Production process of high-toughness ceramic cutting tool

A ceramic cutting tool and production process technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., can solve the problems of low toughness, cracking during use or processing, and inability to clean, and achieves the effect of increasing toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

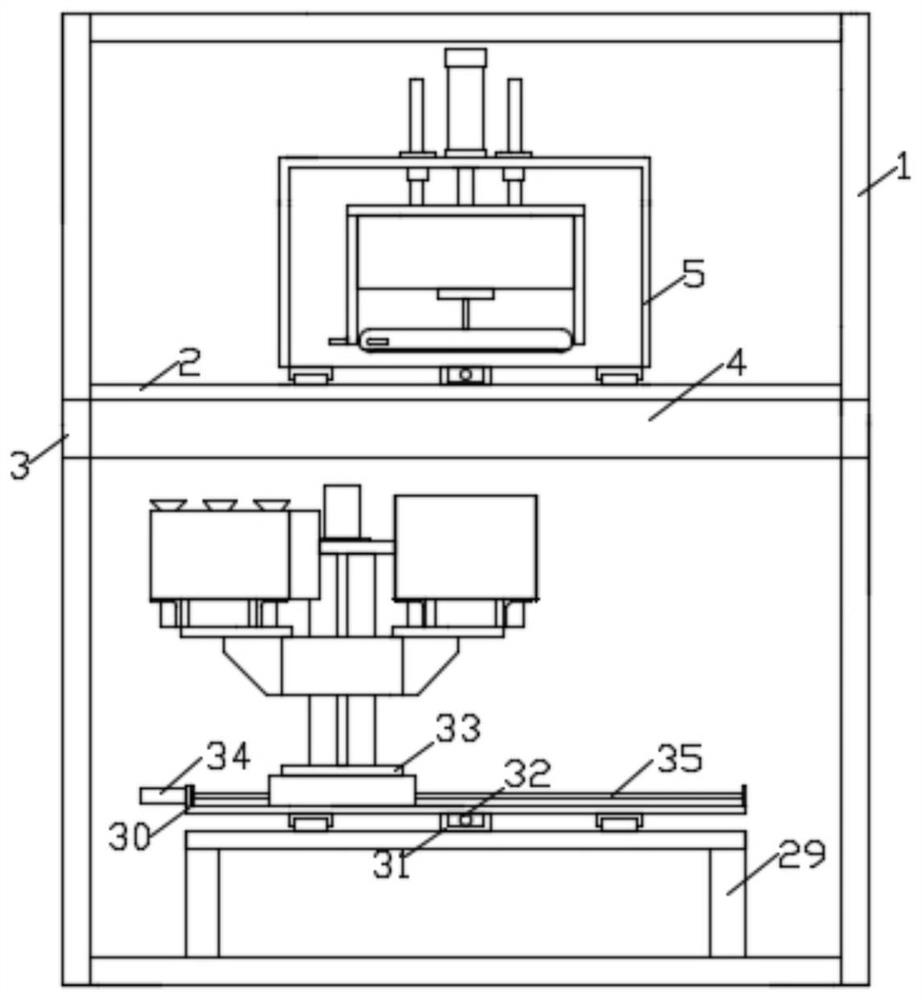

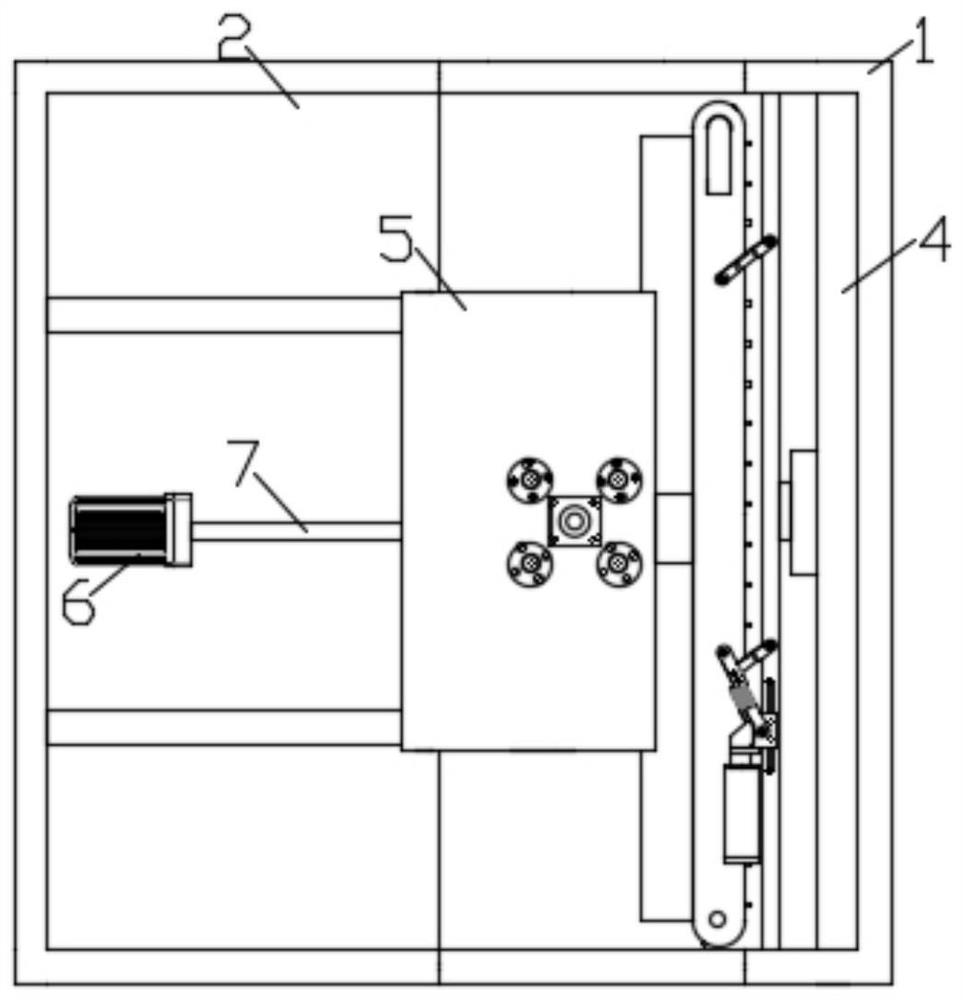

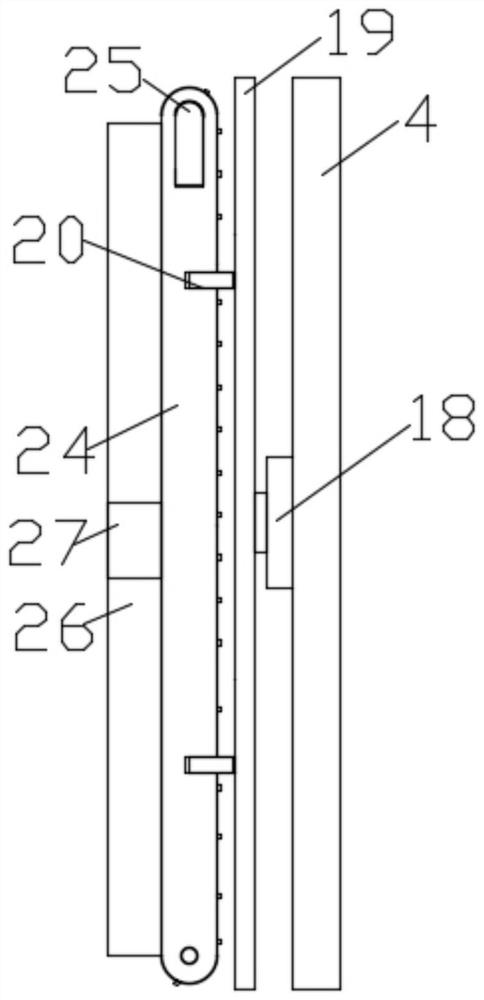

Image

Examples

Embodiment 1

[0037] A production process of a high-toughness ceramic cutter, comprising the steps of:

[0038] Step 1: In parts by weight, weigh 15 parts of nano-silicon carbide, 18 parts of nano-titanium nitride, 10 parts of modified sepiolite powder, 180 parts of absolute ethanol, 6 parts of zirconia whiskers, aluminum hydroxide coated fluorine Calcium 12 parts, silane coupling agent KH5603 parts;

[0039] Step 2: Add zirconia whiskers and aluminum hydroxide-coated calcium fluoride to absolute ethanol, and stir at 200 r / min for 1 hour at room temperature to obtain a mixed slurry;

[0040] Step 3: Mix and ball mill nano-silicon carbide, nano-titanium nitride, modified sepiolite powder, and silane coupling agent KH560, pass through a 300-mesh sieve, and calcinate at 900°C for 0.8 hours to obtain mixed particles;

[0041] Step 4: Add the mixed particles into the mixed slurry and place it in a hot-press sintering furnace, heat-preserve and press-sinter at 1300°C and 25MPa for 2.5 hours, and...

Embodiment 2

[0048] A production process of a high-toughness ceramic cutter, comprising the steps of:

[0049]Step 1: In parts by weight, weigh 30 parts of nano-silicon carbide, 35 parts of nano-titanium nitride, 20 parts of modified sepiolite powder, 250 parts of absolute ethanol, 10 parts of zirconia whiskers, aluminum hydroxide coated fluorine Calcium 20 parts, silane coupling agent KH5605 parts;

[0050] Step 2: Add zirconia whiskers and aluminum hydroxide-coated calcium fluoride to absolute ethanol, and stir at 250 r / min for 2 hours at room temperature to obtain a mixed slurry;

[0051] Step 3: Mix nano-silicon carbide, nano-titanium nitride, modified sepiolite powder, and silane coupling agent KH560 into ball mills, pass through a 400-mesh sieve, and calcinate at 1000°C for 2 hours to obtain mixed particles;

[0052] Step 4: Add the mixed particles into the mixed slurry and place them in a hot-press sintering furnace, heat-preserve and sinter under the conditions of 1500°C and 50MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com