cantilever; the lower part of the support rod is connected with the rotating shaft of the fourth driving mechanism, and the fourth driving mechanism drives the base to rotate, and the base is close to two pressing The distance between the side walls of the blocks is equal to the distance between two compacts. The present invention uses the first pressing block to press down vertically, and then uses the second pressing block to perform horizontal pressing to realize horizontal folding, thereby completing curling. After finishing one side processing, the fourth driving mechanism is used to drive the base to rotate, thereby Realize automatic processing of multiple sides of the material, greatly saving manpower.

Owner:昆山申凌精密金属工业有限公司

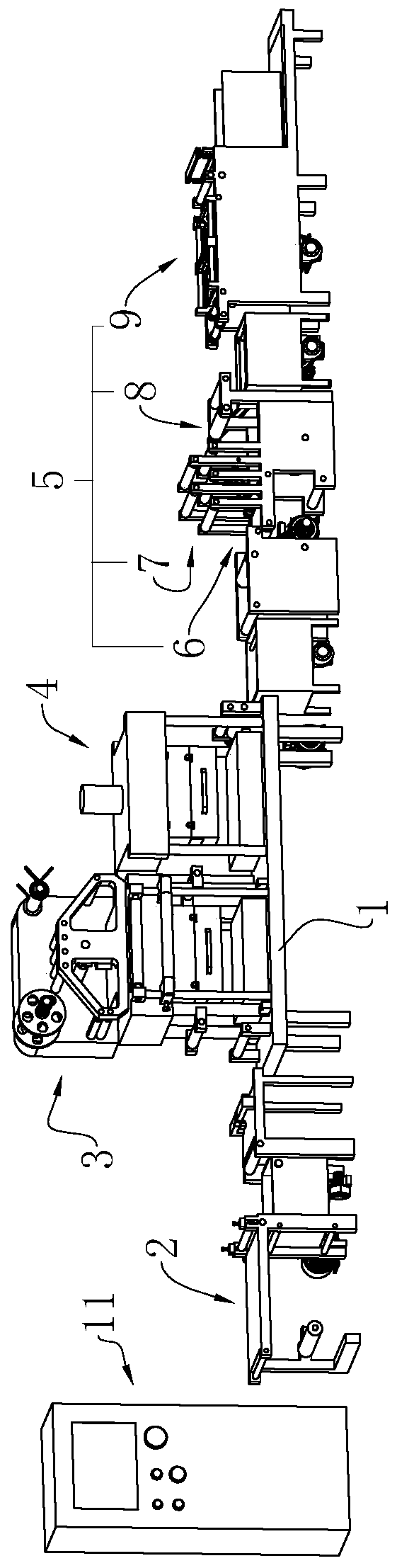

Integrated production line for label production

ActiveCN110948944APrevent disengagementIncrease flexibilityPaper/cardboard articlesRotary pressesProcess engineeringAdhesive

The invention discloses an integrated production line for label production, which is applied to the field of label production lines and solves the technical problem that the label production line canonly process one type of labels. According to the technical scheme, the integrated production line comprises a rack, one side of the rack is provided with a control box, an unwinding device, a gold stamping device, a die cutting device and a material receiving device are sequentially arranged on the side, which is away from the control box, of the rack, the unwinding device is used for placing a label base material, the gold stamping device and the die cutting device are used for processing the label base material, the material receiving device comprises a material stirring and collecting device, a cooling device, a winding device and a folding and unfolding device, the material stirring and collecting device comprises a conveying platform and a waste material roller and is used for collecting hang tag type labels, the winding device comprises a winding roller and a fourth driver connected with the winding roller and is used for winding self-adhesive labels, and the folding and unfolding device used for folding and unfolding the labels is further arranged. The integrated production line has the technical effects that three receiving modes are provided, and one production line can meet the processing and receiving requirements of various types of labels.

Owner:苏州精益达印刷有限公司

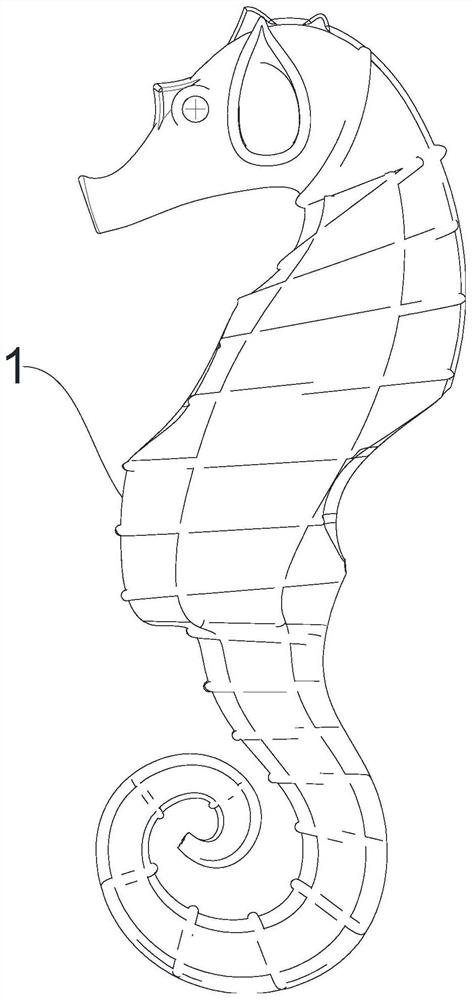

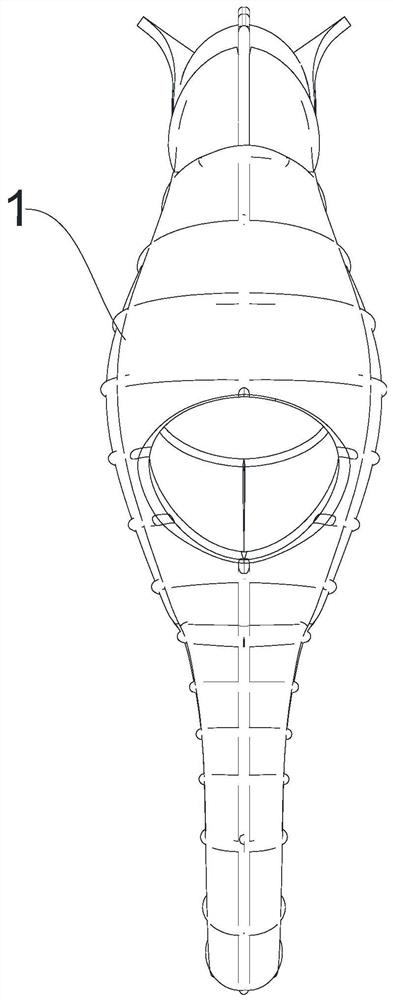

Human body bone ash funeral and interment sacrifice artware and three-dimensional imaging process

PendingCN112225535AAchieve commemorationEasy to collectAdditive manufacturing apparatusReligious equipmentHuman bodyStereoscopic imaging

The invention provides human body bone ash funeral and interment sacrifice artware and a three-dimensional imaging process, and relates to the technical field of funeral and interment sacrifice. The human body bone ash funeral and interment sacrifice artware comprises a funeral and interment sacrifice artware body which is mainly made of human body bone ash. In addition, the invention further provides the three-dimensional imaging process of the human body bone ash funeral and interment sacrifice artware. The process comprises the steps of manufacturing human body bone ash, manufacturing materials and forming the funeral and interment sacrifice artware. Bone ash of relatives can be conveniently stored and sacrificed.

Owner:王瑞刚

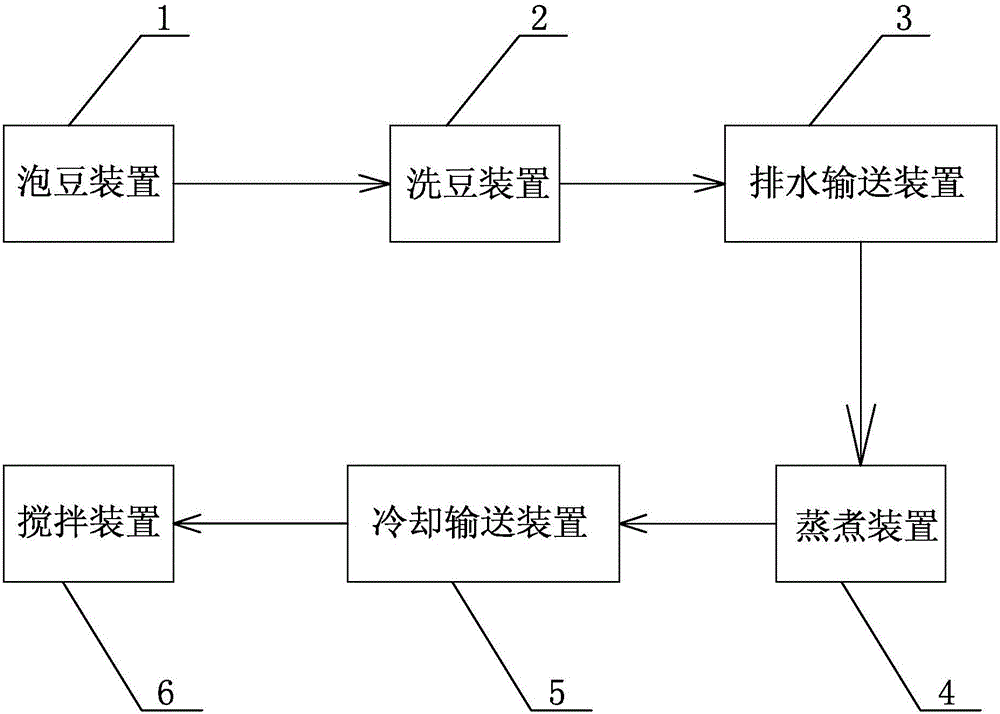

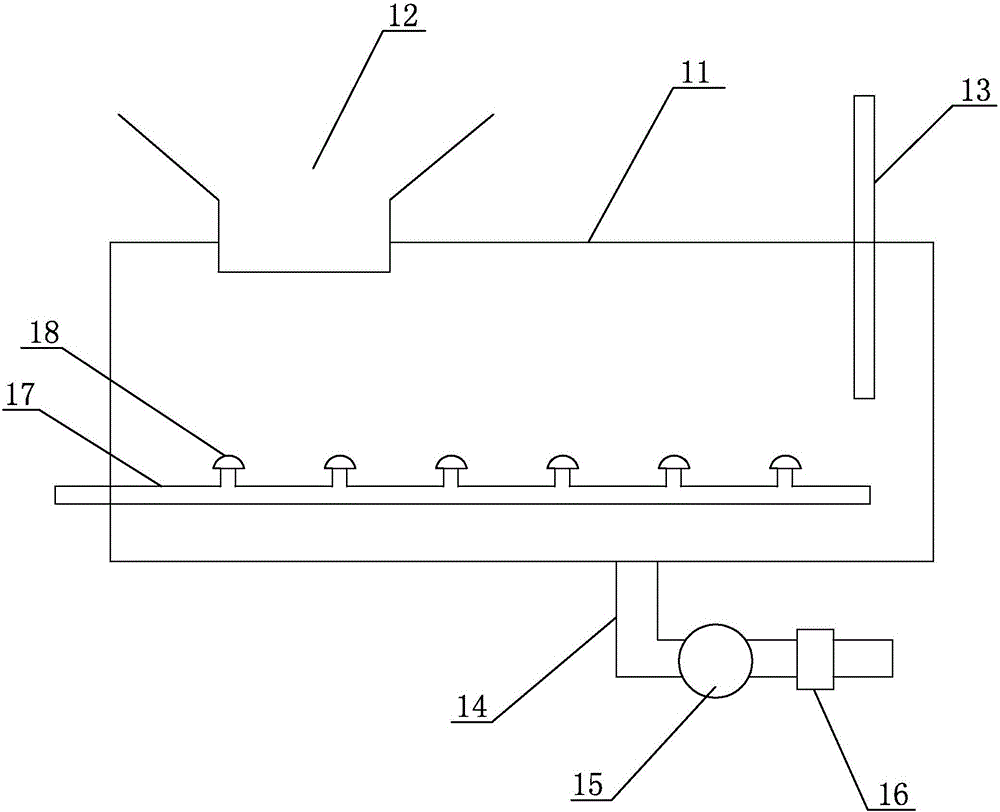

Soybean processing system for preparing fermented soybean oil

InactiveCN106036492AProcessing automationImprove efficiencyFood scienceProcess engineeringIndustrial engineering

The invention discloses a soybean processing system for preparing fermented soybean oil. The soybean processing system comprises a soybean soaking device, a soybean cleaning device, a water draining and conveying device, a cooking device, a cooling and conveying device and a stirring device which are sequentially connected through conveyer belts or conveying tanks, so that soybeans can be automatically processed, and the efficiency is improved. In addition, the processing system disclosed by the invention also has the following advantages that a steam pipe is arranged at the lower part of a soybean soaking box of the soybean soaking device, and a plurality of steam spray heads are arranged on the steam pipe at intervals, so that uniform temperature adjustment can be realized; the soybean cleaning device can realize multistage soybean cleaning through a plurality of cleaning tanks, the structure is simple, and the cleaning effect is good; when a water draining conveyer belt is used for transporting the soybeans, redundant water on the surfaces of the soybeans can be automatically removed, and the cooking effect is guaranteed; and the cooked soybeans are quickly cooled on a cooling conveyer belt by various cooling methods, so that the efficiency is improved.

Owner:鹤山市东古调味食品有限公司

Production process of high-toughness ceramic cutting tool

ActiveCN113087529AImprove toughnessImprove thermal shock resistanceGrinding drivesOther manufacturing equipments/toolsAluminium hydroxideTitanium nitride

The invention discloses a production process of a high-toughness ceramic cutter. By adding nano silicon carbide, nano titanium nitride, modified sepiolite powder, zirconium oxide whiskers and aluminum hydroxide coated calcium fluoride, the toughness, thermal shock resistance and bending strength of the produced ceramic cutting tool are effectively improved. According to GB / T4741-1999 measurement, the bending strength of the high-toughness ceramic cutting tool is 1000 to 1500 MPa. Meanwhile, the invention discloses machining equipment, and the machining equipment can polish one face of the ceramic cutter and clean the other face of the ceramic cutter at the same time. Water is sprayed on the surface of the abrasive belt while the grinding surface is ground, so that chippings can be prevented from splashing while overheating during grinding is prevented; whereas the cleaning of the other side is that sewage generated in the polishing process is recycled and sprayed on the surface of the ceramic cutting tool through filtration and atomization.

Owner:湖南泰鑫瓷业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com