Automatic tender coconut processing machine

A processing machine and green coconut technology, which is applied in the field of automatic green coconut processing machines, can solve the problems of physical and mental damage of operators, different sizes of young coconuts, and large manpower, so as to reduce personnel injury and disability accidents, improve economic benefits, and expand production effect of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

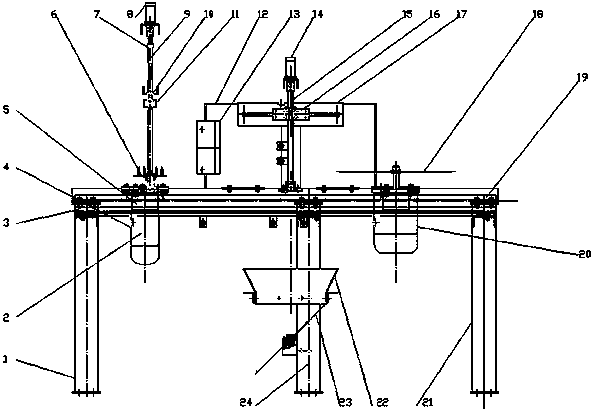

[0016] A frame is provided, and a front linear guide rail 3 is provided on the frame, a rotating nail disc device is arranged on the front linear guide rail 3, a coconut pressing device is arranged above the rotating nail disc device, and a coconut shell is arranged behind the coconut pressing device. Cutting device, the rear of the coconut shell cutting device is provided with a coconut bottom cutting device, and the bottom of the coconut bottom cutting device is provided with a recovery device.

[0017] Described rotary nail disc device is made up of nail disc 6 and the nail disc rotation drive motor 2 that drives nail disc 6 to rotate.

[0018] Described coconut pressing device is provided with compressing servo motor 8, and compressing servo motor 8 links to each other with compressing leading screw 9 by shaft coupling, and compressing leading screw 9 links to each other with pressing frame 7 by leading screw nut pair, presses down A briquetting block 11 is arranged under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com